🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Deep Hole Drilling Machines Market

Deep Hole Drilling Machines Market (By Machine Type (BTA Drilling, Gun Drilling, Skiving & Burnishing), By Operations (CNC, Non-CNC), By End-Use Industry (Oil & Gas, Medical, Automotive, Construction & Mining, Energy, Aerospace, Military & Defense, Others), By Region and Companies)

Jul 2024

Industrial Automation and Equipment

Pages: 144

ID: IMR1177

Deep Hole Drilling Machines Market Overview

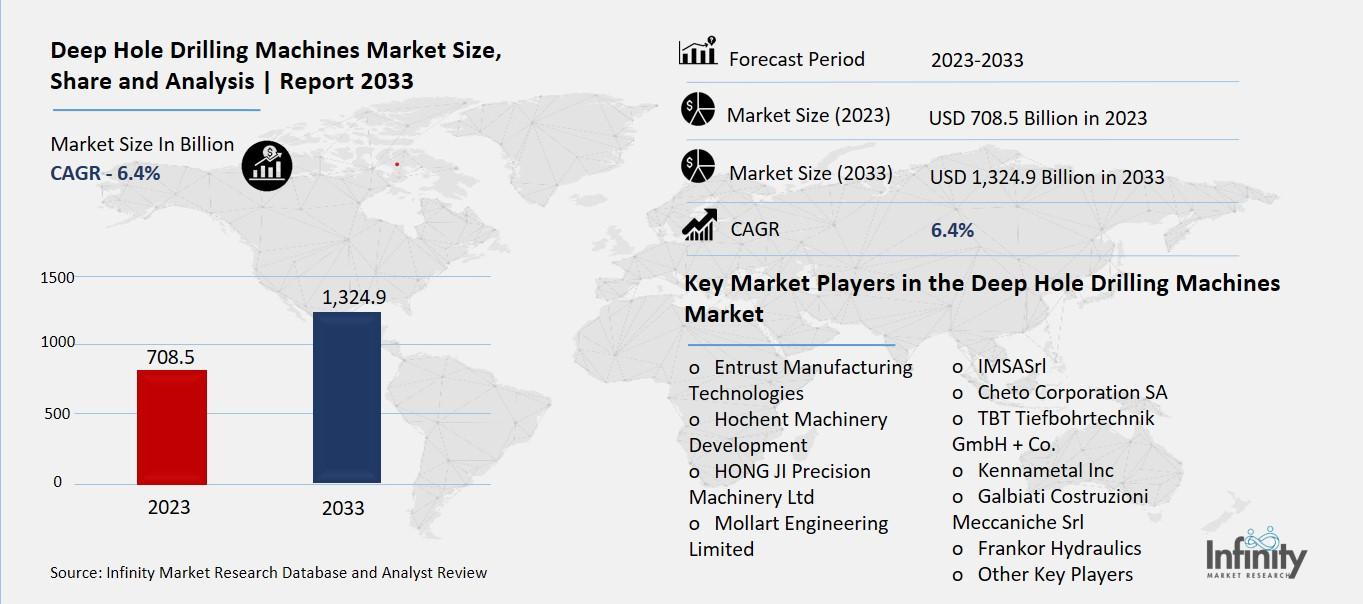

Global Deep Hole Drilling Machines Market size is expected to be worth around USD 1,324.9 Billion by 2033 from USD 708.5 Billion in 2023, growing at a CAGR of 6.4% during the forecast period from 2023 to 2033.

The Deep Hole Drilling Machines Market refers to the industry involved in making and selling specialized equipment used to drill very deep and precise holes into various materials. These machines are crucial for tasks where holes need to be drilled deep into a material, often several meters or even hundreds of meters. They are commonly used in industries like aerospace, automotive, and manufacturing to create parts or components with high accuracy and durability.

As technology advances, deep-hole drilling machines are becoming more advanced themselves. They now come with features that improve their efficiency, precision, and ability to handle different types of materials. The market for these machines is growing because more industries need these precise and deep drilling capabilities, leading to innovations and improvements in the machines themselves.

Drivers for the Deep Hole Drilling Machines Market

Increased Demand for Precision Engineering

One of the main drivers for the deep-hole drilling machines market is the rising demand for precision engineering across various industries. Industries such as aerospace, automotive, and defense require highly accurate and deep holes for their components, which can only be achieved with advanced drilling technology. As these industries continue to innovate and produce more complex and high-performance parts, the need for deep-hole drilling machines that offer superior accuracy and efficiency is growing. This demand is pushing manufacturers to develop machines with enhanced capabilities to meet the stringent requirements of precision engineering.

Advancements in Drilling Technology

Technological advancements in drilling technology are also fueling the growth of the deep-hole drilling machines market. Modern deep-hole drilling machines are equipped with advanced features such as automated controls, improved cooling systems, and enhanced tool life. These innovations not only increase the efficiency and precision of the drilling process but also reduce maintenance costs and downtime. The integration of digital controls and real-time monitoring systems allows for better management and optimization of drilling operations, making these machines more attractive to businesses looking to improve their production processes.

Growth in Aerospace and Defense Sectors

The aerospace and defense sectors are significant contributors to the demand for deep-hole drilling machines. These sectors require components with deep, precise holes for applications such as engine parts, landing gear, and weapon systems. As these industries continue to grow and modernize, they place higher demands on manufacturing processes, including drilling technology. This growth is driving the need for more advanced deep-hole drilling machines that can meet the stringent quality and performance standards required in these critical applications.

Expansion of the Oil and Gas Industry

The oil and gas industry is another major driver for the deep-hole drilling machines market. Deep hole drilling is essential for exploring and extracting resources from deep underground formations. As oil and gas companies seek to explore new reserves and enhance production from existing fields, the demand for deep-hole drilling machines that can perform reliably under challenging conditions is increasing. Innovations in drilling technology are enabling more efficient and cost-effective exploration and extraction processes, supporting the growth of the market in this sector.

Increasing Industrial Automation

The trend towards increasing industrial automation is also contributing to the growth of the deep-hole drilling machines market. Automated drilling systems offer several benefits, including higher precision, reduced labor costs, and improved safety. As industries adopt more automated solutions to enhance their manufacturing processes, the demand for advanced deep-hole drilling machines that integrate seamlessly into automated production lines is rising. This shift towards automation is driving manufacturers to develop drilling machines that can meet the demands of modern, automated production environments.

Rising Demand for Customized Solutions

Finally, the rising demand for customized solutions in various industries is driving the deep-hole drilling machines market. Many companies require drilling machines that can be tailored to their specific needs and applications. As industries continue to seek specialized equipment that can address unique challenges and requirements, manufacturers are focusing on developing customizable deep-hole drilling machines. This trend is encouraging innovation and expanding the range of available solutions, contributing to the overall growth of the market.

Restraints for the Deep Hole Drilling Machines Market

High Initial Costs and Investment Requirements

One of the significant restraints for the deep hole drilling machines market is the high initial cost and investment requirements. Deep hole drilling machines are advanced and complex pieces of equipment, often requiring substantial capital for purchase and installation. This high upfront cost can be a barrier for small and medium-sized enterprises (SMEs) and startups, limiting their ability to invest in such machinery. The significant financial commitment needed to acquire and maintain these machines can deter potential buyers and slow market growth.

Complex Maintenance and Operating Costs

Another challenge is the complex maintenance and operating costs associated with deep-hole drilling machines. These machines require regular maintenance and specialized parts to ensure they function correctly and efficiently. Maintenance can be costly due to the need for skilled technicians and the high price of replacement parts. Additionally, the operation of deep-hole drilling machines often involves high energy consumption, which can lead to increased operational costs. These factors can be a burden for businesses, particularly those with tight budgets or limited resources.

Technological Complexity and Skill Requirements

The technological complexity of deep-hole drilling machines presents another restraint. Modern machines often feature advanced controls, automation, and sophisticated drilling techniques, which require skilled operators to handle effectively. The need for specialized training and technical expertise can be a barrier for businesses looking to adopt these machines. Companies may face difficulties in finding or developing skilled personnel, which can impact their ability to fully utilize the capabilities of advanced drilling equipment.

Limited Market for Specific Applications

The market for deep-hole drilling machines is also constrained by the limited number of applications where these machines are necessary. While deep hole drilling is essential for certain industries like aerospace and oil and gas, its application is more niche compared to other types of drilling equipment. This limited market scope can restrict growth opportunities for manufacturers and reduce overall demand for these machines. Companies that do not serve the primary industries may struggle to find sufficient market demand.

Economic and Market Fluctuations

Economic and market fluctuations can also affect the deep-hole drilling machines market. Changes in economic conditions, such as recessions or downturns in key industries, can lead to reduced investment in capital equipment. For instance, a downturn in the oil and gas sector can significantly impact the demand for deep-hole drilling machines used in exploration and production. Such fluctuations create uncertainty and can affect market stability, making it challenging for manufacturers to predict demand and plan their strategies accordingly.

Opportunity in the Deep Hole Drilling Machines Market

Emerging Markets and Infrastructure Development

One of the significant opportunities in the deep-hole drilling machines market is the growth in emerging markets and infrastructure development. Countries in regions like Asia-Pacific, Africa, and Latin America are experiencing rapid urbanization and industrialization. These regions are investing heavily in infrastructure projects such as roads, bridges, and buildings, which increases the demand for advanced drilling technology. As these markets expand, they present lucrative opportunities for manufacturers of deep-hole drilling machines to enter new territories and tap into the growing infrastructure needs.

Technological Advancements and Innovations

Technological advancements in deep-hole drilling machines offer substantial growth opportunities. Innovations such as automation, real-time monitoring, and advanced materials are enhancing the capabilities and efficiency of drilling machines. For example, the development of more precise control systems and automated features can improve drilling accuracy and reduce operational costs. Manufacturers who invest in research and development to integrate these new technologies can gain a competitive edge and attract customers looking for the latest advancements in drilling machinery.

Growth in Aerospace and Defense Sectors

The aerospace and defense sectors continue to be significant growth drivers for the deep-hole drilling machines market. These industries require high-precision components with deep holes for applications like engine parts, landing gear, and defense equipment. As aerospace and defense technologies evolve, there is an increasing need for advanced drilling solutions to meet the high standards of these sectors. This demand creates opportunities for companies to develop specialized deep-hole drilling machines tailored to the specific requirements of aerospace and defense applications.

Expansion of Oil and Gas Exploration

The expansion of oil and gas exploration and production is another key opportunity for the deep-hole drilling machines market. As companies explore deeper and more challenging reserves, the need for robust and efficient drilling equipment grows. Innovations in drilling technology that enhance performance and reliability in harsh environments can support the oil and gas sector's expansion. Manufacturers who focus on developing drilling machines that can withstand extreme conditions and offer higher efficiency will find significant opportunities in this sector.

Increased Adoption of Renewable Energy

The rise in renewable energy projects presents new opportunities for deep-hole drilling machines. Renewable energy sectors, such as geothermal energy, require deep-hole drilling for resource exploration and development. Geothermal wells often need to be drilled to significant depths to access heat sources, creating a demand for specialized drilling equipment. As the global focus shifts toward sustainable energy solutions, the need for deep-hole drilling machines in the renewable energy sector is likely to increase.

Growth in Customization and Specialized Solutions

There is also a growing demand for customization and specialized solutions in the deep-hole drilling machines market. Many industries require drilling machines tailored to their specific needs, such as unique hole sizes, depths, or materials. Manufacturers who offer customized solutions and can adapt their machines to meet diverse and complex requirements will find new growth opportunities. This trend towards personalization can help businesses differentiate themselves in a competitive market and attract a broader customer base.

Trends for the Deep Hole Drilling Machines Market

Advancements in Automation and Control Systems

One of the prominent trends in the deep-hole drilling machines market is the increasing adoption of automation and advanced control systems. Modern drilling machines are now equipped with sophisticated automation features that enhance precision and reduce the need for manual intervention. Automated systems help in optimizing drilling parameters, improving operational efficiency, and ensuring consistent quality in the output. These advancements allow for real-time monitoring and adjustments, which help minimize errors and maximize productivity. As industries seek more efficient and accurate drilling solutions, the demand for machines with advanced automation features is on the rise.

Integration of IoT and Real-Time Data Analytics

The integration of Internet of Things (IoT) technology and real-time data analytics is transforming the deep-hole drilling machines market. IoT-enabled machines can collect and transmit data regarding their performance, operational status, and maintenance needs. This data is analyzed in real time to provide insights into the drilling process, allowing for proactive maintenance and optimization of operations. By leveraging these technologies, manufacturers and operators can enhance machine performance, reduce downtime, and extend the lifespan of the equipment. The shift towards data-driven decision-making is becoming a key trend in improving the efficiency and reliability of deep-hole drilling operations.

Focus on Energy Efficiency and Sustainability

Energy efficiency and sustainability are becoming increasingly important in the deep-hole drilling machines market. With growing concerns about environmental impact and energy consumption, manufacturers are focusing on developing machines that consume less energy and produce fewer emissions. Innovations such as electric and hybrid drilling machines are gaining traction as they offer reduced environmental impact compared to traditional diesel-powered equipment. The push towards more sustainable drilling solutions is driven by regulatory pressures and the industry's commitment to reducing its carbon footprint. This trend reflects a broader shift towards greener practices across various industrial sectors.

Customization and Specialized Solutions

There is a growing trend towards customization and specialized solutions in deep-hole drilling machines. As industries face unique challenges and requirements, there is a demand for drilling machines tailored to specific applications. Customization can involve modifications to machine size, drilling depth, or material compatibility to meet particular needs. Manufacturers are responding by offering bespoke solutions and adapting their machines to cater to specialized sectors such as aerospace, oil and gas, and renewable energy. This trend highlights the need for flexibility and innovation in meeting diverse customer demands.

Growth in Advanced Materials and Tooling

The use of advanced materials and tooling in deep-hole drilling machines is also a notable trend. Advances in materials science have led to the development of high-performance alloys and coatings that improve the durability and efficiency of drilling tools. These materials can withstand extreme conditions and enhance the performance of drilling operations. Additionally, innovations in tooling technology, such as improved drill bits and cutting tools, contribute to better performance and longer tool life. The adoption of these advanced materials and tooling solutions is helping to drive the evolution of deep-hole drilling machines.

Rise of Remote Operation and Monitoring

Finally, the rise of remote operation and monitoring capabilities is a key trend in the deep-hole drilling machines market. Remote operation technologies allow for drilling machines to be controlled and monitored from a distance, providing greater flexibility and safety. This trend is particularly valuable in hazardous or difficult-to-reach locations where on-site presence is limited. Remote monitoring systems also enable real-time tracking of machine performance and conditions, leading to more effective maintenance and operational management. The increasing adoption of these technologies reflects a move towards more adaptable and responsive drilling solutions.

Segments Covered in the Report

By Machine Type

o BTA Drilling

o Gun Drilling

o Skiving & Burnishing

By Operations

o CNC

o Non-CNC

By End-Use Industry

o Oil & Gas

o Medical

o Automotive

o Construction & Mining

o Energy

o Aerospace

o Military & Defense

o Others

Segment Analysis

By Machine Type Analysis

The BTA Drilling Machines, Gun Drilling Machines, and Skiving & Burnishing Machines segments of the global deep hole drilling machine market are based on the machine type.

Throughout the projection period, BTA Drilling Machines, the most popular drilling machine, is anticipated to expand at a compound annual growth rate of 6.5%. Single-tube system (STS) drilling is referred to as Boring and Trepanning Association (BTA) drilling. This approach uses just one, as opposed to the ejector drilling process's several. Industries using BTA drilling machines include defense, oil & gas, aircraft, steel, aerospace, power, and hydraulic cylinders.

Up to 50 mm diameter holes can be made with a gun drill. These machines have a small hole in the drilling tool through which coolant enters, and a groove on the outside of the tool is used to remove the material being drilled. The purpose of the gun drilling technique was to create precise and straight gun barrels. Drilling that was accurate and clean made this possible.

By Operations Analysis

The global market for deep-hole drilling machines is divided into CNC and non-CNC segments based on how they are operated. Throughout the forecast period, the CNC segment, which currently holds a sizable market share, is anticipated to increase at a CAGR of 6.3%. CNC deep-hole drilling machines can drill deeper, remove more metal more quickly, align more accurately, and work more swiftly. Automated CNC machines are preferred by end users who want precise measurements and faster production times.

For small-scale industrial tasks, deep hole drilling machines without computer control, or CNC, can be employed. Additionally, non-CNCs are less expensive due to the declining cost of automation technologies. A lot of end users purchase non-CNC machinery because of financial limitations. The non-CNC machines are then enhanced and optimized using inexpensive automation software.

By End-Use Industry Analysis

The global market for deep hole drilling machines is divided into the following end-use industries: oil and gas, medical, automotive, energy, aerospace, military & defense, and others.

Aerospace holds a substantial market share and is projected to expand at a compound annual growth rate (CAGR) of 6.9% over the forecast period. Deep hole drilling machines are often essential to the aerospace industry to maintain the necessary accuracy and caliber in the manufacturing of aircraft parts. For many applications in the aerospace sector, including those involving vital pieces like landing gear, turbine blades, and structural elements, deep holes are a necessary need.

Regional Analysis

Asia-Pacific is leading with a market share of over 33.2% and is expanding at a compound annual growth rate of 6.6%. Due to their large factories and expanding industries, China and Japan held a substantial market share for deep-hole drilling machines in the Asia-Pacific area. Additionally, the Asia-Pacific region's markets for autos, heavy machinery, and aircraft are predicted to expand, which may be advantageous for the deep-hole drilling machine market.

Europe's growth is anticipated to accelerate to a 5.4% CAGR during the projected timeframe. The need for deep-hole drilling equipment is projected to increase as European nations focus more on the oil and gas sector. The market for deep-hole drilling machines is expanding in Europe as a result of adopted higher automotive requirements and technological advancements.

Competitive Analysis

The development of the industry, government backing, and market circumstances all affect the expansion of market vendors. So, the providers ought to concentrate on growing their geographic reach and enhancing their offerings. Even though foreign companies hold the lion's share of the market, there are still regional and foreign competitors. During the projection period, the multinational players may increase their global footprint through acquisitions. Additionally, it has been predicted that attempts to build infrastructure in developing countries along with improvements to the global economic environment are driving market growth. This makes it the perfect time to introduce new deep-hole drilling machine models and expand the global market share.

Recent Developments

June 2023: For the company's recently built 5,000-square-foot fabrication section, UNISIG invested USD 1.5 million in Plant Technology and Equipment. The expansion is in keeping with the company's plan to create in-house, high-quality sheet metal components used in UNISIG's product line, from design to completion.

January 2023: A distribution agreement was established between KOREA GUNDRILL and Cheto Corporation S.A. for the South American distribution of their deep-hole drilling machines.

Key Market Players in the Deep Hole Drilling Machines Market

o Entrust Manufacturing Technologies

o Hochent Machinery Development

o HONG JI Precision Machinery Ltd

o IMSASrl

o TBT Tiefbohrtechnik GmbH + Co.

o Galbiati Costruzioni Meccaniche Srl

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 708.5 Billion |

|

Market Size 2033 |

USD 1,324.9 Billion |

|

Compound Annual Growth Rate (CAGR) |

6.4% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Machine Type, Operations, End-Use Industry, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Entrust Manufacturing Technologies, Hochent Machinery Development, HONG JI Precision Machinery Ltd, Mollart Engineering Limited, IMSASrl, Cheto Corporation SA, TBT Tiefbohrtechnik GmbH + Co., Kennametal Inc, Galbiati Costruzioni Meccaniche Srl, Frankor Hydraulics, Other Key Players |

|

Key Market Opportunities |

Emerging Markets and Infrastructure Development |

|

Key Market Dynamics |

Increased Demand for Precision Engineering |

📘 Frequently Asked Questions

1. What would be the forecast period in the Deep Hole Drilling Machines Market?

Answer: The forecast period in the Chrome Plating Market report is 2024-2033.

2. How much is the Deep Hole Drilling Machines Market in 2023?

Answer: The Deep Hole Drilling Machines Market size was valued at USD 708.5 Billion in 2023.

3. Who are the key players in the Deep Hole Drilling Machines Market?

Answer: Entrust Manufacturing Technologies, Hochent Machinery Development, HONG JI Precision Machinery Ltd, Mollart Engineering Limited, IMSASrl, Cheto Corporation SA, TBT Tiefbohrtechnik GmbH + Co., Kennametal Inc, Galbiati Costruzioni Meccaniche Srl, Frankor Hydraulics, Other Key Players

4. What is the growth rate of the Deep Hole Drilling Machines Market?

Answer: Deep Hole Drilling Machines Market is growing at a CAGR of 6.4% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.