🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Flat Airbag Fabric Market

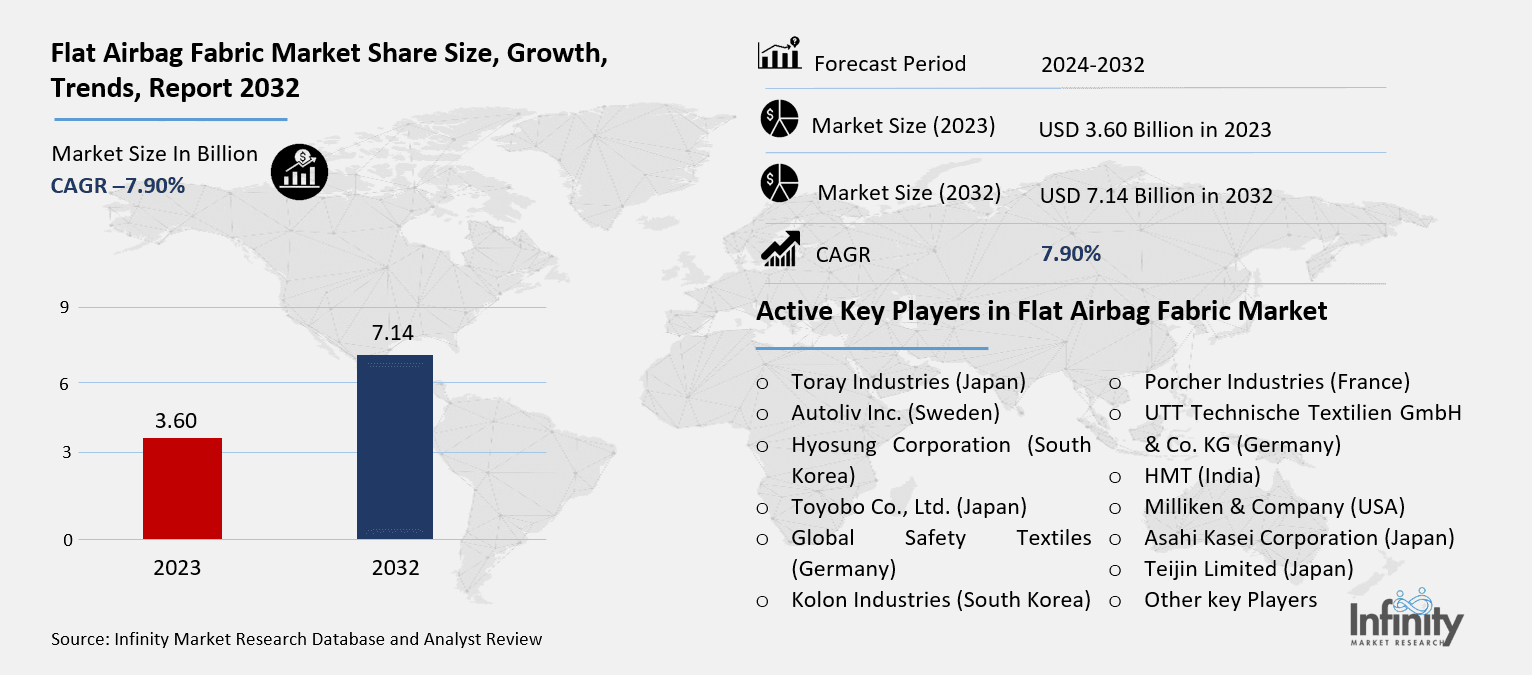

Flat Airbag Fabric Market Global Industry Analysis and Forecast (2024-2032) By Material Type( Nylon, Polyester), By Coating Type( Silicone-coated , Neoprene-coated , Uncoated),By Airbag Type(Front Airbags ,Side Airbags , Curtain Airbags , Knee Airbags), By Vehicle Type( Passenger Vehicles, Commercial Vehicles),By Distribution Channel(OEM (Original Equipment Manufacturer), Aftermarket) and Region

Mar 2025

Automotive Technology

Pages: 138

ID: IMR1835

Flat Airbag Fabric Market Synopsis

Flat Airbag Fabric Market Size Was Valued at USD 3.60 Billion in 2023, and is Projected to Reach USD 7.14 Billion by 2032, Growing at a CAGR of 7.90% From 2024-2032.

The flat airbag fabric market consists in the manufacturing and marketing of certain textile materials meant for automotive airbag systems. These materials are designed to be light-weight, robust, and able to endure high-pressure inflation while nevertheless provide occupant protection in crashes. Usually composed of high-performance synthetic fibers like polyester and nylon, flat airbag materials are subjected to rigorous processing methods including coating and weaving to guarantee best strength, flexibility, and air permeability. Key elements driving the expansion of this market are growing focus on car safety rules, developments in airbag technology, and increasing automobile manufacturing rates.

Rising consumer awareness of car safety features and increasing automotive safety standards have driven significant development in the flat airbag fabric market. Modern cars now feature airbag systems, which are becoming indispensable, and fabric producers are always developing to improve material performance. Because of its seamless construction, which increases airbag deployment efficiency and lowers weight, flat airbag fabrics differ from traditional airbag textues. Modern weaving and coating techniques are used in manufacturing these materials to satisfy legal criteria for impact resistance, durability, and thermal stability.

From passenger vehicles to commercial trucks, global automakers are including flat airbag materials into a broad spectrum of vehicle models. As manufacturers investigate lightweight and sustainable fabric options, the market has also changed in line with the increasing acceptance of electric vehicles (EVs). With a lot of automobile OEMs and textile manufacturers, Asia-Pacific, Europe, and North America are prominent areas in airbag fabric production. Furthermore driving market expansion are strict government rules on car safety including those of the U.S. National Highway Traffic Safety Administration (NHTSA) and the European NCAP (New Car Assessment Program).

Important market participants concentrate on research and development to improve fabric strength and elasticity and lower environmental impact by means of which Manufacturers striving to satisfy environmental standards are adopting sustainable manufacturing techniques include the use of recyclable and bio-based products. Furthermore influencing the direction of flat airbag fabrics are technical developments such nanofiber coatings and smart textiles. Driven by developments in material science and automotive safety systems, the flat airbag fabric market is likely to see consistent increase as demand for enhanced occupant protection keeps rising.

Flat Airbag Fabric Market Outlook, 2023 and 2032: Future Outlook

Flat Airbag Fabric Market Trend Analysis

Trend: Integration of Smart Textiles in Airbag Fabrics

The incorporation of smart textiles to improve safety aspects is one of the most important developments in the flat airbag fabric market. Embedded with sensors and conductive fibers, smart textiles let one monitor car occupants and external collision forces in real time. By varying airbag deployment according on impact intensity, occupant position, and weight, these innovative materials maximize protection during accidents. To create next-generation airbags with adaptive responses to different accident circumstances, manufacturers of textiles and automakers are funding intelligent fabric technologies.

Using smart airbag materials fits the larger industry trend of connected cars and artificial intelligence-driven automotive safety. Smart textiles allow airbag systems to interact with other car safety devices, like seatbelt tensioners and braking systems, therefore guaranteeing a coordinated reaction during an accident. Furthermore enhancing the possibilities of smart airbag materials is research in nanotechnology and conductive coatings, which enables self-healing qualities and increased durability. The demand for clever airbag solutions is likely to grow as safety rules change, so smart textiles will become a market game-changer.

Opportunity: Growing Demand in Emerging Markets

Driven by growing vehicle production, urbanization, and growing safety consciousness, emerging markets offer a rich development possibility for the flat airbag fabric business. Driven by bettering economic conditions and growing middle-class populations, nations including India, Brazil, and China are seeing an increase in car sales. Government programs encouraging car safety, such China's and India's required airbag laws, are increasing demand for airbag materials even more. The demand for locally produced airbag fabrics is likely to rise as automakers set manufacturing sites in these areas.

Furthermore driving demand for sophisticated airbag systems are the spread of ride-sharing and driverless car marketplaces in developing nations. Research and development are being funded by companies to provide reasonably priced airbag fabrics fit for local market needs. Furthermore helping to transfer technologies and increase supply chain efficiency are partnerships between regional car OEMs and worldwide textile manufacturers. The unrealized potential in these fast-growing areas offers a great chance for airbag fabric providers to increase the income sources and market presence.

Driver: Stringent Vehicle Safety Regulations

The main force behind the flat airbag fabric market is strict safety rules enforced by governments and international agencies. Strict safety rules imposed by regulatory agencies as the European NCAP and the NHTSA in the United States call for the airbags to be included in all passenger cars. These rules have resulted in more acceptance of premium airbag textiles able to satisfy strict performance requirements.

Apart from passenger cars, commercial trucks and buses also come under changing safety regulations, therefore increasing the market for airbag materials. The drive toward electrified and driverless cars has made lightweight, high-strength airbag textiles even more important for improving occupant protection while preserving vehicle efficiency. Manufacturers of airbag fabric are emphasizing innovation and compliance as regulatory systems change to fulfill industry standards and guarantee product dependability.

Restraints: High Production Costs

For flat airbag fabric producers, high production costs continue to be a major constraint notwithstanding market expansion. Complex weaving, coating, and testing techniques are part of the manufacturing process to guarantee adherence to safety standards. Advanced materials like polyester and high-tenacity nylon call for specific processing methods that drive higher manufacturing costs.

Furthermore adding to the total cost load are strict quality control policies including impact and thermal resistance tests. Smaller producers could find it difficult to match bigger companies with established economies of scale and supply systems. Consequently, the great expense of production techniques and raw materials can restrict industry price competitiveness and create obstacles to entrance for new market players.

Flat Airbag Fabric Market Segment Analysis:

Flat Airbag Fabric Market Segmented on the basis of Material Type, Coating Type, Airbag Type, Vehicle Type,and Distribution Channel.

By Type

o Nylon

o Polyester

By Distribution Channel

o OEM (Original Equipment Manufacturer)

o Aftermarket

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Material Type, Nylon segment is expected to dominate the market during the forecast period

Material type mostly determines the segmentation of the flat airbag fabric market into polyester and nylon. Perfect for airbag deployment under high-impact conditions, nylon rules the market because of its great strength, flexibility, and heat resistance. Premium and high-performance automobiles, where dependability and longevity are paramount, feature extensively used nylon-based airbag textiles. The material's resistance to high pressures and temperatures improves passenger safety in collisions.

Conversely, polyester airbag textiles are becoming popular because of their environmental advantages and economy. Polyester is lighter than nylon and absorbs less moisture, so lowering the total weight of the car and increasing fuel economy. Particularly in electric and hybrid vehicles, polyester airbag textiles should see more acceptance as manufacturers concentrate on sustainability.

By Distribution Channel, OEM (Original Equipment Manufacturer) segment expected to held the largest share

OEM ( Original Equipment Manufacturer) and aftermarket channels define the market. OEMs have the most market share since manufacturers provide airbag textiles straight to be included into new cars. OEM demand is influenced by automotive safety rules and crash test requirements, which helps to drive high-performance airbag fabric investments. Leading automobile companies work with textile producers to create tailored airbag solutions improving passenger protection.

Thanks to replacement and maintenance of airbag systems, the aftermarket sector is also expanding. Events involving vehicle recalls and airbag deployment need premium fabric replacements. The aftermarket sector is predicted to grow as the global vehicle fleet ages, providing chances for makers of airbag fabrics to meet repair and maintenance requirements.

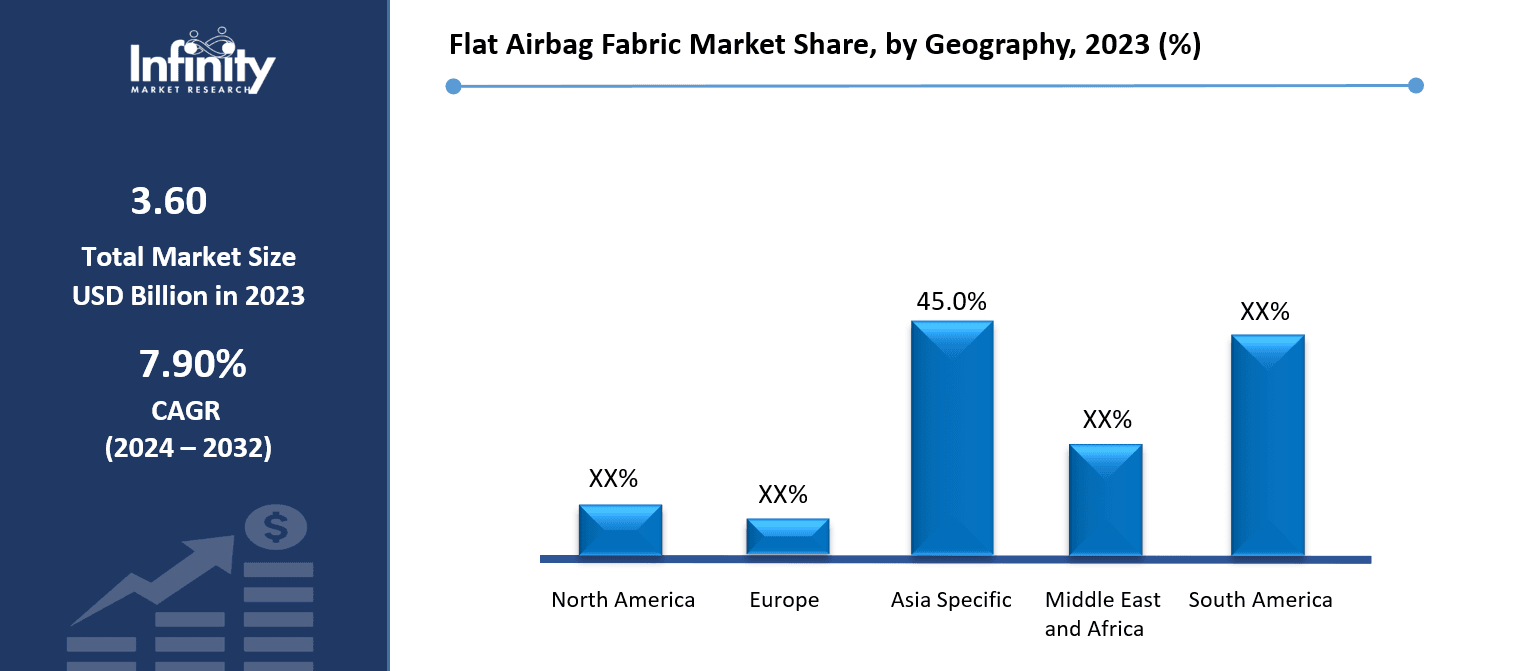

Flat Airbag Fabric Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

Because of strict safety rules and a significant presence of top automakers, North America rules the flat airbag fabric market. The regulatory scene of the area guarantees strong adoption rates of airbags in passenger cars by integrating NHTSA standards.

North American manufacturers also are funding cutting-edge safety innovations including lightweight materials and smart airbags. Key industry participants as well as increasing acceptance of electric cars help to further support the region's leadership in airbag fabric manufacturing.

Flat Airbag Fabric Market Share, by Geography, 2023 (%)

Active Key Players in the Flat Airbag Fabric Market

o Toray Industries (Japan)

o Autoliv Inc. (Sweden)

o Hyosung Corporation (South Korea)

o Toyobo Co., Ltd. (Japan)

o Global Safety Textiles (Germany)

o Kolon Industries (South Korea)

o Porcher Industries (France)

o UTT Technische Textilien GmbH & Co. KG (Germany)

o HMT (India)

o Milliken & Company (USA)

o Asahi Kasei Corporation (Japan)

o Teijin Limited (Japan)

o Other key Players

Global Flat Airbag Fabric Market Scope

📘 Frequently Asked Questions

1. What would be the forecast period in the Flat Airbag Fabric Market research report?

Answer: The forecast period in the Flat Airbag Fabric Market research report is 2024-2032.

2. Who are the key players in the Flat Airbag Fabric Market?

Answer: Toray Industries (Japan), Autoliv Inc. (Sweden), Hyosung Corporation (South Korea), Toyobo Co., Ltd. (Japan), Global Safety Textiles (Germany), Kolon Industries (South Korea), Porcher Industries (France), UTT, Technische Textilien GmbH & Co. KG (Germany) and Other Major Players.

3. What are the segments of the Flat Airbag Fabric Market?

Answer: The Flat Airbag Fabric Market is segmented into Material Type, Coating Type, Airbag Type, Vehicle Type, Distribution Channel and region. By Material Type, the market is categorized into Nylon, Polyester. By Coating Type, the market is categorized into Silicone-coated , Neoprene-coated , Uncoated. By Airbag Type, the market is categorized into Front Airbags ,Side Airbags , Curtain Airbags , Knee Airbags. By Vehicle Type, the market is categorized into Passenger Vehicles, Commercial Vehicles. By Distribution Channel, the market is categorized into OEM (Original Equipment Manufacturer), Aftermarket. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Flat Airbag Fabric Market?

Answer: The flat airbag fabric market consists in the manufacturing and marketing of certain textile materials meant for automotive airbag systems. These materials are designed to be light-weight, robust, and able to endure high-pressure inflation while nevertheless provide occupant protection in crashes. Usually composed of high-performance synthetic fibers like polyester and nylon, flat airbag materials are subjected to rigorous processing methods including coating and weaving to guarantee best strength, flexibility, and air permeability. Key elements driving the expansion of this market are growing focus on car safety rules, developments in airbag technology, and increasing automobile manufacturing rates.

5. How big is the Flat Airbag Fabric Market?

Answer: Flat Airbag Fabric Market Size Was Valued at USD 3.60 Billion in 2023, and is Projected to Reach USD 7.14 Billion by 2032, Growing at a CAGR of 7.90% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.