🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Braze Alloys Market

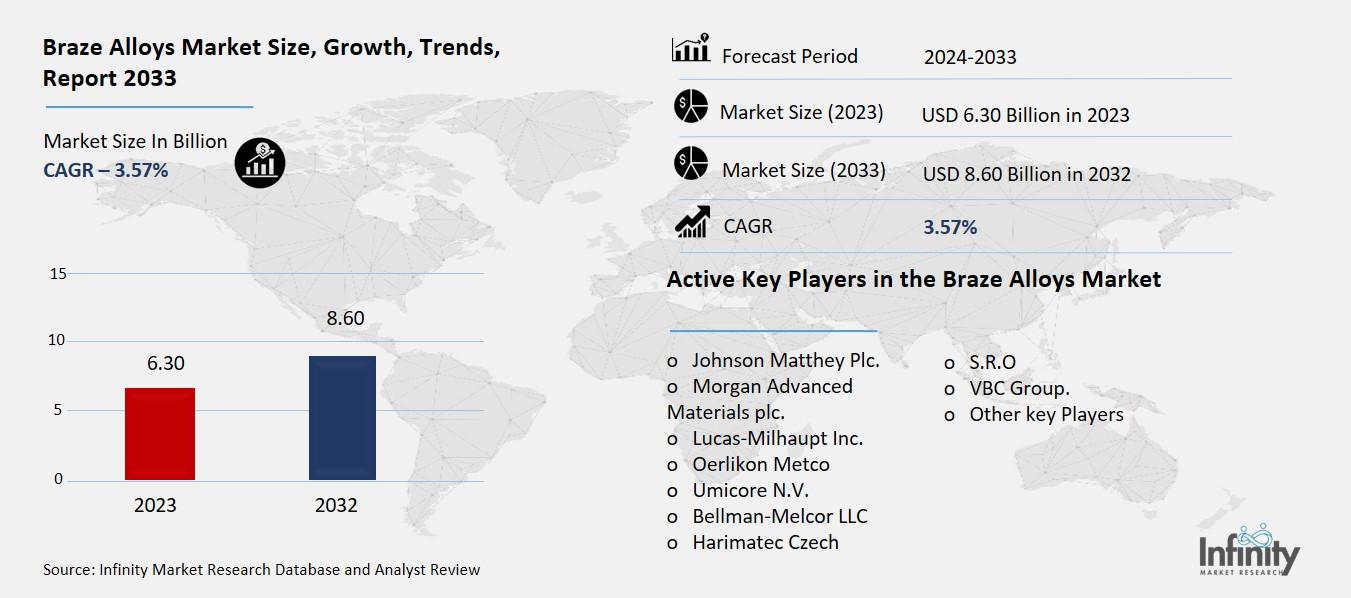

Braze Alloys Market Global Industry Analysis and Forecast (2024-2032) By Product Type (Copper, Gold, Silver, Aluminium, Other Product Types) By Application (Automotive, Electronics, Aerospace and Others) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1417

Braze Alloys Market Synopsis

Braze Alloys Market Size Was Valued at USD 6.30 Billion in 2023, and is Projected to Reach USD 8.60 Million by 2032, Growing at a CAGR of 3.57% From 2024-2032.

The global market for Braze Alloys is defined as the industry producing the raw materials used in brazing, a process that involves the use of filler metals to join metals at their melting points. These alloys, that are usually developed from copper, silver, aluminum and gold, give strong and steady joint connections in different usages like automotive, aerospace, electronics and HVAC materials. The need for braze alloys grows due to the call for high performance in industries relying on duty-cycle applications that necessitate high-temperature and pressure, and corrosion-resistant joints.

The market for braze alloys has been growing slowly over the years since applications for efficient joining technologies are constantly on the rise in the automotive, aerospace, electronics, and industrial industries. Braze alloys are utilized to bond metals and ceramics through a process called brazing which implementation involves the usage of filler metals that melts and flows into a joint between two separate pieces of stock. The value of application of braze alloys results from its efficiency at elevated temperatures and stress, and from the economical aspect – being cheaper than welding or other means of joining. As auto-mobile and aerospace industries, among others, move toward the use of lighter and stronger materials, the requirement of high quality of brazing materials has sharply grown.

The automotive industry has been one of the largest consumers of the braze alloys because they are used to produce the radiators, heat exchanging units, and electronic contacts. Brazing alloys are needed to ensure that the lightweight ever used in the construction of vehicles such as aluminum and composites offer secure and reliable joints due to the rising demand of fuel efficiency and reduced emissions. Brazing alloys used in aerospace applications include those that are used in production of vital parts including the blades of turbines, heat exchangers as well as other higher performance parts that can undergo various heat stresses as well as mechanical stresses. The electronics industry is also one of the most important concurring because braze alloys are used during manufacturing of electronics devices, connectors and semiconductors etc. In addition, novel technologies for braze alloy, as well as its formulations involving the use of advanced braze alloys having better conductor, anti-corrosive, and better strength properties, shall help the market to grow even further in the next few years.

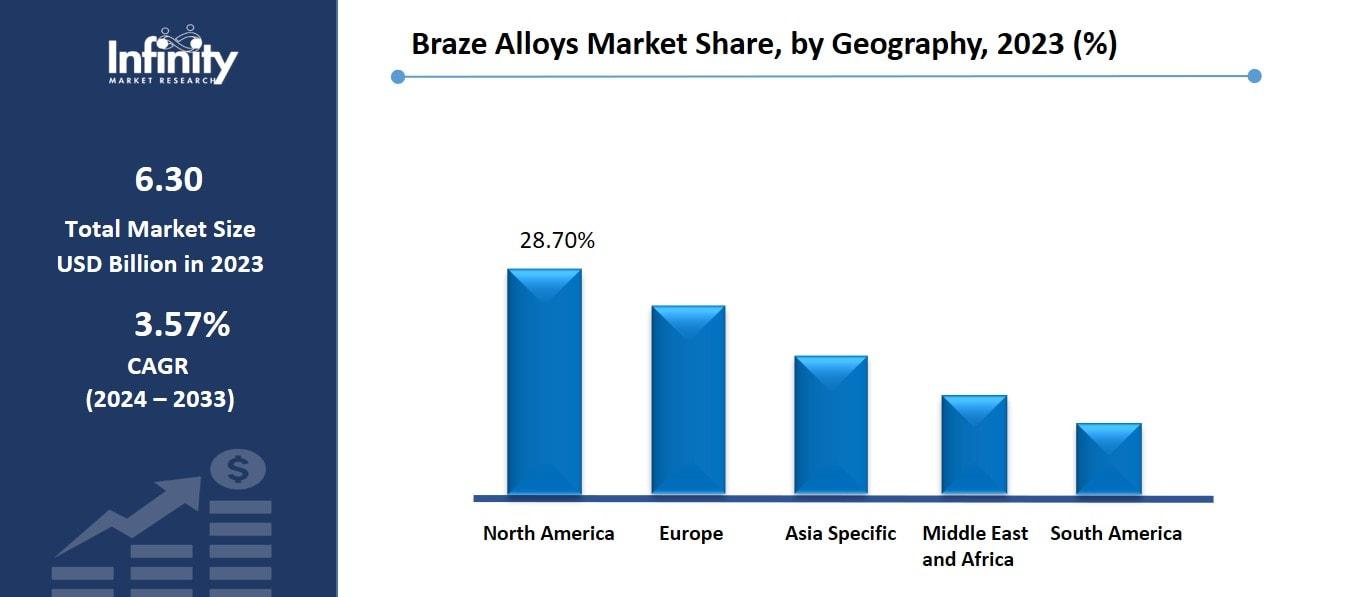

On a regional basis, North America and Europe had formed the most significant share of the global braze alloys market in terms of consumption because of the well-developed industrial infrastructure and massive demand across the automotive, aerospace, and electronics industries. However, due to factors such as industrialization, urbanization and growth/ manufacturing activities in the Asia-Pacific region such as China, Japan & India it is expected to grow at the fast rate. Also, the rising population of electric vehicles and progress in the field of renewable energy sources will create further prospects for brazing materials in the region. The market is also sensitive to changes in price of raw materials and supply chain and shifting environmental legislation that have encouraged manufacturers to seek better and cheaper brazing techniques. Technology being an ever-evolving factor, therefore the global braze alloys market is projected to grow in line with advanced technology opportunities for manufacturers and suppliers to meet changing demand from different industries.

Braze Alloys Market Trend Analysis

Growing Demand for High-Performance Materials in Aerospace, Automotive, Electronics, and HVAC

Some of the major factors that can be attributed to the market are the increasing need of high-performance material in diverse application areas like aerospace, automobile, electronics and HVAC etc. In aerospace application present day demands require material that has low density, high temperature properties and high strength and toughness. This has caused a dramatic increase in the use of, braise alloys which are very instrumental in the joining of vital parts such as turbine blades, heat exchangers, and, combustion chambers. The application of enhanced fuel efficiency and low emission by aerospace sector promotes better development of new and reliable brazing material for high stress conditions. Since the introduction of more complex aerospace products into the market, the dependence on the performance of the braze alloys has become paramount pushing development and usage in this specific sector.

Likewise, growth in automotive industry, especially Electric Vehicles (EVs), in influencing in a positive manner the demand of the braze alloys market. The EV structure demands high-performance brazing materials for connecting significant parts, such as battery packs, motors, and heat exchangers. As car makers chase efficiency and performance in automobile electric systems, the demand for brazing material that can take the heat – and other pressures of use – is growing apace. This trend is also enhanced by efforts to drive the weight of automobiles down for enhanced range and efficiency of electric vehicles, making the application of complex braze alloys even more paramount in the modern automobile fabrication. So whilst both of these industries progress in their respective fields the importance of braze alloys in the enhancement of key components and their reliability and safety is set to remain a key component of their technology.

Drivers

Increasing Demand for High-Performance Materials in Aerospace, Automotive, and Electronics

Since the sectors like aerospace, automotive and electronics are on the upward trend, new material is called to answer to higher temperatures and/or mechanical loads in operation conditions. It needs materials that can offer sufficient strength while at the same time, have sustainable durability under conditions of heat and pressure usage and mechanical stresses. These applications demand materials that haveoptimum thermal conductivities and braze alloys are a perfect fit because theydecompose at high temperatures and dissipate heat effectively. Also, they show high tensile and wear resistant properties to adequately support the mechanical pressure exerted by machinery, engines and vital parts in such industries.

Beside best mechanical properties and thermal characteristics, the corrosion resistance of braze alloys also ranked them firstly for utilizing in the severe circumstance including aerospace, automotive industries. Such components as turbine blades, vehicle’s engine, and other electrical devices are used in working environments where corrosion can cause major adverse effects on both, efficiency and durability. Adhesive and cohesive strength of a joining process and the capacity not to degrade the mechanical properties of the joined parts are the major important factors required in such application. This makes braze alloys essential especially where performance and durability are equally important making it to be widely used in many fields hence the demanding market.

Restraints

High Cost of Raw Materials

A major weak point that still binds the global braze alloys market is high cost of the raw materials used to manufacture braze alloys. The common uses of the metals are gold, silver and palladium in the manufacturing of braze alloys because of their good characteristics such as high melting temperatures and good resistance to corrosion. But these metals are not only costly but also their costs shift with varying market prices as well. These materials can be regarded as cost sensitive, the prices of which depend on general market trends, conflicts and sanctions, and limited resources of ores. These fluctuations in prices result to unpredictable cost of production, thus a difficult time for the producers to set standard prices on their products.

Due to this reason, manufacturers, especially small and medium business entities, face the problem of expensive raw materials in the form of braze alloys. Such alloys may not make economic sense in such companies to adopt in their operations since they are operating with scarce resources, competing against companies who may be financially muscular to absorb such costs. Therefore, the lack of desire of SMEs to adopt the braze alloys hinders the expansion of the market growth at a wider industrial front. This price sensitivity becomes an important consideration in limiting the growth of braze alloys into other applications especially in common areas that are sensitive to cost.

Opportunities

Rising Need for Specialized Braze Alloys in High-Performance EV Components

Increasing utilization of enhanced materials in automotive segment including the EV segment is opening up thriving opportunities for the braze alloys market. EVs use components which need to offer firmness, heat transfer property and anti-corrosion capability for instance battery packs, motors and heat exchangers. Such performance requirements have further created the need for dedicated braze alloys that would respond to light weight metals and parts and also meet the target vehicle’s performance and reliability factors. For example, many manufacturers continue to optimize the performance of EVs in order to increase battery life and reduce charging time, which requires the use of high-end supplier materials capable of withstanding these conditions, thus providing ample market opportunity for braze alloys.

Furthermore the focus of automobile industry towards production of economical cars is forcing research for new material that can provide lightweight yet strong solutions. This trend is consistent with the increasing demand for braze alloys used to offer tensile strength, high heat resistance, and low density of components such as engine and transmission as well as cooling system parts. The impressive scope shown by manufactures to develop new alloys to address these changing needs has been an avenue to achieving market growth in the braze alloys market. Such a growth demand for braze alloys sparked by innovation also complements the rise in the use of electric vehicles in automotive industries, which offer promising growth for the braze alloys market.

Braze Alloys Market Segment Analysis

Braze Alloys Market Segmented on the basis of by Product Type, By Application.

By Type

o Copper

o Gold

o Silver

o Aluminium

o Other Product Types

By Application

o Automotive

o Electronics

o Aerospace

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Product Type, Copper segment is expected to dominate the market during the forecast period

Copper is one of the most commonly used metals globally and is celebrated for its great thermal and electrical conductivity. This makes it an important element in electrical and electronics uses such as wiring, cables and printed circuit boards. Moreover, it is used on platforms for plumbing system, roofs, and industrial equipment due to it ductile and malleable nature. These attributes have placed copper in the basin of perennial material in construction and industries; especially where the factors of durability and efficiency are vital.

The increasing electrification needed for electric vehicles (EVs) and renewable energy systems is playing a large role in increasing demand for copper. For batteries, motors, and charging infrastructure, copper is needed for EVs, and for wind turbines and solar panels, copper is needed as a material for energy transmission. Thus the forecasts for copper demand remain strong, as the world has embarked on green energy production and transmission. This continuous shift makes copper the most essential material for the attainment of future energy and technology prospects.

By Application, Automotive segment expected to held the largest share

Automotive is a large consumer of metals for instance aluminum, copper and other precious metals that are very essential in car production. Aluminum is extensively used in auto-mobile industry in the form of lightweight vehicle frames , body panels, which enhance fuel efficiency and decrease emissions. Due to its better conductivity, copper plays a strategic role in the wiring, electrical, and motor industries more so in EVs. Platinum and palladium are used in the production of ‘catalytic converters’ which are very importantly used in emitting control in vehicles to meet some environmental standards.

In the automobile industry, the increasing use of EV and hybrid vehicles is recasting the metal demand by changing the overall structure in a fundamental way. New generation automobiles demand more copper for battery, charging systems and electrical architecture, power trains although lightweight metals like aluminum are needed for best energy return. We noted that emission control in internal combustion engine hybrids still require precious metals. It is, therefore, evident that metals are playing a new role of influencing energy efficiency and sustainability in the automobile industry.

Braze Alloys Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

North America remains the largest consumer of braze alloys because of the rapid development of aerospace and automotive industries within the region. The aerospace industry is consumer of high-performance brazing alloys that include those used in turbine engines, heat exchanging systems and structural parts. Furthermore, the automobile industry practiced widely in the United States and Mexico employs brazing alloys for the fabrication of parts such as radiators, engine, and transmission gasket systems. With the increased attention from auto makers toward better fuel economy and low emission systems, the demand for high thermal resistance and durability of brazing materials is expected to grow in this region.

Besides aerospace and automotive industry, North America receives considerable uplift from the various improvement in the field of electronic packaging technologies. Accordingly, as the electronics industry progresses and the industry in the United States develops particularly growing interest in semiconductors and microelectronics, the need for brazing alloys is also increasing. Additionally, the increasing commercialization of electric vehicles across the United States and Canada contributes significantly to market growth because electric vehicles’ parts generally require brazing processes. Military and Commercial Aviation requirements for the aerospace manufacturing are some of the forces that have driven the need for the braze alloys and again has helped boost North America as one of the largest markets for these materials.

Braze Alloys Market Share, by Geography, 2023 (%)

Active Key Players in the Braze Alloys Market

o Johnson Matthey Plc.

o Morgan Advanced Materials plc.

o Lucas-Milhaupt Inc.

o Oerlikon Metco

o Umicore N.V.

o Bellman-Melcor LLC

o Harimatec Czech

o S.R.O

o VBC Group.

o Other key Players

Global Braze Alloys Market Scope

|

Global Braze Alloys Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 6.30 Billion |

|

Forecast Period 2024-32 CAGR: |

3.57% |

Market Size in 2032: |

USD 8.60 Billion |

|

|

By Product Type |

· Copper · Gold · Silver · Aluminium · Other Product Types | |

|

By Application |

· Automotive · Electronics · Aerospace · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Increasing Demand for High-Performance Materials in Aerospace, Automotive, and Electronics | ||

|

Key Market Restraints: |

· High Cost of Raw Materials | ||

|

Key Opportunities: |

· Rising Need for Specialized Braze Alloys in High-Performance EV Components | ||

|

Companies Covered in the report: |

· Johnson Matthey Plc., Morgan Advanced Materials plc., Lucas-Milhaupt Inc., Oerlikon Metco, Umicore N.V., Bellman-Melcor LLC, Harimatec Czech, S.R.O, VBC Group. and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Braze Alloys Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Braze Alloys Market?

Answer: Johnson Matthey Plc., Morgan Advanced Materials plc., Lucas-Milhaupt Inc., Oerlikon Metco, Umicore N.V., Bellman-Melcor LLC, Harimatec Czech, S.R.O, VBC Group. and Other Major Players.

3. What are the segments of the Braze Alloys Market?

Answer: The Braze Alloys Market is segmented into By Product Type, By Application and region. By Product Type, the market is categorized into Copper, Gold, Silver, Aluminium, Other Product Types. By Application, the market is categorized into Automotive, Electronics, Aerospace and Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Braze Alloys Market?

Answer: The global braze alloys market refers to the industry involved in the production and distribution of materials used in brazing processes, which is a method of joining metals by melting and flowing a filler metal into the joint. These alloys, typically made from a combination of metals such as copper, silver, aluminum, and gold, are designed to provide strong, durable bonds in various applications, including

5. How big is the Biodegradable Engine Oil Market?

Answer: Braze Alloys Market Size Was Valued at USD 6.30 Billion in 2023, and is Projected to Reach USD 8.60 Million by 2032, Growing at a CAGR of 3.57% From 2024-2032

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.