🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Carbide Ceramic Coating Market

Carbide Ceramic Coating Market Global Industry Analysis and Forecast (2024-2032) By Type (Tungsten Carbide Coating, Titanium Carbide Coating, Chromium Carbide Coating), By Technology (Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), High-Velocity Oxygen Fuel (HVOF), Flame Spraying), By End-User Industry (Aerospace, Automotive, Marine, Electronics, Industrial Equipment, Oil & Gas) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1505

Carbide Ceramic Coating Market Synopsis

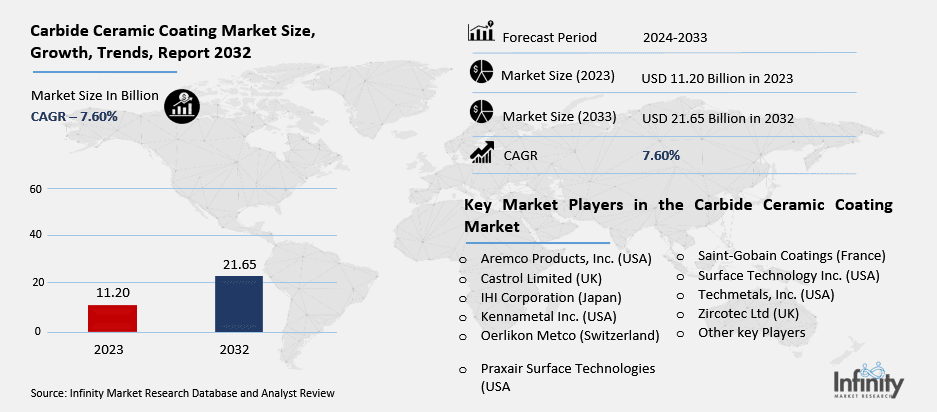

Carbide Ceramic Coating Market Size Was Valued at USD 11.20 Billion in 2023, and is Projected to Reach USD 21.65 Billion by 2032, Growing at a CAGR of 7.60 % From 2024-2032.

Carbide Ceramic Coating Market deals with the use of carbide ceramics; tungsten carbide, titanium carbide, and chromium carbide on surfaces to minimize wear rate, increase hardness, and improve the overall longevity of a surface. These coatings are generally employed in aerospace, automotive, oil and gas, and electronics industries where high value added and durable materials that can stand tough conditions of harsh environments are required in order to increase service life of equipments and parts.

The Carbide Ceramic Coating Market worldwide is expanding at a significant rate because components used in industries that demand long-lasting and sternly resistant materials are [...]. Driving forces include enhanced coating technologies, increasing automobile and airplane industries, and increasing utilization of oil and gas sectors. North America and Europe are privilege markets; however, Asia-Pacific is predicted to grow its market quickly due to the speedy industrialization throughout countries such as China and India.

They add that increased use of high-performance coatings in parts of industrial machinery, aerospace, and automotive applications will drive the development of carbide ceramic coatings. In the future, with the development of deposition techniques such as CVD and PVD, carbide ceramic coatings may be benefited from enhanced coating effectiveness and quality. Thus, eve though the market shows promising potentials and there are many opportunities for market players, there may be threats on its progress at the same time: for example, high production costs or limited awareness of the market in developed countries might turn into obstacles for market players in the future in certain states, including those of the developing countries.

Carbide Ceramic Coating Market Outlook, 2023 and 2032: Future Outlook

Carbide Ceramic Coating Market Trend Analysis

Eco-Friendly Coatings, The Future of Carbide Ceramic Technology

One emerging trend in the carbide ceramic coating market is the increased availably of ecofriendly technologies. It has been established that executives are managing companies and directing their research towards creation of functional coatings that will meet performance requirements and at the same time conform to legal requirements on environmental conservation. This trend is evident most in the Aerospace and automotive industries as standards have been set high on emission and material safety.

Another trend is multifunctional synergy of progressive coatings among which it is possible to single out the High-Velocity Oxygen Fuel (HVOF) and Flame Spraying. They also disclose increased corrosion resistance, elevated adhesion of the coating and enhanced physical properties of the deposited material, these all has made these techniques more applicable in all industrial and oil and gas industry.

Wear Resistance Demand Drives Market Growth

Thus, one of the main growth stimuli for the carbide ceramic coating market is the growth of various fields requiring wear-resistant materials such as automotive, aerospace, and industrial production. Such industries demand materials with high endurance levels characterized by high temperature, friction and high corroding environment. These properties make carbide ceramic coatings necessary and thus widely used.

Also, the expansion of the oil and gas industry and the equipment in use with harsh operating conditions is another driver to the carbide ceramic coatings market. These coatings’ effectiveness in increasing the durability and efficiency of handling and exploratory tools is gaining significance, contributing to the increased use of such coatings in energy applications.

High Costs, A Barrier to Widespread Coating Adoption

One restricting factor to the carbide ceramic coating market is the high cost that is often incurred when using these coatings. Despite these performance gains, the costs of carbide coatings, are largely in the purchase price of the carbide material, as well as the technologies needed for deposition; these costs can prove to be quite high for small companies or industries, or those with a smaller capital budget.

The following is that carbide ceramic coatings are not well known and used in the emerging economy. As the business heads toward manufacturing areas like Asia-Pacific and Latin America, still, many firms may not be aware of the benefits of carbide coatings; hence the slow market uptake.

Emerging Economies, A Goldmine for Coating Providers

With leading emerging economies such as China and India fast industrializing, there is huge potential to increase market player’s stakes in carbide ceramic coating industry. As economies of the manufacturing industries in countries such as India, China, and Brazil progress, the usage of carbide ceramic coating in the Industrial machinery and Automotive industries may be expected to rise.

Moreover, the current trend is toward sustainability, which creates a basis for the formation of more environmentally friendly carbide ceramic coatings. The companies which shall endeavor to come up with these new coatings with the efficiency of containing toxic products while at the same time being environmentally friendly will gain competitive advantage in the global market, attracting industries which are very sensitive to environmental issues

.

Carbide Ceramic Coating Market Segment Analysis

Carbide Ceramic Coating Market Segmented on the basis of By Type, By Technology and By End-User Industry.

By Type

o Tungsten Carbide Coating

o Titanium Carbide Coating

o Chromium Carbide Coating

By Technology

o Chemical Vapor Deposition (CVD)

o Physical Vapor Deposition (PVD)

o High-Velocity Oxygen Fuel (HVOF)

o Flame Spraying

By End Use

o Aerospace

o Automotive

o Marine

o Electronics

o Industrial Equipment

o Oil & Gas

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Tungsten Carbide Coating segment is expected to dominate the market during the forecast period

The carbide ceramic coating market is described by three primary types of coatings, which include tungsten carbide coatings, titanium carbide coatings, and chromium carbide coatings. The main types have their distinctive features that qualify them for various utilities. Tungsten carbide coatings are well-known products for its high hardness and wear properties that are commonly used in machine tools and cutting instruments. Titanium carbide coatings are used in many areas, particularly where high temperature service and properties are essential say in aerospace or auto business. Chromium carbide coatings are one of the most resistant coatings to corrosion and can be used in oil and gas industries mainly due to exposure to corrosive environments.

By Technology, Chemical Vapor Deposition (CVD) segment expected to held the largest share

Down the line carbide ceramic coating market segment, we divide it with the help of cutting-edge technologies like Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), High-Velocity Oxygen Fuel (HVOF), and Flame Spraying. These two techniques are very important in the preparation of thin, uniform layers true to dimensions and shape. Flame spraying and High Velocity Oxy Furnace (HVOF) are preferred to create thicker coatings with better clinging to the substrate and mostly applied for industrial and high usage purpose. CVD and PVD have relatively longer deposition time and thickness uniformity, while HVOF and Flame spraying may have better wear resistance and mechanical properties under high operating conditions.

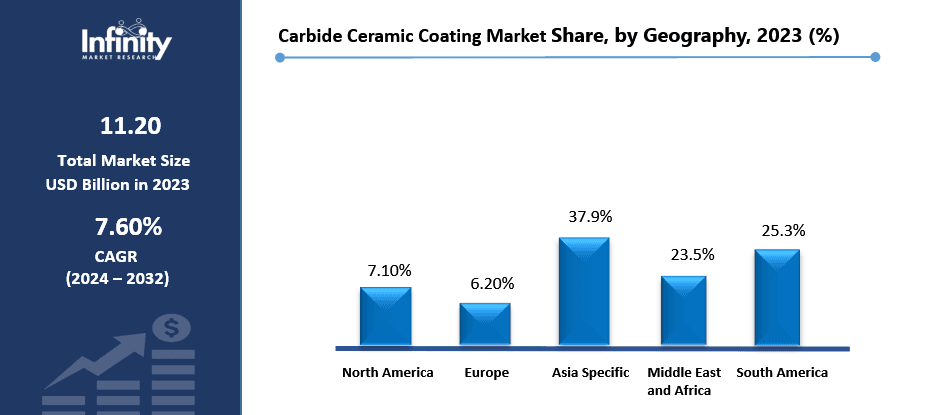

Carbide Ceramic Coating Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast period

Tapping deep into industrial and manufacturing growths of emerging markets like China and India are expected to contribute significantly in Asia-Pacific to the global carbide ceramic coating market. These countries are experiencing rising investments in the aerospace, automotive, and industrial manufacturing industries; therefore, carbide ceramic coatings are in high demand. The affordable production capacities in the given region also define the market trends.

The increasing car manufacture and aviation industries across Asia-Pacific region drives the demand for such coatings. As these industries further develop and advance, the need for carbide ceramic coatings as a means for improving life and efficiency of parts is forecasted to remain strong, solidifying the area as a market mainstay.

Carbide Ceramic Coating Market Share, by Geography, 2023 (%)

Active Key Players in the Carbide Ceramic Coating Market

o Aremco Products, Inc. (USA)

o Castrol Limited (UK)

o IHI Corporation (Japan)

o Kennametal Inc. (USA)

o Oerlikon Metco (Switzerland)

o Praxair Surface Technologies (USA)

o Saint-Gobain Coatings (France)

o Surface Technology Inc. (USA)

o Techmetals, Inc. (USA)

o Zircotec Ltd (UK)

o Other key Players

Global Carbide Ceramic Coating Market Scope

|

Global Carbide Ceramic Coating Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 11.20 Billion |

|

Forecast Period 2024-32 CAGR: |

7.60 % |

Market Size in 2032: |

USD 21.65 Billion |

|

Segments Covered: |

By Type |

· Tungsten Carbide Coating · Titanium Carbide Coating · Chromium Carbide Coating | |

|

By Technology |

· Chemical Vapor Deposition (CVD) · Physical Vapor Deposition (PVD) · High-Velocity Oxygen Fuel (HVOF) · Flame Spraying | ||

|

By End-User Industry |

· Aerospace · Automotive · Marine · Electronics · Industrial Equipment · Oil & Gas | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Industrial Expansion Fuels Carbide Ceramic Coatings Adoption | ||

|

Key Market Restraints: |

· Awareness Gaps in Emerging Markets Limit Market Reach | ||

|

Key Opportunities: |

· Sustainable Coatings, The Green Revolution in Carbide Ceramic Coatings | ||

|

Companies Covered in the report: |

· Praxair Surface Technologies (USA), Oerlikon Metco (Switzerland), Saint-Gobain Coatings (France), IHI Corporation (Japan), Kennametal Inc. (USA), Castrol Limited (UK), Surface Technology Inc. (USA), Zircotec Ltd (UK), Techmetals, Inc. (USA), Aremco Products, Inc. (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Carbide Ceramic Coating Market research report?

Answer: The forecast period in the Carbide Ceramic Coating Market research report is 2024-2032.

2. Who are the key players in the Carbide Ceramic Coating Market?

Answer: Praxair Surface Technologies (USA), Oerlikon Metco (Switzerland), Saint-Gobain Coatings (France), IHI Corporation (Japan), Kennametal Inc. (USA), Castrol Limited (UK), Surface Technology Inc. (USA), Zircotec Ltd (UK), Techmetals, Inc. (USA), Aremco Products, Inc. (USA) and Other Major Players.

3. What are the segments of the Carbide Ceramic Coating Market?

Answer: The Carbide Ceramic Coating Market is segmented into By Type, By Technology, By End-User Industry and region. By Type, the market is categorized into Tungsten Carbide Coating, Titanium Carbide Coating, Chromium Carbide Coating. By Technology, the market is categorized into Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), High-Velocity Oxygen Fuel (HVOF), Flame Spraying. By End-User Industry, the market is categorized into Aerospace, Automotive, Marine, Electronics, Industrial Equipment, Oil & Gas. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Carbide Ceramic Coating Market?

Answer: Carbide Ceramic Coating Market deals with the use of carbide ceramics; tungsten carbide, titanium carbide, and chromium carbide on surfaces to minimize wear rate, increase hardness, and improve the overall longevity of a surface. These coatings are generally employed in aerospace, automotive, oil and gas, and electronics industries where high value added and durable materials that can stand tough conditions of harsh environments are required in order to increase service life of equipments and parts.

5. How big is the Carbide Ceramic Coating Market?

Answer: Carbide Ceramic Coating Market Size Was Valued at USD 11.20 Billion in 2023, and is Projected to Reach USD 21.65 Billion by 2032, Growing at a CAGR of 7.60 % From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.