🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Electroless Plating Market

Electroless Plating Market Global Industry Analysis and Forecast (2024-2032) by Type (Nickel, Copper, Gold, Silver, Others), Application (Automotive, Electronics, Aerospace, Industrial Machinery, Medical Devices, Others), End User (Automotive, Electronics, Aerospace, Industrial, Medical, Others) and Region

Jan 2025

Healthcare

Pages: 138

ID: IMR1533

Electroless Plating Market Synopsis

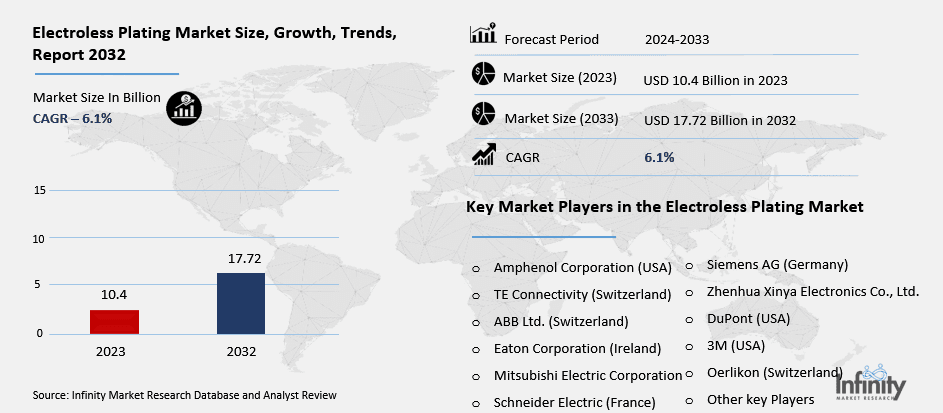

Electroless Plating Market Size Was Valued at USD 10.4 Billion in 2023, and is Projected to Reach USD 17.72 Billion by 2032, Growing at a CAGR of 6.1% From 2024-2032.

The Electroless Plating Market therefore spells to do with the deposition of a metal layer on the surface of an object without employing an outside electric current. This process is based on the chemical reduction deposition which put the consistent layer of metal to the base materials such as metals, plastics and ceramics, and more. Electroless plating is applied for enhancing various properties of surface like anti-corrosive, wear resistant, electrically conductive and aesthetic point of view. Most of the metals that are deposited in the electro less plating process involves; Nickel copper gold and silver and palladium among others. Electroless plating differ from electroplating in that the process does not rely electricity to drive the actual metal depositing but rather it relies on a chemical precipitation, which occurs in a solution composed of metal ions, reducing agents and other chemicals. It has many merits, namely precise deposition thickness, increased service duration, and better functioning in automotive, electronics, aerospace, and so on.

The Electroless Plating Market has had constant growth in the Europe Electroless Plating Market, and this growth has been occasioned by the rising need for high performing materials in various sectors. As auto, electronics, aerospace and telecommunication industries require more reliable parts with better performance and longer life, electro less plating has been found to be a very effective method of depositing thin layers of metals on substrate such as nickle, gold or copper. This market is predicted to show an upward trend in the future due to the development in the plating processes and the material used in coating. Increased usage of electroless plating due to the possibility to coate geometries and non-conductive substrates but also to the need for efficient and environmentally friendly methods.

In geographical area, currently and in the near future the market is expandable and has shown remarkable growth in North America, Europe and Asia-Pacific. Such areas as electronics and automotive raising in these territories, forecasted demand for wear-resistant coatings as well as components with improved electric conductivity Moreover, there are increasing aspects in environmental consciousness and the demand for green coating techniques that necessitate more novel electroless plating solutions on the market. Consequently, the market is on the brink of experiencing increased demand, especially for ever more elaborate applications demanding high-performance coatings, including electrical connectors, automotive components, and medical equipment.

Electroless Plating Market Outlook, 2023 and 2032: Future Outlook

Electroless Plating Market Trend Analysis

Trend: Growing Demand for Eco-Friendly Coating Processes

A major driving factor that forms the Electroless Plating Market trends is the shift towards more environmentally friendly plating processes. Due to increasing global concern to reduce environmental issues and conform to regulatory requirements, many players in the market have shifted focus directed towards more development of new electroless plating products. The conventional plating method requires the use of chemical compounds, which are dangerous, and generates dangerous products threatening the ecosystem and employees.

In order to counter these issues, the industry is moving away from the conventional plating techniques involving heavy metals and toxic chemicals, large amounts of waste water, and enormous consumption of water and energy. This development corresponds with the global energy conversation towards sustainability where both producers and consumers, in this case manufacturers and users of food products, stand to benefit from its positive impacts to the economy as well as environmental effects.

Driver: Increasing Demand from Automotive and Electronics Industries

The Electroless Plating Market has been fueled by the incredibly rising trend of usage of advanced materials across key sectors such as automotive and electronics. Since automotive manufacturers are always in the process of looking for ways to increase part durability, performance, as well as appearance, electroless plating has proven to be efficient and cost friendly advantage. This is even more so where the component requires enhanced corrosion protection and wear characteristics as is the case with engine parts, connectors, sensors and electronics. Likewise, the electronics industry is exploiting more the electroless plating by using the material as connectors, circuit boards and semiconductors since uniform coating and electrical conductivity are essential on those products. Hence, electroless plating allows for coating of such hard geometries and non-conductive material hence making it crucial as industry requirements for such coatings increases.

Restraint: High Cost of Electroless Plating Process

However, the Electroless Plating Market is not without some weaknesses, chiefly the high costs that would be incurred in the process. Electroless plating requires the use of special chemicals and sophisticated equipment, and in this issue, it could be costly as compared with electrical plating. This cost factor poses a challenge to SMEs or any company that has a relatively small budget to spend on electroless plating thus small scale production. However, the process entails a strict regulation of temperature, pH and chemical concentration which can enhance the operating cost. Therefore, the capital-intensive nature of electroless plating operations’ initial establishment and the endeavor to achieve and sustain acceptable levels of quality continue to pose hurdles to the producers.

Opportunity: Technological Advancements and Expanding Applications

The Electroless Plating Market has some significant opportunities for growth, particularly through the use of technologies and development in applications. For example, continuous improvement of the electroless plating technology, including the appearances of new advanced technological processes, acts as the main driver of the market. For instance, improvement of the plating technology, its improved adhesion characteristic and effectual coating thickness control mechanism are enhancing the efficiency of the technology.

CDCs have observed new applications in different fields, such as medical applications, renewable energy, and at nanoscale. Miniaturization is another driving force which has seen the use of electroless plating found in electronics and telecommunication to be a good chance as movements towards miniaturization in microelectronic devices. Thus, the electroless plating can remain a promising direction for offering solutions for new top-level industries and their products.

Electroless Plating Market Segment Analysis

Electroless Plating Market Segmented on the basis of type, application and end user.

By Type

o Nickel

o Copper

o Gold

o Silver

o Others

By Application

o Automotive

o Electronics

o Aerospace

o Industrial Machinery

o Medical Devices

o Others

By End User

o Automotive

o Electronics

o Aerospace

o Industrial

o Medical

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Nickel segment is expected to dominate the market during the forecast period

The global Nickel-based electroless plating market is anticipated to grow at a higher growth rate on account of its high abrasion, corrosion advantages and hardness that moisture various application. Nickel has many applications in automotive, electronics, aerospace and other industries where hard and corrosion resistant coatings are needed. The technique of electroplating of nickel is excellent on the steel, aluminium, the plastics and other related surfaces that further fuels the demand. The increasing trend in the demand for nickel-plated components especially in various industries that seek high performance material also imply that the nickel segment is set to dominate the electroless plating market throughout the forecast period.

However, versatility of the nickel plating is also a reason for its promotion so much. In cases of connectors, sensors, medical devices, and many others, uniform coatings on complex geometries make nickel to perform far much better. This has led to its use in the TODD manufacturing activities especially in the areas of high mechanical strength, wear and tear, and electrical conduction. The market for electroless plating solutions will indeed grow in the future because with the increased usage in the global electronic devices, automotive, and industries afterward machinery the utilization of nickel based electroless plating will retain its dominance majorly among the material types.

By Application, Automotive segment expected to held the largest share

The automotive industry is expected to take the biggest share owing to their rising need for excellent, long-lasting components across the Electroless Plating Market. The electroless plating is widely used in automotive manufacturing since it contributes to the necessity of manufacturing parts that should have wear resistance, corrosion resistance, the capacity of electrical conductivity or such as the engine part, connectors and electrical contacts. As the world shifts towards leaner vehicles with improved fuel efficiency electroless plating proves to offer a befitting answer to meet these needs to increase the life span and strength of an inferior vehicle part used in automobiles. In addition, growth from electric vehicles (EVs) is also sharply anticipated to boost the demand in the automotive industry since electroless plating finds its application in several parts of EVs including battery connectors, power electronics etc.

Further, changing trends in the automotive industry towards the use of advanced materials should be seen to enhance the demand for the electroless plating. Because manufacturers are focusing on the quality, durability and appearance of vehicles, electroless plating for the parts like sensors, brakes, and transmission systems is widely used. The growth in automotive sector, along with new technologies always are in process of development it will be most beneficial for the growth of the electroless plating market in the forecasted year.

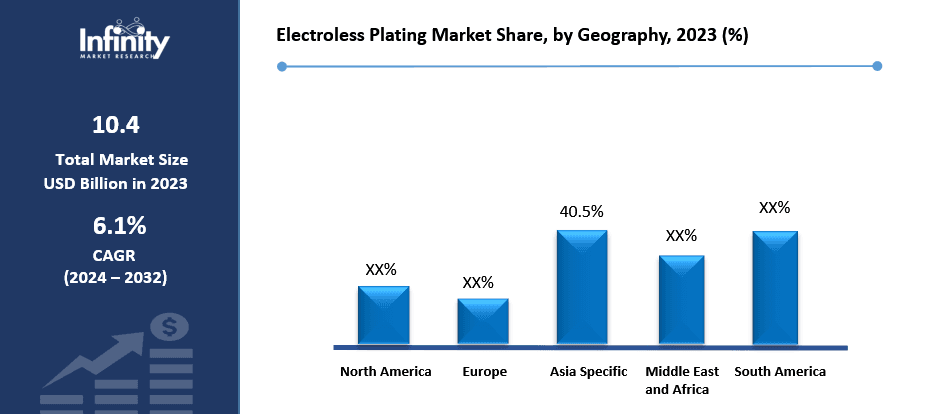

Electroless Plating Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

According to the market analysis for 2023, it was identified that the Asia-Pacific region was dominant in the Electroless Plating Market with maximum market share across the globe. This is primarily due to the well-developed industrial region in regions of Asia, especially in China, Japan and Korea which remains the largest consumer of electroless plating solutions in automobile, electronics and aerospace industry. Apparent growth in the use of electroless plating technologies has been observed due to the rising demand of electronic items, automotive spare parts and intricate machineries in this region.

Also, it is for the same reason that the Asia-Pacific region has the highest market share, thanks to the increasing pace of industrialization of the region with manufacturing companies setting their bases especially in India and China. Asia-Pacific is also likely to sustain its place because of the high rate at which the industrialization is progressing and because of the growing popularity of these high-performance products particularly in automotive and electronics industries.

Electroless Plating Market Share, by Geography, 2023 (%)

Active Key Players in the Electroless Plating Market

o Atotech (Germany)

o Axalta Coating Systems (USA)

o BASF SE (Germany)

o DOW Inc. (USA)

o Electroless Nickel Plating Inc. (USA)

o Harris Products Group (USA)

o Henson Electroless Plating (USA)

o Johnson Matthey (UK)

o MacDermid Enthone Industrial Solutions (USA)

o Mitsubishi Materials Corporation (Japan)

o NPT (Electroless Plating) Limited (UK)

o Platting Precision (USA)

o SIFCO ASC (USA)

o Umicore (Belgium)

o UPT (India)

o Other key Players

Global Electroless Plating Market Scope

|

Global Electroless Plating Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 10.4 Billion |

|

Forecast Period 2024-32 CAGR: |

6.1% |

Market Size in 2032: |

USD 17.72 Billion |

|

Segments Covered: |

By Type |

· Nickel · Copper · Gold · Silver · Others | |

|

By Application |

· Automotive · Electronics · Aerospace · Industrial Machinery · Medical Devices · Others | ||

|

By End User |

· Automotive · Electronics · Aerospace · Industrial · Medical · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Increasing Demand from Automotive and Electronics Industries | ||

|

Key Market Restraints: |

· High Cost of Electroless Plating Process | ||

|

Key Opportunities: |

· Technological Advancements and Expanding Applications | ||

|

Companies Covered in the report: |

· Atotech (Germany), Axalta Coating Systems (USA), BASF SE (Germany), DOW Inc. (USA), Electroless Nickel Plating Inc. (USA), Harris Products Group (USA), Henson Electroless Plating (USA), Johnson Matthey (UK), MacDermid Enthone Industrial Solutions (USA), Mitsubishi Materials Corporation (Japan), NPT (Electroless Plating) Limited (UK) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Electroless Plating Market research report?

Answer: The forecast period in the Electroless Plating Market research report is 2024-2032.

2. Who are the key players in the Electroless Plating Market?

Answer: Atotech (Germany), Axalta Coating Systems (USA), BASF SE (Germany), DOW Inc. (USA), Electroless Nickel Plating Inc. (USA), Harris Products Group (USA), Henson Electroless Plating (USA), Johnson Matthey (UK), MacDermid Enthone Industrial Solutions (USA), Mitsubishi Materials Corporation (Japan), NPT (Electroless Plating) Limited (UK) and Other Major Players.

3. What are the segments of the Electroless Plating Market?

Answer: The Electroless Plating Market is segmented into Type, Application, End User and region. By Type, the market is categorized into Nickel, Copper, Gold, Silver, Others. By Application, the market is categorized into Automotive, Electronics, Aerospace, Industrial Machinery, Medical Devices, Others. By End User, the market is categorized into Automotive, Electronics, Aerospace, Industrial, Medical, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Electroless Plating Market?

Answer: The Electroless Plating Market therefore spells to do with the deposition of a metal layer on the surface of an object without employing an outside electric current. This process is based on the chemical reduction deposition which put the consistent layer of metal to the base materials such as metals, plastics and ceramics, and more. Electroless plating is applied for enhancing various properties of surface like anti-corrosive, wear resistant, electrically conductive and aesthetic point of view. Most of the metals that are deposited in the electro less plating process involves; Nickel copper gold and silver and palladium among others. Electroless plating differ from electroplating in that the process does not rely electricity to drive the actual metal depositing but rather it relies on a chemical precipitation, which occurs in a solution composed of metal ions, reducing agents and other chemicals. It has many merits, namely precise deposition thickness, increased service duration, and better functioning in automotive, electronics, aerospace, and so on.

5. How big is the Electroless Plating Market?

Answer: Electroless Plating Market Size Was Valued at USD 10.4 Billion in 2023, and is Projected to Reach USD 17.72 Billion by 2032, Growing at a CAGR of 6.1% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.