🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Aluminium Anodizing Dyes Market

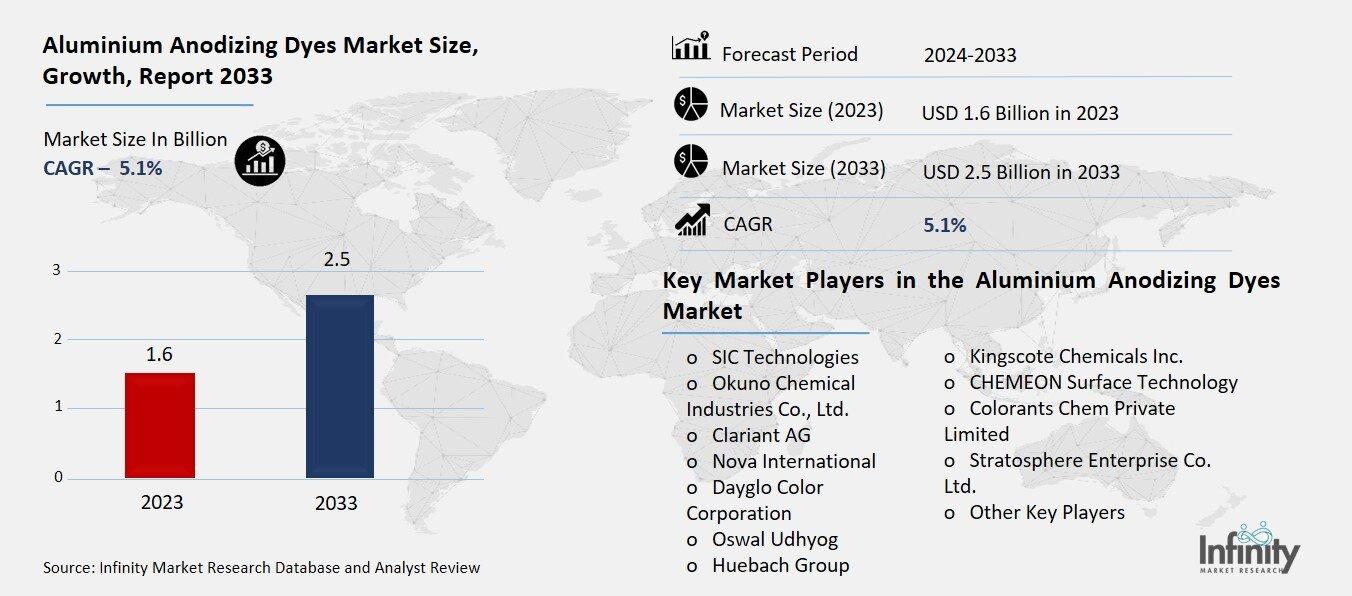

Global Aluminium Anodizing Dyes Market (By Type, Sulfuric or Color Anodizing (Type II), Chromic Acid Anodizing (Type I), Hardcoat Anodizing (Type III), and Other Types; By Application, Automotive, Electronics, Consumer Goods, Architectural, Aerospace & Defense, and Other Application; By Region and Companies), 2024-2033

Nov 2024

Chemicals and Materials

Pages: 138

ID: IMR1293

Aluminium Anodizing Dyes Market Overview

Global Aluminium Anodizing Dyes Market acquired the significant revenue of 1.6 Billion in 2023 and expected to be worth around USD 2.5 Billion by 2033 with the CAGR of 5.1% during the forecast period of 2024 to 2033. The Aluminum anodizing dyes market is growing rapidly, and it is due to the growing trends of using aluminium products with improved aesthetics and corrosion resistant in automobile, aerospace, construction and consumer electronics.

The process not only gives an Aluminium surface the ability to withstand corrosion and wear, and also offers a rich colour palette for aluminium. The market is highly differentiated in terms of dye formulations and even provides organic and inorganic dyes for different applications. The improvement in dye chemistry technology has resulted in increased number of high performant dyes to be introduced into the market hence increasing the market growth through improved color stability and color consistency.

Drivers for the Aluminium Anodizing Dyes Market

Increasing Demand for Aesthetics

Changing consumer trends in industries like automobiles and the consumer durables segment, demanding products that boast of a good aesthetics are the key factors that are expected to bolster the market for anodizing dyes, in the near future. Automotive applications are therefore stressing more on look in order to increase appeal, knowing fully well that even color and finish plays a crucial role on the decision of a customers to buy the car. Aluminium anodized surfaces are capable of a broad spectrum of bright and lasting colors and polished finishes for aesthetics, and applying a hard wearing and scratch resistant surface for exterior and interior parts.

Similary, in the consumer products, from electronics to every other household appliance is using anodized surface finishes to lure consumers. Some anodizing services help in giving equipment an aesthetic appearance in order to give it a glamorous look that reflects quality and therefore a higher price.

Restraints for the Aluminium Anodizing Dyes Market

Competition from Alternative Finishing Technologies

The presence of alternative surface finishing methods, particularly powder coating, poses a notable challenge to the growth of the aluminum anodizing dyes market. Powder coating has gained popularity across various industries due to its ability to deliver similar aesthetic qualities and performance characteristics as anodized finishes. It offers a wide range of colors and textures, providing manufacturers with versatile options for product differentiation. Furthermore, powder coating is often perceived as a more cost-effective solution, especially for large-scale production runs, as it can be applied in thicker layers and offers improved coverage.

Opportunity in the Aluminium Anodizing Dyes Market

Innovations in Dye Application Techniques

Innovations in dye application techniques and the introduction of high-performance dyes are pivotal factors that can significantly enhance product offerings in the aluminum anodizing dyes market, ultimately attracting new customers. Advances in application technologies, such as the development of automated anodizing processes and improved dyeing systems, streamline production and improve the consistency and quality of the finished products. These innovations allow for greater precision in color matching and uniformity, addressing a key concern for manufacturers aiming to meet stringent aesthetic and performance standards.

High-performance dyes, designed to withstand harsh environmental conditions and provide exceptional color stability, are also transforming the market landscape. These dyes can enhance the longevity of anodized finishes, reducing the risk of fading or discoloration over time. As industries increasingly prioritize durability and sustainability, the demand for these advanced dye solutions is likely to rise.

Trends for the Aluminium Anodizing Dyes Market

Integration of Smart Technologies

The integration of smart technologies in manufacturing processes, particularly through the adoption of automated anodizing systems, is increasingly prevalent in the aluminum anodizing dyes market. These advancements significantly enhance operational efficiency and ensure consistent quality in dye application, addressing some of the traditional challenges associated with manual anodizing processes. Automated systems streamline production by reducing human error, improving precision in dye application, and minimizing variations in color and finish. This leads to a more uniform product, which is crucial for manufacturers looking to meet stringent customer specifications and maintain brand integrity.

Segments Covered in the Report

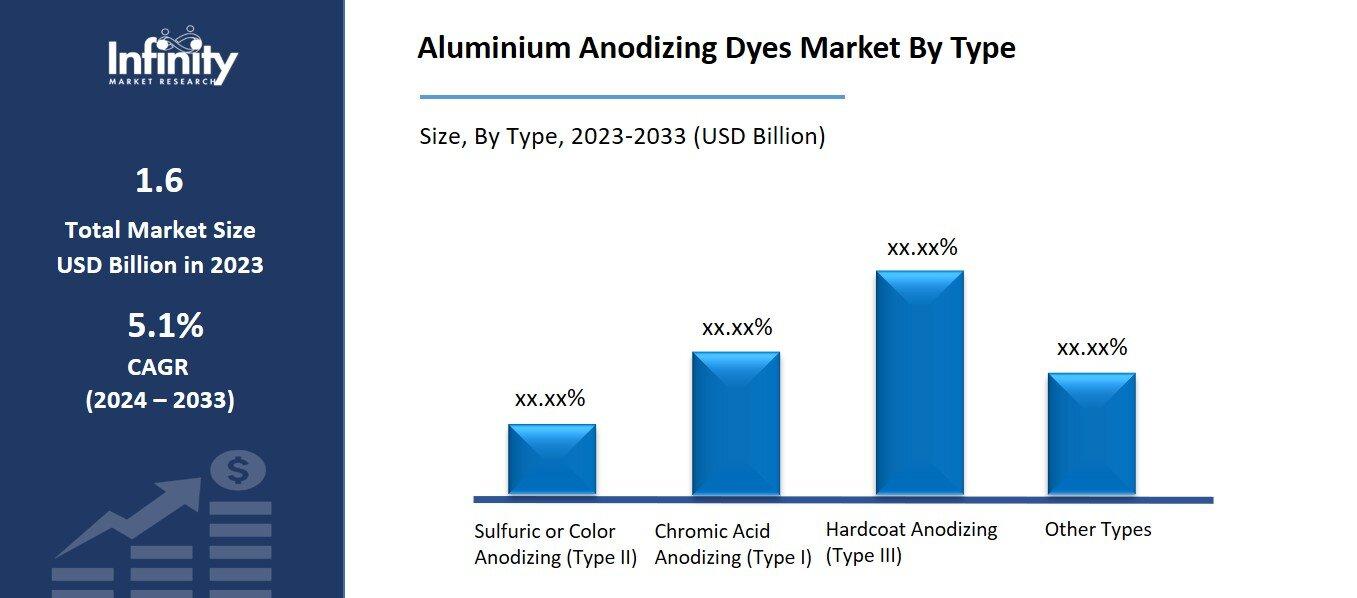

By Type

o Sulfuric or Color Anodizing (Type II)

o Chromic Acid Anodizing (Type I)

o Hardcoat Anodizing (Type III)

o Other Types

By Application

o Automotive

o Electronics

o Consumer Goods

o Architectural

o Aerospace & Defense

o Other Application

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into sulfuric or color anodizing (type II), chromic acid anodizing (type I), hardcoat anodizing (type III), and other types. Among these, sulfuric or color anodizing (type II) segment acquired the significant share around 31.4% in the market owing to widespread applicability and versatility. This type of anodizing is favored for its ability to produce a broad spectrum of vibrant colors while enhancing the corrosion resistance and durability of aluminum products.

The sulfuric anodizing process involves immersing aluminum in an acid electrolyte bath, which creates a thick oxide layer that can be dyed in various colors, making it ideal for industries such as automotive, consumer goods, and architecture, where aesthetic appeal is crucial. Additionally, the compatibility of sulfuric anodizing with a range of dyes allows for customization and personalization, catering to specific consumer preferences and design requirements.

By Application Analysis

On the basis of application, the market is divided into automotive, electronics, consumer goods, architectural, aerospace & defense, and other application. Among these, automotive segment held the prominent share of the market due to the industry's increasing focus on aesthetics, durability, and weight reduction. The automotive sector extensively utilizes anodized aluminum for various components, including exterior trims, wheels, and interior fittings, where both visual appeal and performance are crucial.

Anodizing not only enhances the visual characteristics of aluminum parts through vibrant and customizable colors but also improves their resistance to corrosion and wear, making them suitable for exposure to harsh environmental conditions. Additionally, the lightweight nature of anodized aluminum contributes to overall vehicle efficiency by reducing weight, which is essential for improving fuel economy and performance—a growing priority as manufacturers seek to meet stringent emissions regulations.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 34.1% of the market. The region benefits from a robust manufacturing infrastructure and a well-established automotive industry, which are significant consumers of anodized aluminum products. As automotive manufacturers increasingly emphasize lightweight materials and aesthetic enhancements, the demand for high-quality anodizing dyes has surged, driving market growth.

Moreover, North America is home to numerous leading companies and innovative players in the anodizing sector, fostering advancements in technology and product development. These companies are actively investing in research and development to create high-performance dyes that meet the evolving needs of various industries, including aerospace, electronics, and consumer goods.

Competitive Analysis

The competitive landscape of the aluminum anodizing dyes market is characterized by a diverse array of players ranging from established multinational corporations to specialized niche manufacturers. Key market participants focus on innovation, product differentiation, and strategic collaborations to enhance their competitive positioning. Leading companies invest significantly in research and development to create high-performance, eco-friendly dyes that meet the evolving demands of industries such as automotive, aerospace, and consumer goods.

Recent Developments

In November 2022, Surtec is expanded its partnership with Okuno Chemical Industries in Europe, leveraging their successful collaboration in Japan to provide European customers with innovative surface treatment solutions and high-performance products from Okuno, a leader in the field.

In January 2022, the Heubach Group and SK Capital Partners completed the acquisition of Heubach's global colorants business, now operating under the Heubach brand. This merger creates a leading global provider of pigment technology, offering a wide range of color solutions, including organic, inorganic, and anti-corrosive pigments, as well as pigment preparations, dyes, colorants, and specialty materials.

Key Market Players in the Aluminium Anodizing Dyes Market

o SIC Technologies

o Okuno Chemical Industries Co., Ltd.

o Clariant AG

o Nova International

o Dayglo Color Corporation

o Oswal Udhyog

o Huebach Group

o Kingscote Chemicals Inc.

o CHEMEON Surface Technology

o Colorants Chem Private Limited

o Stratosphere Enterprise Co. Ltd.

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.6 Billion |

|

Market Size 2033 |

USD 2.5 Billion |

|

Compound Annual Growth Rate (CAGR) |

5.1% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

SIC Technologies, Okuno Chemical Industries Co., Ltd., Clariant AG, Nova International, Dayglo Color Corporation, Oswal Udhyog, Huebach Group, Kingscote Chemicals Inc., CHEMEON Surface Technology, Colorants Chem Private Limited, Stratosphere Enterprise Co. Ltd., and Other Key Players. |

|

Key Market Opportunities |

Innovations in Dye Application Techniques |

|

Key Market Dynamics |

Increasing Demand for Aesthetics |

📘 Frequently Asked Questions

1. Who are the key players in the Aluminium Anodizing Dyes Market?

Answer: SIC Technologies, Okuno Chemical Industries Co., Ltd., Clariant AG, Nova International, Dayglo Color Corporation, Oswal Udhyog, Huebach Group, Kingscote Chemicals Inc., CHEMEON Surface Technology, Colorants Chem Private Limited, Stratosphere Enterprise Co. Ltd., and Other Key Players.

2. How much is the Aluminium Anodizing Dyes Market in 2023?

Answer: The Aluminium Anodizing Dyes Market size was valued at USD 1.5 Billion in 2023.

3. What would be the forecast period in the Aluminium Anodizing Dyes Market?

Answer: The forecast period in the Aluminium Anodizing Dyes Market report is 2024-2033.

4. What is the growth rate of the Aluminium Anodizing Dyes Market?

Answer: Aluminium Anodizing Dyes Market is growing at a CAGR of 5.1% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.