🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Dimethylvinylchlorosilane Market

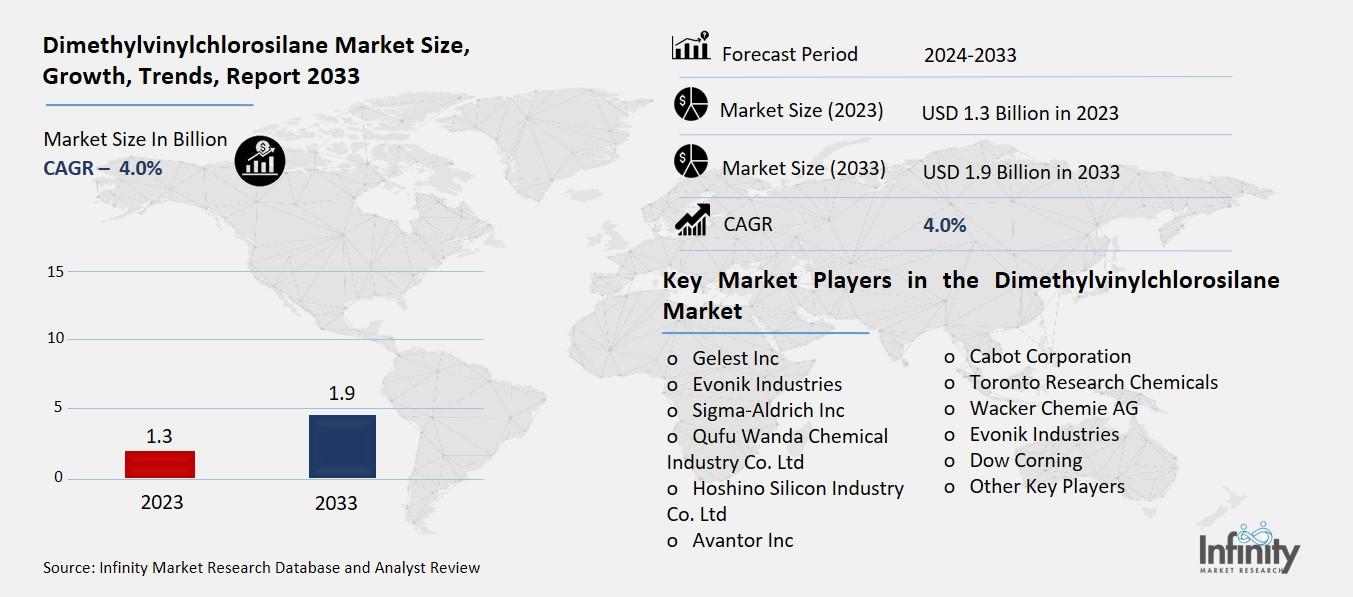

Global Dimethylvinylchlorosilane Market (By Grade, Upto 98% Purity and 99% Purity; By Application, Silicone Sealants, Silicone Rubber, Printing Inks & Toners, Paints & Coatings, Cable Compounds & Gels, and Adhesives; By Region and Companies), 2024-2033

Dec 2024

Chemicals and Materials

Pages: 138

ID: IMR1344

Dimethylvinylchlorosilane Market Overview

Global Dimethylvinylchlorosilane Market acquired the significant revenue of 1.3 Billion in 2023 and expected to be worth around USD 1.9 Billion by 2033 with the CAGR of 4.0% during the forecast period of 2024 to 2033. The global market for dimethylvinylchlorosilane is a small market segment within the overall organosilicon compounds market, which is specifically used as a reagent in the production of several silicone polymers and resins. This compound is well known across the electronics, automotive, construction and health care industries as it plays essential functions of providing thermal stability, water proofing and chemical resistance to end products.

The market is driven by increasing requirement of improved performance in new and enhanced applications such as adhesives, sealants, and coatings. Asia Pacific has the largest growth rate attributed to the electronics and construction industry while North America and Europe contribute to the new specialty silicone products.

Drivers for the Dimethylvinylchlorosilane Market

Growing Demand for Silicone-Based Products

The increasing usage of silicone in electronics, automotive and construction industries play a crucial role in the demand for DMVCS, an intermediate for silicone production. In the electronics industry silicone is often used due to its solutions thermal stability, dielectric constant, and resistance to environmental conditions for uses such as encapsulation, electronics coatings and sealing especially for sensitive electronic parts.

Automotive industry uses silicone to produce robust, heat and mechanical stress-resistant gaskets, seals and adhesives that impact on the performance and durability of cars. In construction applications, silicone-based polymer finds use in sealants, adhesives, and coatings because it is characterized by water resistance, flexibility, and heat resistant to UV type of threatening conditions of the modern building structures.

Restraints for the Dimethylvinylchlorosilane Market

Stringent Environmental Regulations

Regulations governing the production and handling of organosilicon compounds, including dimethylvinylchlorosilane, present significant compliance challenges for manufacturers. These regulations often focus on mitigating the environmental impact, ensuring workplace safety, and managing hazardous materials effectively. For instance, strict guidelines may mandate proper storage and transportation of chlorosilanes to prevent accidental releases or chemical reactions.

Additionally, emissions from manufacturing processes must adhere to stringent environmental standards to minimize volatile organic compounds (VOCs) and other pollutants. Compliance requires substantial investments in advanced production technologies, waste management systems, and safety protocols, which can increase operational costs.

Opportunity in the Dimethylvinylchlorosilane Market

Expansion in Renewable Energy Applications

The increasing adoption of silicone materials in renewable energy technologies, particularly solar panels and wind turbines, offers significant growth opportunities for the dimethylvinylchlorosilane market. In solar panels, silicones are used for their excellent sealing, bonding, and encapsulating properties, which enhance the durability and efficiency of photovoltaic systems by protecting them against moisture, UV radiation, and temperature fluctuations. Similarly, in wind turbines, silicones play a crucial role in manufacturing robust adhesives, sealants, and coatings that can withstand harsh environmental conditions and mechanical stress.

As the global push for renewable energy intensifies, driven by environmental concerns and government incentives, the demand for high-performance silicone materials is expected to surge. This trend creates a lucrative opportunity for manufacturers of dimethylvinylchlorosilane, which is a vital precursor in the production of these advanced silicone solutions.

Trends for the Dimethylvinylchlorosilane Market

Digital Transformation in Manufacturing

The adoption of advanced manufacturing techniques and automation is transforming the production landscape of dimethylvinylchlorosilane, leading to improved efficiency and cost reduction. Automated systems enable precise control over reaction conditions, ensuring consistent product quality and reducing material wastage. Technologies such as real-time monitoring, predictive maintenance, and AI-driven process optimization enhance operational efficiency by minimizing downtime and maximizing throughput.

Furthermore, automated handling systems mitigate safety risks associated with the production and storage of volatile organosilicon compounds, ensuring compliance with stringent safety regulations. These advancements not only lower production costs but also improve scalability, allowing manufacturers to meet growing market demands effectively.

Segments Covered in the Report

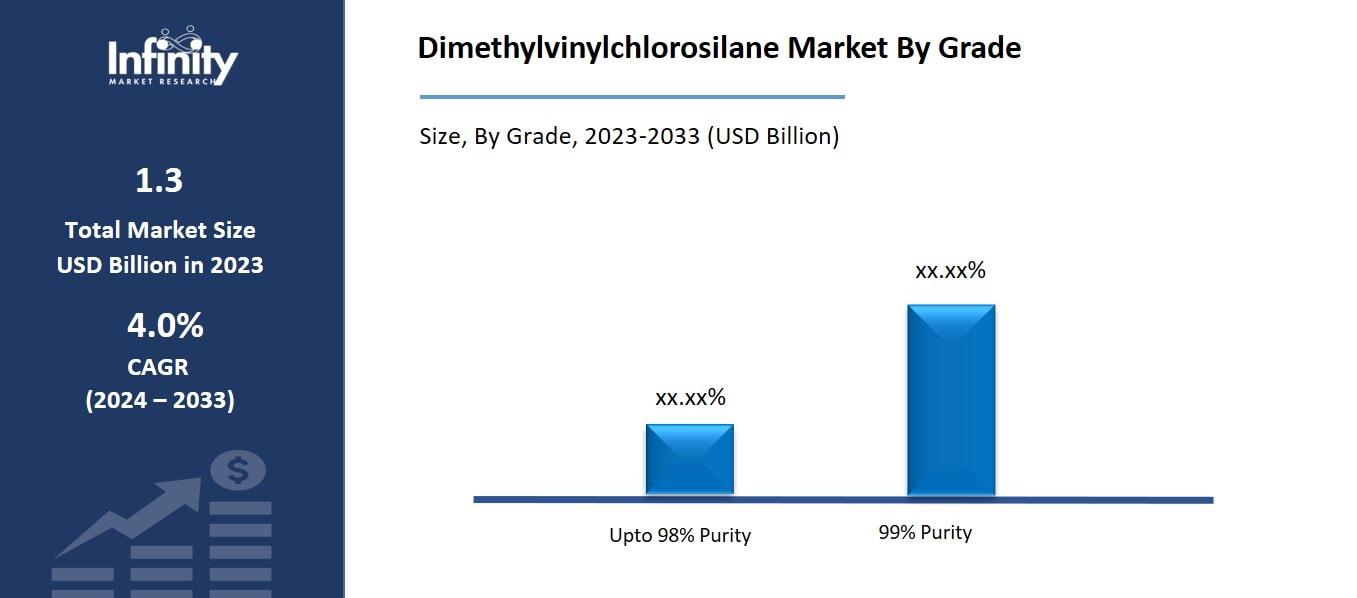

By Grade

o Upto 98% Purity

o 99% Purity

By Application

o Silicone Sealants

o Silicone Rubber

o Printing Inks & Toners

o Paints & Coatings

o Cable Compounds & Gels

o Adhesives

Segment Analysis

By Grade Analysis

On the basis of grade, the market is divided into upto 98% purity and 99% purity. Among these, 99% purity segment acquired the significant share in the market owing to its widespread application in high-performance and precision-demanding industries. The superior purity level ensures minimal impurities, making it ideal for producing advanced silicone polymers used in electronics, medical devices, and specialty coatings. Industries requiring strict quality standards, such as semiconductors and healthcare, favor the 99% purity grade for its reliability and consistency in delivering optimal performance. Additionally, the growing emphasis on producing high-quality silicone materials to meet the rising demand for durable and efficient solutions further drives the preference for the 99% purity segment in the market.

By Application Analysis

On the basis of application, the market is divided into silicone sealants, silicone rubber, printing inks & toners, paints & coatings, cable compounds & gels, and adhesives. Among these, silicone sealants held the prominent share of the market due to its extensive use in commercial and industrial applications. Silicone sealants are widely employed in the construction and automotive sectors for their exceptional properties, including flexibility, weather resistance, and durability. They are essential for sealing joints and gaps in infrastructure projects, ensuring longevity and structural integrity, especially in high-stress environments. The increasing demand for sustainable and energy-efficient buildings has further bolstered the adoption of silicone sealants, as they contribute to better insulation and moisture resistance.

Regional Analysis

Asia Pacific Dominated the Market with the Highest Revenue Share

Asia Pacific held the most of the share of 30.6% of the market due to its robust industrial base and rapid economic development. Key drivers include the expansion of end-use industries such as electronics, automotive, and construction, which heavily rely on silicone-based materials. Countries like China, Japan, South Korea, and India are major contributors, with China leading as a global manufacturing hub for silicone products due to its cost-effective production capabilities and abundant raw material availability.

The region also benefits from increasing infrastructure projects and technological advancements in sectors like renewable energy, further fueling demand. Additionally, growing investments in research and development and the presence of leading silicone manufacturers solidify Asia-Pacific's dominant position in the market.

Competitive Analysis

The dimethylvinylchlorosilane market is characterized by intense competition, driven by the presence of several key players focusing on innovation, capacity expansion, and strategic collaborations. Leading manufacturers prioritize advancements in production technologies to enhance product quality and reduce costs, ensuring a competitive edge. Companies are also heavily investing in R&D to develop high-purity grades and environmentally friendly manufacturing processes to align with evolving regulatory standards and sustainability goals. Strategic partnerships, mergers, and acquisitions are common strategies to expand market presence and gain access to emerging markets, particularly in Asia-Pacific.

Key Market Players in the Dimethylvinylchlorosilane Market

o Gelest Inc

o Evonik Industries

o Sigma-Aldrich Inc

o Qufu Wanda Chemical Industry Co. Ltd

o Hoshino Silicon Industry Co. Ltd

o Avantor Inc

o Cabot Corporation

o Toronto Research Chemicals

o Wacker Chemie AG

o Evonik Industries

o Dow Corning

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.3 Billion |

|

Market Size 2033 |

USD 1.9 Billion |

|

Compound Annual Growth Rate (CAGR) |

4.0% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Grade, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Gelest Inc, Evonik Industries, Sigma-Aldrich Inc, Qufu Wanda Chemical Industry Co. Ltd, Hoshino Silicon Industry Co. Ltd, Avantor Inc, Cabot Corporation, Toronto Research Chemicals, Wacker Chemie AG, Evonik Industries, Dow Corning, and Other Key Players. |

|

Key Market Opportunities |

Expansion in Renewable Energy Applications |

|

Key Market Dynamics |

Growing Demand for Silicone-Based Products |

📘 Frequently Asked Questions

1. Who are the key players in the Dimethylvinylchlorosilane Market?

Answer: Gelest Inc, Evonik Industries, Sigma-Aldrich Inc, Qufu Wanda Chemical Industry Co. Ltd, Hoshino Silicon Industry Co. Ltd, Avantor Inc, Cabot Corporation, Toronto Research Chemicals, Wacker Chemie AG, Evonik Industries, Dow Corning, and Other Key Players.

2. How much is the Dimethylvinylchlorosilane Market in 2023?

Answer: The Dimethylvinylchlorosilane Market size was valued at USD 1.3 Billion in 2023.

3. What would be the forecast period in the Dimethylvinylchlorosilane Market?

Answer: The forecast period in the Dimethylvinylchlorosilane Market report is 2024-2033.

4. What is the growth rate of the Dimethylvinylchlorosilane Market?

Answer: Dimethylvinylchlorosilane Market is growing at a CAGR of 4.0% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.