🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

3D Fabric Market

3D Fabric Market Global Industry Analysis and Forecast (2024-2032) By Type( Woven, Knitted, Non-Woven, Braided),By Material(Polyester, Polypropylene, Nylon, Cotton, Others),By Application(Apparel, Automotive, Aerospace, Construction, Medical, Industrial, Others),By End-User(Consumer Goods, Industrial, Healthcare, Automotive & Transportation, Others) and Region

Jan 2025

Semiconductor and Electronics

Pages: 138

ID: IMR1487

3D Fabric Market Synopsis

3D Fabric Market Size Was Valued at USD 9.7 Billion in 2023, and is Projected to Reach USD 15.6 Billion by 2032, Growing at a CAGR of 5.4% From 2024-2032.

The 3D fabric industry concerns the manufacture and use of multifunctional and multilayered fabrics that have specific mechanical characteristics satisfying various essential requirements in various industries such as automotive, aerospace, medical and construction industries. These fabrics are made employing various manufacture processes which include weaving, knitting or braiding to develop fabric structures of more than two layers connected to one another in such a manner that they provide better sturdiness, flexibility, and attractiveness as contrasted to simple two-dimensional fabric.

The 3D fabrics market size has increased over the last decade with the development of textile manufacturing technologies and rising usage of advanced materials in industries. These fabrics are described by improved mechanical characteristics, lightweight constructions, and increased thermal and acoustic insulation that enables using these fabrics in the clothing industry, over aerospace industries. This accounts for the increasing need for the markets related to sustainable and high-performance materials, as influenced by the current and anticipated needs of the industries. Meanwhile, the embedding of smart technologies into three-dimensional fabrics has created new opportunities for functions, such as wearable devices and smart system application. The global market is divided by type and application to show the variation in products and their distinct functions.

These developing economies have huge market potential since a rise in industrialization as well as improvements in the current Central Business District infrastructure is inevitable. Nonetheless, there are some risks in the market including high cost of production and the fact that it requires extensive technological support. As more and more applications go for 3D fabrics, the manufacturing people are pushing to see what may be done to make manufacturing easier and make more uses for this material. New trends such as environment friendly material in production and mechanized manufacturing procedures are considered as fundamental in defining the direction of the 3D fabric market in the future.

3D Fabric Market Outlook, 2023 and 2032: Future Outlook

3D Fabric Market Trend Analysis

Trend: Adoption of Smart 3D Fabrics

Smart 3D fabrics are an innovative category in the textile materials that offer structural benefits coming from three-dimensional textile structures along with the added functions of sensing, monitoring and communication. These fabrics are advanced than the simple fabrics since they are infused with features such as built-in sensors, conductive yarns, and incorporated actuators that provide real time detail and response systems. Some of the innovations include using them in health monitoring garments in healthcare industries, vehicle and aircraft industries use them in safety and efficiency improvements.

The necessity of smart 3D fabrics is proportional to the ever rising need to incorporate more value-added functions and properties into materials that were originally used simply to put over one’s body. For instance, in wearables, these fabrics enable tracking features such as fitness tracking and temperature control, which customers wish for due to their individual requirements. Even as research enters the future, there are great possibilities of enhancing such smart fabrics through a combination of nanotechnology and IoT; both a boon for both producers and purchasers.

Opportunity: Expansion into Sustainable 3D Fabrics

New business sustainability has become one of the main opportunities for the 3D fabric market, corresponding to tendencies in the global industry to minimize environmental nuisance and encourage environmentally-friendly policies. There is a growing trend in the use of renewable raw materials in the manufacture of sustainable 3D fabrics including organic cotton, recycled polyester and biodegradable fibers. This change is not only has positive environmental impact, but what is also important is the fact that the current trend is associated with consumers’ concerns with ethically made products.

Due to their lightweight, durability and low energy absorption properties, the construction and automotive industry are the two major markets for sustainable 3D fabrics. In addition, rules established by the government and policies linked to enforcing aids in the use of efficient technologies are motivators to producers to engage in green manufacture. This opportunity therefore call for innovation and more importantly partnerships in combating the environment issues with out compromising the competitive edge in the global market.

Driver: Growing Demand in Aerospace and Automotive Industries

The commercial use of the 3D fabric market is also influenced by the aerospace and automotive sectors because they require lighter products with superior performance. 3D fabrics are used in aerospace applications which include seats, acoustic and thermal insulation and as reinforcements to composites for fuel efficiency and comfort to passengers. Alike, the automotive industry uses these fabrics for interiors trims and linings, air bags and structural reinforcements for increased safety and strength.

This demand is driven by improvements in fabric production technology allowing it to provide specialized 3D fabrics to fit the different requirements of industries. Besides, the trends towards the increased energy efficiency and reduced emissions in transport industries can be linked with the peculiarities of 3D fabrics, which can become one of the key elements for making transport vehicles more sustainable.

Restraints: High Production Costs

Antecedently, high production cost resulting from employing sophisticated technology techniques and expensive raw materials forms a chief restrictive factor in the 3D fabric market. Many of the steps of developing multi-layer, multiple-plane constructions involve complex tools and hierarchy management approaches like 3D weaving and 3D knitting which raises the cost. In addition, the application of specialized and costly materials such as carbon fibers and aramid fibers increases the cost of bikes making them out of reach for small manufacturing firms and markets.

To minimize these challenges, firms are directing effort and resources towards improving efficiency, new ways of production such as automation, and relevant use of material. However there is appearance of such efforts that does not however show a significant characteristics of initial the routinization processes require a huge investment.

3D Fabric Market Segment Analysis

3D Fabric Market Segmented on the basis of type, material, application and end user.

By Type

o Woven

o Knitted

o Non-Woven

o Braided

By Application

o Apparel

o Automotive

o Aerospace

o Construction

o Medical

o Industrial

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Woven segment is expected to dominate the market during the forecast period

Based on the fabric type 3D fabric market comprises of woven, knitted, non-woven and braided each of them provides unique solution based on the application. Woven 3D fabrics have high endurance, impressive tensile strength and as such are used in aerospace and industrial applications. While knitted 3D fabrics are flexible and elastic materials suitable for applications in apparel and medical industries. Non-woven fabrics are versatile and easily produced with relatively low costs and primarily used in disposable products such as medical and hygiene products and construction.

More particularly, light-weighted 3D fabrics woven by using braid construction are used for their mechanical strength and application suitability such as reinforced composites and automotive parts. The varieties within these types further illustrate the flexibility of application of 3D fabrics in satisfying different market needs and promoting technological advancement in the production of new products.

By Application, Apparel segment expected to held the largest share

3D fabrics are widely used in various fields including but not limited to; fashion, car industry, airplanes, building and construction, healthcare, and manufacture industries. For the clothing product line, these fabrics are characterized by comfort, breathability, and attractive appearance applicable both for fashionable and practical clothing lines. The automobiles and aircraft industry uses 3D fabrics for its lightweight parts which enhance the vehicle’s mileage and safety.

3D fabrics are used in construction industry for reinforcement materials and insulation to support sustainability in construction. In general, the medical industry gains from the employment of 3D fabrics in processes such as prosthetics and implants and as wound healing materials because of the compatibility of 3D fabrics to biological systems and versatility of applications. Some of the more conventional applications are filtration and automobile reinforcements and clearly communicates the versatility of 3D fabrics in various industrial industries and the ability to meet many market requirements.

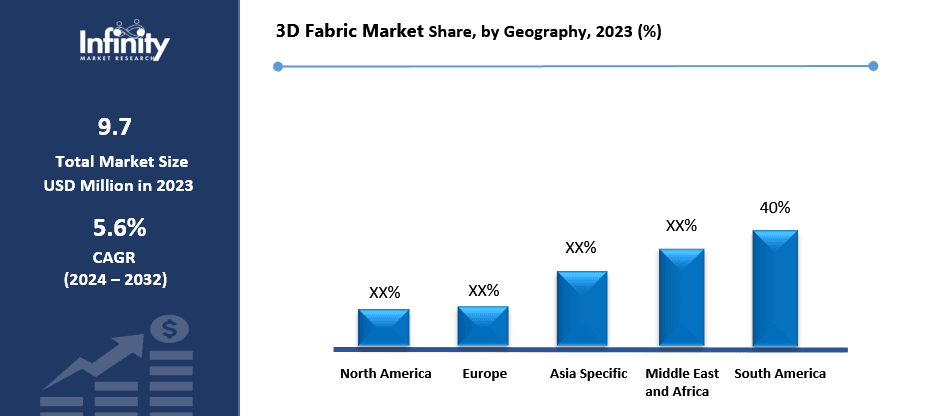

3D Fabric Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

North American region holds the largest market proportion in the 3D fabric market due to the presence of highly developed manufacturing technologies and higher emphasis on research and development. The market for advanced aerospace, automotive, and medical industries successfully anchors the need for the development of 3D fabrics in the region. Also, there is increasing concerns in sustainability and technology integration which has boosted the adoption of 3D fabrics in various applications and.

Industry players as well as agencies of the North American government as well as key players in the industry continue to increase support for and work with various research institutions in order to develop and expand the market. The existing facilities and expertise on high-performance materials are other great fundamentals to the regions to make them giants in the 3D fabric market.

3D Fabric Market Share, by Geography, 2023 (%)

Active Key Players in the 3D Fabric Market

o Sigmatex (United Kingdom)

o 3D Weaving (France)

o Textum (United States)

o SGL Carbon (Germany)

o BGF Industries (United States)

o Parabeam (Netherlands)

o SAERTEX (Germany)

o Bally Ribbon Mills (United States)

o A&P Technology (United States)

o Kordsa (Turkey)

o SELCOM (Italy)

o Metyx Composites (Turkey)

o Other key Players

Global 3D Fabric Market Scope

|

Global 3D Fabric Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 9.7 Billion |

|

Forecast Period 2024-32 CAGR: |

5.4% |

Market Size in 2032: |

USD 15.6 Billion |

|

Segments Covered: |

By Type |

· Woven · Knitted · Non-Woven · Braided | |

|

By Application |

· Apparel · Automotive · Aerospace · Construction · Medical · Industrial · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Demand in Aerospace and Automotive Industries | ||

|

Key Market Restraints: |

· High Production Costs | ||

|

Key Opportunities: |

· Expansion into Sustainable 3D Fabrics | ||

|

Companies Covered in the report: |

· Sigmatex (United Kingdom), 3D Weaving (France), Textum (United States), SGL Carbon (Germany), BGF Industries (United States), Parabeam (Netherlands), SAERTEX (Germany) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the 3D Fabric Market research report?

Answer: The forecast period in the 3D Fabric Market research report is 2024-2032.

2. Who are the key players in the 3D Fabric Market?

Answer: Sigmatex (United Kingdom), 3D Weaving (France), Textum (United States), SGL Carbon (Germany), BGF Industries (United States), Parabeam (Netherlands), SAERTEX (Germany) and Other Major Players.

3. What are the segments of the 3D Fabric Market?

Answer: The 3D Fabric Market is segmented into Type, Material, Application, End User and region. By Type, the market is categorized into Woven, Knitted, Non-Woven, Braided. By Material, the market is categorized into Polyester, Polypropylene, Nylon, Cotton, Others. By Application, the market is categorized into Apparel, Automotive, Aerospace, Construction, Medical, Industrial, Others. By End-User, the market is categorized into Consumer Goods, Industrial, Healthcare, Automotive & Transportation, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the 3D Fabric Market?

Answer: The 3D fabric industry concerns the manufacture and use of multifunctional and multilayered fabrics that have specific mechanical characteristics satisfying various essential requirements in various industries such as automotive, aerospace, medical and construction industries. These fabrics are made employing various manufacture processes which include weaving, knitting or braiding to develop fabric structures of more than two layers connected to one another in such a manner that they provide better sturdiness, flexibility, and attractiveness as contrasted to simple two-dimensional fabric.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.