🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Fast Cure Epoxy Resin Market

Fast Cure Epoxy Resin Market Global Industry Analysis and Forecast (2024-2032) By Type(One-Component, Two-Component, Others),By Application( Adhesives & Sealants, Coatings & Paints, Composites, Electrical & Electronics, Construction, Automotive, Aerospace, Others),By End-Use Industry( Building & Construction, Automotive & Transportation, Electrical & Electronics, Marine, Industrial, Others),By Curing Mechanism( Heat Cure, UV Cure, Room Temperature Cure) and Region

Mar 2025

Chemicals and Materials

Pages: 138

ID: IMR1833

Fast Cure Epoxy Resin Market Synopsis

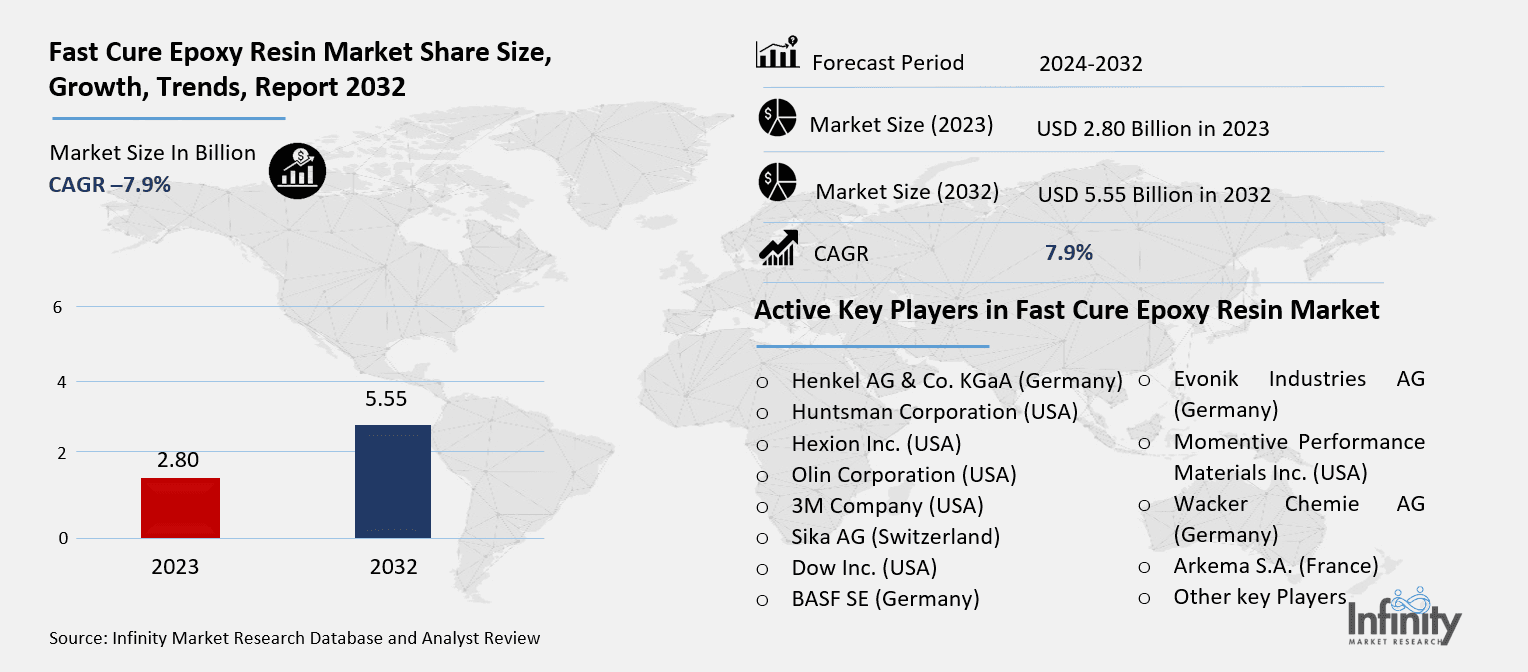

Fast Cure Epoxy Resin Market Size Was Valued at USD 2.80 Billion in 2023, and is Projected to Reach USD 5.55 Billion by 2032, Growing at a CAGR of 7.9% From 2024-2032.

quick recovery For uses needing great efficiency and quick turnaround times, epoxy resin—a particular form of epoxy resin intended for fast setting and curing—is perfect. Wide-ranging application of these resins in sectors including construction, automotive, aerospace, electronics, and coatings is justified by their outstanding adhesion, mechanical strength, chemical resistance, and durability. Each designed to meet particular performance criteria, they come in several forms including one- and two-component systems.

Quick healing Because epoxy resin offers fast-setting, high-performance bonding and protective coatings, it has become rather popular in several different fields. Depending on formulation and external curing circumstances, rapid cure variations can set in minutes to several hours unlike normal epoxy resins, which might take several hours to cure. In sectors including automotive manufacture, construction, and electronics where production speed and efficiency are vital, this quality makes them priceless. Because of their outstanding mechanical and chemical characteristics, these resins find great usage in adhesives, coatings, composites, and electronic encapsulation.

Fast cure epoxy resins have great adaptability among their main benefits. Systems of one- and two-component nature define the market. Common use in electronics and automotive applications, one-component resins cure by heat activation. For building, aerospace, and composite uses two-component resins—which cure upon mixing—are preferred. High-temperature resistance, impact strength, and flexibility are just a few of the particular needs the composition can be adjusted to satisfy. Fast cure epoxy resins have been adopted even more in the automotive and aerospace sectors because to the increasing demand for lightweight materials since they improve performance while lowering general weight.

Environmental rules have also affected market expansion since producers created low-VOC and solvent-free epoxy resins to follow strict standards. Driven by the demand for environmentally responsible substitutes for conventional petrochemical-based formulations, sustainable and bio-based epoxy resins have also become rather popular. Furthermore resulting from technical developments are epoxy resins with UV-curable and nanotechnology-enhanced mechanical qualities and even faster curing periods. Driven by developments in material science, expanding industrial applications, and a growing focus on sustainability, the rapid cure epoxy resin market is overall expected for continuous increase.

Fast Cure Epoxy Resin Market Outlook, 2023 and 2032: Future Outlook

Fast Cure Epoxy Resin Market Trend Analysis

Trend: Growing Adoption of UV-Curable Fast Cure Epoxy Resins

The rapid cure epoxy resin market is seeing one the most noticeable developments in UV-curable epoxy resin adoption. When exposed to UV light, these resins cure practically instantly, thus lowering processing time and energy usage. Where speed and accuracy are paramount, UV-curable rapid cure epoxy resins are becoming more and more used in sectors including electronics, automotive, and coatings. UV curing removes the need for extended drying times, so improving production and lowering running costs unlike conventional curing techniques depending on heat or chemical reactions.

Furthermore in development are UV-curable epoxy resins with better characteristics like durability, chemical resistance, and adhesion. Their capacity to create translucent, biocompatible, and high-strength, transparent materials is driving their increasing use in 3D printing, optical applications, and medical devices Furthermore in line with the increasing focus on sustainability in production techniques is UV curing's environmentally benign character, which lowers emissions and waste. Driven by technical developments and growing demand for high-performance, fast-curing materials, UV-curable fast cure epoxy resins are therefore likely to see notable increase.

Opportunity: Expansion in the Renewable Energy Sector

Particularly in wind energy and solar panel uses, the fast cure epoxy resin market offers a major prospect in the renewable energy industry. High-performance adhesives, varnishes, and composite materials able to resist demanding environmental conditions while guaranteeing long-term durability have become in demand as wind turbines and solar panels are progressively installed all around. Lightweight but durable composite blades for wind turbines depend critically on fast cure epoxy resins, which provide excellent mechanical qualities and tolerance to adverse weather conditions.

These resins are applied in protective coatings and encapsulants in solar panel manufacture to improve efficiency, lower deterioration, and increase durability. Driven by government incentives, environmental concerns, and developments in energy storage technology, the worldwide move toward renewable energy sources is quickening. The demand for creative materials like fast cure epoxy resins will increase as the renewable energy sector expands, thereby providing producers with profitable chances to create specific formulas fit for the demands of this developing sector.

Driver: Rising Demand for Lightweight and High-Performance Materials

The rapid cure epoxy resin market is driven in great part by the growing need for lightweight and high-performance materials in sectors including automotive, aerospace, and construction. Manufacturers are always looking for materials with best strength to weight ratios, corrosion resistance, and thermal stability while cutting total weight. Widely employed in composite applications, fast cure epoxy resins help to produce lightweight components improving structural integrity and fuel economy in aircraft and cars.

These resins also find use in improved adhesives, sealants, and coatings used in the building sector to increase longevity and lower maintenance costs. Fast cure epoxy resins are being adopted more and more as energy efficiency, regulatory compliance, and sustainability take front stage. New formulations with improved mechanical and thermal characteristics are coming out of constant research and development, therefore confirming their preferred use in high-performance applications.

Restraints: High Cost and Technical Limitations

The great cost of fast cure epoxy resins still limits market expansion even with increasing demand. Fast cure formulations, unlike conventional resins, demand complex manufacturing procedures and specific raw components, therefore raising their total cost. This element restricts their use in price-sensitive sectors, especially in developing areas where material choice depends much on cost issues.

Manufacturers also face difficulties from technological constraints including brittleness, restricted flexibility, and difficulties with large-scale curing techniques. Achieving the ideal balance between fast curing, mechanical strength, and flexibility remains a difficult task even if research attempts try to overcome these problems by changed formulas and additive additions. Expanding market penetration and guaranteeing more general acceptance across many industrial sectors depend on addressing these constraints.

Fast Cure Epoxy Resin Market Segment Analysis

Fast Cure Epoxy Resin Market Segmented on the basis of type, curing mechanism ,application and end user.

By Type

o One-Component

o Two-Component

o Others

By Application

o Adhesives & Sealants

o Coatings & Paints

o Composites

o Electrical & Electronics

o Construction

o Automotive

o Aerospace

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, One-Component segment is expected to dominate the market during the forecast period

One-component, two-component, and other specialist formulas separate the fast cure epoxy resin market. Usually heat or UV light, one-component epoxy resins are pre-mixed and need outside activation to start curing. Their simplicity of use and ability to cure quickly under regulated circumstances help them to be extensively used in electrical and automotive applications. Extensive use in building, aerospace, and high-performance composite applications; two-component epoxy resins provide more flexibility in formulation and cure upon blending two reactive components.

Factors including application requirements, processing circumstances, and desired performance characteristics will help one-component or two-component epoxy resins be chosen. For structural bonding and high-strength composite applications, two-component resins are preferable even if one-component resins are preferred for automated manufacturing and precise applications. The continuous development of hybrid and specialized formulas is extending the possibilities of fast cure epoxy resins in many different fields.

By Application, Adhesives & Sealants segment expected to held the largest share

Applications ranging from adhesives and sealants to coatings and paints, composites, electrical and electronics, construction, automotive, aerospace, and others find fast cure epoxy resins in great use. Growing need for high-strength bonding solutions in automotive, construction, and electronics sectors drives the category of adhesives and sealants to rule. Perfect for structural bonding uses, these resins offer great adhesion, quick drying, and environmental element resistance.

Fast cure epoxy resins are vital for industrial coatings, marine coatings, and protective finishes in paints since they provide exceptional resistance against corrosion, chemicals, and wear. Because they can improve mechanical qualities while lowering weight, their use in composites—especially in aerospace and wind energy applications—is growing. Key consumers of these resins also are the electronics and electrical industries, which use them for encapsulation, insulation, and circuit board protection.

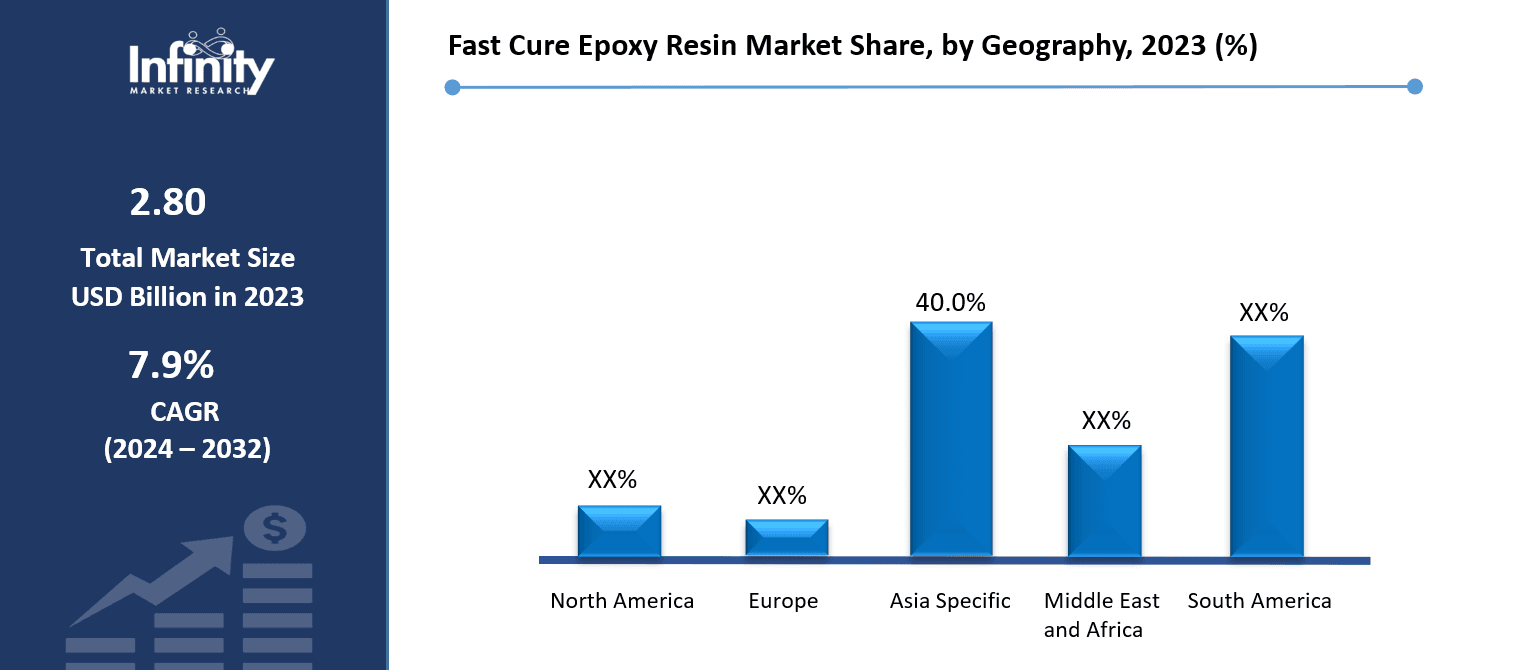

Fast Cure Epoxy Resin Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

Driven by great demand from sectors including automotive, aerospace, construction, and electronics, North America rules the rapid cure epoxy resin industry. Leading manufacturing and research facilities in the area help to inspire ongoing epoxy resin technological innovation. Strong environmental rules have also pushed low-VOC and sustainable formulations forward.

Further driving market expansion in North America are the increasing focus on lightweight materials, energy economy, and innovative manufacturing technologies. Key players and a developed industrial foundation guarantees that the area stays leading edge in fast cure epoxy resin developments.

Fast Cure Epoxy Resin Market Share, by Geography, 2023 (%)

Active Key Players in the Fast Cure Epoxy Resin Market

o Henkel AG & Co. KGaA (Germany)

o Huntsman Corporation (USA)

o Hexion Inc. (USA)

o Olin Corporation (USA)

o 3M Company (USA)

o Sika AG (Switzerland)

o Dow Inc. (USA)

o BASF SE (Germany)

o Evonik Industries AG (Germany)

o Momentive Performance Materials Inc. (USA)

o Wacker Chemie AG (Germany)

o Arkema S.A. (France)

o Other key Players

Global Fast Cure Epoxy Resin Market Scope

|

Global Fast Cure Epoxy Resin Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 2.80Billion |

|

Forecast Period 2024-32 CAGR: |

7.9% |

Market Size in 2032: |

USD 5.55 Billion |

|

Segments Covered: |

By Type |

· Two-Component · Others | |

|

By Application |

· Coatings & Paints · Composites · Electrical & Electronics · Construction · Automotive · Aerospace · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Rising Demand for Lightweight and High-Performance Materials | ||

|

Key Market Restraints: |

· High Cost and Technical Limitations | ||

|

Key Opportunities: |

· Expansion in the Renewable Energy Sector | ||

|

Companies Covered in the report: |

· Henkel AG & Co. KGaA (Germany), Huntsman Corporation (USA), Hexion Inc. (USA), Olin Corporation (USA), 3M Company (USA), Sika AG (Switzerland), Dow Inc. (USA), BASF SE (Germany) , Evonik Industries AG (Germany) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Fast Cure Epoxy Resin Market research report?

Answer: The forecast period in the Fast Cure Epoxy Resin Market research report is 2024-2032.

2. Who are the key players in the Fast Cure Epoxy Resin Market?

Answer: Henkel AG & Co. KGaA (Germany), Huntsman Corporation (USA), Hexion Inc. (USA), Olin Corporation (USA), 3M Company (USA), Sika AG (Switzerland), Dow Inc. (USA), BASF SE (Germany) , Evonik Industries AG (Germany) and Other Major Players.

3. What are the segments of the Fast Cure Epoxy Resin Market?

Answer: The Fast Cure Epoxy Resin Market is segmented into Type, Application, Curing Mechanism ,End User and region. By Type, the market is categorized into One-Component, Two-Component, Others. By Application, the market is categorized into Adhesives & Sealants, Coatings & Paints, Composites, Electrical & Electronics, Construction, Automotive, Aerospace, Others. By End-Use Industry, the market is categorized into Building & Construction, Automotive & Transportation, Electrical & Electronics, Marine, Industrial, Others. By Curing Mechanism, the market is categorized into Heat Cure, UV Cure, Room Temperature Cure. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Fast Cure Epoxy Resin Market?

Answer: quick recovery For uses needing great efficiency and quick turnaround times, epoxy resin—a particular form of epoxy resin intended for fast setting and curing—is perfect. Wide-ranging application of these resins in sectors including construction, automotive, aerospace, electronics, and coatings is justified by their outstanding adhesion, mechanical strength, chemical resistance, and durability. Each designed to meet particular performance criteria, they come in several forms including one- and two-component systems.

5. How big is the Fast Cure Epoxy Resin Market?

Answer: Fast Cure Epoxy Resin Market Size Was Valued at USD 2.80Billion in 2023, and is Projected to Reach USD 5.55 Billion by 2032, Growing at a CAGR of 7.9% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.