🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Coextruded Multilayered Film Market

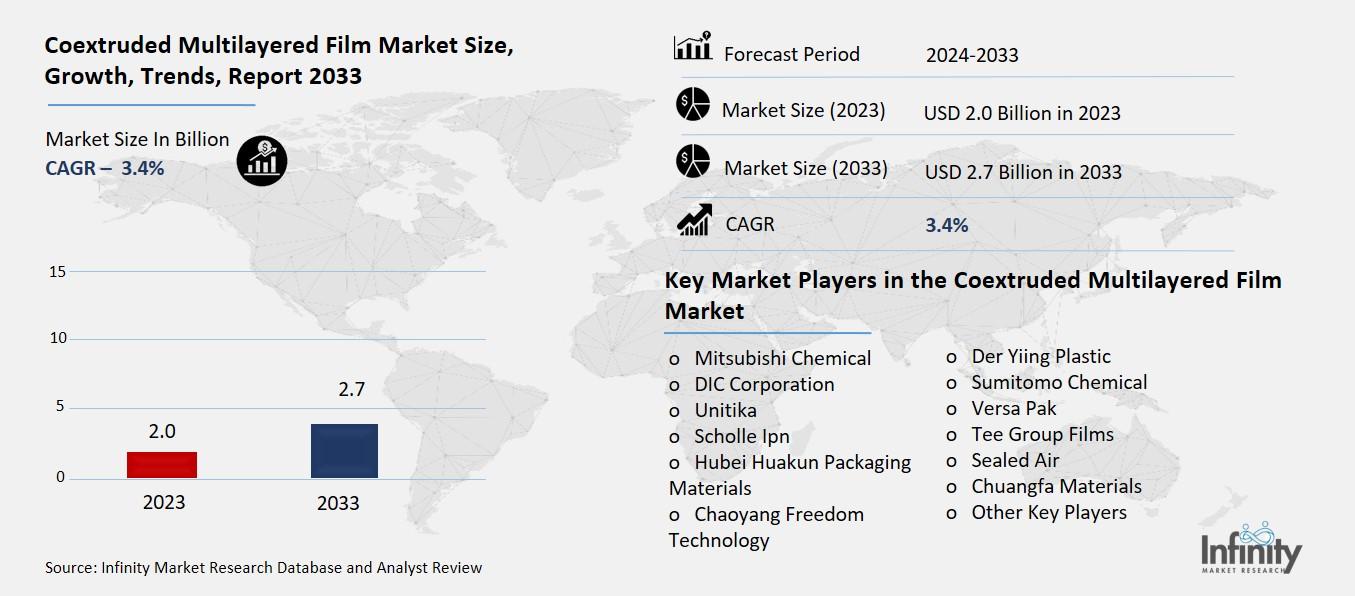

Global Coextruded Multilayered Film Market (By Type, Below 0.2mm, 0.2mm-0.7mm, and More Than 0.7mm; By Application, Medical Device Packaging, Industrial Materials, Food Packaging, Transfusion Bags, and Other Applications; By Region and Companies), 2024-2033

Dec 2024

Packaging and Transports

Pages: 138

ID: IMR1357

Coextruded Multilayered Film Market Overview

Global Coextruded Multilayered Film Market acquired the significant revenue of 2.0 Billion in 2023 and expected to be worth around USD 2.7 Billion by 2033 with the CAGR of 3.4% during the forecast period of 2024 to 2033. Coextruded multilayered film market is the market for films produced and used through the coextrusion process, which is the process of extruding several layers of various polymers to form a single film. These laminated films incorporate different aspects of at least two materials offering barrier, mechanical and flexibility to cater a certain packaging need.

This is due to the increasing requirement for sophisticated packaging materials in wide industrial segments including food, medicines, electronics and consumer products. The benefits of coextruded films include; better barrier properties against moisture, oxygen and light, longer shelf life and cheaper than most packaging media. Also, coextrusion expands the possible options for the use of biodegradable or recyclable polymers that matches todays sustainability trends.

Drivers for the Coextruded Multilayered Film Market

Rising Demand for Advanced Packaging Solutions

The trends in the packaging demand indicate the need for more and better packaging solutions to meet consumers’ needs and further tap into product-shelf life, protection, and convenience needs in sectors such as food, drugs, and other consumer durable goods. In the food industry for instance, customers want the food to be fresher yet their shelf life should be longer to avoid deterioration. Solutions as to the packaging that has the ability to protect products from the environmental conditions, for example moisture, oxygen, and light should enable meeting such expectations. Likewise, in the area of pharmaceutical and especially in the cases of products that are sensitive to environmental conditions the issue of product quality is crucial. It’s important to use packaging that retains the potency of a drug; this packaging should also ensure that the products sterility is maintained; and that the packaging cannot be tampered with. In consumer goods, especially personal care and cosmetic products, packaging has to protect the product from the external environment besides creating a positive appeal to the user, the pack should be easy to handle and open.

Restraints for the Coextruded Multilayered Film Market

Material Compatibility Issues

Ensuring the compatibility of various polymers during the coextrusion process presents a significant challenge in the production of multilayer films. Coextrusion involves the simultaneous extrusion of different polymer layers, and for these layers to adhere effectively to one another, the materials must have compatible chemical and physical properties. If the polymers do not bond properly, it can result in weak spots, delamination, or compromised barrier properties in the final film. This issue limits the selection of materials that can be used together, as not all polymers are compatible in terms of their melting points, viscosities, or surface energy.

Opportunity in the Coextruded Multilayered Film Market

Growing Demand for Sustainable Packaging

With the increasing global emphasis on sustainability, there is significant potential for the development of biodegradable and recyclable coextruded films, which can cater to the growing demand for eco-friendly packaging solutions across various industries. Traditional plastic films, while effective in terms of barrier properties and performance, contribute to environmental pollution due to their non-biodegradable nature and difficulties in recycling. This has led to a shift towards using more sustainable materials in packaging, driven by both regulatory pressures and consumer preferences for environmentally responsible products.

Biodegradable coextruded films, made from materials such as plant-based biopolymers or biodegradable plastics, offer an alternative to conventional plastics, breaking down naturally over time and minimizing environmental impact. These films are particularly desirable in industries like food packaging, where sustainability and reduced waste are top priorities.

Trends for the Coextruded Multilayered Film Market

Rise in E-commerce Packaging

The growth of online retail has significantly increased the demand for protective and sustainable packaging solutions, creating a unique opportunity for coextruded films. As e-commerce continues to expand, the need for packaging that can protect products during transit, prevent damage, and ensure the product arrives in perfect condition has become more critical than ever. Products shipped through various channels often face rough handling, exposure to varying environmental conditions, and long shipping times, all of which require packaging that can withstand such challenges. Coextruded films, with their multi-layered construction, offer superior durability and protection by combining materials with different properties such as strength, flexibility, and moisture resistance into a single, cohesive packaging solution.

Segments Covered in the Report

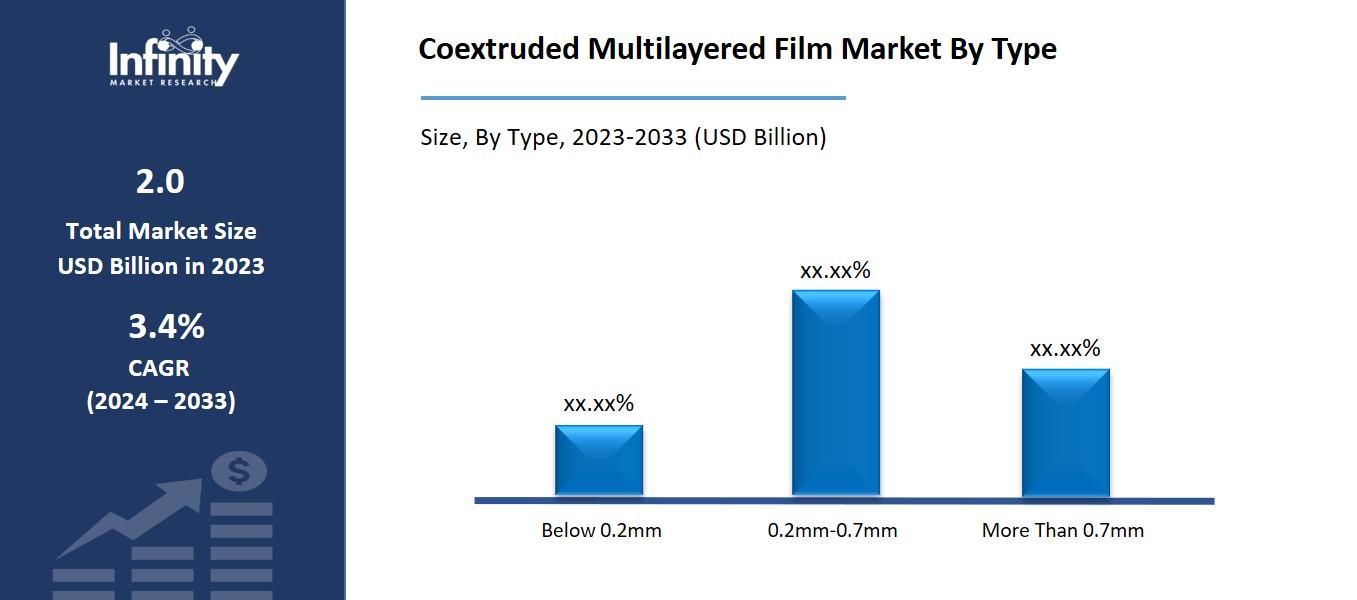

By Type

o Below 0.2mm

o 0.2mm-0.7mm

o More Than 0.7mm

By Application

o Medical Device Packaging

o Industrial Materials

o Food Packaging

o Transfusion Bags

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into below 0.2mm, 0.2mm-0.7mm, and more than 0.7mm. Among these, 0.2mm-0.7mm segment acquired the significant share in the market. This thickness range is commonly used in various applications, including food packaging, medical device packaging, and industrial materials, due to its optimal balance between durability and flexibility. Films within this thickness range provide sufficient strength to protect products while maintaining the necessary flexibility for processing and sealing. Additionally, the 0.2mm to 0.7mm segment offers versatility in meeting diverse packaging requirements across multiple industries.

By Application Analysis

On the basis of application, the market is divided into medical device packaging, industrial materials, food packaging, transfusion bags, and other applications. Among these, food packaging segment held the prominent share of the market due to the increasing demand for packaging solutions that enhance the shelf life, safety, and convenience of food products. Coextruded films offer superior barrier properties against moisture, oxygen, and light, which are essential for preserving the quality and freshness of perishable items. Additionally, these films can be tailored to meet specific packaging requirements, such as providing tamper-evident features or incorporating easy-tear properties, further driving their adoption in the food industry.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 34.1% of the market due to a combination of factors such as advanced technological infrastructure, high demand for innovative packaging solutions, and the presence of major end-use industries. The region is home to some of the world's largest food processing, pharmaceutical, and consumer goods companies, all of which require high-performance packaging to maintain product quality, extend shelf life, and meet regulatory standards. In particular, the food packaging sector in North America benefits significantly from coextruded films, which offer superior barrier properties against moisture, oxygen, and contaminants, ensuring that perishable goods stay fresh during transportation and storage.

Moreover, North America has been at the forefront of sustainability initiatives, with increasing consumer demand for eco-friendly packaging driving the adoption of biodegradable and recyclable coextruded films. Government regulations and industry standards encouraging sustainability have further propelled this shift.

Competitive Analysis

The competitive landscape of the coextruded multilayered film market is marked by the presence of several key players, including large multinational packaging companies, regional manufacturers, and emerging innovators. These companies compete primarily on the basis of product innovation, sustainability, cost-effectiveness, and the ability to meet diverse customer needs across industries such as food packaging, pharmaceuticals, and consumer goods. Major players in the market have focused on expanding their product portfolios by incorporating advanced coextrusion technologies, allowing them to offer films with enhanced barrier properties, durability, and flexibility, which are essential for the protection of sensitive products during transportation and storage.

Recent Developments

In November 2023, BASF announced that studies conducted by the independent institute cyclos-HTP GmbH confirmed the recyclability of multilayer films containing polyamide 6 (PA6) and ethyl vinyl alcohol (EVOH) copolymer. These findings are crucial for the development of European "Design for Recycling" guidelines, promoting more sustainable packaging solutions.

Key Market Players in the Coextruded Multilayered Film Market

o Mitsubishi Chemical

o DIC Corporation

o Unitika

o Scholle Ipn

o Hubei Huakun Packaging Materials

o Chaoyang Freedom Technology

o Der Yiing Plastic

o Sumitomo Chemical

o Versa Pak

o Tee Group Films

o Sealed Air

o Chuangfa Materials

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 2.0 Billion |

|

Market Size 2033 |

USD 2.7 Billion |

|

Compound Annual Growth Rate (CAGR) |

3.4% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Mitsubishi Chemical, DIC Corporation, Unitika, Scholle Ipn, Hubei Huakun Packaging Materials, Chaoyang Freedom Technology, Der Yiing Plastic, Sumitomo Chemical, Versa Pak, Tee Group Films, Sealed Air, Chuangfa Materials, and Other Key Players. |

|

Key Market Opportunities |

Growing Demand for Sustainable Packaging |

|

Key Market Dynamics |

Rising Demand for Advanced Packaging Solutions |

📘 Frequently Asked Questions

1. Who are the key players in the Coextruded Multilayered Film Market?

Answer: Mitsubishi Chemical, DIC Corporation, Unitika, Scholle Ipn, Hubei Huakun Packaging Materials, Chaoyang Freedom Technology, Der Yiing Plastic, Sumitomo Chemical, Versa Pak, Tee Group Films, Sealed Air, Chuangfa Materials, and Other Key Players.

2. How much is the Coextruded Multilayered Film Market in 2023?

Answer: The Coextruded Multilayered Film Market size was valued at USD 2.0 Billion in 2023.

3. What would be the forecast period in the Coextruded Multilayered Film Market?

Answer: The forecast period in the Coextruded Multilayered Film Market report is 2024-2033.

4. What is the growth rate of the Coextruded Multilayered Film Market?

Answer: Coextruded Multilayered Film Market is growing at a CAGR of 3.4% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.