🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Condensate Polishing Device Market

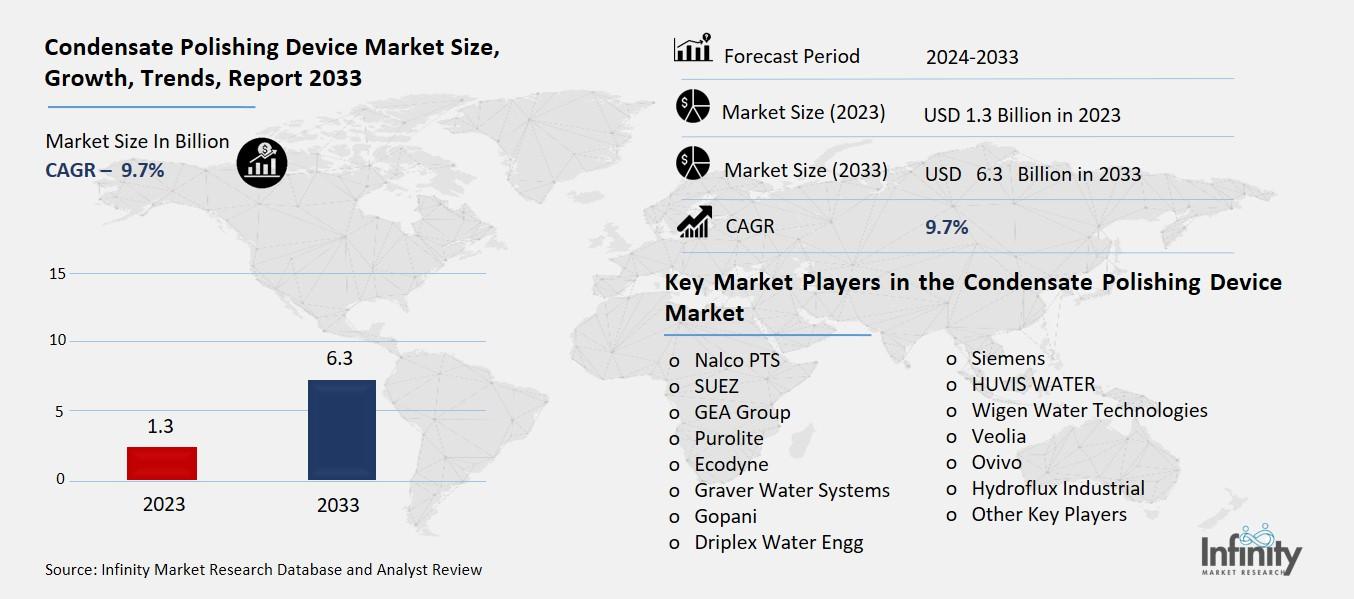

Global Condensate Polishing Device Market (By Type, Cation Bed Polisher and Mixed Bed Polisher; By Application, Food, Power Plant, Pharmaceutical, and Other Applications; By Region and Companies), 2024-2033

Nov 2024

Healthcare

Pages: 138

ID: IMR1330

Condensate Polishing Device Market Overview

Global Condensate Polishing Device Market acquired the significant revenue of 1.3 Billion in 2023 and expected to be worth around USD 3.3 Billion by 2033 with the CAGR of 9.7% during the forecast period of 2024 to 2033. The condensate polishing device is a highly relevant product in the water treatment and power generation industries, which recognize the importance of cleaner condensate water to guarantee the performance of the boiler. These devices are required for removal of silica, sodium, dissolved solids etc. from the condensate in order to avoid corrosion, scaling, and fouling in high pressure steam turbine.

The market is thus propelled by rising application in thermal and nuclear power plant applications as well as in water treatment for industrial applications. Recent technology in ion exchange resins, in reverse osmosis and the mixed-bed systems has grown to ensure that these devices are more reliable and efficient.

Drivers for the Condensate Polishing Device Market

Advancements in Water Treatment Technology

Condensate polishing devices have particularly benefitted from advances in mixed-bed systems and high-efficiency ion exchange resins. The systems involve the use of cation and anion exchange resins packed in a single tank to offer excellent water treatment process whose conductivity levels will be ultra-low, hence the removal of charged impurities in the water. This leads to improved water conditions, essential for power plant which uses high pressure steam turbines and boilers.

In the same ways, advanced high efficiency Ion exchange resins with enhanced chemical stability, and capacity provide enhanced ion removal rate and extended service life, hence mitigating time-associated losses such as downtime and maintenance. Most of these innovations do not only increase operational productivity but also respond to the increasing market need for efficient and ecofriendly water treatment processes.

Restraints for the Condensate Polishing Device Market

Limited Awareness in Developing Regions

The lack of awareness about the benefits of condensate polishing devices remains a significant barrier to market growth, particularly in developing regions. Many industries in these areas are either unaware of the long-term cost savings or underestimate the critical role these devices play in maintaining the efficiency and longevity of boiler systems and turbines. This knowledge gap often leads to reliance on less effective water treatment methods, resulting in higher operational costs due to corrosion, scaling, and equipment breakdowns.

Moreover, the absence of educational initiatives, technical workshops, and targeted marketing campaigns by manufacturers limits the exposure of these solutions to potential end-users. Bridging this awareness gap through industry outreach programs, partnerships with local distributors, and demonstrations of tangible benefits could unlock substantial market opportunities in these regions.

Opportunity in the Condensate Polishing Device Market

Retrofit and Upgrade Projects

The modernization of aging power plants and industrial facilities presents a significant growth opportunity for condensate polishing device manufacturers. Many of these facilities operate with outdated water treatment systems that are less efficient, leading to higher maintenance costs, reduced operational efficiency, and increased risks of equipment failure. Upgrading to advanced condensate polishing devices can help these plants achieve better water purity levels, extend the lifespan of critical components, and comply with stricter environmental and operational regulations.

Manufacturers can capitalize on this demand by offering retrofit solutions and customized systems designed to integrate seamlessly with existing infrastructure. Additionally, incentives from governments and regulatory bodies to adopt energy-efficient and sustainable technologies further encourage facility upgrades, creating a robust market for innovative condensate polishing solutions.

Trends for the Condensate Polishing Device Market

Adoption of Advanced Technologies

The integration of nanotechnology and hybrid systems into condensate polishing devices is transforming the industry by enhancing both efficiency and reliability. Nanotechnology enables the development of advanced materials with superior adsorption capabilities and higher surface area, allowing for the removal of ultra-fine contaminants that traditional methods may miss. These nanoscale materials improve ion exchange processes, reduce regeneration frequency, and lower operational costs.

Hybrid systems, which combine multiple purification technologies such as ion exchange, reverse osmosis, and membrane filtration, offer versatile and highly effective solutions tailored to complex industrial needs.

Segments Covered in the Report

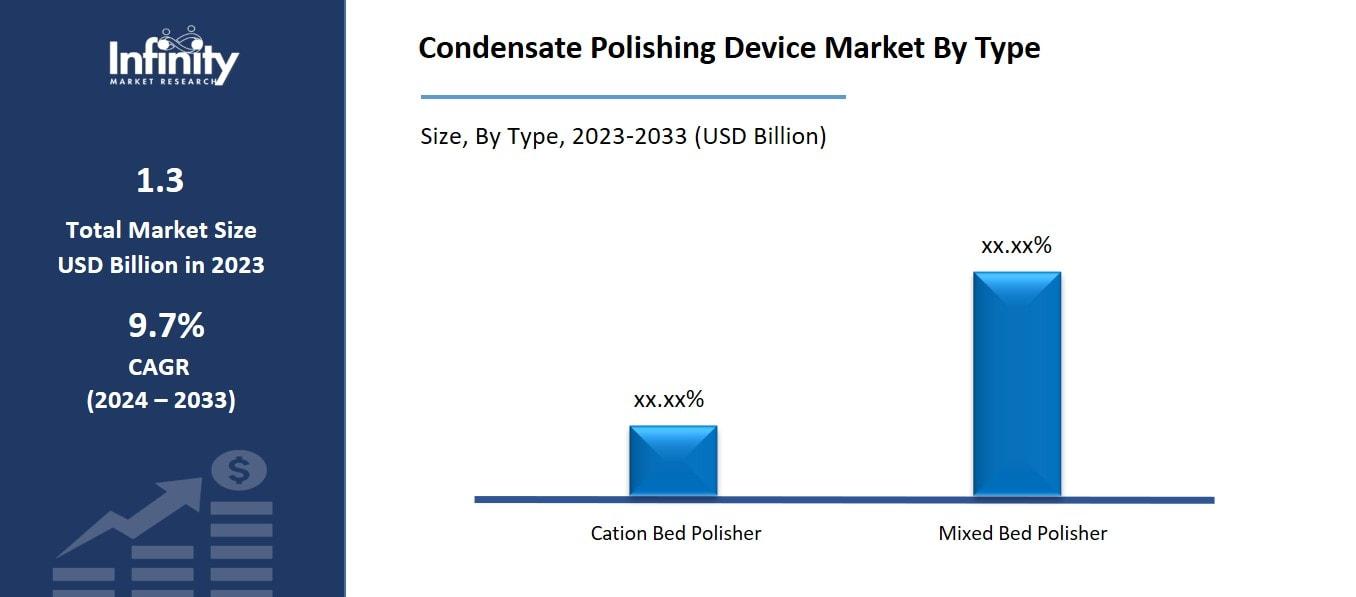

By Type

o Cation Bed Polisher

o Mixed Bed Polisher

By Application

o Food

o Power Plant

o Pharmaceutical

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into cation bed polisher and mixed bed polisher. Among these, mixed bed polisher segment acquired the significant share in the market owing to its superior efficiency in removing both cationic and anionic impurities, resulting in higher water purity levels. Mixed bed polishers combine cation and anion exchange resins within a single unit, enabling comprehensive ion removal and ensuring the production of high-quality condensate. This capability is particularly crucial in industries such as power generation and pharmaceuticals, where stringent water quality standards are mandatory. The enhanced performance and versatility of mixed bed polishers make them a preferred choice over cation bed polishers, which primarily target cationic impurities.

By Application Analysis

On the basis of application, the market is divided into food, power plant, pharmaceutical, and other applications. Among these, commercial held the prominent share of the market due to the critical need for high-purity water in power generation processes to prevent corrosion, scaling, and fouling in boilers and turbines. Condensate polishing devices are essential in maintaining the efficiency and longevity of equipment in thermal and nuclear power plants.

The increasing global demand for energy, coupled with stringent regulatory standards for water quality in power generation, has further propelled the adoption of these devices in this sector. Consequently, the power plant segment continues to be the primary driver of growth in the condensate polishing device market.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 31.6% of the market. The region’s well-established industrial and energy infrastructure, including numerous thermal and nuclear power plants, drives consistent demand for advanced water treatment solutions. Strict regulatory standards for water quality and environmental compliance in countries like the United States and Canada further fuel the adoption of condensate polishing devices.

Additionally, the presence of leading manufacturers and ongoing investments in research and development have facilitated the introduction of innovative and efficient systems tailored to industry needs. The region's focus on modernizing aging power plants and adopting sustainable practices also contributes to its market leadership, ensuring steady growth and high revenue generation.

Competitive Analysis

The condensate polishing device market is characterized by intense competition, driven by the presence of both established players and emerging companies striving to capture market share. Key players focus on product innovation, leveraging advanced technologies such as nanotechnology, hybrid systems, and smart monitoring solutions to differentiate their offerings. Strategic collaborations, mergers, and acquisitions are common, enabling companies to expand their geographical reach and enhance their product portfolios. Leading manufacturers emphasize customer-specific solutions, targeting diverse industries such as power generation, pharmaceuticals, and food processing.

Key Market Players in the Condensate Polishing Device Market

o Nalco PTS

o SUEZ

o GEA Group

o Purolite

o Ecodyne

o Graver Water Systems

o Gopani

o Driplex Water Engg

o Siemens

o HUVIS WATER

o Wigen Water Technologies

o Veolia

o Ovivo

o Hydroflux Industrial

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.3 Billion |

|

Market Size 2033 |

USD 6.3 Billion |

|

Compound Annual Growth Rate (CAGR) |

9.7% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Nalco PTS, SUEZ, GEA Group, Purolite, Ecodyne, Graver Water Systems, Gopani, Driplex Water Engg, Siemens, HUVIS WATER, Wigen Water Technologies, Veolia, Ovivo, Hydroflux Industrial, and Other Key Players. |

|

Key Market Opportunities |

Retrofit and Upgrade Projects |

|

Key Market Dynamics |

Advancements in Water Treatment Technology |

📘 Frequently Asked Questions

1. Who are the key players in the Condensate Polishing Device Market?

Answer: Nalco PTS, SUEZ, GEA Group, Purolite, Ecodyne, Graver Water Systems, Gopani, Driplex Water Engg, Siemens, HUVIS WATER, Wigen Water Technologies, Veolia, Ovivo, Hydroflux Industrial, and Other Key Players.

2. How much is the Condensate Polishing Device Market in 2023?

Answer: The Condensate Polishing Device Market size was valued at USD 1.3 Billion in 2023.

3. What would be the forecast period in the Condensate Polishing Device Market?

Answer: The forecast period in the Condensate Polishing Device Market report is 2024-2033.

4. What is the growth rate of the Condensate Polishing Device Market?

Answer: Condensate Polishing Device Market is growing at a CAGR of 9.7% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.