🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Ceramic Coatings Market

Ceramic Coatings Market Global Industry Analysis and Forecast (2024-2032) By Product (Oxide, Carbide, Nitride, Other) By Technology (Thermal Spray, Physical Vapor Deposition, Chemical Vapor Deposition, Other. By Application (Transportation & Automotive, Energy, Aerospace & Defense, Industrial goods, Healthcare, Others) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1688

Ceramic Coatings Market Synopsis

Ceramic Coatings Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

The scope of the ceramic coatings market is defined as the global market consisting of companies and materials intended for applying advanced ceramics to enhance outer layers of substrates. These coatings usually has material like silicon carbide, alumina and zirconia to assist in offering protection to a surface from wear, corrosion heat and chemical attack in addition it enhance the surface performance and durability. Internal/External: Implemented in automotive industries, aerospace, energy and health care & electronics industries, it contributes features like high heat stability, low wear & tear, attractiveness in the looks thereby increasing product life cycle, productivity.

Market growth factors pyro has base on the observation that the ceramic coatings market is open to market growth factors by virtue of the fact that requirement for better material safeguard and working in many sectors. Ceramic coatings exhibit high temperature stability, corrosion and wear protection and low friction and therefore ideal for important operational uses in automotive, aerospace, industrial and consumer product sectors. Automotive is one of the largest application segment of ceramic coating because the manufactures and consumers are always in search for the component that will enhance the efficiency of fuel, reduces the overall emission and increases the life span of car. Because coatings offer protection against wear in high heat and abrasive environments, auto producers are increasingly applying them to engines and exhaust components and any other possible part that may be subjected to heavy abuse in the use of the automobile. In addition, as much pressure as has been applied by environment standard setting bodies to industries to develop technologies that could reduce friction and therefore enhance fuel economy the more is invested in ceramic coatings to expand their use.

In aerospace industry, it is widely used for protecting and increasing the service life of such products as turbine engines, landing gears etc, which is used under the condition of high temperature, wear and corrosion. Combined with the emphasis on raising Aircraft operational efficiency and performance and with ever more rigorous and demanding working conditions there is a robust market driving force in this industry requiring ceramic coatings. Further, the availability of new materials and technologies of use of coatings strengthen the use of ceramic coatings to a even broader range of product types. For instance, technology applications including; medial devices, electronics, industrial machinery that utilizes ceramic coatings are emerging as new growth avenues. They are applied where there is a need to increase reliability and efficiency of part that can be exposed to chemical attack, high temperature or mechanical stresses. For these reasons the excellent thermal conducting property, chemical inerancy and low co-efficient of friction of ceramic coating make it attractive in several applications.

Beyond their end-use applications, ceramic coatings’ growth is also experienced in new diverse applications due to the development in the material science of ceramics such as the integration of nanotechnology in the manufacture of the new generation of coatings. Consequently, the nanocoatings with enhanced hardness, adhesion and corrosion and wear resistant properties are emerging to meet the needs of growing industries that require serviceable high performance coatings. Further, technological advancements are continuing to drive the market higher by incorporating new properties like improvement in the optical property, self cleaning property and better resistance towards environment parameter. An additional parameter that contributes to the growth in the demand for these coatings is the use of thin layers of such a high performance characteristic. At the current stage, North America and Europe can be predetermined as the biggest consumers of the ceramic coatings due to the long-term development of manufacturing industries and paying considerable attention to improving performance in transport and aerospace industries. Nevertheless, Asia-Pacific will have the greatest percentage increase in the course of the forecast period because of impending industrialization, a developing automotive industry, and actual investments in structures. It is a fact that some countries like China and India are experiencing higher growth for manufacturing processes which in turn, bring higher use of ceramic coating to cover machinery parts and other related goods in industries. As the market is expanding day by day, the major players in the ceramic coatings industry would still look forward to enhance more the coating solutions even beyond through additional improvements with the aid of developments in material sciences for specific uses in various sectors.

The global ceramic coatings market can be expected to be chock-a-block with opportunities prompted by enhanced research and development activities and sustainability and performance-related issues. New trends in coating formulation, for example, green coatings: the method that will produce least impact on the environment compared to other coating techniques is progressively becoming popular. The opportunities to increase the life of a product, or at least decrease the rate of its degradation, and not least, cast a positive light on energy savings through ceramically coated surfaces are expected to keep the market going. Further, the global trend that points towards high-performance coatings in the increasing markets of automotive and industrial application will uplift the growth of global ceramic coatings markets. Therefore, it can be suggested that the market of ceramic coatings has all the potential for futher development in connection with the technological advances made, the growth of industrial capacity, and the need to fully realize the potential of the material with high performance and operational characteristics meeting the requirements of various branches.

Ceramic Coatings Market Trend Analysis

Trend

Rising Demand for High-Performance Materials

The factors affecting the growth of the Ceramic Coatings Market are the increasing usage of various material coatings such as wear resistant, thermal resistant and chemical resistant material coatings. These characteristics justify why ceramic coatings are held to possess tremendous utility within several fields including automotive, aerospace, as well as in manufacturing industries. In automobile production, ceramic coatings are applied to enhance the structures utilised in the construction of engines and for decreased friction hence enhanced fuel efficiency. Similarly in the aerospace sector, the situation with the turbine blades is the same since these blades have to be coated with ceramic due to its high temperature and pressure bearing capacity; in fact the efficiency and reliability in this significant part is improved.

Handling several elements that are taken through high heat, abrasiveness and corrosive environments, an usage of ceramic coating is another crucial field where it’s applied on industrial portions of parts and equipment. About the increased durability wear and tear surface coatings lessen the amount of repairs and replacements required hence more saving are made. In almost every field, there is a gradual transition towards increased use of harder and more wear-resistant high-performance materials with an eye on efficiency and cost reduction and thus it comes as no surprise that individuals seek ceramic coatings as system enablers in high-wear conditions.

Drivers

Automotive Sector as a Key Driver for Ceramic Coatings

One of probably the most vital segments affecting the evolution of the ceramic coatings market is automotive since these coatings are a powerful tool to enhance the looks of a car and protect its surface. Ceramic coatings as the name suggests may are layers on vehicles to shield from some environmental factors that include dust, water and the ultraviolet light that affects the painted surface of cars. For car owners and car makers who are always in search of long lasting solution to give their cars back the look and also protection, the market for ceramic coatings has been enhanced. These characteristics are not only protective and add the improved view to the appearance of the automobile but also protect the painting on the body of the vehicle against frequent drawing.

Further the shift in the motor industry to the use of electric vehicles or EVs has also supported the use of ceramic coatings. Since more EV manufacturers are moving toward the use of environmentally sustainable materials, using ceramic coatings is a benefit given the factor of the environment. Such coating provide long lasting barrier on the vehicles hence they are environmental friendly and reduce maintenance costs thus improving vehicle performance. This will help to fuel further growth of the adoption of the ceramic coatings market globally as consumers move towards new ‘greener’ methods of transport through increased use of more EVs.

Restraints

High Initial Cost of Ceramic Coatings

The largest challenge that the ceramic coatings has is finding its way past the extremely high price of the coating wherein their nascent stage or early development. In this case, the functional ceramic coatings and particularly the advanced functional coatings are much more expensive than other type of coatings. This cost difference makes the ceramic coating to be less interesting to industries that would seek to save costs, and which may comprise of small businesses or start-ups. In the case of the evaluation of the long term costs it might not always be easy to do because the start up business might not be able to buy the ceramics because of the high initial cost that comes with it although the coatings might have long term benefits such as higher durability and lower maintenance costs.

Moreover, the application of ceramic coatings may be complex, and all these factors lead to high product cost. Such coatings may require special applicators and qualified staff to ensure that the right surface tension and coating thickness and rights performance characteristics. This can lead to extra operational costs such as labour and equipments hence the total cost of applying ceramic coatings is high. This makes ceramic coatings to be expensive to achieve the end results meaning that the industries stand to benefit from this innovation may not indulge themselves in the process of acquiring this form of coating due to the added costs.

Opportunities

Sustainability and Environmental Benefits

It is possible to note the most promising prospect in the supplies and demands of the ceramic coatings in auto industry it is primary utilizes of protective coatings. Ceramic coating overpowers most vehicles in terms of both the aesthetic and defense, proposing the maximum safeguarding againstwilting, scraping, and heat. This is particularly useful where the vehicles to be used are susceptible to adverse environmental conditions. Automotive products can now boast of ceramic coatings as manufacturers decide to focus on the longevity of the cars and taking care of them than they do on purchase. This opportunity also rises with the use of electric vehicles and luxury cars as the consumers seek high performance solutions to complement the durability and style of the vehicle while at the same time feeling luxurious.

However, there is a little shift towards sustainability in the automotive industry as of today because environmental issues compel the use of environmentally friendly materials and assets in automotive industries. Non toxic developed ceramic coatings come under this growing niche of more sustainable and fuel efficient automotive which in turn brings down the emissions. Perhaps, it is appropriate to emphasize that due to lower requirements for services, and the trend towards increasing fuel efficiency, ceramic coatings contribute to the creation of eco-friendly automotive products. In the aggregate, this trend, along with key growth of the technologies applicable to ceramics, provides for great development of the ceramic coatings market in areas based on automotive where strict environmental demands are enforced.

Ceramic Coatings Market Segment Analysis

Ceramic Coatings Market Segmented on the basis of By Product, By Technology, By Application.

By Product

o Oxide

o Carbide

o Nitride

o Other

By Technology

o Thermal Spray

o Physical Vapor Deposition

o Chemical Vapor Deposition

o Other

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Product, Oxide segment is expected to dominate the market during the forecast period

Oxide coatings are among the most prevalent ceramic coatings, valued for their exceptional thermal stability, corrosion resistance, and dielectric properties. These coatings are essential in high-temperature environments, such as those found in gas turbines, industrial equipment, and automotive components. Their ability to act as a robust barrier against oxidation and wear makes them indispensable in industries like aerospace and energy, where components are routinely exposed to extreme conditions. Oxide coatings enhance the durability and efficiency of machinery and systems, reducing maintenance costs and downtime, which is crucial in mission-critical applications.

With ongoing advancements in material science, the demand for oxide coatings continues to rise, driven by the need to extend the lifespan of components in harsh environments. The development of new oxide formulations has broadened their application scope, addressing challenges such as thermal cycling and chemical exposure. Additionally, the global push for energy efficiency and sustainable solutions is further fueling the adoption of oxide coatings, as they contribute to improved performance and longevity in renewable energy systems and other environmentally conscious technologies.

By Application, Transportation & Automotive segment expected to held the largest share

Ceramic coatings are integral to the automotive industry, providing exceptional heat resistance, wear protection, and enhanced engine efficiency. These coatings are extensively applied to critical components such as engines, exhaust systems, and brake systems to improve their performance and durability under high-stress conditions. By reducing wear and corrosion, ceramic coatings help extend the life span of automotive parts, leading to lower maintenance costs and increased reliability. Additionally, their ability to withstand extreme temperatures makes them particularly effective in optimizing the performance of internal combustion engines and exhaust systems.

The growing shift toward electric vehicles (EVs) has further amplified the demand for ceramic coatings. In EVs, these coatings play a pivotal role in thermal management, particularly in battery components, where maintaining optimal temperature is crucial for safety and efficiency. Ceramic coatings also contribute to lightweighting strategies by enabling the use of advanced materials that require surface protection. As the automotive industry increasingly focuses on sustainability and energy efficiency, the adoption of ceramic coatings is expected to accelerate, driven by their ability to enhance the performance and longevity of both traditional and next-generation vehicles.

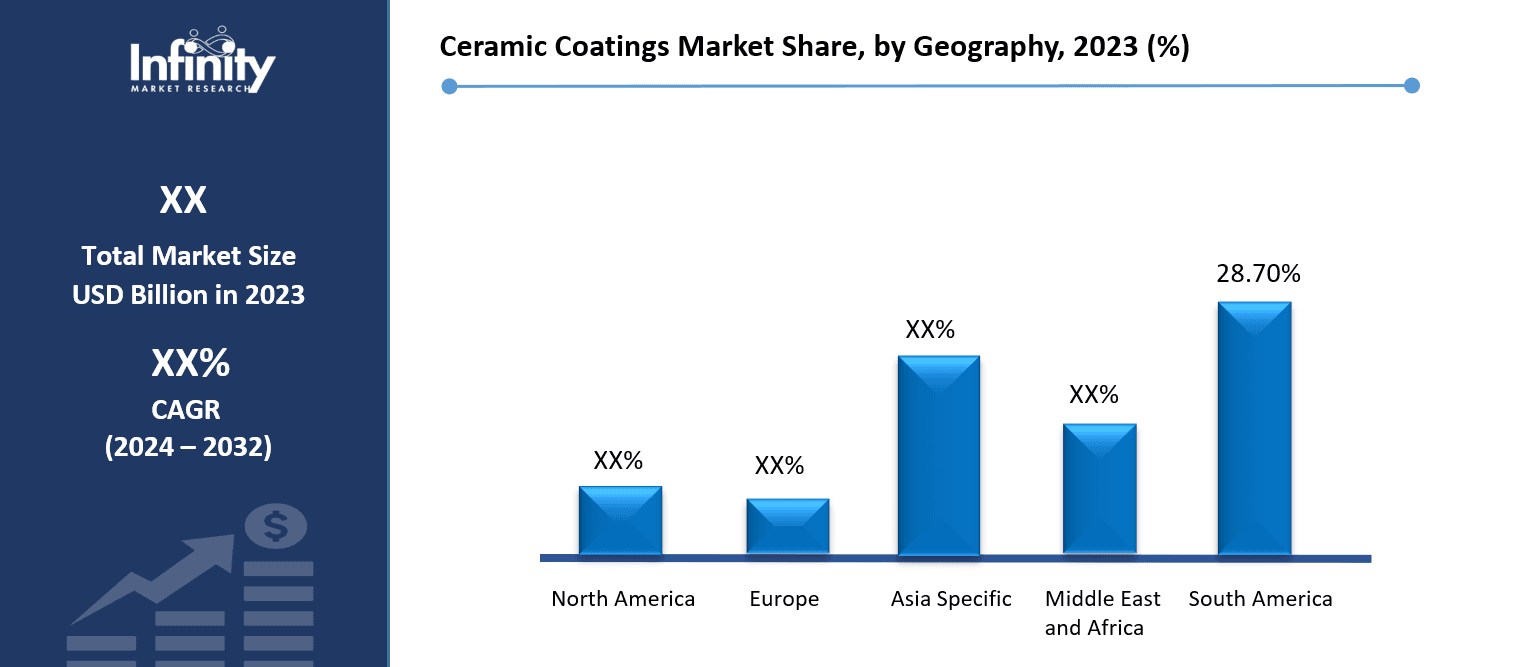

Ceramic Coatings Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

The market for ceramic coatings in North America is also expanding gradually primarily due to growing demands from every sector including aerospace, automotive, and medical industries. As before the US is one country that has not relented in promoting this market especially in aerospace applications. This ever-repeated demand of coating for aerospace due to heat resistance models, by virtue of high temperature exigency in engine and blades of turbines. Moreover, ceramics are also being used in the automotive applications because of the ability to extend the life span of vehicles and improve efficiencies of exhaust systems, engine and brake parts. These coatings are a step up from corrosion protection, wear and tear and fuel consumption; all areas of concern in the automotive business in how to deliver long-lasting efficient and energy-friendly cars.

The region is further helped by sustainable growth that only occurs through advancements in technology, as major participants in the ceramic coatings market have not rushed into the research and development of higher end solutions for the various sectors. North American has large amounts of the manufacturing and application companies which plays important roles in the support of a number of industries. In addition, this region has the practice of green products as well energy saving which will in turn improve the usage of ceramic coatings. The benefit of these coatings is that energy is saved, product durability is improved, and the impact resultant from manufacturing operations is minimized. As noted again, the automotive and energy market will lead the demand in the ceramic coatings industry hence the constant growth throughout North America.

Ceramic Coatings Market Share, by Geography, 2023 (%)

Active Key Players in the Ceramic Coatings Market

o Praxair Technology, Inc. (Linde PLC)

o Aremco

o APS Materials, Inc.

o Cetek Cermaic Technologies Ltd.

o Keronite

o Saint-Gobain S.A.

o Element 119

o NANOSHINE GROUP CORP

o Ultramet

o Other key Players

Global Ceramic Coatings Market Scope

|

Global Ceramic Coatings Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Product |

· Oxide · Carbide · Nitride · Other | |

|

By Technology |

· Thermal Spray · Physical Vapor Deposition · Chemical Vapor Deposition · Other | ||

|

By Application |

· Transportation & Automotive · Energy · Aerospace & Defense · Industrial goods · Healthcare · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Automotive Sector as a Key Driver for Ceramic Coatings | ||

|

Key Market Restraints: |

· High Initial Cost of Ceramic Coatings | ||

|

Key Opportunities: |

· Sustainability and Environmental Benefits | ||

|

Companies Covered in the report: |

· Praxair Technology, Inc. (Linde PLC), Aremco, APS Materials, Inc., Cetek Cermaic Technologies Ltd., Keronite, Saint-Gobain S.A., Element 119, NANOSHINE GROUP CORP, Ultramet and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Ceramic Coatings Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Ceramic Coatings Market?

Answer: Praxair Technology, Inc. (Linde PLC), Aremco, APS Materials, Inc., Cetek Cermaic Technologies Ltd., Keronite, Saint-Gobain S.A., Element 119, NANOSHINE GROUP CORP, Ultramet and Other Major Players.

3. What are the segments of the Ceramic Coatings Market?

Answer: The Ceramic Coatings Market is segmented into By Product, By Technology, By Application and region. By Product, the market is categorized into Oxide, Carbide, Nitride, Other. By Technology, the market is categorized into Thermal Spray, Physical Vapor Deposition, Chemical Vapor Deposition, Other. By Application, the market is categorized into Transportation & Automotive, Energy, Aerospace & Defense, Industrial goods, Healthcare, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Ceramic Coatings Market?

Answer: The scope of the ceramic coatings market is defined as the global market consisting of companies and materials intended for applying advanced ceramics to enhance outer layers of substrates. These coatings usually has material like silicon carbide, alumina and zirconia to assist in offering protection to a surface from wear, corrosion heat and chemical attack in addition it enhance the surface performance and durability. Internal/External: Implemented in automotive industries, aerospace, energy and health care & electronics industries, it contributes features like high heat stability, low wear & tear, attractiveness in the looks thereby increasing product life cycle, productivity.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.