🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Conformal Coatings Market

Conformal Coatings Market (By Product (Acrylic, Epoxy, Urethane, Silicone, Parylene), By Application (Consumer Electronics, Automotive, Medical, Aerospace & Defense, Others), By Region and Companies)

Jul 2024

Chemicals and Materials

Pages: 110

ID: IMR1138

Conformal Coatings Market Overview

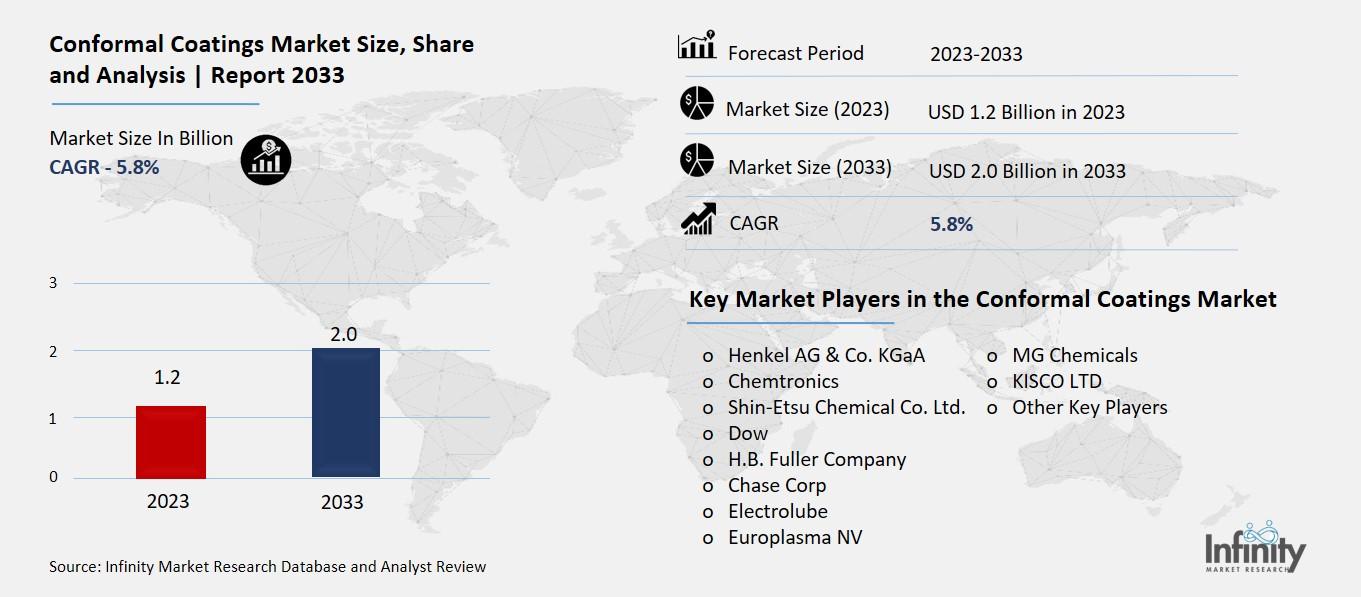

Global Conformal Coatings Market size is expected to be worth around USD 2.0 Billion by 2033 from USD 1.2 Billion in 2023, growing at a CAGR of 5.8% during the forecast period from 2023 to 2033.

The Conformal Coatings Market refers to the industry focused on protective coatings used to safeguard electronic components. These coatings are applied in a thin layer over the electronic circuitry to protect it from moisture, dust, chemicals, and temperature extremes. This is important because it helps prevent damage and extends the life of electronic devices. Industries such as automotive, aerospace and consumer electronics heavily rely on conformal coatings to ensure the reliability and longevity of their products.

In simple terms, think of conformal coatings as a protective shield for electronic gadgets. Just like you might put a case on your phone to protect it from drops and scratches, manufacturers use these special coatings to protect the delicate parts inside all kinds of electronic devices. The market for these coatings is growing because as our world becomes more digital, there's an increasing need to protect all the tiny, sensitive parts inside our devices from the harsh environments they might be exposed to.

Drivers for the Conformal Coatings Market

Growing Electronics Industry

The conformal coatings market is experiencing significant growth due to the booming electronics industry. As electronic devices become more advanced and compact, the need for reliable protection of electronic circuits increases. Conformal coatings are essential in protecting delicate electronic components from environmental factors like moisture, dust, and chemicals. This protection is crucial for the longevity and reliability of devices such as smartphones, tablets, and wearable technology. The continuous innovation and miniaturization in the electronics sector drive the demand for high-quality conformal coatings.

Advancements in Coating Technologies

Technological advancements in coating methods are another major driver for the conformal coatings market. New techniques, such as UV-curable and environmentally friendly coatings, have emerged, offering faster processing times and reduced environmental impact. These innovations not only improve the performance of the coatings but also make them more appealing to manufacturers looking to enhance production efficiency and adhere to stricter environmental regulations. The development of coatings with lower volatile organic compounds (VOCs) is particularly noteworthy, as they meet the growing demand for sustainable manufacturing processes.

Rising Automotive Industry

The automotive industry also plays a significant role in driving the conformal coatings market. Modern vehicles increasingly rely on complex electronic systems for everything from engine management to advanced driver assistance systems. Conformal coatings ensure that these electronic components are protected from harsh environmental conditions, such as temperature fluctuations and humidity. This protection is vital for the safety and performance of the vehicle, making conformal coatings an integral part of the automotive manufacturing process. The growing adoption of electric vehicles, which have even more sophisticated electronic systems, further boosts the demand for conformal coatings.

Increased Applications in Aerospace and Defense

The aerospace and defense sectors are significant contributors to the growth of the conformal coatings market. These industries require highly reliable electronic components that can withstand extreme conditions. Conformal coatings provide the necessary protection to ensure that these components function correctly and safely in demanding environments. The coatings are used in various applications, including avionics, radar systems, and defense electronics, where failure is not an option. The increasing investment in aerospace and defense technologies continues to drive the demand for advanced conformal coatings.

Environmental Regulations and Sustainability

Stricter environmental regulations and the global push for sustainability are also driving the conformal coatings market. Manufacturers are developing coatings that comply with these regulations by reducing harmful emissions and using eco-friendly materials. The shift towards sustainable manufacturing practices is gaining momentum, and conformal coatings with low VOC content are becoming more popular. This trend not only helps in reducing the environmental footprint but also aligns with the corporate responsibility goals of many companies, further driving market growth.

Increasing Investment and Strategic Expansion

Finally, significant investments and strategic expansions by key market players are propelling the conformal coatings market forward. Companies are investing heavily in research and development to improve existing products and explore new applications. Collaborations and partnerships between coating manufacturers and major industrial firms are driving innovation and expanding the market reach. These strategic moves are essential in keeping up with the rising demand and ensuring that the conformal coatings market continues to grow robustly in the coming years.

Restraints for the Conformal Coatings Market

High Costs of Repair

One of the main restraints for the conformal coatings market is the high cost associated with repairs. When conformal coatings get damaged, fixing them can be quite expensive. This is due to the intricate process needed to apply and remove these coatings without harming the underlying electronic components. The high repair costs can be a deterrent for many businesses, especially smaller ones, which might avoid using conformal coatings despite their protective benefits.

Decline in the Automotive Sector

The automotive sector has faced a decline in recent years, which has negatively impacted the conformal coatings market. With fewer cars being produced and sold, the demand for conformal coatings used in automotive electronics has dropped. This decline is particularly notable in regions like North America and Europe, where the automotive industry has seen significant slowdowns. The overall reduction in automotive manufacturing means less need for coatings that protect vehicle electronic systems from environmental stressors.

Environmental and Health Concerns

There are growing environmental and health concerns related to the use of certain chemicals in conformal coatings. Many traditional coatings contain volatile organic compounds (VOCs), which can be harmful to both the environment and human health. Regulations are becoming stricter, requiring manufacturers to find less damaging alternatives. While there have been advancements in developing low-VOC and environmentally friendly coatings, the transition can be slow and costly for companies, limiting the market's growth potential.

Technical Challenges

Applying conformal coatings correctly requires a high level of technical expertise. Inaccurate application can lead to issues such as insufficient coverage, which compromises the protection of the electronic components. Moreover, achieving a uniform coating, especially on complex and miniaturized electronic assemblies, is challenging and requires specialized equipment and skilled labor. These technical challenges can discourage some companies from adopting conformal coatings, thereby restraining market growth.

Market Fragmentation

The conformal coatings market is quite fragmented, with numerous small and medium-sized players offering a wide range of products. This fragmentation can lead to inconsistencies in product quality and performance, making it difficult for end-users to select the right coating for their specific needs. The lack of standardization in the market also poses a challenge, as it can result in compatibility issues and unreliable protection for electronic devices.

Opportunity in the Conformal Coatings Market

Increasing Demand from the Electronics Industry

The Conformal Coatings Market is poised for significant growth, driven primarily by the rising demand from the electronics industry. These coatings are applied to electronic circuit boards to protect them from moisture, chemicals, dust, and temperature extremes, thereby enhancing their reliability and longevity. As electronic devices become more integrated into daily life and industries like automotive, aerospace, and consumer electronics expand, the need for reliable conformal coatings escalates.

Technological Advancements in Coating Materials

Recent advancements in coating materials have further fueled the market's growth prospects. Innovations in silicone, acrylic, epoxy, and polyurethane coatings have improved their performance characteristics, such as flexibility, adhesion, and resistance to environmental stressors. These advancements not only cater to current market demands but also pave the way for new applications in emerging technologies like flexible electronics and wearable devices.

Expanding Applications Across Diverse Industries

The market is witnessing broadening applications across diverse industries beyond electronics. Industries such as automotive, aerospace, medical devices, and telecommunications are increasingly adopting conformal coatings to protect sensitive components from harsh environments. This expansion into new sectors is creating additional growth avenues for manufacturers and suppliers in the conformal coatings market.

Regional Market Dynamics

Regionally, Asia-Pacific holds a dominant position in the conformal coatings market, driven by the presence of major electronics manufacturers and the rapid industrialization in countries like China, Japan, South Korea, and Taiwan. North America and Europe also contribute significantly, owing to the robust presence of automotive and aerospace industries that require high-performance coatings for electronic components.

Environmental Regulations and Sustainability Trends

The market is also influenced by stringent environmental regulations concerning volatile organic compounds (VOCs) and hazardous substances in coating formulations. Manufacturers are increasingly focusing on developing eco-friendly coatings that comply with regulatory standards while meeting performance requirements. This shift towards sustainable practices is not only a regulatory necessity but also a competitive advantage in the market.

Emerging Markets and Future Growth Prospects

Looking ahead, emerging markets in Latin America, the Middle East, and Africa present untapped opportunities for market players. The increasing industrialization, infrastructure development, and rising disposable incomes in these regions are expected to drive demand for electronic devices and, consequently, for conformal coatings. Moreover, advancements in nanotechnology and smart coatings are anticipated to open new frontiers in the market, enhancing functionalities such as self-healing and self-cleaning properties.

Trends for the Conformal Coatings Market

Growing Demand for High-Performance Coatings

The Conformal Coatings Market is witnessing several key trends that are shaping its future trajectory. One prominent trend is the increasing demand for high-performance coatings that offer superior protection against moisture, chemicals, and other environmental factors. As industries like electronics, automotive, aerospace, and medical devices continue to demand greater reliability and durability from their components, there is a growing preference for coatings that can withstand harsh conditions without compromising performance.

Shift towards Environmentally Friendly Formulations

A significant trend in the market is the shift towards environmentally friendly formulations. Regulatory pressures and consumer preferences for sustainable products have prompted manufacturers to develop conformal coatings with lower VOC content and reduced environmental impact. This trend towards eco-friendly coatings is not only driven by compliance with stringent regulations but also by the desire to enhance brand reputation and appeal to environmentally conscious customers.

Rise of Conformal Coatings for Flexible Electronics

Another emerging trend is the adoption of conformal coatings for flexible electronics. With the increasing popularity of wearable devices, flexible displays, and printed electronics, there is a growing need for coatings that can conform to intricate and bendable surfaces while providing robust protection. Innovations in coating materials and application techniques are enabling manufacturers to meet these unique requirements and expand their presence in the flexible electronics market.

Integration of Nanotechnology in Coating Development

The integration of nanotechnology into coating development is also a notable trend. Nanocoatings offer enhanced properties such as improved adhesion, scratch resistance, and self-cleaning capabilities. By leveraging nanomaterials, manufacturers can enhance the performance of conformal coatings and cater to demanding applications in high-tech industries. The ongoing research and development in nanotechnology are expected to drive further advancements in coating functionalities.

Adoption of Robotics and Automation in Coating Processes

Automation and robotics are increasingly being adopted in coating processes, reflecting a trend towards enhanced precision, efficiency, and consistency in application. Automated dispensing systems and robotic arms are being used to apply conformal coatings with accuracy and uniformity, reducing human error and ensuring high-quality outcomes. This trend is particularly relevant in industries where stringent quality control and productivity are paramount.

Focus on Advanced Testing and Quality Assurance

Lastly, there is a growing emphasis on advanced testing and quality assurance protocols in the conformal coatings market. Manufacturers are investing in testing methodologies to assess coating performance under real-world conditions, including temperature variations, humidity, and chemical exposure. By providing comprehensive performance data, suppliers can demonstrate the reliability and durability of their coatings, thereby instilling confidence among end-users and fostering long-term relationships.

Segments Covered in the Report

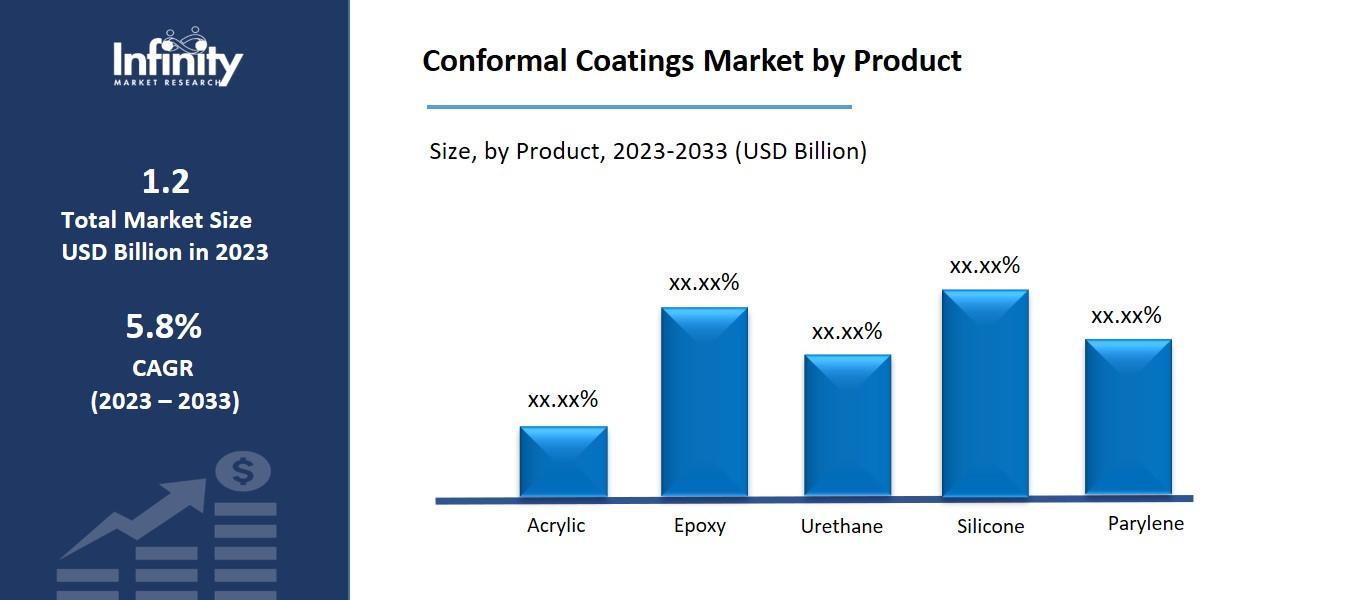

By Product

o Acrylic

o Epoxy

o Urethane

o Silicone

o Parylene

By Application

o Consumer Electronics

o Automotive

o Medical

o Aerospace & Defense

o Others

Segment Analysis

By Product Analysis

In terms of product share, acrylic dominated the global market for conformal coatings in 2023, accounting for about 46.7% of total revenue. Acrylic coatings may easily have their viscosity adjusted, which makes them a perfect compound for creating a variety of application-grade-based coatings. Furthermore, drying time is noticeably faster than that of its equivalents. Its versatility in the electronics and automotive sectors is made possible by this characteristic.

Furthermore, the heat that acrylics release during the curing process reduces the possibility of harming heat-sensitive components, which encourages the expansion of the conformal coatings business. Epoxy conformal coatings have dielectric qualities and a strong solvent resistance, making them ideal for use on printed circuit boards in electronic device applications. These coatings are used in the production of circuit boards and household goods because they are strong and abrasion-resistant.

The strong moisture resistance, chemical resistance, and abrasion resistance of urethane conformal coating are well known. Because of its difficulty in removal, it can be employed in aircraft applications, which helps to mitigate the issues related to fuel vapor exposure of aerospace components.

By Application Analysis

In 2023, the consumer electronics sub-segment held the greatest revenue share of over 43.9% in the worldwide conformal coatings market application segment. Since the COVID-19 epidemic, consumer electronics have become more and more popular because of the expanding tendency of smaller electronic circuit boards. Conformal coatings are in high demand since these circuit boards are exposed to dust, high temperatures, humidity, and other airborne pollutants.

Manufacturers of conformal coatings have been prompted to introduce new solutions in response to the expanding consumer electronics market. For example, Dow unveiled DOWSIL CC-2588 Conformal Coating in October 2021. This silicone-based coating was created to shield electronic components and printed circuit boards (PCBs). Conformal coating DOWSIL CC-2588 cures at room temperature to save energy and makes ultraviolet light examination easier, which may increase demand for it in the consumer electronics market.

Global attention is turning more and more toward decarbonization as environmental problems associated with gasoline-powered cars grow. International governments and automakers have been compelled by this to create fuel-efficient hybrid and electric vehicles. The demand for electronic components like sensors, entertainment devices, and GPS in cars is predicted to increase as intelligent vehicles become more common. This can also fuel the expansion of conformal coatings, which are used to safeguard automotive electronics.

Regional Analysis

With a revenue share of almost 50.8% for the area as a whole in 2023, Asia Pacific led the competition. Key industries such as the aerospace, automotive, consumer electronics, and manufacturing sectors are the main drivers of the demand for conformal coatings in the Asia Pacific region. The Asia-Pacific area is expected to require 17,620 new passenger and freighter aircraft, according to a news release issued by Airbus in February 2022. It is anticipated that this will be fueled by the area's population growth.

Furthermore, as per Airbus, the cargo traffic in Asia-Pacific is expected to increase at 3.6% per annum, leading to a doubling in air freight in the region by 2040, thus positively impacting the market for conformal coatings in the area. North America has witnessed a growing demand for advanced electronics, including GPS systems and other related products in the automotive industry. The e-commerce industry has seen an upward trend in the region, resulting in increased sales of commercial vehicles in the area to cater to this industry.

The International Air Transport Association (IATA) reports that North American airlines recovered quickly from the vaccination launch and began accepting vaccinated passengers in the region in November 2021. Increased aircraft sales have occurred in the area as a result of aircraft carriers placing fresh orders as a result of the passenger traffic rebound. The functioning devices are shielded from shocks, vibrations, and extremely high and low temperatures by conformal coatings. The United States' expanding aircraft industry is anticipated to drive growth in the conformal coatings market.

Competitive Analysis

Henkel AG & Co. KGaA, Chemtronics, Shin-Etsu Chemical Co., Ltd., Dow, and H.B. Fuller Company are the major companies in the global conformal coatings market. A few media outlets and smaller regional firms are also present. Well-known companies like Henkel AG & Co. KGaA are investing in conformal coatings startups to bolster their market share.

For instance, Henkel AG & Co. KGaA stated in October 2020 that it had invested in Actnano, a start-up business focused on advanced materials with its headquarters located in Massachusetts, USA. Actnano offers customized conformal coating technology for printed circuit board protection in numerous applications throughout expanding electronics markets.

Recent Developments

May 2023: To improve its customized client service, CHT Germany GmbH constructed a new production plant in Bangladesh's Meghna Industrial Economic Zone (MIEZ).

July 2022: The acquisition of NuCera Solutions, a company that produces concentrated polymers and polymerization technology for demanding applications worldwide, was announced by Chase Corporation.

Key Market Players in the Conformal Coatings Market

o Henkel AG & Co. KGaA

o Chemtronics

o Shin-Etsu Chemical Co. Ltd.

o Dow

o H.B. Fuller Company

o Chase Corp

o Electrolube

o Europlasma NV

o MG Chemicals

o KISCO LTD

o Other Key Players

Report Scope

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.2 Billion |

|

Market Size 2033 |

USD 2.0 Billion |

|

Compound Annual Growth Rate (CAGR) |

5.8% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

- |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Product, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Henkel AG & Co. KGaA, Chemtronics, Shin-Etsu Chemical Co. Ltd., Dow, H.B. Fuller Company, Chase Corp, Electrolube, Europlasma NV, MG Chemicals, KISCO LTD, Other Key Players |

|

Key Market Opportunities |

Increasing Demand from the Electronics Industry |

|

Key Market Dynamics |

Increased Applications in Aerospace and Defense |

📘 Frequently Asked Questions

1. How much is the Conformal Coatings Market in 2023?

Answer: The Conformal Coatings Market size was valued at USD 1.2 Billion in 2023.

2. What would be the forecast period in the Conformal Coatings Market?

Answer: The forecast period in the Conformal Coatings Market report is 2023-2033.

3. Who are the key players in the Conformal Coatings Market?

Answer: Henkel AG & Co. KGaA, Chemtronics, Shin-Etsu Chemical Co. Ltd., Dow, H.B. Fuller Company, Chase Corp, Electrolube, Europlasma NV, MG Chemicals, KISCO LTD, Other Key Players

4. What is the growth rate of the Conformal Coatings Market?

Answer: Conformal Coatings Market is growing at a CAGR of 5.8% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.