🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Automotive Suspension Ball Joint Market

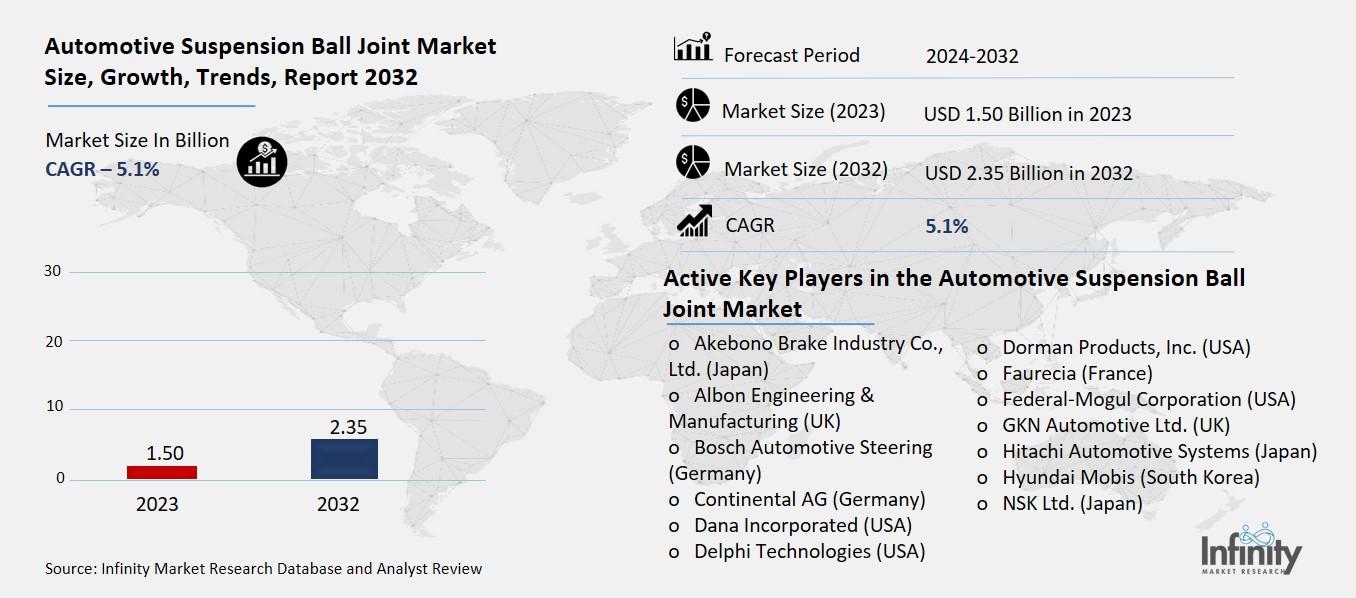

Automotive Suspension Ball Joint Market Global Industry Analysis and Forecast (2024-2032) by Product Type (Load-Carrying Ball Joints, Non-Load-Carrying Ball Joints), Vehicle Type (Passenger Cars, Light Commercial Vehicles, Heavy Commercial Vehicles), Material (Steel, Aluminum, Others) and Region

Jan 2025

Automotive Technology

Pages: 138

ID: IMR1610

Automotive Suspension Ball Joint Market Synopsis

Automotive Suspension Ball Joint Market Size Was Valued at USD 1.50 Billion in 2023, and is Projected to Reach USD 2.35 Billion by 2032, Growing at a CAGR of 5.1% From 2024-2032.

Automotive suspension ball joint market can be described as the industry particularly developed to include the manufacturing and selling of ball joints that are used in the car suspension suspension mechanisms. Ball joints are important assemblies of the cars suspension system since they mend the link between the wheels axel and the car’s body by allowing the wheel to rotate in any direction as it absorbs shocks of the ride. These joints are meant to bear forces during motion of the vehicle, which include stability and control of the car. Automotive suspension ball joint is manufactured from high strength materiel like steel aluminum or its alloys and is expected to withstand normal and abnormal wear during car usage for a long time and at the same time should have the ability to bear the load requirements efficiently. The component is in high demand in the following concerns: global automotive industry; High-producing automobile regions; Better automobile performance; Automobile safety assistance; and Reduction of vehicle weight. Important trends that have an impact on the market include electrification of vehicles, new generation of autonomous driving systems and growing global demand for passenger and commercial vehicles.

Currently, the market for automotive suspension ball joint has experienced considerable growth in the recent past due to an enhanced production of automobile in the global markets especially in the developing countries such as China, India and Brazil. This growth is catalyzed by the need for increased vehicle safety through the installation of superior quality suspension systems, which use these ball joints. There are ball joints, which are an inseparable part of the suspension assembly, and play a significant role in appropriate working of the steering and suspension systems for both the light and commercial vehicles. The materials that make up vehicles are changing and have more technology, so ball joints are now improving to require more opportunity to be utilized, lighter in weight and more effective.

Also, current market has the 30 % of growth because of EVs, which need different EPS systems because of the different center of gravity and driving traits, compared to ICE vehicles. The increase in use of power-saving vehicles such as Electric and hybrid automobile has forced auto industries to diversify the kind of suspension ball joints material they use. Also, additional requirements for additional spare parts and increasing vehicle pools also help in the constant growth of the market. Nonetheless, the future growth trends are positive in this market which has problems such as instability of input material price and difficulties in the requirement of more accurate and efficient production method to manufacture high precision parts at relatively cheaper price.

Automotive Suspension Ball Joint Market Outlook, 2023 and 2032: Future Outlook

Automotive Suspension Ball Joint Market Trend Analysis

Trend: Advancements in Material Technology

An emerging trend apparent in automotive suspension ball joint market is the continuous innovation in the manufacture of new material for the ball joints that are lighter and stronger. Conventional ball joints are mainly produced with steel or cast iron; however, the current trends in the manufacturing industry involve the use of carbon fiber composites, high strength alloys as well as the lightweight metals like aluminum to minimize the weight of vehicles as a method of enhancing fuel conservation. These innovations help in decreasing the total weight of the suspension system in addition to; increasing the life and stability of ball joint(s) and their performance abilities under present day use. Also, the specifications of a material with higher corrosion resistant are more and more adopted for elongating the durability of ball joints because it beneficial especial for the area having high corrosiveness, including the snow district or coastal zone. Prospective changes in material selection towards a higher level is envisaged to add momentum to the market due to the constant demand in vehicle efficiency, performance, and durability.

Driver: Increasing Vehicle Production and Aftermarket Demand

The largest factor influencing growth in the automotive suspension ball joint market is the production of cars where developed nations and the emergent markets are major contributors. With the increase in the production of automobiles across the world there is always the demand for high quality auto spare parts such as ball joints. The automotive market is arguably a globally growing market thanks to factors such as population growth, emerging urbanization, and enhanced disposable incomes particularly in the newer world. Such factors have resulted in the increase in numbers of vehicles in operation, thus increasing the need for suspension parts. Second, aftermarket sales of spare parts are always high because, as shocks and springs wear out, suspension systems require replacement. Requiring occasional replacement of its suspension systems and constant repair of these parts in old cars guarantees the market demand for ball joints. These trends have given a good market chance to suspension ball joint’s manufactures because both OEM and after market is steadily increasing especially in developed and developing countries.

Restraint: Fluctuating Raw Material Prices

Another factor that holds back the growth of growth in the automotive suspension ball joint industry is the changeable price of raw materials, especially the metals like steel, aluminum and high strength alloys, which are mandatory for manufacturing ball joints. These materials are sensitive to market fluctuations, such as disruptions in global supply chain and trade, or international conflict. This leads to higher costs of production, and this means that in order to make lower costs for the manufacturer or higher value to the end consumers, the prices have to be adjusted to an extent that will ensure a balance is achieved. Moreover, the heavy dependence of certain DFI on a limited number of suppliers of raw materials can enhance the problem especially when there are supplies’ hiccups. Automotive suspension ball joint manufacturers need to manage the risks occasioned by raw material price changes by sourcing from more suppliers or using cheaper materials that possess equal mechanical properties.

Opportunity: Growth in Electric Vehicle (EV) Market

Another important market attracting the automotive suspension ball joint is the increasing growth in the usage of electric vehicles or EVs. They pointed out that the use of electric cars has continued to rise across the globe owing to factors like in environmental impact, regulatory measures in emissions, and the development of technologies in electric vehicles. The increased amount of electric vehicles on the roads creates the need for suspension systems for EVs different from those used for traditional vehicles. While designing and manufacturing electric vehicles, the weight distribution is different from that of an internal combustion engine vehicle because of the position of battery pack; it influences the design and installation of the suspension components.

It is for these differences that ball joints used in EV suspension systems have to be more sophisticated, lighter in weight and robust This has called for the development of new and enhanced ball joints. In addition, since the batteries that power the electric cars are expected to be marketed as high-performance car models, automotive consumers will demand higher-quality suspension products that can deliver better handling, comfort and safety. The overall market for EVs is full of opportunities for companies who manufacture automotive suspension ball joints because the market demands for electronic vehicles are increasing day by day.

Automotive Suspension Ball Joint Market Segment Analysis

Automotive Suspension Ball Joint Market Segmented on the basis of Product Type, Vehicle Type and Material.

By Product Type

o Load-Carrying Ball Joints

o Non-Load-Carrying Ball Joints

By Applications

o Passenger Cars

o Light Commercial Vehicles

o Heavy Commercial Vehicles

By Materials

o Steel

o Aluminum

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Product Type, Load-Carrying Ball Joints segment is expected to dominate the market during the forecast period

During the forecast period, the load-carrying ball joints segment is also anticipated to lead the automotive suspension ball joint market. This kind of ball joints are used to bear the loads that come with the suspension systems, hence the correct functioning of suspension is not possible without such ball joints. Load-carrying ball joints are used to support the current chassis in the vehicle and to act as shock absorbers especially for vehicles that are used intensively for instance, trucks, SUVS and off road Jeep type. The constantly increasing need for such vehicles and the development of new load-carrying technologies will continue to propel the market for such ball joints. Also, the saturation of this segment through the use of electric and hybrid vehicles that need a different type of suspension system adds to the expected domination of this segment.

Growing trends like that of increasing vehicle weight due to the battery pack requirements in electric vehicles will likely require higher standard ball joints that are durable and can perform efficient load carrying for a long time. Automobile manufacturers are concentrating on increasing the load-bearing capacity, durability and corrosion protection on these ball joints to cater for the emerging new generation automobiles. Also, further advancements in material science such as manufacturing of high strength alloys and composites are anticipated to directly make load-carrying ball-joints more powerful and longer lasting to continue battering their competitors out of the market.

By Vehicle Type, Passenger Cars segment expected to held the largest share

The automotive suspension ball joint market is expected to be led by the passenger cars segment. From the global vehicle perspective, passenger cars dominate the roads and hence need suspension systems that will offer viability, comfort and safety to the user. As the market for the passenger car continues to expand as well as in the Asian-Pacific and Latin American regions the market for suspension parts such as ball joints also increases. Facteurs: the rising manufacture of compact cars, sedans, and SUVs, all of which need a high-performance passenger car suspension system. Moreover, due to the increasing concerns in vehicle safety and comfort during driving, manufactures are coming up with sophisticated suspension setups that employ superb ball joints to improve on handling and ride comfort.

In addition, increasing electric and hybrid passenger vehicle demand is also creating high demand for suspension ball joints in this segment. Since the uptake of electric vehicles (EVs) and Hybrid electric vehicles (HEVs) in the market is bound to rise, there will be a corresponding rise in the market for ball joints used in the manufacture of specialized suspensions. The distribution of weight in EVs and HEVs is different from that of ordinary vehicles and thus have different suspension requirements. Consequently, the passenger car segment is expected to continue its dominance over the market throughout the forecast period in terms of conventional as well as new vehicle kinds.

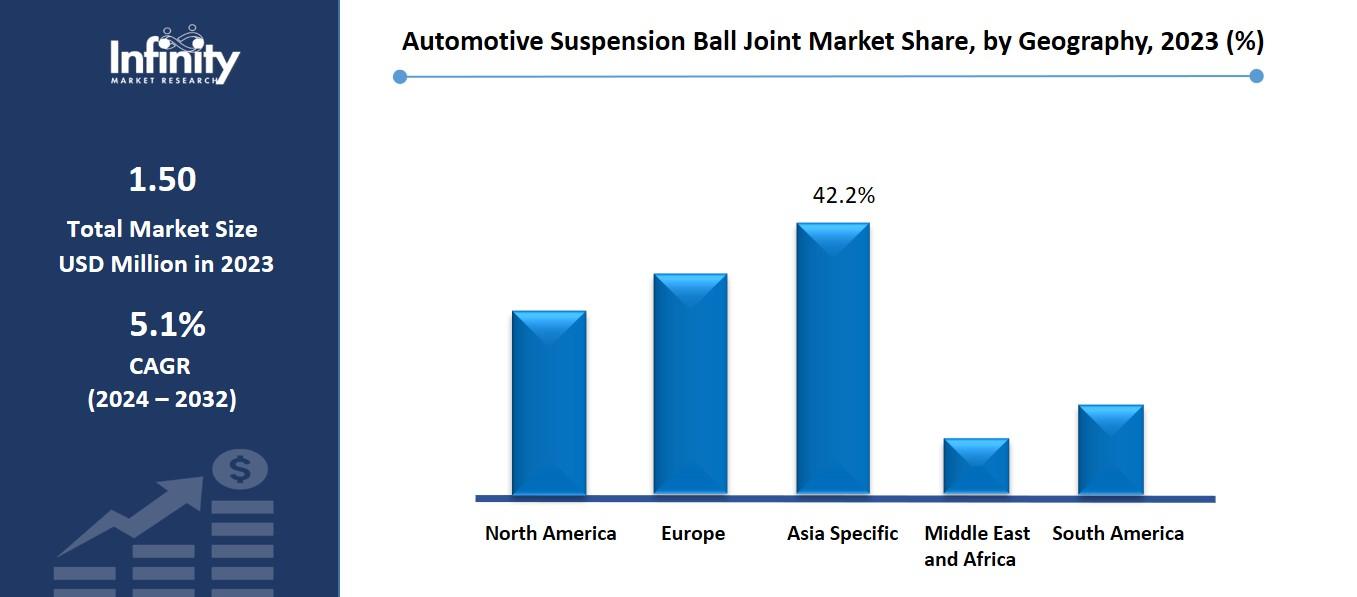

Automotive Suspension Ball Joint Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

According to analysis, by the year 2023 the Asia Pacific region will compose the largest share of the automotive suspension ball joint market in the global industry. This has been occasioned by the fact that the analyzed regions have a large Automotive Manufacturing Sector, especially in nations such as China, Japan, South Korea, and India. China being the largest automobile manufacturer and consumer in the world, has enormous automobile production capability. Industry prospect of automotive suspension ball joints in the region is rooted in the rising automotive manufacturing for local use as well as exports. Also, the growing use of electric vehicles in the Asia-Pacific countries is significantly boosting the requirement for better suspension components like ball joints. Another factor that connotes favourable regional dominance through 2023 and an approximate market share of over 40% is the region’s strong automotive industry that is experiencing stretched growth in terms of vehicle production.

Automotive Suspension Ball Joint Market Share, by Geography, 2023 (%)

Active Key Players in the Automotive Suspension Ball Joint Market

o Akebono Brake Industry Co., Ltd. (Japan)

o Albon Engineering & Manufacturing (UK)

o Bosch Automotive Steering (Germany)

o Continental AG (Germany)

o Dana Incorporated (USA)

o Delphi Technologies (USA)

o Dorman Products, Inc. (USA)

o Faurecia (France)

o Federal-Mogul Corporation (USA)

o GKN Automotive Ltd. (UK)

o Hitachi Automotive Systems (Japan)

o Hyundai Mobis (South Korea)

o NSK Ltd. (Japan)

o TRW Automotive (USA)

o ZF Friedrichshafen AG (Germany)

o Other key Players

Global Automotive Suspension Ball Joint Market Scope

|

Global Automotive Suspension Ball Joint Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 1.50 Billion |

|

Forecast Period 2024-32 CAGR: |

5.1% |

Market Size in 2032: |

USD 2.35 Billion |

|

Segments Covered: |

By Product Type |

· Load-Carrying Ball Joints · Non-Load-Carrying Ball Joints | |

|

By Vehicle Type |

· Passenger Cars · Light Commercial Vehicles · Heavy Commercial Vehicles | ||

|

By Material |

· Steel · Aluminum · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Increasing Vehicle Production and Aftermarket Demand | ||

|

Key Market Restraints: |

· Fluctuating Raw Material Prices | ||

|

Key Opportunities: |

· Growth in Electric Vehicle (EV) Market | ||

|

Companies Covered in the report: |

· Akebono Brake Industry Co., Ltd. (Japan), Albon Engineering & Manufacturing (UK), Bosch Automotive Steering (Germany), Continental AG (Germany), Dana Incorporated (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Automotive Suspension Ball Joint Market research report?

Answer: The forecast period in the Automotive Suspension Ball Joint Market research report is 2024-2032.

2. Who are the key players in the Automotive Suspension Ball Joint Market?

Answer: Akebono Brake Industry Co., Ltd. (Japan), Albon Engineering & Manufacturing (UK), Bosch Automotive Steering (Germany), Continental AG (Germany), Dana Incorporated (USA) and Other Major Players.

3. What are the segments of the Automotive Suspension Ball Joint Market?

Answer: The Automotive Suspension Ball Joint Market is segmented into Product Type, Vehicle Type, Material and region. By Product Type, the market is categorized into Load-Carrying Ball Joints, Non-Load-Carrying Ball Joints. By Vehicle Type, the market is categorized into Passenger Cars, Light Commercial Vehicles, Heavy Commercial Vehicles. By Material, the market is categorized into Steel, Aluminum, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Automotive Suspension Ball Joint Market?

Answer: Automotive suspension ball joint market can be described as the industry particularly developed to include the manufacturing and selling of ball joints that are used in the car suspension suspension mechanisms. Ball joints are important assemblies of the cars suspension system since they mend the link between the wheels axel and the car’s body by allowing the wheel to rotate in any direction as it absorbs shocks of the ride. These joints are meant to bear forces during motion of the vehicle, which include stability and control of the car. Automotive suspension ball joint is manufactured from high strength materiel like steel aluminum or its alloys and is expected to withstand normal and abnormal wear during car usage for a long time and at the same time should have the ability to bear the load requirements efficiently. The component is in high demand in the following concerns: global automotive industry; High-producing automobile regions; Better automobile performance; Automobile safety assistance; and Reduction of vehicle weight. Important trends that have an impact on the market include electrification of vehicles, new generation of autonomous driving systems and growing global demand for passenger and commercial vehicles.

5. How big is the Automotive Suspension Ball Joint Market?

Answer: Automotive Suspension Ball Joint Market Size Was Valued at USD 1.50 Billion in 2023, and is Projected to Reach USD 2.35 Billion by 2032, Growing at a CAGR of 5.1% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.