🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Automotive Predictive Maintenance Market

Automotive Predictive Maintenance Market (By Component (Solutions, Integrated, Standalone, Services, Managed Services, Professional Service), By Vehicle Type (Passenger Cars, Light Commercial Vehicles, Heavy Duty Trucks, Buses and Coaches), By Technology (IoT, Big Data & Data Analytics, Business Intelligence (BI), Cloud Computing, 5G) By Application (Oil Change, Transmission Checkup, Belt Change, Brake and Tire Inspection, Coolant Replacement, Engine Air Filter, Cabin Filter, Others Application), By Region and Companies)

Jun 2024

Automobiles

Pages: 151

ID: IMR1113

Automotive Predictive Maintenance Market Overview

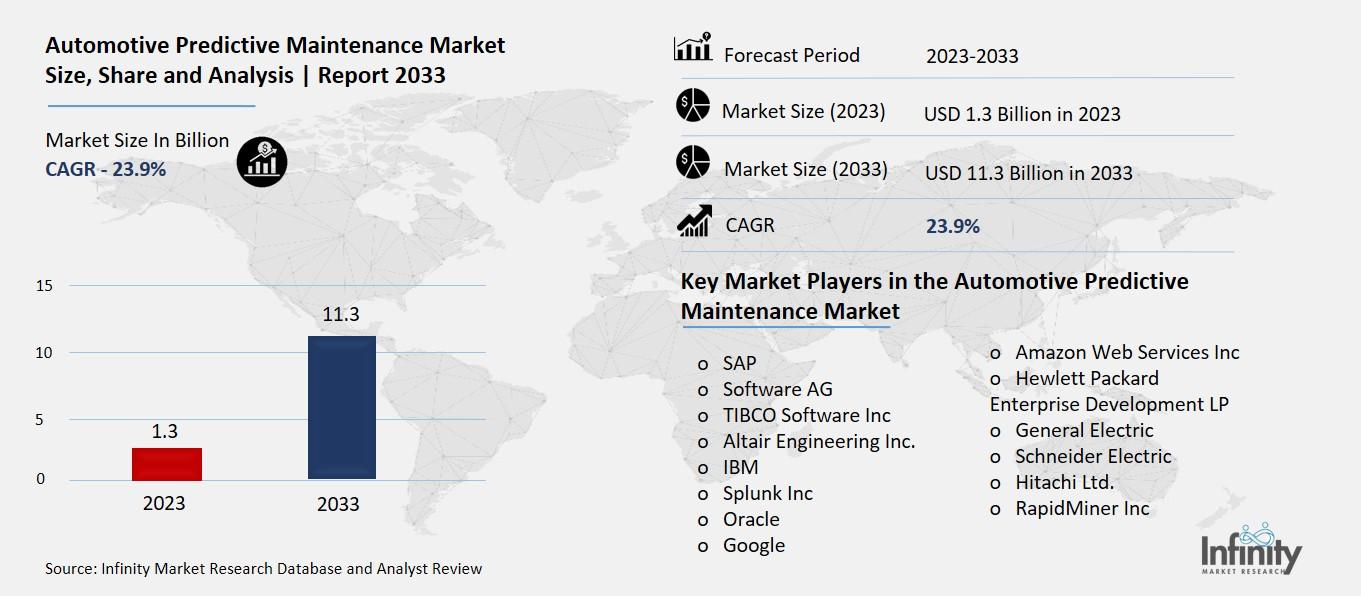

Global Automotive Predictive Maintenance Market size is expected to be worth around USD 11.3 Billion by 2033 from USD 1.3 Billion in 2023, growing at a CAGR of 23.9% during the forecast period from 2023 to 2033.

Automotive Predictive Maintenance is all about using technology to predict when a vehicle might need repairs or maintenance before it breaks down. It's like having a smart system in your car that can tell you if something is going wrong before it becomes a big problem. This is done using sensors and computers inside the vehicle that monitor engine performance, tire pressure, and other important factors.

Automotive predictive maintenance aims to prevent unexpected breakdowns and keep vehicles running smoothly. By analyzing data from these sensors, the system can detect early signs of trouble. This allows mechanics to fix issues early on, saving car owners and businesses time and money. It's a way to keep vehicles in good condition and avoid the hassle and cost of major repairs. This technology is becoming more common as cars become smarter and more connected, helping to improve safety and reliability on the road.

Drivers for the Automotive Predictive Maintenance Market

Advancements in Sensor Technology

One of the key drivers for the Automotive Predictive Maintenance market is advancements in sensor technology. Modern vehicles are equipped with a variety of sensors that monitor different parts of the car, such as engine temperature, tire pressure, and brake wear. These sensors collect data in real-time and send it to a central computer system. By analyzing this data, predictive maintenance systems can detect potential issues before they cause a breakdown. As sensor technology continues to improve, these systems become more accurate and reliable, driving the adoption of predictive maintenance solutions.

Rise of IoT and Connectivity

The Internet of Things (IoT) and connectivity are playing a significant role in the growth of the Automotive Predictive Maintenance market. Vehicles are increasingly connected to the internet, allowing them to transmit data to remote servers for analysis. This connectivity enables real-time monitoring of vehicle health and performance metrics, even when the vehicle is in use. IoT platforms can analyze large volumes of data to identify patterns and anomalies that indicate potential problems. As more vehicles become connected, the demand for predictive maintenance solutions that leverage IoT technology is expected to rise.

Cost Savings and Efficiency Gains

Predictive maintenance offers substantial cost savings and efficiency gains for vehicle owners and fleet operators. By predicting when components are likely to fail, maintenance can be scheduled proactively during planned downtime, reducing the likelihood of unscheduled repairs that disrupt operations. This approach minimizes the risk of costly breakdowns and extends the lifespan of vehicle components. Fleet operators, in particular, benefit from reduced maintenance costs and increased vehicle uptime, leading to improved operational efficiency and higher customer satisfaction.

Increased Focus on Vehicle Safety and Reliability

Vehicle safety and reliability are top priorities for consumers and businesses alike. Predictive maintenance enhances vehicle safety by ensuring that critical components are in optimal condition. For example, monitoring brake wear can prevent accidents caused by brake failure. Reliability is also improved as vehicles experience fewer breakdowns and unplanned downtime. This is especially important in industries such as logistics and transportation, where reliability directly impacts service levels and operational costs.

Growing Adoption of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are becoming integral to predictive maintenance systems. These technologies can analyze complex data patterns and learn from historical maintenance records to predict when and where maintenance is needed. AI-powered predictive maintenance systems can adapt and improve their accuracy over time, making them more effective at identifying potential issues before they occur. As AI and ML technologies continue to evolve, their application in automotive predictive maintenance is expected to grow, driving market expansion.

Regulatory Support and Industry Standards

Regulatory support and industry standards play a crucial role in driving the adoption of predictive maintenance solutions in the automotive sector. Governments and regulatory bodies are increasingly emphasizing vehicle safety and environmental protection, which encourages the use of technologies that improve vehicle reliability and reduce emissions. Industry standards ensure the interoperability and reliability of predictive maintenance systems, fostering trust and confidence among consumers and businesses.

Restraints for the Automotive Predictive Maintenance Market

Initial Investment and Implementation Costs

One of the main restraints for the Automotive Predictive Maintenance market is the initial investment and implementation costs associated with deploying predictive maintenance systems. While these systems can offer long-term cost savings by reducing unplanned downtime and maintenance costs, the upfront investment can be significant. This includes the cost of sensors, data storage, software development, and integration with existing systems. For small and medium-sized enterprises (SMEs) and individual vehicle owners, the high initial costs may deter adoption, especially if they do not have the resources to invest in new technology.

Complexity and Integration Challenges

The complexity of integrating predictive maintenance systems into existing vehicle fleets and IT infrastructure poses a challenge for many organizations. Vehicles may have different makes and models, each with its own set of sensors and data protocols. Integrating these diverse systems into a unified predictive maintenance platform can be technically challenging and time-consuming. Additionally, older vehicles may lack the necessary sensors or connectivity capabilities, requiring costly retrofits or upgrades to enable predictive maintenance functionalities.

Data Privacy and Security Concerns

The collection and analysis of large volumes of vehicle data raise significant privacy and security concerns. Predictive maintenance systems rely on continuous monitoring of vehicle performance and operational data, which may include sensitive information about the vehicle's location, usage patterns, and driver behavior. Ensuring the secure storage and transmission of this data is critical to prevent unauthorized access and data breaches. Compliance with data protection regulations, such as GDPR in Europe or CCPA in California, adds complexity and cost to implementing predictive maintenance solutions.

Skills and Training Requirements

Effective implementation of predictive maintenance systems requires skilled personnel who can interpret data insights and take appropriate actions. There is a shortage of professionals with expertise in data analytics, machine learning, and automotive engineering, which can hinder the adoption and deployment of predictive maintenance solutions. Training existing staff or hiring new talent with the necessary skills can be time-consuming and expensive for organizations, particularly SMEs with limited resources.

Resistance to Change and Cultural Factors

Resistance to change within organizations and cultural factors can also impede the adoption of predictive maintenance practices. Some businesses may be reluctant to shift from traditional reactive maintenance strategies to proactive predictive maintenance approaches. This resistance may stem from a lack of understanding of the benefits of predictive maintenance or a preference for familiar routines. Additionally, organizational culture and hierarchical structures can influence decision-making processes, making it challenging to implement new technologies and workflows.

Opportunity in the Automotive Predictive Maintenance Market

Rising Demand for Connected Cars and IoT

The opportunity for Automotive Predictive Maintenance is closely tied to the increasing adoption of connected cars and Internet of Things (IoT) technologies. As vehicles become more connected, they generate vast amounts of data that can be analyzed in real-time to predict maintenance needs. According to industry reports, the number of connected cars worldwide is expected to grow significantly, reaching over 300 million by 2025. This growth presents a substantial opportunity for predictive maintenance solutions, as automakers and fleet operators seek to leverage IoT to improve vehicle reliability and reduce operational costs.

Cost Savings and Operational Efficiency

Predictive maintenance offers significant cost savings and operational efficiency gains for vehicle owners and fleet operators. By identifying potential issues before they lead to breakdowns, predictive maintenance helps to minimize unplanned downtime and reduce maintenance costs. Studies have shown that predictive maintenance can reduce maintenance costs by up to 25% and increase equipment uptime by 30%, translating into substantial savings for businesses. These cost savings are particularly attractive in industries such as logistics, transportation, and construction, where vehicle downtime can have a significant impact on productivity and profitability.

Enhanced Safety and Reliability

Improved vehicle safety and reliability are key opportunities for the Automotive Predictive Maintenance market. By proactively identifying and addressing maintenance issues, predictive maintenance helps to prevent accidents and breakdowns caused by faulty vehicle components. This is particularly important for fleet operators and transportation companies, where vehicle reliability directly impacts customer satisfaction and operational efficiency. Enhancing vehicle safety also aligns with regulatory requirements and consumer expectations for safer transportation options.

Growing Adoption of AI and Machine Learning

The growing adoption of Artificial Intelligence (AI) and Machine Learning (ML) technologies presents an opportunity for predictive maintenance solutions. AI and ML algorithms can analyze large volumes of vehicle data to detect patterns and anomalies that indicate potential maintenance issues. These technologies can continuously learn and improve their predictive capabilities over time, making them more effective at predicting and preventing breakdowns. As AI and ML continue to advance, their application in automotive predictive maintenance is expected to grow, driving market expansion.

Expansion of Fleet Management Solutions

Fleet management solutions are increasingly incorporating predictive maintenance capabilities to optimize vehicle performance and reduce operating costs. These solutions offer comprehensive vehicle monitoring, maintenance scheduling, and performance analytics, enabling fleet operators to proactively manage their vehicle fleets. With the global fleet management market projected to grow significantly, there is a growing opportunity for predictive maintenance providers to integrate their solutions into existing fleet management platforms.

Regulatory Support and Industry Standards

Regulatory support and industry standards play a crucial role in creating opportunities for predictive maintenance solutions in the automotive sector. Governments and regulatory bodies are increasingly emphasizing vehicle safety, emissions reductions, and operational efficiency, which drive the adoption of technologies that improve vehicle reliability and performance. Compliance with industry standards ensures the interoperability and reliability of predictive maintenance systems, fostering trust and confidence among consumers and businesses.

Trends for the Automotive Predictive Maintenance Market

Rise of Predictive Analytics and Big Data

One of the prominent trends in the Automotive Predictive Maintenance market is the rise of predictive analytics and big data. As vehicles become more connected, they generate massive amounts of data about their performance, health, and usage patterns. Predictive analytics uses this data to identify patterns and predict when maintenance will be needed, even before any issues occur. Big data technologies enable the analysis of this large volume of data in real-time, allowing for proactive maintenance strategies. According to industry reports, the predictive maintenance market is expected to grow significantly, driven by advancements in data analytics and the increasing adoption of IoT technologies in vehicles.

Integration of AI and Machine Learning

AI and Machine Learning (ML) are playing a crucial role in advancing predictive maintenance capabilities. These technologies can analyze complex data patterns to predict equipment failures and recommend maintenance actions. AI algorithms can learn from historical data to continuously improve accuracy and reliability in predicting maintenance needs. ML models can also adjust to new data patterns and variables, making them adaptable to different vehicle types and operating conditions. This trend is expected to continue growing as automotive manufacturers and service providers leverage AI and ML to enhance predictive maintenance solutions.

Adoption of Condition Monitoring Systems

Condition monitoring systems are becoming increasingly popular in the Automotive Predictive Maintenance market. These systems continuously monitor the condition of vehicle components, such as engines, brakes, and transmission systems, in real-time. They use sensors to collect data on factors like temperature, vibration, and fluid levels, which are then analyzed to detect abnormalities or wear. Condition monitoring systems enable early detection of potential failures, allowing for timely maintenance and minimizing unplanned downtime. This trend is driven by the desire to maximize vehicle uptime and reduce maintenance costs.

Shift towards Proactive Maintenance Strategies

There is a noticeable shift towards proactive maintenance strategies in the automotive industry. Instead of waiting for components to fail, automotive companies and fleet operators are adopting predictive maintenance solutions to schedule maintenance based on actual equipment conditions and performance data. This proactive approach helps prevent costly breakdowns, improving vehicle reliability, and reducing maintenance costs. The adoption of proactive maintenance strategies is expected to increase as predictive maintenance technologies become more advanced and cost-effective.

Increase in Remote Monitoring and Diagnostics

Remote monitoring and diagnostics capabilities are becoming integral to automotive predictive maintenance solutions. These capabilities allow service providers to monitor vehicle health and performance remotely, using IoT connectivity and telematics. Remote monitoring enables real-time data analysis and alerts for potential issues, even when the vehicle is in operation. This trend is particularly beneficial for fleet operators, as it allows them to manage their vehicles more efficiently and effectively, reducing operational costs and improving overall fleet management.

Growing Demand for Cloud-Based Solutions

There is a growing demand for cloud-based predictive maintenance solutions in the automotive sector. Cloud-based platforms offer scalability, flexibility, and accessibility, allowing automotive companies to store and analyze large volumes of data efficiently. These solutions enable real-time collaboration and data sharing among stakeholders, including manufacturers, service providers, and fleet operators. Cloud-based predictive maintenance also facilitates integration with other enterprise systems, such as ERP and CRM, enhancing overall operational efficiency and decision-making.

Segments Covered in the Report

By Component

- Solutions

- Integrated

- Standalone

- Services

- Managed Services

- Professional Service

By Vehicle Type

- Passenger Cars

- Light Commercial Vehicles

- Heavy Duty Trucks

- Buses and Coaches

By Technology

- IoT

- Big Data & Data Analytics

- Business Intelligence (BI)

- Cloud Computing

- 5G

By Application

- Oil Change

- Transmission Checkup

- Belt Change

- Brake and Tire Inspection

- Coolant Replacement

- Engine Air Filter

- Cabin Filter

- Others Application

Segment Analysis

By Component Analysis

The automotive predictive maintenance (PDM) market is divided into two segments based on components: services and solutions. With a 61.8% market share, the solution industry dominated the PDM market. The solution forecasts an anomaly in the operation of essential equipment by utilizing data collected by several Internet of Things sensors and performing thorough data analysis. As such, it serves as the primary revenue generator for the predictive maintenance (PDM) industry.

Depending on their demands, businesses can decide to directly use managed services for their operations. Furthermore, it is anticipated that the expanding need for employee training, efficient use of these solutions, support for integration and implementation, and other factors would encourage the growth of the services sector.

By Vehicle Type Analysis

The market is segmented into passenger cars, light commercial vehicles, heavy-duty trucks, buses, and coaches based on the type of vehicle. With a 60.7% market share, passenger automobiles are the largest segment in the automotive predictive maintenance market. This is because there are so many passenger cars on the road today and there is a growing need for preventative measures that increase dependability and safety. In passenger cars, predictive diagnostics and remote monitoring are frequently used to find possible problems before they become serious problems.

Electronics makers can replace bulky and impractical traditional thermoelectric parts with integrated silicon (Si), germanium (Ge), and gallium arsenide (GaAs). With the introduction of these semiconductor elements, there has been a noticeable shift towards smaller products, which has made electronic gadgets more portable and compact. Of all the readily available semiconductor components on the market, silicon is the most superior.

By Technology

With a 34.9% market share, the Internet of Things (IoT) category led the automotive predictive maintenance market by technology system. Utilizing sensors and other IoT devices, IoT-based predictive maintenance solutions for the automotive sector often track the health of a car's vital parts, like the engine, brakes, and transmission. These devices gather data, which is then instantly processed in real-time using machine learning algorithms and advanced analytics to forecast when maintenance is needed.

In the worldwide automotive predictive maintenance market, business intelligence (BI) is critical because it enables analysts to interpret data to obtain understanding and make defensible judgments. Predictive maintenance saves downtime and maintenance costs by using data analytics to track the performance of vehicles and equipment to foresee problems and stop them before they happen. The global automotive predictive maintenance market uses machine learning algorithms, predictive modeling, and data visualization as business intelligence tools. These programs give businesses insight into possible problems before they arise and help them identify patterns and trends in vehicle performance data.

By Application Analysis

With a 23.2% market share, oil changes lead the vehicle predictive maintenance industry based on application. This fast-growing sector uses cutting-edge technology to predict and stop mechanical problems in automobiles. The creation of predictive maintenance programs for oil changes is one area of concentration in this field. Vehicles have historically relied on a time-based system for oil changes, requiring them to be performed every few months or thousands of kilometers.

Unfortunately, this approach may be inefficient since it does not take into account the actual condition of both the oil and engine. predictive maintenance systems for oil changes employ sensors and data analytics to monitor the condition of the oil as well engine and then predict when it needs changing. This helps optimize timing, reduce maintenance expenses, and protect engines from damage.

As connected cars become more commonplace, the demand for vehicle safety and dependability grows, and data-driven maintenance strategies become more important. Some of the major players in this market are Bosch, IBM, Intel, and Siemens. The global automotive predictive maintenance market for tire and brake inspection is anticipated to grow significantly over the expected years.

Regional Analysis

Based on less vehicle downtime, increased safety, and cheaper repair costs, North America is expected to hold the greatest market share—43%. North America's adoption of modern technologies, the presence of large auto businesses, and the growing emphasis on vehicle safety and reliability have contributed to the region's strong market share in the worldwide automotive predictive maintenance industry. In North America, the market for automobile predictive maintenance is dominated by the US.

Due to the region's thriving automotive sector, technological advancements, and laws aimed at promoting vehicle safety and emissions reduction, Europe is a significant market for automotive predictive maintenance. In this sense, the top three European markets are Germany, France, and the UK.

Considering the growing popularity of connected automobiles and the expansion of nations like China, India, and Japan, the automotive predictive maintenance market is anticipated to rise rapidly in the Asia Pacific region. This area is also home to several significant car suppliers and manufacturers, which encourages market growth.

Competitive Analysis

To obtain a competitive edge in the market, businesses are actively involved in strategic alliances, product development, mergers, and acquisitions, among other growth tactics. They also make significant R&D investments to improve their current products and launch fresh, cutting-edge solutions, especially for the automobile sector. The global market for automobile predictive maintenance is very competitive, with several well-established and up-and-coming companies providing a range of products and services.

Recent Developments

Customer relationship management (CRM) solutions provider Salesforce and Qualcomm Technologies, Inc. established a strategic alliance in January 2023 to build Automotive Cloud, an advanced connected car platform tailored to the automotive sector.

Microsoft and Israeli auto data company Otonomo struck a contract in January 2023 to send connected vehicle data directly into Microsoft Maps.

Key Market Players in the Automotive Predictive Maintenance Market

- SAP

- Software AG

- TIBCO Software Inc

- Altair Engineering Inc.

- IBM

- Splunk Inc

- Oracle

- Amazon Web Services Inc

- Hewlett Packard Enterprise Development LP

- General Electric

- Schneider Electric

- Hitachi Ltd.

- RapidMiner Inc

- Operational Excellence (OPEX) Group Ltd

- Dingo

- PTC

- CHIRON Swiss SA

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.3 Billion |

|

Market Size 2033 |

USD 11.3 Billion |

|

Compound Annual Growth Rate (CAGR) |

23.9% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Component, Vehicle Type, Technology, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Software AG, TIBCO Software Inc., Altair Engineering Inc., IBM, Splunk Inc., Oracle, Google, Amazon Web Services, Inc., Hewlett Packard Enterprise Development LP, General Electric, Schneider Electric, Hitachi, Ltd., RapidMiner Inc., Operational Excellence (OPEX) Group Ltd, Dingo, PTC, CHIRON Swiss SA |

|

Key Market Opportunities |

Rising Demand for Connected Cars and IoT |

|

Key Market Dynamics |

Advancements in Sensor Technology |

📘 Frequently Asked Questions

1. How much is the Automotive Predictive Maintenance Market in 2023?

Answer: The Automotive Predictive Maintenance Market size was valued at USD 1.3 Billion in 2023.

2. What would be the forecast period in the Automotive Predictive Maintenance Market report?

Answer: The forecast period in the Automotive Predictive Maintenance Market report is 2023-2033.

3. Who are the key players in the Automotive Predictive Maintenance Market?

Answer: Software AG, TIBCO Software Inc., Altair Engineering Inc., IBM, Splunk Inc., Oracle, Google, Amazon Web Services, Inc., Hewlett Packard Enterprise Development LP, General Electric, Schneider Electric, Hitachi, Ltd., RapidMiner Inc., Operational Excellence (OPEX) Group Ltd, Dingo, PTC, CHIRON Swiss SA

4. What is the growth rate of the Automotive Predictive Maintenance Market?

Answer: Automotive Predictive Maintenance Market is growing at a CAGR of 23.9% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.