🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Ceramic Matrix Composites (CMC) Market

Ceramic Matrix Composites (CMC) Market Global Industry Analysis and Forecast (2024-2032) Fiber Type (Continuous Fiber, Discontinuous Fiber), Matrix Type (Oxide/Oxide CMC, Carbon/Carbon CMC, SiC/SiC CMC), Application (Engine Components, Heat Shields, Brake Systems, Electrical Components, Other Applications), End-Use Industry (Aerospace & Defense, Automotive, Energy, Industrial, Electronics) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1520

Ceramic Matrix Composites (CMC) Market Synopsis

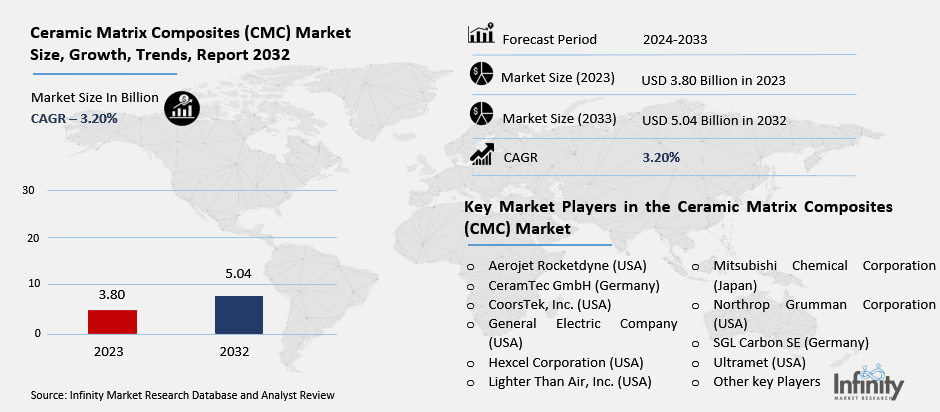

Ceramic Matrix Composites (CMC) Market Size Was Valued at USD 3.80 Billion in 2023, and is Projected to Reach USD 5.04 Billion by 2032, Growing at a CAGR of 3.20 % From 2024-2032.

CMC is a class of reinforced composites comprised of ceramic fibers set in a ceramic matrix for higher properties with closure to a certain degree of thermal stability, mechanical strength, and damage tolerance. These materials are mostly applied in aerospace, automobile, energy and industrial segments, which the conventional materials prove unsuitable at high performance standards. CMCs own exceptional resistance to thermal shock, wear and corrosion that make them suitable in high stress applications.

The ceramic matrix composites or CMC market is in a high growth phase and has found good traction especially in aerospace, automotive and energy industries where the use of high and better performance material is inevitable. CMCs are chosen mainly because they possess high temperature tolerance, lightweight nature with high strength, and high sturdiness against environmental factors. New findings in this area are expected to continue designing new ways and expanding the use of such composites.

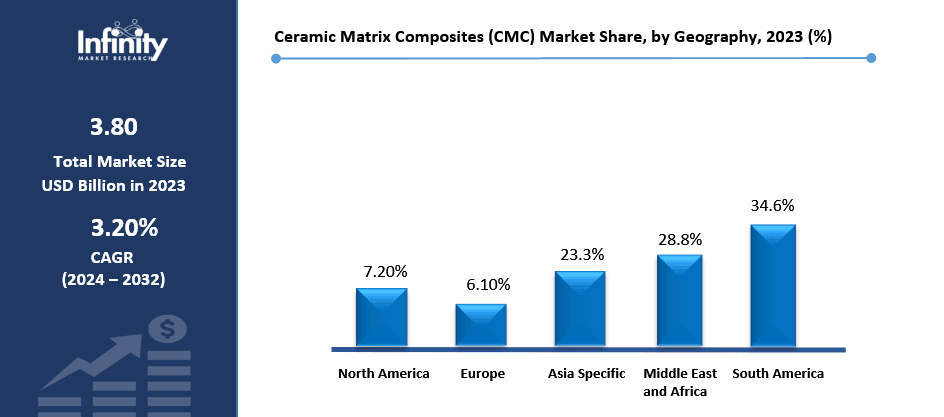

On a regional basis, North America has the largest share of the market because of the advanced aerospace and defense sector present in the region and its key players’ strong focus on CMC technologies. Asia Pacific is equally showing immense potential which is due to booming automotive industry in China and Japan. The global market for CMCs is expected to remain on an upward trend, because manufacturers look for more sophisticated materials, which could help achieve better fuel consumption rates, performance, and durability.

Ceramic Matrix Composites (CMC) Market Outlook, 2023 and 2032: Future Outlook

Ceramic Matrix Composites (CMC) Market Trend Analysis

Flying High, Key Trends Shaping the CMC Market

The current state in the Ceramic Matrix Composites (CMC) market shows that there is a need to produce materials that are lighter in weight to improve on the performance efficiency of modern airplanes and automobiles. The importance for high reliability and low cost for CMC products has led companies to focus on the development of better manufacturing technologies such as advanced sintering and impregnation processes. Moreover, the ever growing demand of CMCs in the production of turbine blades and heat shields is developing innovation.

Another important trend is the growth of interest to the use of CMCs in energy and industrial application viewpoints, especially for applications where materials must possess heat resistance and chemical stability. It has therefore stimulated developmental studies on CMCs for application in reactors, power plants, and other systems where the components are expected to work under severe operating conditions.

Fueling Innovation, Drivers Powering CMC Market Growth

The increasing demand for lightweight and high-performance products in aerospace and automotive sectors is expected to remain a major force in the growth of the CMC market. CMCs provide higher thermal stability and it is possible to decrease weight of the parts such as the engine and heat shiled and thus obtain improved fuel efficiency and performance. As the advanced applications for energy efficient solutions grows more relevant in the market, CMCs are growing more essential.

Also, the increasing concern for environmental issues is also contributing to growth in the consumption of CMCs. These help in reducing emission and fuel consumption in vehicles and aircraft the main reason why industries that need to meet environmental standards find these materials very useful. Future advances in CMC technologies will probably increase the application of CMC in different sectors.

Breaking Barriers, Challenges Holding Back CMC Market Growth

One of the biggest challenges in the market for Ceramic Matrix Composites is the expensive manufacturing of these evolved materials. The production of CMCs includes certain steps like weaving of fibers, sintering, and chemical vapor infiltration which makes the CMC expensive. This poses a problem for many small firms, or firms from emerging markets, to integrate these materials in sizeable quantities.

Another major cost-benefit constraint is the fact that it is difficult to scale up the process of CMC production, thus limiting its use. New production technologies that have emerged have not quite solved this problem, and the absolute production volumes of high-strength fiber reinforced plastic parts are still comparatively low and cannot match the growing demand aside from fully mature components and systems this remains a significant problem in applications where first-cost is a major issue such as automotive manufacturing.

New Horizons, Opportunities Unlocking CMC Market Potential

New generation material requirements of aerospace and Defence sectors create vast prospects for CMC market. Is It Becoming A Promising Solution For These Sectors As They Look For Strategies On How To Enhance Fuels Economy And /Or Minimize Their Environmental Footprints? The modern hypersonic vehicles and advanced space crafts can be developed as opportunities for CMCs in the environment where other materials would be unable to operate.

Further, the automotive sector is expanding its investment on CMCs as components in EV batteries and car brake systems, and in engine parts. Since EVs are slowly gaining popularity, the major factor of CA campuses CMC market growth will be light weight yet high strength material types. Moreover, new projects connected with the energy systems involving nuclear reactors and power plant stations are also potential CMC solutions.

Ceramic Matrix Composites (CMC) Market Segment Analysis

Ceramic Matrix Composites (CMC) Market Segmented on the basis of Fiber Type, Matrix Type and Application.

By Type

o Continuous Fiber

o Discontinuous Fiber

By Matrix Type

o Oxide/Oxide CMC

o Carbon/Carbon CMC

o SiC/SiC CMC

By Application

o Engine Components

o Heat Shields

o Brake Systems

o Electrical Components

o Other Applications

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

Fiber Type, Continuous Fiber segment is expected to dominate the market during the forecast period

Ceramic Matrix Composites (CMC) can be broadly classified by the fiber type segment into the Continuous Fiber and Discontinuous Fiber segments. Unidirectional CMCs offer unmatched mechanical properties along with dimensional stability over large reinforced fibers and as such make their use in turbine blade and engine parts feasible. Discontinuous fiber CMCs, as previously said, has the versatility in design utilization and is used where extremely complicated shape is desired or a design that needs much less money to produce. Both of them help to determine the lightweight and high-temperature functionality of the CMCs.

Matrix Type, Oxide/Oxide CMC segment expected to held the largest share

The matrix type segment of Ceramic Matrix Composites (CMC) is divided into Oxide/Oxide CMC, Carbon/Carbon CMC and SiC/SiC CMC. Oxide/Oxide CMCs are known to have best thermal and chemical endurance for instance in air craft industry. Carbon/Carbon CMCs exhibit superior performance in thermal conduction and are mainly used in applications such as brake system and heat protect shields. SiC/SiC CMCs possess high oxidation tolerance and find application in thermal management systems such as in gas turbine and nuclear reactors.

Ceramic Matrix Composites (CMC) Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

North American region holds largest share in the ceramic matrix composites (CMC) market owing to its advanced aerospace and defence industry wherein CMCs are applied in engine parts, heat protectants, and others. The region enjoys much research and development, fusion of government departments and firms in the market. As the CMC technologies develop North America may continue to dominate the market for the production of transmission capacities.

Additionally, it has felt presence of leading market players and research institutions which enhances the market in the region. The growing trend towards fuel-efficient and green material in aerospace, automotive applications and energy sectors underlines North America’s position in the CMC market even further.

Ceramic Matrix Composites (CMC) Market Share, by Geography, 2023 (%)

Active Key Players in the Ceramic Matrix Composites (CMC) Market

o Aerojet Rocketdyne (USA)

o CeramTec GmbH (Germany)

o CoorsTek, Inc. (USA)

o General Electric Company (USA)

o Hexcel Corporation (USA)

o Lighter Than Air, Inc. (USA)

o Mitsubishi Chemical Corporation (Japan)

o Northrop Grumman Corporation (USA)

o SGL Carbon SE (Germany)

o Ultramet (USA)

o Other key Players

Global Ceramic Matrix Composites (CMC) Market Scope

|

Global Ceramic Matrix Composites (CMC) Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 3.80 Billion |

|

Forecast Period 2024-32 CAGR: |

3.20 % |

Market Size in 2032: |

USD 5.04 Billion |

|

Segments Covered: |

Fiber Type |

· Continuous Fiber · Discontinuous Fiber | |

|

Matrix Type |

· Oxide/Oxide CMC · Carbon/Carbon CMC · SiC/SiC CMC | ||

|

Application |

· Engine Components · Heat Shields · Brake Systems · Electrical Components · Other Applications | ||

|

End-Use Industry |

· Aerospace & Defense · Automotive · Energy · Industrial · Electronics | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· On the Fast Track, Key Drivers for CMC Market Expansion | ||

|

Key Market Restraints: |

· Overcoming Hurdles, Restraints Impacting CMC Adoption | ||

|

Key Opportunities: |

· The Next Big Thing, Emerging Opportunities in the CMC Market | ||

|

Companies Covered in the report: |

· General Electric Company (USA), Hexcel Corporation (USA), SGL Carbon SE (Germany), CoorsTek, Inc. (USA), Ultramet (USA), Mitsubishi Chemical Corporation (Japan), CeramTec GmbH (Germany), Northrop Grumman Corporation (USA), Lighter Than Air, Inc. (USA), Aerojet Rocketdyne (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Ceramic Matrix Composites (CMC) Market research report?

Answer: The forecast period in the Ceramic Matrix Composites (CMC) Market research report is 2024-2032.

2. Who are the key players in the Ceramic Matrix Composites (CMC) Market?

Answer: General Electric Company (USA), Hexcel Corporation (USA), SGL Carbon SE (Germany), CoorsTek, Inc. (USA), Ultramet (USA), Mitsubishi Chemical Corporation (Japan), CeramTec GmbH (Germany), Northrop Grumman Corporation (USA), Lighter Than Air, Inc. (USA), Aerojet Rocketdyne (USA) and Other Major Players.

3. What are the segments of the Ceramic Matrix Composites (CMC) Market?

Answer: The Ceramic Matrix Composites (CMC) Market is segmented into Fiber Type, Matrix Type, Application, End User and region. Fiber Type, the market is categorized into Continuous Fiber, Discontinuous Fiber. Matrix Type, the market is categorized into Oxide/Oxide CMC, Carbon/Carbon CMC, SiC/SiC CMC. Application, the market is categorized into Engine Components, Heat Shields, Brake Systems, Electrical Components, Other Applications, End-Use Industry the market is categorized into, Aerospace & Defense, Automotive, Energy, Industrial, Electronics. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Ceramic Matrix Composites (CMC) Market?

Answer: CMC is a class of reinforced composites comprised of ceramic fibers set in a ceramic matrix for higher properties with closure to a certain degree of thermal stability, mechanical strength, and damage tolerance. These materials are mostly applied in aerospace, automobile, energy and industrial segments, which the conventional materials prove unsuitable at high performance standards. CMCs own exceptional resistance to thermal shock, wear and corrosion that make them suitable in high stress applications.

5. How big is the Ceramic Matrix Composites (CMC) Market?

Answer: Ceramic Matrix Composites (CMC) Market Size Was Valued at USD 3.80 Billion in 2023, and is Projected to Reach USD 5.04 Billion by 2032, Growing at a CAGR of 3.20 % From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.