🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Diphenyl Carbonate Through Oxidative Carbonylation Market

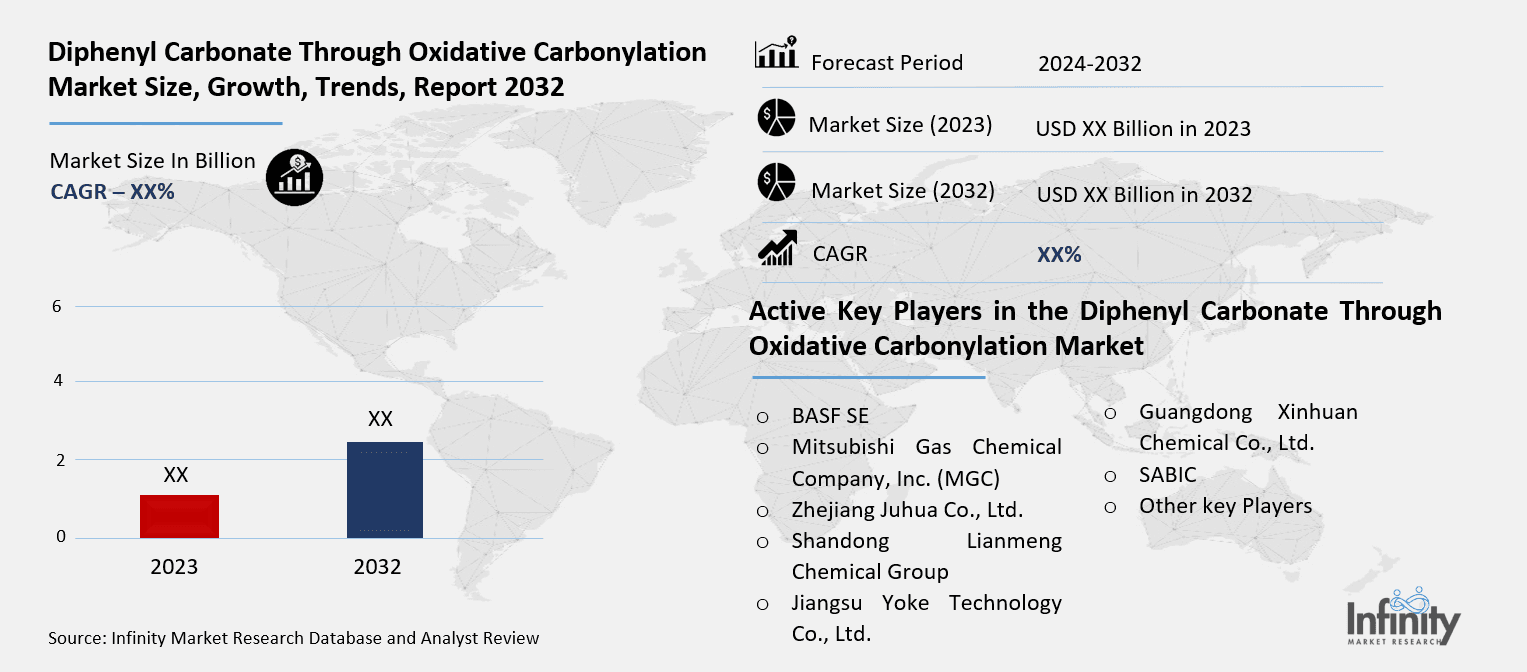

Diphenyl Carbonate Through Oxidative Carbonylation Market Global Industry Analysis and Forecast (2024-2032) By Application (Polycarbonate Production, Pharmaceuticals, Agriculture, Other Applications) By End-Use Industry (Automotive, Electronics, Construction, Medical Devices, Other Industries) By Production Process, (Oxidative Carbonylation , Other Production Methods. By Type (High Purity Diphenyl Carbonate, Industrial-Grade Diphenyl Carbonate) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1710

Diphenyl Carbonate Through Oxidative Carbonylation Market Synopsis

Diphenyl Carbonate Through Oxidative Carbonylation Market growth is projected to reach USD XX Billion in 2023, at a XX% CAGR by driving industry size, share, segments research, top company analysis, trends and forecast report 2024 to 2032.

The Diphenyl Carbonate through Oxidative Carbonylation market deals with the industry concerned with the synthesis and application of diphenyl carbonate (DPC), a widely used chemical substance, using an oxidative carbonylation method. This method is caused by the reaction of phenol with carbon monoxide and oxygen to form diphenyl carbonate normally though a catalyst. DPC is intermediate in making polycarbonate plastics, pharmaceuticals and agrochemicals. These include; increasing demand for high-performance plastics skin, manufacturing technologies, and the expansion of products to various industries such as the automotive, electronics, packaging, and others.

The Diphenyl Carbonate (DPC) through oxidative carbonylation has been emerging as an important segment of the chemical industry owing to the growing interests for better production techniques. DPC is an essential application intermediate in the manufacture of polycarbonate plastics utilized in various industries comprising automobile, electronics, medical devices, and construction. Formerly, DPC was synthesized by employing phosgenation method; this method poses threats that are environmental and unsafe. Nevertheless, recently a new approach of oxidative carbonylation process emerged, which provided a revolution in this field in comparison with other dangerous and unsafe methods. In this process phenol reacts with carbon monoxide and oxygen under the catalytic effect of a suitable catalyst to produce DPC without any effects of dangerous reagents such as phosgene. This green method is also approved with the help of regulatory policies are the most demanded nowadays as manu facturers tend to improve their ecological standards and increase the level of sustainability of production.

Market through oxidative carbonylation of DPC is expected to have huge growth as polycarbonate materials demand increases. Polymer DPC has many uses because of the properties of the polycarbonates; they offer top-quality durability, visibility, and mechanical strength with high impact resistance that is suitable to applications in electronics, automotive, and medical industries. Consequently, industries are pursuing lightweight and durable materials and this quest will the lead to a demand for polycarbonates and consequently the liquid DPC. The automotive application is a major force behind this demand because the trend towards lightweight high-performance plastics, replacing more conventionally used materials such as metals, in automobile production is steadily rising as one way of enhancing fuel efficiency. Besides, the rising production rates of consumer electronics and medical equipment, the latter of which uses polycarbonates for optical lenses and protective shields as well as the production of various other components of consumer electronics, is expected to enhance the growth of the DPC market.

Future developments in oxidative carbonylation and harmony study comparability practices shall be instrumental in keeping this industry functional. Better selectivity of the catalyst and reaction conditions, as well as the enhancement in the design of reactors engaged in the fixed bed are enabling the manufacturers to improve yields and reduce energy consumption. Such developments do not only make the procedure cheaper but also play a role in minimizing carbon impacts thus walking the talk in theconcept of sustainable manufacturing taking root across the world. The current prevalent issues of energy efficiency and sustainability in the chemical industry provide a favorable background for further development of DPC produced through oxidative carbonylation – it may become economically profitable and environmentally friendly. Moreover, increasing concerns and shifting towards the use of renewable and bio based feedstock for the manufacturing of chemicals is expected to drive the market as manufacturers look towards alternatives to the more traditional petrochemical feedstock.

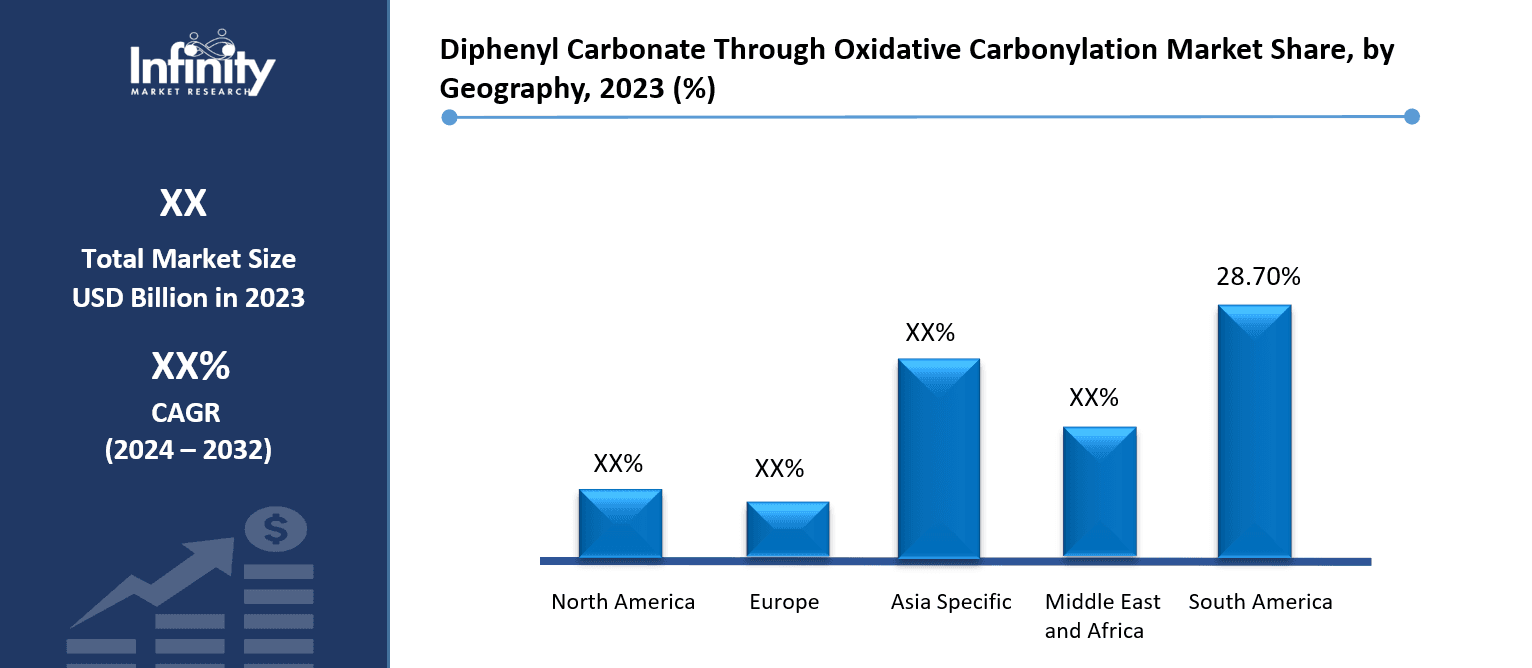

On a regional basis, the Asia-Pacific market is likely to have the largest share in the DPC market through oxidative carbonylation due to large-scale production and higher demand for polycarbonate material. Investor countries for this type of technology include China Japan, and South Korea since these countries boast of vibrant industrial businesses such as automobile, electronics, and construction. Moreover, there are government policies encouraging the use of cleaner technologies and, in particular, decreasing carbon emission levels also contribute to the growth of the markets in these regions. North America is the other large consumer market mainly associated with the United States which is well equipped with chemical manufacturing companies apart from this they are focusing more on sustainable production. Another is Europe that has quite strict environmental standards that are improving the adoption of oxidative carbonylation methods due to the push towards the use of greener technologies.

However, the market has factors that may pose as threats and jeopardize the growth of the DPC through oxidative carbonylation market. The expensive raw materials, especially carbon monoxide, and difficul性的 carbonylation reaction are potential problems which may hinder the simmer process and its economization in the future. Also, the fixed cost for establishing oxidative carbonylation plants are quite high which put off new entrants into the market because they cannot afford to make the initial investments. Superior catalysts and reactor technologies are being developed and the future outlook is that cost of manufacturing will reduce as it becomes attractive to more original equipment manufacturers.

In summary, the global market of the DPC through oxidative carbonylation has huge development space, for several aspects, the demand for polycarbonate materials, the advancement of technology in carbonylation synthesis, and the enhancement of sustainable chemical industry. While industries keep on going forward on cutting down their negative impact to the environment in fulfilling the requirements of high performance materials, the demand for DPC synthesized through oxidative carbonylation is expected to increase. But bottlenecks associated with cost and product differentiation will have to be ironed out in order to sustain the growth in the foreseeable future. This is because DPC through oxidative carbonylation opens up the opportunity to further advance through application of right technologies and strategic investments that would propel the technology in Asian-Pacific, North American, European and other upcoming markets.

Diphenyl Carbonate Through Oxidative Carbonylation Market Trend Analysis

Trend

Growth of Oxidative Carbonylation in DPC Production

A fast growth of oxidative carbonylation in the Diphenyl Carbonate (DPC) market is noticeable because of a constantly rising demand for the utilization of eco-friendly and effective chemical processes. This method has come out as a cleaner and highly efficient compared to conventional production methods mainly because it employs carbon monoxide and oxygen and so, most of the dangerous reagents are eliminated, as well as the major by-products. Such a shift towards oxidative carbonylation dovetails with the need for cleaner and environ, mentally friendly operations worldwide. This is because as industries like electronics, automotive, and pharmaceuticals product incorporate through materials that need DPC particularly polycarbonate, the market has experienced a tremendous rise of this factor.

The movement more towards eco-friendly production processes has been compounded by increased legal enforcement on the adoption of sustainable production processes. International governments are enforcing strict measures on emissions and wastes and various industries are looking for ways to cut their usage. For this reason, firms are now looking into new methods and systems that will not only conform to these regulatory requirements but will also improve efficiency and reduce costs. This is making oxidative carbonylation to advance further in DPC production to meet market and environmental challenge.

Drivers

Growing Demand for Polycarbonate in Lightweight and Durable Materials

The increasing use of polycarbonate resins in lightweight and durable applications has stimulated the need for Diphenyl Carbonate (DPC) commonly used in production of the former. Presently, polycarbonate finds diverse applications across different industries such as automotive, due to its high impact strength and transparency for applications like car-headlights, sunroof or other automobile parts. Emerging technology systems such as electric vehicles (EVs) and efficient cars that employ lightweight material for energy efficiency purposes have favored polycarbonate demand. This megatrend is helping the growth of DPC market – automotive industry has been using more polycarbonate based material due to need for lighter vehicles to improve fuel efficiency.

In addition, consumer electronics is a major driver in the demand for polycarbonate, which has extensive uses in manufacturing tough and clear products such as telephone covers, computer lid, and tablet skins. Polycarbonate resins will be increasingly relied on in electronics as technology develops and consumers show continued preference for lightweight high strength products. Such factors explain a higher necessity for DPC since manufacturers use the given intermediate to create high-quality polycarbonate resins. Therefore, growth of end uses in polycarbonate across industries enhances market of DPC with help of oxidative carbonylation.

Restraints

High Cost of Raw Materials

The capital barrier in the Diphenyl Carbonate through Oxidative Carbonylation market also looks at high costs involved in purchasing some of its critical raw materials, including phenol and carbon monoxide. These materials also increase production cost since they make up a large portion of the production which is economically unproportional when mass production is involved. Moreover, the reaction conditions for oxidative carbonylation are stiff that increases its operational costs. It requires the control of temperature and pressure and most other factors and this can only be addressed by the use of technology and personnel. These factors not only lead to higher operational costs, but also restrain the scale of the process, therefore, leaving little room for the growth of small market participants.

Also, high environmental standards and the risks of handling dangerous reagents such as carbon monoxide also negatively affect the market’s growth. These are measures taken with an aim of eliminating adverse impacts on the environment while in the process they incur some extra cost in compliance with guidelines, protection measures, as well as handling wastes. Since carbon monoxide is a lethal gas, special precautions must be used to reduce the incidence of accidents; these measures add to the complexity of processes. Indeed in some areas these regulations may be too harsh and firms may be forced to establish extra capital for safety measures and environmental compliance before accessing new markets.

Opportunities

Expansion of DPC Applications in the Electronics Sector

The electronics segment presents one of the biggest development opportunities for the Diphenyl Carbonate (DPC) through oxidative carbonylation market. DPC polymer is the basis of manufacturing polycarbonate, a higher value-added plastic material that is witnessing rising applications in the manufacture of optical lenses, electrical parts, and other electronics goods because of its exceptional properties. These are the lightweight materials, durable, heat resistant that is why they can be used in smartphones, laptops, cars parts etc. The market for portable and more efficient electronics that last longer is expected to go up in the future, based on this, the demand for polycarbonate will also increase in future and thus the demand for DPC also increases. Because of this, the opportunities for producers of DPC have arisen especially those who are targeting on the benefits of oxidative carbonylation to ensure it feeds the growing market.

Moreover, the market for electronics is continually moving toward miniaturization and slimming and more powerful gadgets also favor DPC in electronics. The electronics industry is using polycarbonate for applications that are not only mechanical and thermal, but also applications that necessitate light transmission, such as LED lenses, screens and other displays. As these applications grow, especially with the development of augmented reality (AR), virtual reality (VR) and other trend-setting technologies, there will be a strong demand for high quality polycarbonate material derived from DPC. This presents a favorable incremental market opportunity for manufacturers that use oxidative carbonylation processes which are environmentally more acceptable and cost effective routes to produce polycarbonate and trigger further market growth in the electronics segment.

Diphenyl Carbonate Through Oxidative Carbonylation Market Segment Analysis

Diphenyl Carbonate Through Oxidative Carbonylation Market Segmented on the basis of By Application, By Production Process, By End-Use Industry, By Type.

By Application

o Polycarbonate Production

o Pharmaceuticals

o Agriculture

o Other Applications

By Production

o Oxidative Carbonylation

o Other Production Methods

By Type

o High Purity Diphenyl Carbonate

o Industrial-Grade Diphenyl Carbonate

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Application, Polycarbonate Production segment is expected to dominate the market during the forecast period

Diphenyl carbonate is a key chemical used in the production of polycarbonates, which are known for their strength, transparency, and impact resistance. These properties make polycarbonates highly desirable in several industries, including automotive, construction, and electronics. In the automotive industry, polycarbonate materials are used for producing lightweight yet durable components such as headlamps, windows, and dashboards. Similarly, in the construction sector, polycarbonate sheets and panels are utilized for their strength and insulation properties in roofing, glazing, and facades. The electronics industry also benefits from polycarbonates, where they are used in the production of durable screens, housings, and components for devices like smartphones, laptops, and televisions.

As demand for high-performance, lightweight materials continues to rise, the polycarbonate market is expected to grow steadily. Advancements in automotive design, such as the push for electric vehicles, are driving the need for more efficient, lighter materials that improve fuel efficiency and performance. Similarly, the growing demand for advanced consumer electronics that require durable and aesthetically pleasing components further fuels the need for polycarbonate. As these industries evolve and require materials with enhanced properties, the demand for diphenyl carbonate, the precursor for polycarbonate production, is set to increase, offering continued growth prospects in the coming years.

By Type, High Purity Diphenyl Carbonate segment expected to held the largest share

High-purity diphenyl carbonate plays a crucial role in industries such as pharmaceuticals, electronics, and medical devices, where the need for superior quality materials is paramount. In pharmaceuticals, it is used in the production of active pharmaceutical ingredients (APIs) and drug intermediates, where any impurities could compromise the efficacy and safety of medications. In electronics, high-purity diphenyl carbonate is essential for creating polycarbonates used in precision components such as lenses, screens, and protective housings. Similarly, in medical devices, materials made from high-purity diphenyl carbonate are used for critical equipment like syringes, IV tubing, and diagnostic tools, where product reliability and safety are non-negotiable.

As advanced technologies continue to evolve, the demand for high-purity diphenyl carbonate is expected to increase, driven by the growth in these high-end applications. The pharmaceutical industry’s focus on developing more sophisticated and specialized drugs, coupled with the electronics industry's continuous push for smaller, more efficient devices, both contribute to the rising need for materials that meet stringent purity standards. Furthermore, the aging global population and the subsequent rise in healthcare needs are expected to expand the market for medical devices, further driving demand for high-purity diphenyl carbonate in the coming years. This growth reflects the increasing importance of high-quality chemical intermediates to support technological advancements and innovation across these sectors.

Diphenyl Carbonate Through Oxidative Carbonylation Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Currently, North America has significant market growth due to the requirement of the kinds of products that use Diphenyl carbonate as the precursor in generating polycarbonate goods. Mucopolymer which is a highly versatile material used in diverse products like consumer electronics goods, automotive trim and construction, is the key product. Owing to a strong industrial backing combined with well-developed manufacturing capacity, North America remains a key consumer as well as producer of the polycarbonate. The rising trend of the use of high-performance materials in automotive and electronics industries that creates direct pressure on the use of polycarbonate also fuels the DPC demand.

Further, the stabilising regional market rules and the market share featuring key market participants involved in the chemical industry are cardinal to sustaining market growth. North America is experiencing a growing demand for components for electric vehicles that also require a significant amount of polycarbonate – a primary driver of DPC consumption. Nonetheless, competition risks are identified by both analysts as the market may experience such challenges as constantly increasing environmental concerns or strict rules and regulation of chemical manufacturing. These factors may limit the ability of DPC production to increase its production scale, and thus, the manufacturer may be forced to adopt clean technologies and regulatory changes.

Diphenyl Carbonate Through Oxidative Carbonylation Market Share, by Geography, 2023 (%)

Active Key Players in the Diphenyl Carbonate Through Oxidative Carbonylation Market

o BASF SE

o Mitsubishi Gas Chemical Company, Inc. (MGC)

o Zhejiang Juhua Co., Ltd.

o Shandong Lianmeng Chemical Group

o Jiangsu Yoke Technology Co., Ltd.

o Guangdong Xinhuan Chemical Co., Ltd.

o SABIC

o Other key Players

Global Diphenyl Carbonate Through Oxidative Carbonylation Market Scope

|

Global Diphenyl Carbonate Through Oxidative Carbonylation Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Application |

· Polycarbonate Production · Pharmaceuticals · Agriculture · Other Applications | |

|

By End-Use Industry |

· Automotive · Electronics · Construction · Medical Devices · Other Industries | ||

|

By Production Process |

· Oxidative Carbonylation · Other Production Methods | ||

|

By Type |

· High Purity Diphenyl Carbonate · Industrial-Grade Diphenyl Carbonate | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Demand for Polycarbonate in Lightweight and Durable Materials | ||

|

Key Market Restraints: |

· High Cost of Raw Materials | ||

|

Key Opportunities: |

· Expansion of DPC Applications in the Electronics Sector | ||

|

Companies Covered in the report: |

· BASF SE, Mitsubishi Gas Chemical Company, Inc. (MGC), Zhejiang Juhua Co., Ltd., Shandong Lianmeng Chemical Group , Jiangsu Yoke Technology Co., Ltd. , Guangdong Xinhuan Chemical Co., Ltd. , SABIC and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Diphenyl Carbonate Through Oxidative Carbonylation Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Diphenyl Carbonate Through Oxidative Carbonylation Market?

Answer: BASF SE, Mitsubishi Gas Chemical Company, Inc. (MGC), Zhejiang Juhua Co., Ltd., Shandong Lianmeng Chemical Group , Jiangsu Yoke Technology Co., Ltd. , Guangdong Xinhuan Chemical Co., Ltd. , SABIC and Other Major Players.

3. What are the segments of the Diphenyl Carbonate Through Oxidative Carbonylation Market?

Answer: The Market is segmented into By Application, By Production Process, By End-Use Industry, By Type and region. By Application, the market is categorized into Polycarbonate Production, Pharmaceuticals, Agriculture, Other Applications. By End-Use Industry, the market is categorized into Automotive, Electronics, Construction, Medical Devices, Other Industries. By Production Process, the market is categorized into Oxidative Carbonylation , Other Production Methods. By Type, the market is categorized into High Purity Diphenyl Carbonate, Industrial-Grade Diphenyl Carbonate. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Diphenyl Carbonate Through Oxidative Carbonylation Market?

Answer: The Diphenyl Carbonate through Oxidative Carbonylation market deals with the industry concerned with the synthesis and application of diphenyl carbonate (DPC), a widely used chemical substance, using an oxidative carbonylation method. This method is caused by the reaction of phenol with carbon monoxide and oxygen to form diphenyl carbonate normally though a catalyst. DPC is intermediate in making polycarbonate plastics, pharmaceuticals and agrochemicals. These include; increasing demand for high-performance plastics skin, manufacturing technologies, and the expansion of products to various industries such as the automotive, electronics, packaging, and others.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.