🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Copper-Based Master Alloy Market

Copper-Based Master Alloy Market Global Industry Analysis and Forecast (2024-2032) By Type (Copper-Aluminum Master Alloy, Copper-Manganese Master Alloy, Copper-Zirconium Master Alloy, Copper-Tin Master Alloy, Copper-Nickel Master Alloy, Other Copper-Based Alloys) By Application (Deoxidation, Grain Refinement, Alloying Element, Others) By End-Use Industry (Electrical and Electronics, Automotive and Transportation, Construction, Industrial Equipment, Marine, Aerospace, Others) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1525

Copper-Based Master Alloy Market Synopsis

Global Copper-Based Master Alloy Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

The Copper Based Master Alloy Market is defined as the industry that deals in the manufacturing, sale and use of master alloys predominantly containing copper coupled with other alloying components like aluminum, manganese, silicon, or nickel. These master alloys find uses in the metallurgical processes to augment the mechanical thermal and corrosion resistant properties of the end products metals. They rank well in the process of compounding to act as additives key in controlling compositions in automotive, aircraft, electrical, and construction industries. Industry is stimulated by the continued growth of markets and applications, particularly driven by new manufacturing technologies that are demanding performance materials and pushing an increasing focus on high performance, lightweight, durable and more sustainable materials.

The global market of copper-based master alloy is gradually growing year by year because of the growing demand in different industries including automotive, electronics industry, construction industry etc. Copper based alloy inter mediates, which play central roles in synthesis of advanced materials, are essential to improve mechanical properties, corrosion resistance and electrical conductivity. Automotive industry continues to be the biggest buyer owing to the increasing use of electric vehicles (EVs) and the increased focus on lightweighting. At the same time, development of electronics and telecommunications is stimulating the application of copper based alloys in connectors, circuit boards etc. owing to its high conductivity. This trend is backed up by the advancement in urbanization and infrastructure applications across the global especially in the developing nations that trigger the use of copper based alloys in construction activities.

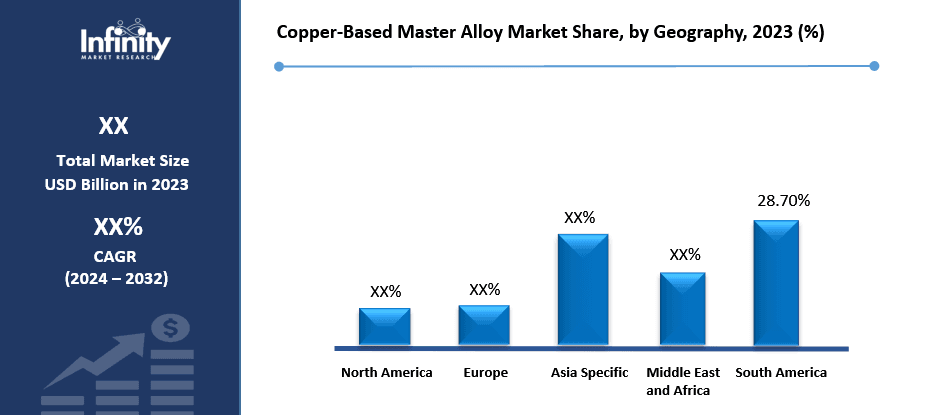

Regionally, the Asia-Pacific region has the largest share in the copper-based master alloy market due to its considerable manufacturing industry growth rate and a growing automobile and electronics industry. Among continents, Asia dominates market growth due to increased investment in infrastructure projects and, most importantly, industrial technological development of countries such as China, India, and South Korea. On the other hand, North America and Europe also shows strong growth supported by technology advancement and shifting towards green energy solution. The authors, while anticipating further growth in sustainability concerns across different industries, are of the opinion that the market for recyclable and copper-based master alloys will experience an improved volume of interest.

Copper based master alloy market is expected to grow in the future and new developments in terms of alloy compositions and metal production technologies are expected to open new avenues for the usage of copper master alloys. The market also rises through the adoption of new technologies such as 3D printing and AI-generated production enhancement, making it cheaper. But factors like the uncertain nature of raw material costs as well as issues of environmental impact of mineral extraction and processing may act as barriers to growth. Nevertheless, the coupled obstacles are projected to sustain a positive trend led by the continued industrial and technology demands.

Copper-Based Master Alloy Market Trend Analysis

Trend

Enhanced Performance in Automotive and Aerospace Applications

Originally, the copper-based master alloy has starting to gain popularity recently due to the use of automobiles and aerospace that considered the master alloy with high mechanical and thermal properties and high corrosion resistance. Such alloys are crucial in the improvement of the performance of some of the most sensitive parts due to factors such as strength, conductivity and durability. With the transition to lighter and environmentally friendly automobiles and aerocoach, these alloys are used to obtain excellent machinability and durability of components, leading to higher car or plane efficiency and minimized service time. This trend has been especially noticeable in applications for high-reliability parts including engine components, heat exchangers and connectors.

In addition, new compositions and metallurgical treatments of copper based master alloys have provided solutions to enhance the range of properties within the copper based system to suit the certain applications. Many kinds of alloying elements and production technologies allow increasing the control level of some parameters which are significant for particular applications, such as tensile strength, thermal conductivity, and corrosion resistance. From this adaptability, these alloys have gained wide acceptance across so many industrial areas since it is fro both extra high performance able to stringent operational conditions as well as tailored meet specific and unique demand.

Drivers

Increasing Demand in the Automotive Sector

The global copper-based master alloy market is mainly influenced by one particular segment that is widely in use in the automotive industry: the increment of the automotive industry. Coppers based alloys are pertinent for manufacturing parts ……because of their excellent electrical and thermal conductivity, corrosion resistance and relatively high strength to weight ratio. These alloys are commonly used in wiring systems, connectors and heat exchangers in the automobiles so that optimum quality and long lasting performance is achieved. This has been further enhanced by a growing use in electric vehicles (EVs) in which copper based master alloys are used to manufacture electric parts that form the backbone of EV functionality such as charging circuits and equipment. Increased focus on eco-friendly mobility solutions simply shifts focus onto materials that need to deliver superior performance while being as environmentally friendly as possible, such as the copper-based alloys.

Likewise, copper based master alloys are in great demand in the aerospace industry which is one of the primary growth drivers in the market. Aviation industries need material that has a low density and is strong and rigid to improve aerodynamics and consumption of fuel. Copper based alloys satisfy these conditions as well as providing increased protection to severe environment conditions. Thus, the steady growth of the aerospace industry, which is fueled by rising air traffic and growth of air space defense projects in various countries, will inevitably result in even greater use of these alloys in the aircraft manufacturing and repair industry which is already of tremendous importance to the industry.

Restraints

Fluctuating Copper Prices

The biggest problem in the entire copper-based master alloy market is the volatility of the copper price as well as that of the other alloying additives. Copper being the most critical constituent in the fabrication of these alloys functions as one of the most important cost setters. When there is a sharp change in the price of copper in the global market owing to a shift in supply and demand ratios, or some political instability or some speculative activities in the concerned market, the cost of preparing master alloys containing copper also changes significantly. Its volatility means that manufacturers who used to receive stable input prices needed to maintain their revenues will now need to think twice. It also impacts the policy maker, particularly touching on the pricing models of end user who rely on these alloy for intended use in the automobile industry, aerospace industry, electronics industries among others.

These clear indications of price fluctuations can thus be a nightmare to the actual manufacturers when planning to implement long-term sourcing strategies. During periods of copper prices hikes, the cost of manufacturing might be affected, and this forces the manufacturers to either recall their products or downgrade and kill projects. On the other hand, the manufacture of copper products risks stagnating the market and not passing the benefits of low price per copper gram back to the consumer. Such uncertainties can affect the industry by deterring long-term investments that are required for the growth of market and development of new products in the copper based master alloy sector.

Opportunities

Rising Demand for High-Performance Materials in Aerospace, Automotive, and Electronics

The growth of high-performance products remains one of the largest opportunities within the copper-based master alloy market that are expected hugely across aerospace, automotive, and electronics sectors. With advancement of these sectors, much stress is laid on to get materials having better mechanical properties like strength, corrosion resistance and conductivity etc. These requirements can be met by copper based master alloys as these show high durability in both applications and conditions. For example, aerospace industries rely on copper-based alloys for products such as; turbine blades and electrical connectors since these materials as most of the times used in high intense heat and in extreme conditions. The increased drive to lightweight and fuel efficient automobiles offers copper based alloys a chance in parts such as heat exchangers, batteries, and electrical systems.

In the electronics industry for example production of nano gadgets where miniaturization and high performance are important factors , copper based master alloys are well sought because of their high electrical conductivity and their ability to withstand mechanical wear. As phones, computers and other electronics keep getting better, they need materials that can meet their increasing levels of performance as well as cost effectiveness and dependability. Consequently, application requirements in these industries are shifting toward the use of copper alloys for certain performance levels, and the copper-based master alloys market is accordingly expanding. Further opening up of new markets is bound to occur with increased technological development as it seeks more distinct types of alloys that tailor to industries, thus driving the copper based master alloy market.

Copper-Based Master Alloy Market Segment Analysis

Copper-Based Master Alloy Market Segmented on the basis of By Type, By Application, By End-Use Industry.

By Type

o Copper-Aluminum Master Alloy

o Copper-Manganese Master Alloy

o Copper-Zirconium Master Alloy

o Copper-Tin Master Alloy

o Copper-Nickel Master Alloy

o Other Copper-Based Alloys

By Application

o Deoxidation

o Grain Refinement

o Alloying Element

o Others

By End Use

o Electrical and Electronics

o Automotive and Transportation

o Construction

o Industrial Equipment

o Marine

o Aerospace

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Copper-Aluminum Master Alloy segment is expected to dominate the market during the forecast period

Copper-Aluminum Master Alloys are seen as a premium raw material because they improve the properties of copper in use applications that require increased strength and corrosion resistance coupled with improved machinability. Aluminum is added to copper to increase the tensile strength of copper that makes it capable to with stand mechanical loads without losing its inherent characteristic such as conductivity. These alloys are widely applied in electrical & electronics industries since parts that are designed to work under extreme conditions of heat and corrosive atmospheres ought to have their performance undeteriorated. Better oxidation resistance of the Copper-Aluminum Master Alloys contributes to longer product life and dependable performance in electrical contacts, connectors and other vital applications.

Aside from electrical and electronics, these Copper-Aluminum Master Alloys are ideal for welding and brazing use because of their greater strength and resistance to oxidation. Copper aluminum exemplifies good thermal conductivity and easy formability, thus creating a very effective metal joining process which does not degrade the needed mechanical properties of the parts being joined. This flexibility shows that Copper-Aluminum Master Alloys is an invaluable component in numerous applications in industries such as pipe manufacturing, heat exchange and automotive industries where and when strength and performance are important aspects to be considered.

By End-Use Industry, Electrical and Electronics segment expected to held the largest share

The electrical and electronics industry mostly uses copper-based master alloys since they possess desirable characteristics including high electrical conductivity, good resistance to corrosion and high thermal stability. These characteristics make copper alloys to be very vital equipments to be used in development of electrical connectors, contacts or other parts that are vital in circuits and devices. There is a common use of Copper based alloys, particularly Copper Aluminum and Copper Zirconium master alloys in the fabrication of high efficiency electrical parts. The alloys guarantee good electrical conduction accompanied by strength and durability which is important in parts that should perform inside high-stress settings.

Copper Aluminum and Copper Zirconium master alloys are much sought after in application where strength as well as conductivity is desirable such as in electronics. Copper-Aluminum presents higher levels of strength, which is critical for elements that suffer mechanical loads, while Copper-Zirconium increases high temperature characteristics and grain entrusted reliability. In combination, these alloys are instrumental in the development of strong and long-standing electrical parts so that they may function effectively in simple everyday appliances to complex structures contained in large industries. In electronics industry, their application ensures that devices continue to have efficiency in their operation within extreme conditions.

Copper-Based Master Alloy Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

In North America, the Copper-Based Master Alloy market is spurred by the well-established manufacturing sector in topics like automobile, electronics, and construction. Markets in the U.S. and Canada have demonstrated a conspicuous increase in usage of copper alloys due to their high corrosion resistance and applications in electrical conductivity. This is especially the case in complex industries such as automotive where it is imperative to have high performance material in order to manufacture dependable automotive parts. In addition, other industries such as aerospace, industrial also have significant demands for such products due to significant reliance on copper based alloys to guarantee efficiency, reliability and durability of machines, equipment etc,.

The market in North America is also roller to the infrastructure in this region and also to the constant advances towards more technological products. Manufacturing sustainability and competitiveness enhancement measures are promoted by the government, and therefore market development is encouraged. It is noteworthy that these initiatives do not only spur progress of new alloys’ production methods but also contribute to the boost of investments in further research. Therefore, high purity Copper Based Master Alloys to address the dynamic need of progressive industries is a knowledge area developing a fertile market in North America.

Copper-Based Master Alloy Market Share, by Geography, 2023 (%)

Active Key Players in the Copper-Based Master Alloy Market

o Kymera International

o KBM Affilips

o Yamato Metal

o Belmont Metals

o Milward Alloys

o Metallurgical Products Company

o Hebei Sitong New Metal Material

o Sichuan Lande Industry

o Affinerie de la Meuse

o Pyrotek

o Heinrich Schneider

o Bongsan Co., Ltd.

o Other key Players

Global Copper-Based Master Alloy Market Scope

|

Global Copper-Based Master Alloy Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Type |

· Copper-Aluminum Master Alloy · Copper-Manganese Master Alloy · Copper-Zirconium Master Alloy · Copper-Tin Master Alloy · Copper-Nickel Master Alloy · Other Copper-Based Alloys | |

|

By Application |

· Deoxidation · Grain Refinement · Alloying Element · Others | ||

|

By End-Use Industry |

· Electrical and Electronics · Automotive and Transportation · Construction · Industrial Equipment · Marine · Aerospace · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Increasing Demand in the Automotive Sector | ||

|

Key Market Restraints: |

· Fluctuating Copper Prices | ||

|

Key Opportunities: |

· Rising Demand for High-Performance Materials in Aerospace, Automotive, and Electronics | ||

|

Companies Covered in the report: |

· Kymera International, KBM Affilips, Yamato Metal, Belmont Metals, Milward Alloys, Metallurgical Products Company, Hebei Sitong New Metal Material, Sichuan Lande Industry, Affinerie de la Meuse, Pyrotek, Heinrich Schneider, Bongsan Co., Ltd. and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Copper-Based Master Alloy Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Copper-Based Master Alloy Market?

Answer: Kymera International, KBM Affilips, Yamato Metal, Belmont Metals, Milward Alloys, Metallurgical Products Company, Hebei Sitong New Metal Material, Sichuan Lande Industry, Affinerie de la Meuse, Pyrotek, Heinrich Schneider, Bongsan Co., Ltd. and Other Major Players.

3. What are the segments of the Copper-Based Master Alloy Market?

Answer: The Copper-Based Master Alloy Market is segmented into By Type, By Application, By End-Use Industry and region. By Type, the market is categorized into Copper-Aluminum Master Alloy, Copper-Manganese Master Alloy, Copper-Zirconium Master Alloy, Copper-Tin Master Alloy, Copper-Nickel Master Alloy, Other Copper-Based Alloys. By Application, the market is categorized into Deoxidation, Grain Refinement, Alloying Element, Others. By End-Use Industry, the market is categorized into Electrical and Electronics, Automotive and Transportation, Construction, Industrial Equipment, Marine, Aerospace, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Copper-Based Master Alloy Market?

Answer: The Copper Based Master Alloy Market is defined as the industry that deals in the manufacturing, sale and use of master alloys predominantly containing copper coupled with other alloying components like aluminum, manganese, silicon, or nickel. These master alloys find uses in the metallurgical processes to augment the mechanical thermal and corrosion resistant properties of the end products metals. They rank well in the process of compounding to act as additives key in controlling compositions in automotive, aircraft, electrical, and construction industries. Industry is stimulated by the continued growth of markets and applications, particularly driven by new manufacturing technologies that are demanding performance materials and pushing an increasing focus on high performance, lightweight, durable and more sustainable materials.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.