🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Ferro Silicon Market

Ferro Silicon Market Global Industry Analysis and Forecast (2024-2032) By Grade Type(Low-Carbon Ferro Silicon, Medium-Carbon Ferro Silicon, High-Carbon Ferro Silicon), By Application(Steel Manufacturing, Cast Iron Manufacturing, Other Alloys), By End-Use Industry(Automotive, Construction, Industrial Machinery, Aerospace, Energy & Power, Others) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1422

Ferro Silicon Market Synopsis

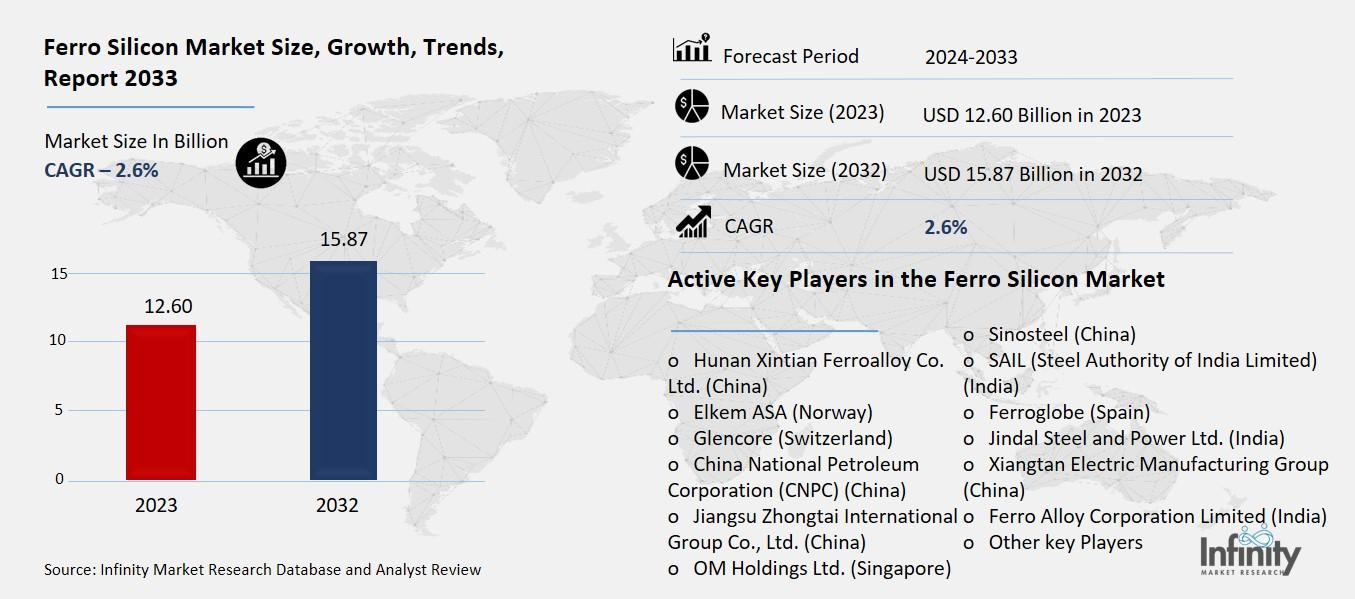

Ferro Silicon Market Size Was Valued at USD 12.60 Billion in 2023, and is Projected to Reach USD 15.87 Billion by 2032, Growing at a CAGR of 2.6% From 2024-2032.

Ferro Silicon is a coated metallurgical product made from iron and silicone, primarily used as a deoxidizing agent in steelmaking industries. It is used in almost all industries to enhance on the characteristics of steel and other types of metals. Ferro Silicon is produced by heating silica with coke in presence of Iron. The addition to its usage in steel making, it also helps in improving cast iron characteristics and assists in production of many other alloys that improve them in aspects such as strength, hardness and corrosion.

The Ferro Silicon market has close relation to the world metallurgy and industrial production industries. and is mainly utilised for anode effect, where it serves to enhance the quality and stability of the metal by reducing its oxygen content. Ferro silicon is also a vital input in the making of cast iron and in the manufacture of other sorts of alloys. The general consumption of Ferro Silicon has been propelled by the sector needs in construction, automotive, manufacturing and other industries that require high grade metallic products. Market expansion has mainly been driven by increased demand for smart steel alloys and high performance metals across many fields.

However, research on Ferro Silicon has also surged in the recent past due to increased industrialization in Asia-Pacific region, which is one of the global economic growth’s zones. The above trend is complemented with growth in infrastructure construction, automotive and manufacturing industries especially in emerging markets such as China and India. Also, technological developments in the steel making and alloy construction industry has heightened the application of Ferro Silicon. This factor have made it an essential material used in different other high performance applications thus increasing its demand.

Environmental and sustainability factors also explain the development of the Ferro Silicon market. Manufactures are now putting more attention in developing green technologies, especially on energy efficiency and so to produce Ferro Silicon. This is expected to force manufacturers to look for other methods of production hence the Ferro Silicon demand for sustainable use will be boosted. Further, the demand for Ferro Silicon in energy and lightweight application in automotive and aerospace industries is rising steadily. Such industries, which invest in fuel economy and low emission, look to Ferro Silicon for suppliers of high strength and lightweight materials that conform to regulatory meas.

Ferro Silicon Market Outlook, 2023 and 2032: Future Outlook

Ferro Silicon Market Trend Analysis

Trend : Sustainable Manufacturing and Green Ferro Silicon

An important development in the Ferro Silicon business is the move towards the reduction of emissions during the production process. In the procession of Ferro Silicon, producers of this product have been able to incorporate environmental friendly methods due to increasing concern among industries today. This includes using renewable sources of energy, conserving energy in the ferrosilicon production processes and techniques of storing carbon. Benchmarking done by major industries and governments on green products like green Ferro Silicon which is manufacture with less damaging effects to the environment, will mean that there will be increased demand.

There is an emerging concern of sustainability in manufacturing Ferro Silicon with growing global concern of environmental conservation and use of energy efficient product. Producers of steel and alloy require material with high strength and good durability and at the same time meet the environmental requirements. To meet these demands Ferro Silicon producers are working on upgrading the processes of production thus reducing energy use and hazardous emissions. This is likely to continue as stringents regulatory measures on the emissions of greenhouse gases are enhanced and as there continues to be inclination Toward environmentally sustainable products.

Opportunity : Growth in Steel Manufacturing

A major opportunity that is discretionary in the Ferro Silicon market is the increasing raw material demand for steel by construction and automobile industries. In particular, high quality Ferro Silicon is needed to manufacture steel grades required for these industries. Increased pace of infrastructural advancements worldwide and the increasing automobile industry will always have a demand for Ferro Silicon to improve the quality of steel products. This makes it possible for manufacturers to take advantage of the increasing demand of advanced steel alloys that need Ferro Silicon for deoxidation or for inclusion in alloy composites.

Automotive is expected to be the leading consumer of Ferro Silicon as car makers seek to obtain high-strength lightweight materials to enhance vehicle fuel economy and safety. Thus, increased sales of electric vehicles (EVs) and other superior vehicles will require more specialized steel alloys, increasing the use of Ferro Silicon. Moreover, advancement of Eco friendly and high strength steel products based on Ferro Silicon, offer long term consistent growth prospects for industry in diverse sectors.

Driver: Industrialization and Urbanization

The only major factor propelling the growth of Ferro Silicon market is the increasing industrialization and urbanization processes in the emerging APAC countries. While extending their industrial and infrastructure industries China, India, and Southeast Asian countries have emerged as chief consumers of high-quality steel and alloy steel. Ferro Silicon is an indispensable ingredient in the formation of steel and other alloys due to its ability to improve the characteristics of the final product including those used in building construction, automobiles, manufacturing industries among others. Continued urbanization has also boosted other large regions in demand for steel with relation to infrastructure development, leading to higher demand for Ferro Silicon.

Moreover, the global drive toward infrastructure development, urbanization and industrialization particularly in the developing countries is a major opportunity for Ferro Silicon market. As the growth of these regions escalate their construction of more cities, transport and manufacturing structures there will be even higher demands for the high strength steel and especially alloys. Ferro silicon as a material enhances the quality and performance of steel used in these processes and thus continue to drive the growth of the market.

Restraint: Fluctuating Raw Material Prices

An added restraint in the Ferro Silicon market is the uncertainty of the price of its raw materials of which include silica and coke in the production of Ferro Silicon. These raw materials could be more expensive depending on the disruptions in the supply chain new political changes and changes in the demand. Such variations will cause an unpredictable price change that can lead to high costs in the production of Ferro Silicon, therefore low profits. Besides, high dependence on a few suppliers of ferrosilicon raw materials can destabilize the market rate of ferro silicon, which is an unfavourable factor for the growth of the market.

Volatility in raw material prices impact the cost model of the industries that Ferro Silicon is consumed by, for instance, steel making and alloys. This cost can be transferred to consumers which will result into Products becoming expensive and hence a low market demand. The high volatility of the price of raw materials is still a major concern for the Ferro Silicon market since manufacturers still need to set reasonable prices for the products.

Ferro Silicon Market Segment Analysis

Ferro Silicon Market Segmented on the basis of grade type, application and end user.

By Grade Types

o Low-Carbon Ferro Silicon

o Medium-Carbon Ferro Silicon

o High-Carbon Ferro Silicon

By Applications

o Steel Manufacturing

o Cast Iron Manufacturing

o Other Alloys

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Grade Type, Low-Carbon Ferro Silicon segment is expected to dominate the market during the forecast period

Low Carbon Ferro silicon Low Carbon Ferro silicon is made with restricted carbon addition and is generally below one whole number. The method is for the most part applied to the steel industry where low carbon content must be achieved to yield a high purity steel. The specific customers for lowcarbon Ferro Silicon include the steel, automotive and construction sectors that demand high quality steel produced through low carbon pathways. This type of grade comes with the benefits of achieving improved mechanical properties of the resultant steel such as increased tensile strength and reistance to corrosion.

Low-carbon Ferro Silicon is also used in many alloy preparations where the amount of carbon in the alloys must be kept at minimum levels of the alloy specification. It is one of the core raw materials used in production of premium and high quality steel alloys which are tremendously valued by industries that deal with materials that possess extremely high strength, durability and ability to withstand harsh conditions. The demand for this grade type should increase due to growing concerns of industries for higher performance materials which conform to tight quality standards.

Medium carbon ferrosilicon It is Silicon containing slightly higher percentage of carbon than low carbon Ferro Silicon but the carbon is also restricted to enable the produced steel possess certain properties. This grade is typically employed in the manufacture of alloy steels because the content of carbon is intermediate: it helps to increase the hardness and tensile strength of material. Medium-carbon Ferro Silicon is also used in the production of such cast iron products as have moderate strengths and ductility. Medium-carbon Fermosilicon is used extensively in construction, heavy machinery, and automotive industries because of the qualities exhibited by both low and high-carbon materials. MIG-SG-35 forecast that with further industrialization and development of infrastructure, medium-carbon Ferro Silicon will be used widely as material for construction that is strong, durable and malleable that can suit the conditions and environment. The versatility in the manner in which the carbon content in Ferro Silicon can be adjusted to suit certain applications is perhaps its most attractive quality in very many industrial uses.

High-Carbon Ferro Silicon High-carbon Ferro Silicon contains a considerable amount of carbon probably greater than 6%. This type of grade is most often used in the manufacture of high carbon steel where higher carbon content is needed for products such as tool steels high strength alloys or cast iron. The high carbon content makes the steel hard and has high wear resistance properties that make it suitable to be used In mostly used in industries such as the mining industries, aerospace industries and car manufacturing industries.It is also added where the silicon carbide forms in the melt require high carbon to do so, for instance in the production of heavy machine steels or abrasion resistant components. Since high-carbon Ferro Silicon is essential in the manufacture of alloy and in steel producing industries, and since industries are constantly looking for stronger and more durable materials for specific uses, there is no better place for high-carbon Ferro Silicon than in the alloy and steel industries.

By Application, Steel Manufacturing segment expected to held the largest share

Ferro Silicon consumes a large portion of its production in steel manufacturing, since it has significant application in the deoxidation process. Ferro Silicon is used to degasify molten steel, making the material lighter and purer due to the decrease of oxygen level. This increases the strength of the steel and qualifies it for usage in civil, automotive and manufacturing fairly industries. Ferro Silicon also has its part to play in high-alloy steels that are required in specific uses for instance aerospace and military. To this effect, the demand for steel is strongly associated with economic development, process of constructions, globalization, and industrialization. Since nation’s continue to grow and put construction infrastructure more especially for steel, the demand for steel and hence Ferro Silicon will also grow steadily. Also, modern automotive vehicles, structures, buildings, and many other sectors use high-quality lightweight steels, which can be synthesized with the aid of Ferro Silicon to manufacture the necessary high-strength, advanced alloys.

Among industries Ferro Silicon is also used in the manufacture of cast iron as an alloying component. Cast iron is made by mixing iron with many other elements, and amongst all the elements Ferro Silicon is added to make it better in all round qualities and characteristics. The process of alloying enhances the hardness, wearing capacity and strength to extremes of the cast iron, for use in engine blocks, pipes and various other parts of the machinery. Cast iron is still on high demand through variety of manufacturing industries for instance automotive, machinery and construction industries due to its relatively cheap and durable nature. To prevent low quality cast iron products from being produced, Ferro Silicon is very important especially in boosting the strength of the product. Thus, it may be pointed out that the use of Ferro Silicon in cast iron manufacturing is set to increase as industrial production and infrastructure development increase.

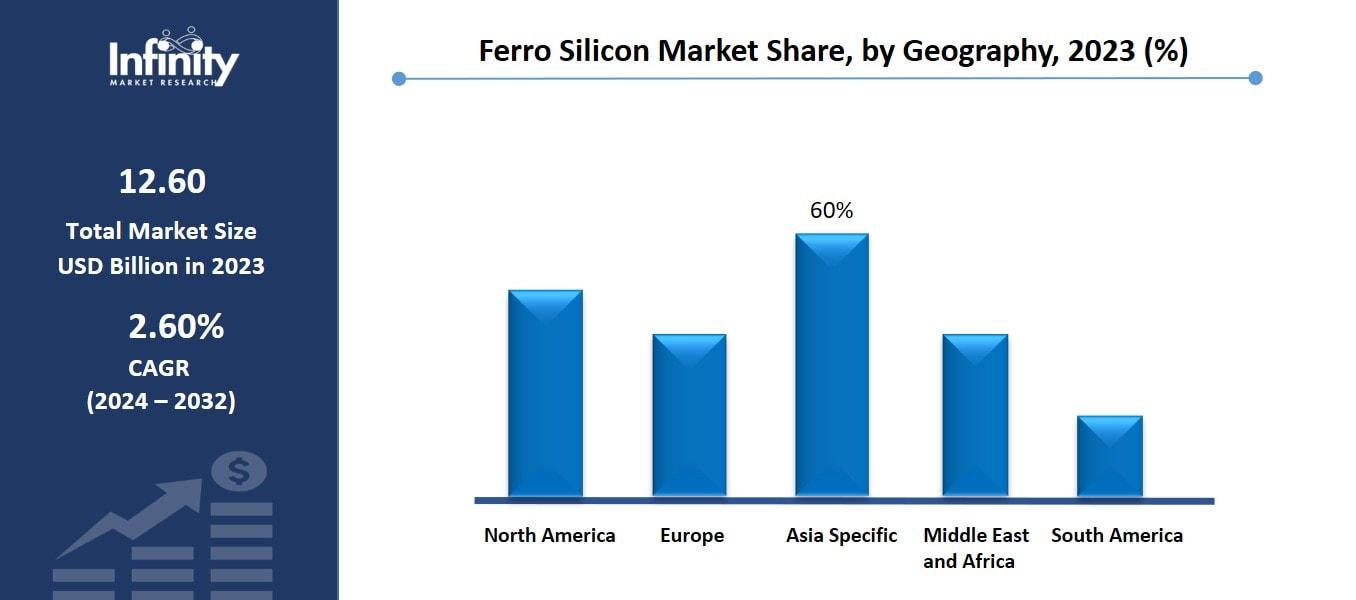

Ferro Silicon Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

The Asia Pacific region spearheads the Ferro Silicon marketattributable to the increased level of industrialization and infrastructure activities in the region, higher demands for steel and alloys. As the major steel producers and with increasing manufacturing industries China and India drive the Ferro Silicon market forward. China for instance is the largest consumer with large steel industry being the prime driver to the high consumption of Ferro Silicon alloy. The expansion of automotive, construction and infrastructure industries in the region increases the application of Ferro Silicon for production of high quality steel and alloys.

Further, more, there is large production of Ferro Silicon producers more so in the region thus being the biggest producer of the alloy. With the help of increasing industrialization in various ASEANs and other part of Asia-Pacific, the growth in demand for Ferro Silicon is anticipated and hence remains as a stronghold for this region in global market. In addition, there is investment on infrastructure and, industrial enlargement that raise demands on mileage putting into use superior Ferro Silicon.

Ferro Silicon Market Share, by Geography, 2023 (%)

Active Key Players in the Ferro Silicon Market

o Hunan Xintian Ferroalloy Co. Ltd. (China)

o Elkem ASA (Norway)

o Glencore (Switzerland)

o China National Petroleum Corporation (CNPC) (China)

o Jiangsu Zhongtai International Group Co., Ltd. (China)

o OM Holdings Ltd. (Singapore)

o Sinosteel (China)

o SAIL (Steel Authority of India Limited) (India)

o Ferroglobe (Spain)

o Jindal Steel and Power Ltd. (India)

o Xiangtan Electric Manufacturing Group (China)

o Ferro Alloy Corporation Limited (India)

o Other key Players

Key Industry Developments in the Ferro Silicon Market

In July 2023, Green Ferro Alloy announced its plans to build Oman’s first silicon metal plant, which would serve as feedstock to the global ferrosilicon industry.

In February 2023, OM Holdings Ltd’s (OMH) ferroalloy smelting plant in Samalaju Industrial Park, Indonesia announced that it will construct additional ferrosilicon lines in its plants to develop high-grade products.

Global Ferro Silicon Market Scope

|

Global Ferro Silicon Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 12.60 Billion |

|

Forecast Period 2024-32 CAGR: |

2.6% |

Market Size in 2032: |

USD 15.87 Billion |

|

Segments Covered: |

By Grade Type |

· Low-Carbon Ferro Silicon · Medium-Carbon Ferro Silicon · High-Carbon Ferro Silicon | |

|

By Application |

· Steel Manufacturing · Cast Iron Manufacturing · Other Alloys | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Industrialization and Urbanization | ||

|

Key Market Restraints: |

· Fluctuating Raw Material Prices | ||

|

Key Opportunities: |

· Growth in Steel Manufacturing | ||

|

Companies Covered in the report: |

· Hunan Xintian Ferroalloy Co. Ltd. (China), Elkem ASA (Norway), Glencore (Switzerland), China National Petroleum Corporation (CNPC) (China), Jiangsu Zhongtai International Group Co., Ltd. (China), OM Holdings Ltd. (Singapore), Sinosteel (China), SAIL (Steel Authority of India Limited) (India), Ferroglobe (Spain), and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Ferro Silicon Market research report?

Answer: The forecast period in the Ferro Silicon Market research report is 2024-2032.

2. Who are the key players in the Ferro Silicon Market?

Answer: Hunan Xintian Ferroalloy Co. Ltd. (China), Elkem ASA (Norway), Glencore (Switzerland), China National Petroleum Corporation (CNPC) (China), Jiangsu Zhongtai International Group Co., Ltd. (China), OM Holdings Ltd. (Singapore), Sinosteel (China), SAIL (Steel Authority of India Limited) (India), Ferroglobe (Spain), and Other Major Players.

3. What are the segments of the Ferro Silicon Market?

Answer: The Ferro Silicon Market is segmented into Grade Type, Application, End User and region. By Grade Type, the market is categorized into Low-Carbon Ferro Silicon, Medium-Carbon Ferro Silicon, High-Carbon Ferro Silicon. By Application, the market is categorized into Steel Manufacturing, Cast Iron Manufacturing, Other Alloys. By End-Use Industry, the market is categorized into Automotive, Construction, Industrial Machinery, Aerospace, Energy & Power, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Ferro Silicon Market?

Answer: Ferro Silicon is a coated metallurgical product made from iron and silicone, primarily used as a deoxidizing agent in steelmaking industries. It is used in almost all industries to enhance on the characteristics of steel and other types of metals. Ferro Silicon is produced by heating silica with coke in presence of Iron. The addition to its usage in steel making, it also helps in improving cast iron characteristics and assists in production of many other alloys that improve them in aspects such as strength, hardness and corrosion.

5. How big is the Ferro Silicon Market?

Answer: Ferro Silicon Market Size Was Valued at USD 12.60 Billion in 2023, and is Projected to Reach USD 15.87 Billion by 2032, Growing at a CAGR of 2.6% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.