🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Flexo Inks Market

Flexo Inks Market Global Industry Analysis and Forecast (2024-2032) By Type(Water-Based, Solvent-Based, UV-Curable),By Resin Type( Polyurethane, Acrylic, Polyamide, Cellulose-Based, Others),By Application(Flexible Packaging, Commercial Printing, Others),By End-Use Industry(Food & Beverage, Pharmaceuticals, Cosmetics & Personal Care, Consumer Goods, Industrial) and Region

Mar 2025

Chemicals and Materials

Pages: 138

ID: IMR1837

Flexo Inks Market Synopsis

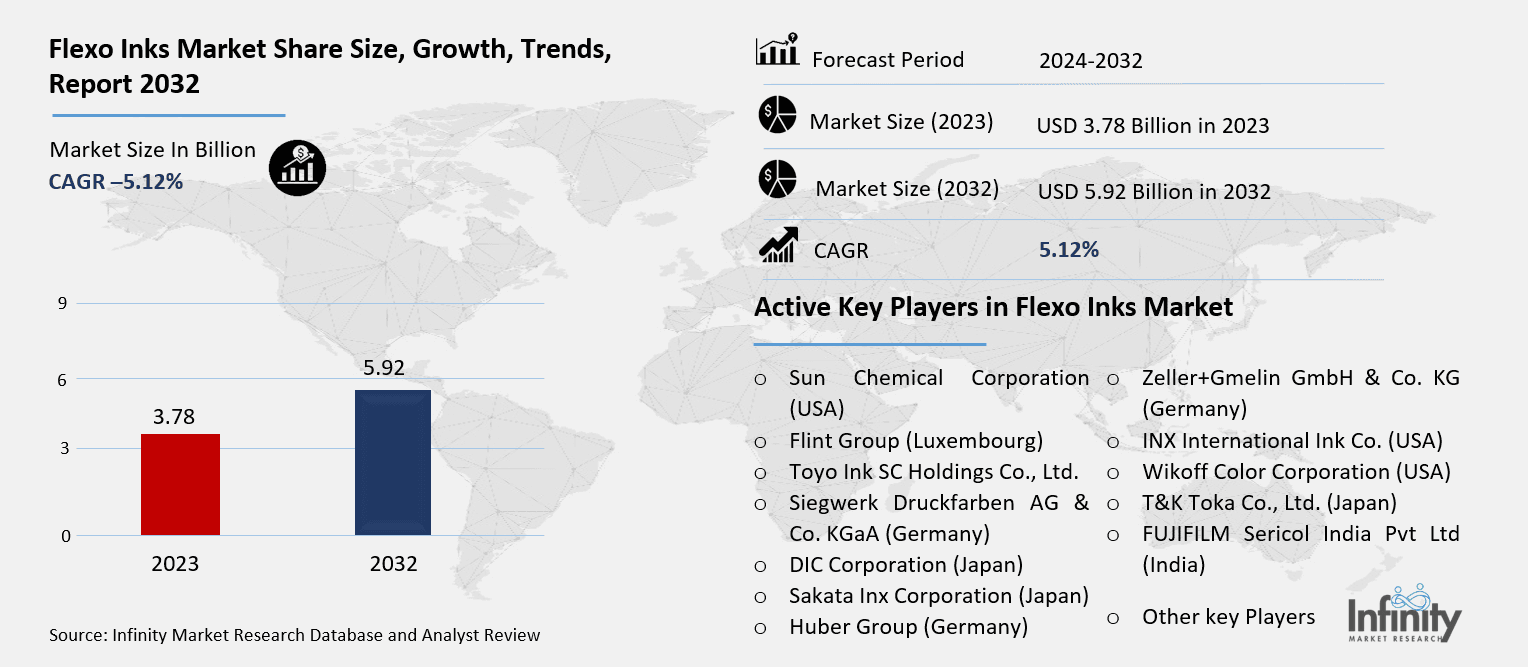

Flexo Inks Market Size Was Valued at USD 3.78 Billion in 2023, and is Projected to Reach USD 5.92 Billion by 2032, Growing at a CAGR of 5.12% From 2024-2032.

Flexographic inks are specific formulas used in the flexible and fast printing method flexography. Perfect for packaging uses, these inks are meant to stick to a range of substrates including plastic, foil, acetate film, and paper. Low viscosity of flexographic inks allows quick drying and effective manufacturing—qualities necessary for mass printing processes. Depending on the printing needs and environmental concerns, the several types of inks—water-based, solvent-based, and UV-curable—have different benefits.

The desire for effective, premium printing solutions and the growing packaging sector have spurred notable increase in the flexographic inks market. Flexography is a desirable alternative for packaging materials like labels, flexible packaging, and corrugated containers since its printability on several substrates. Different ink types—water-based, solvent-based, and UV-curable—each suited for particular uses and regulatory conditions help to segment the industry.

Because they generate less volatile organic compounds (VOCs) than solvent-based inks, water-based inks are becoming more and more popular from environmental advantages. This fits the worldwide move toward environmentally friendly packaging alternatives. Applications where durability and vivid colors—qualities of which solvent-based inks are well-known—rule still apply. Fast drying periods and great print quality make UV-curable inks fit for high-speed printing operations.

With great demand from the food and beverage sector, the packaging sector is still the principal use for flexographic inks. The demand for aesthetically pleasing and instructive packaging has driven flexographic printing—a low-cost, fast-paced production method. Furthermore driving the market is the growing need for corrugated packaging brought about by the expansion of e-commerce.

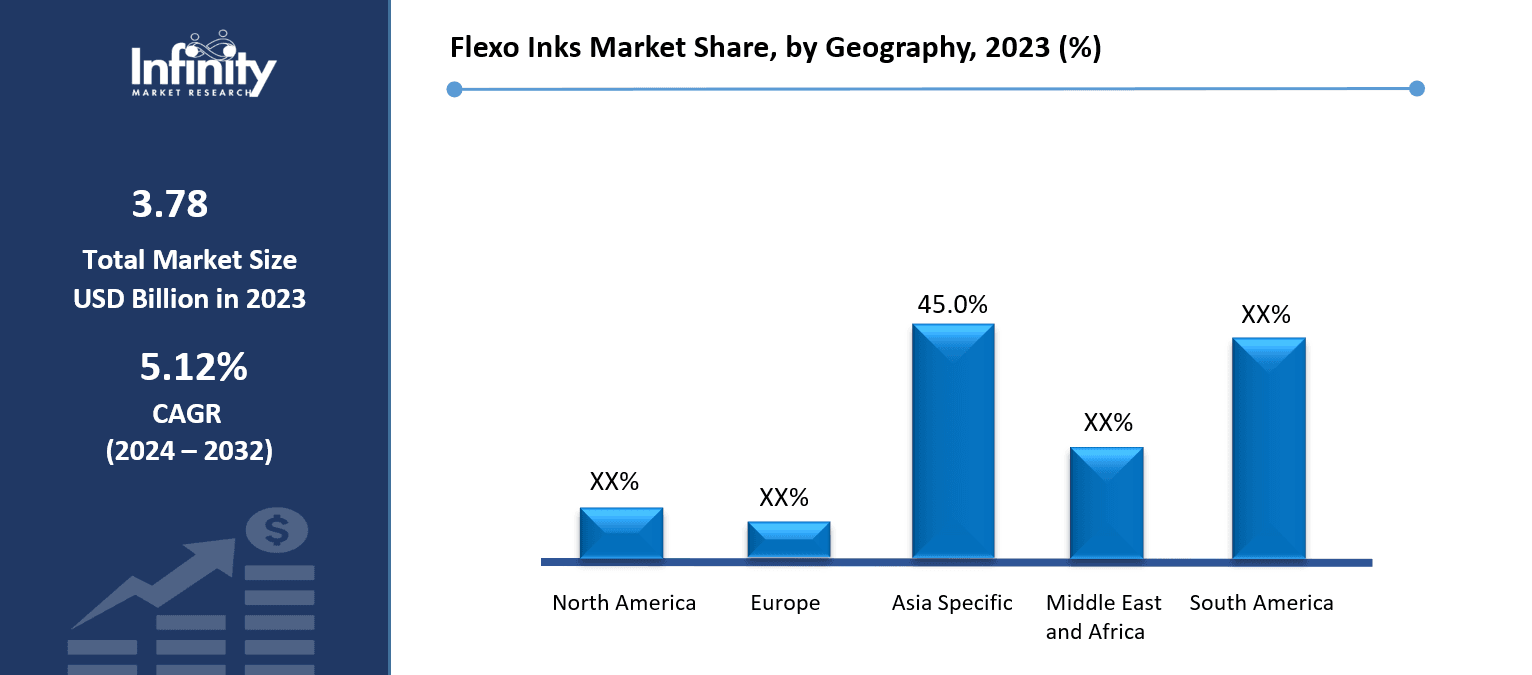

Geographically, the Asia-Pacific area leads the market; this is ascribed to its growing manufacturing industry and rising demand for packaged goods. Countries like China and India have grown to be major centers for flexographic ink use by means of packaging manufacture. With an eye on technology developments and environmentally friendly ink solutions, North America and Europe also have sizable market share.

Important participants in the market are funding research and development to create inks that satisfy changing industry criteria and environmental rules. Customized solutions, improved print quality, and operational efficiency are being developed by means of cooperation between ink manufacturers and packaging firms. Digital integration is another trend the market is seeing as technologies like color management systems and workflow automation are used to increase accuracy and lower manufacturing times.

Flexo Inks Market Outlook, 2023 and 2032: Future Outlook

Flexo Inks Market Trend Analysis

Trend: Shift Towards Sustainable Inks

Sustainable and environmentally friendly ink formulas are clearly shifting the flexographic inks market. Increasing consumer awareness and strict environmental laws meant to lower the ecological impact of printing operations drive this development mostly. Manufacturers are reacting by creating UV-curable and water-based inks that generate less volatile organic compounds (VOCs), therefore reducing air pollution and health risks related with conventional solvent-based inks.

Apart from responding to legal demands, this trend toward sustainability is a purposeful endeavor to satisfy the rising demand for environmentally friendly packaging solutions. Companies are looking for packaging that fits their environmental obligations more and more, so printers are using inks that enable recyclability and lower environmental effect. Derived from renewable resources, bio-based inks—which provide a reasonable substitute combining performance with environmental responsibility—are also becoming popular.

Opportunity: Expansion in Emerging Markets

For the flexographic inks sector, emerging markets provide a notable development potential. Rapid industrialization and urbanization in areas such Asia-Pacific, Latin America, and some of Africa are driving higher consumer expenditure and a growing middle class. Demand for packaged goods, including food, beverages, and consumer products, driven by this economic change, is increasing the requirement of effective and premium printing solutions.

Businesses in the flexographic inks market can take advantage of this possibility by developing a presence in these areas by means of strategic alliances, local manufacturing facilities, and customized product offers that satisfy regional tastes and legal criteria. Investing in these developing areas not only diversifies corporate portfolios but also sets businesses to profit from the long-term paths of these countries.

Driver: Growth of the Packaging Industry

The flexographic inks market is mostly driven by the strong growth of the packaging sector. The desire for varied packaging solutions has been driven by factors such growing consumerism, the explosion of e-commerce, and the demand for handy and longer-lasting items. Known for its adaptability and economy, flexographic printing has evolved into the dominant technique for manufacturing premium packaging materials in many different fields, including food and beverage, medicines, and personal care.

Flexographic inks' capacity to adhere to a broad spectrum of substrates and developments in ink formulas improving print quality and durability have helped to explain their acceptance in the packaging sector. Demand for creative and dependable flexographic inks is projected to keep rising as firms keep stressing packaging as a major difference and a tool for consumer involvement.

Restraints: Fluctuating Raw Material Prices

The fluctuation of raw material prices presents difficulties for the flexographic inks market. Key ingredients include pigments, resins, and solvents are prone to price swings impacted by things like supply chain interruptions, geopolitical concerns, and variations in crude oil prices. These price differences could influence ink producers' profit margins and cause end users to pay more, therefore influencing demand.

Companies are looking at alternate raw materials, investing in supply chain resilience, and using low-cost manufacturing techniques to help to offset this constraint. Furthermore, the creation of inks using less raw resources or more easily accessible sustainable materials can assist to lessen the effect of price swings. Two more key tactics to negotiate the difficulties presented by raw material price fluctuation are developing close ties with suppliers and practicing strategic procurement.

Flexo Inks Market Segment Analysis

Flexo Inks Market Segmented on the basis of type, resin type, application and end user.

By Type

o Water-Based

o Solvent-Based

o UV-Curable

By Application

o Packaging

o Commercial Printing

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Water-Based segment is expected to dominate the market during the forecast period

Mostly, flexo inks fall into three categories: UV-curable, solvent-based, and water-based. Because of their low VOC emissions and environmental advantages, water-based flexo inks find extensive application in the commercial printing and packaging sectors. Applications needing regulatory compliance favor them especially in food packaging. Still, they might have restrictions in terms of drying speed and adhesion to non-porous materials, which fuels ongoing demand for solvent-based substitutes.

Perfect for printing on plastic films and flexible packaging, solvent-based flexo inks provide exceptional adhesion, durability, and print quality. These inks are still in demand in sectors needing high-performance printing solutions even if VOC emissions raise some questions. Conversely, UV-curable flexo inks are becoming popular because of their short curing times, low environmental effect, and great print quality. In high-speed printing uses especially, they are highly preferred and should see major expansion in the next years.

By Application, Packaging segment expected to held the largest share

Flexo inks are extensively used in packaging, commercial printing, and other applications such as labeling and decorative printing. Packaging is the largest application segment, driven by the increasing demand for flexible and sustainable packaging solutions in food, beverage, and pharmaceutical industries. The rise of e-commerce and demand for visually appealing packaging are further fueling the need for high-quality flexo inks.

Commercial printing is another key segment, encompassing newspapers, catalogs, and promotional materials. The ability of flexo inks to deliver vibrant colors and cost-effective printing solutions makes them ideal for large-scale commercial printing applications. Additionally, the others category includes applications such as security printing and textile printing, where flexo inks are used for their durability and compatibility with various substrates.

Flexo Inks Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

Driven by fast industrialization, rising demand for packaged goods, and printing industry growth, Asia-Pacific is the major region in the flexo inks market. Strong manufacturing industries, rising disposable incomes, and growing consumer demand for premium printed packaging help nations like China, India, and Japan be leading suppliers. The thriving e-commerce industry in the area increases the necessity of creative and appealing packaging solutions even more.

Furthermore impacting the acceptance of water-based and UV-curable flexo inks in the area is the change toward sustainable printing techniques. Government rules endorsing environmentally friendly inks and investments in cutting-edge printing technology are enhancing the potential possibilities of the market in Asia-Pacific. Key ink producers and a well-established supply chain help to underline even more the region's supremacy.

Flexo Inks Market Share, by Geography, 2023 (%)

Active Key Players in the Flexo Inks Market

o Sun Chemical Corporation (USA)

o Flint Group (Luxembourg)

o Toyo Ink SC Holdings Co., Ltd. (Japan)

o Siegwerk Druckfarben AG & Co. KGaA (Germany)

o DIC Corporation (Japan)

o Sakata Inx Corporation (Japan)

o Huber Group (Germany)

o Zeller+Gmelin GmbH & Co. KG (Germany)

o INX International Ink Co. (USA)

o Wikoff Color Corporation (USA)

o T&K Toka Co., Ltd. (Japan)

o FUJIFILM Sericol India Pvt Ltd (India)

o Other key Players

Key Industry Developments in the Flexo Inks Market

April 2023: Flint Group announced the launch of its new flexographic ink line, EcoFlex. EcoFlex is a water-based ink that is designed to be environmentally friendly and meet the needs of today's sustainability-conscious consumers.

May 2023: Sun Chemical Corporation launched its new flexographic ink line, FlexoSolve. FlexoSolve is a solvent-based ink that is designed to provide high quality printing and performance on a variety of substrates.

June 2023: Siegwerk Druckfarben AG announced the acquisition of the flexographic ink business of Huber Group. The acquisition is expected to strengthen Siegwerk's position in the global flexographic ink market.

Global Flexo Inks Market Scope

|

Global Flexo Inks Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 3.78 Billion |

|

Forecast Period 2024-32 CAGR: |

5.12% |

Market Size in 2032: |

USD 5.92 Billion |

|

Segments Covered: |

By Type |

· Water-Based · Solvent-Based · UV-Curable | |

|

By Application |

· Packaging · Commercial Printing · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Rising Demand for Food-Grade Inks | ||

|

Key Market Restraints: |

· Volatility in Raw Material Prices | ||

|

Key Opportunities: |

· Increasing Demand for Flexible Packaging | ||

|

Companies Covered in the report: |

· Sun Chemical Corporation (USA), Flint Group (Luxembourg), Toyo Ink SC Holdings Co., Ltd. (Japan), Siegwerk Druckfarben AG & Co. KGaA (Germany), DIC Corporation (Japan), Sakata Inx Corporation (Japan), Huber Group (Germany) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Flexo Inks Market research report?

Answer: The forecast period in the Flexo Inks Market research report is 2024-2032.

2. Who are the key players in the Flexo Inks Market?

Answer: Sun Chemical Corporation (USA), Flint Group (Luxembourg), Toyo Ink SC Holdings Co., Ltd. (Japan), Siegwerk Druckfarben AG & Co. KGaA (Germany), DIC Corporation (Japan), Sakata Inx Corporation (Japan), Huber Group (Germany) and Other Major Players.

3. What are the segments of the Flexo Inks Market?

Answer: The Flexo Inks Market is segmented into Type, Resin Type,Application, End User and region. By Type, the market is categorized into Water-Based, Solvent-Based, UV-Curable. By Resin Type, the market is categorized into Polyurethane, Acrylic, Polyamide, Cellulose-Based, Others. By Application, the market is categorized into Flexible Packaging, Commercial Printing, Others. By End-Use Industry, the market is categorized into Food & Beverage, Pharmaceuticals, Cosmetics & Personal Care, Consumer Goods, Industrial. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Flexo Inks Market?

Answer: Flexographic inks are specific formulas used in the flexible and fast printing method flexography. Perfect for packaging uses, these inks are meant to stick to a range of substrates including plastic, foil, acetate film, and paper. Low viscosity of flexographic inks allows quick drying and effective manufacturing—qualities necessary for mass printing processes. Depending on the printing needs and environmental concerns, the several types of inks—water-based, solvent-based, and UV-curable—have different benefits.

5. How big is the Flexo Inks Market?

Answer: Flexo Inks Market Size Was Valued at USD 3.78 Billion in 2023, and is Projected to Reach USD 5.92 Billion by 2032, Growing at a CAGR of 5.12% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.