🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Flotation Reagents Market

Flotation Reagents Market Global Industry Analysis and Forecast (2024-2032) By Type (Coal, Graphite, Coke, Non-Sulfhide-Ores, Sulfhide Ores, Phosphate, Others) By Application (Coal, Graphite, Coke, Non-Sulfhide-Ores, Sulfhide Ores, Phosphate, Others) By End-use Band,(Mining and Metallurgy, Water Treatment Plants, Oil and Gas Industry, Others) and Region

Feb 2025

Chemicals and Materials

Pages: 137

ID: IMR1808

Flotation Reagents Market Synopsis

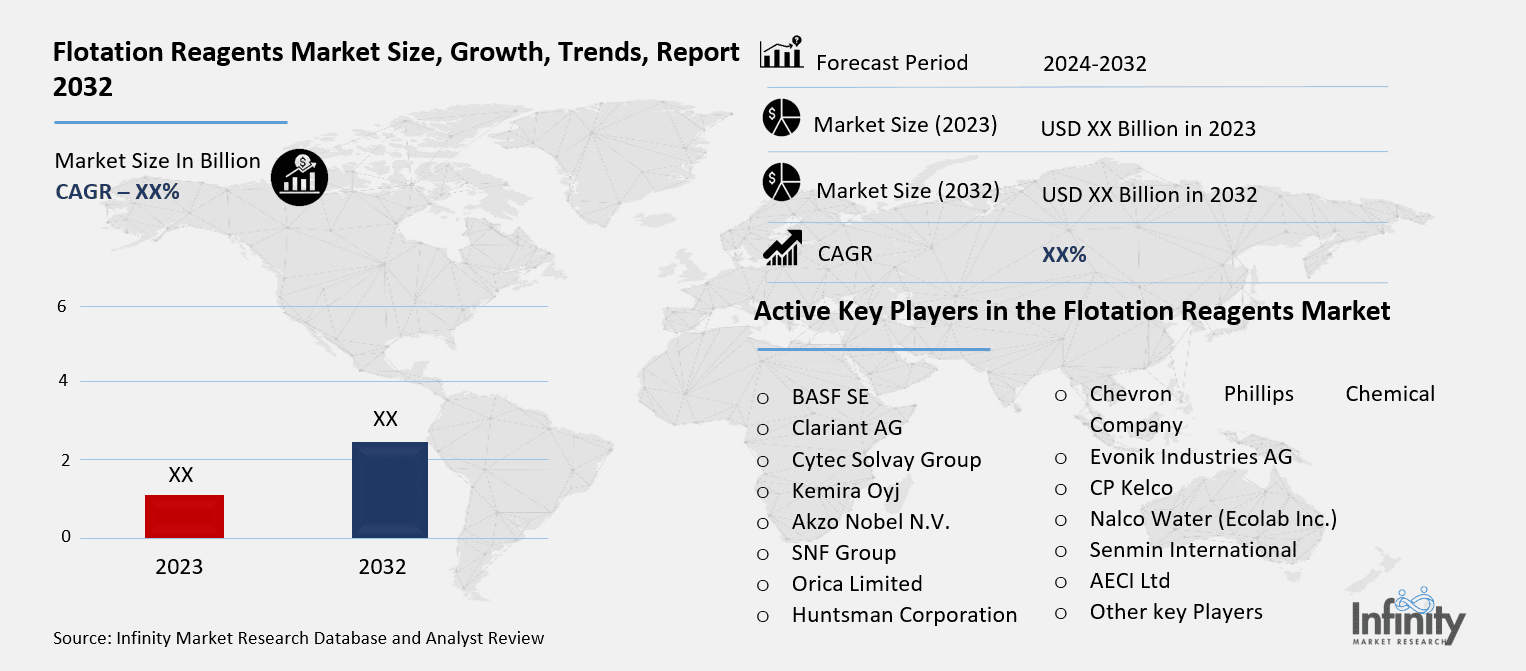

Flotation Reagents Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

In the mineral processing sector especially in the extraction and beneficiation of different ores, the flotation reagents market is rather important. During the flotation process, these reagents—chemical tools—help to separate precious minerals from ore. Rising demand for minerals including copper, gold, iron, and other non-ferrous metals—which are vital in many sectors like construction, automotive, and electronics—has supported steady expansion in the industry. Rising mining activity, especially in developing nations, has driven demand for flotation reagents, so orienting the market for ongoing growth.

Environmentally friendly flotation reagents have emerged from the mining sector's increasing attention on sustainability and environmental issues. Companies have been driven to innovate in the manufacturing of more efficient yet less detrimental to the environment reagents by regulatory demands and growing relevance of reducing environmental footprints. As they fit more stringent environmental rules, biodegradable and non-toxic reagents are becoming increasingly popular and fast adopted on international markets.

Geographically, where mining operations abound, the flotation reagents market is expanding in areas including Asia-Pacific, Latin America, and Africa. Driven by the demand for mineral resources in the expanding industrial sectors, these areas show great market potential. Key markets where flotation reagent use is rising are China, India, Brazil, and South Africa. Furthermore, the continuous infrastructure development in these areas increases the need for metals, therefore broadening the flotation reagent market.

The flotation reagents market has difficulties like changing raw material costs, which affect the cost of production, and the necessity of constant innovation to satisfy environmental and legal criteria notwithstanding the favorable growth prospect. The cyclical character of the mining sector, whereby low mineral prices can influence investments in newly proposed mining projects, influences the market also. Long-term development is likely to be driven, nonetheless, by improvements in flotation technologies and reagent formulations, therefore guaranteeing that the market stays dynamic and sensitive to the changing needs of the worldwide mining sector.

Flotation Reagents Market Trend Analysis

Trend

Rising Global Demand for Metals Driving Efficient Flotation Processes

Driven by their growing use in electronics, building, and renewable energy applications, metals such copper, gold, and lithium—whose global demand is rising—have stimulated the need for more effective flotation techniques. Mining activities are under more pressure to increase production and lower costs as these metals become indispensable for the manufacturing of infrastructure and high-tech equipment. Since they are used to separate valuable minerals from ores, hence enhancing the efficiency and yield of the mining process, flotation reagents are essential to this operation. This increased need for efficient and optimal flotation techniques—which are necessary to get high metal recovery rates—is driving market development.

The creation of advanced flotation reagents is much underlined in response to changing industry needs. These reagents minimize the loss of unwanted components and provide improved selectivity, therefore enabling more exact separation of precious minerals. Furthermore, the drive toward sustainability has spurred developments in environmentally friendly flotation reagents meant to lower the effects of mining operations. Businesses are funding new technologies that mix low toxicity levels and decreased ecological footprints with strong separation powers. Advancements in flotation technology combined with an increasing focus on environmental responsibility are driving the creation of next-generation reagents to satisfy both economic and regulatory needs, hence transforming the flotation reagents market.

Opportunity

Increased Demand for Efficient Flotation Reagents in Asia-Pacific and Latin America

The growth of the mining sector presents one of the most interesting prospects for the flotation reagents market, especially in developing areas like Asia-Pacific and Latin America. Resource exploration and exploitation are rising significantly as these areas keep undergoing fast development. Major actors in the worldwide mining industry are nations including China, India, Brazil, and Chile; the need for flotation reagents is resulting from the rising need for precious metals, minerals, and other natural resources. Essential in nature, these compounds help to separate precious minerals from ores during the beneficiation process, therefore enabling mineral processing activities. Manufacturers of flotation reagents thus have lots of chances to become rather prominent in these developing countries.

Another main driver of the need for flotation reagents in these areas is growing attention on more affordable and effective mining techniques. Innovative chemicals that improve the flotation process are in more demand as mining companies try to maximize recovery rates and cut running expenses. Manufacturers have the chance to provide cutting-edge reagents that not only enhance performance but also fit with sustainability objectives by lowering environmental effects. For example, highly sought after reagents are those that cut the usage of dangerous compounds or minimize water consumption. Flotation reagent suppliers clearly have a chance to offer customized solutions that fit the particular needs of these fast growing markets as mining activities in Asia-Pacific and Latin America get underway.

Flotation Reagents Market Segment Analysis

Flotation Reagents Market Segmented on the basis of By Type, By Application, By End-use

By Type

o Coal

o Graphite

o Coke

o Non-Sulfhide-Ores

o Sulfhide Ores

o Phosphate

o Others

By Application

o Mining and Metallurgy

o Water Treatment Plants

o Oil and Gas Industry

o Others

By End Use

o Mining and Metallurgy

o Water Treatment Plants

o Oil and Gas Industry

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Coal segment is expected to dominate the market during the forecast period

Coal plays a vital role in the global energy landscape, particularly in electricity generation, steel production, and cement manufacturing. It is primarily used as a fuel in power plants, where it is combusted to produce steam, driving turbines to generate electricity. This makes coal a crucial energy source in regions where alternative energy infrastructure is still underdeveloped. In addition to energy generation, coal is an essential input in metallurgy, where it serves as a reducing agent in the extraction of metals, especially in the production of steel. Its ability to provide high heat and energy in industrial processes makes it indispensable in the production of steel, a material integral to infrastructure development, construction, and manufacturing.

Despite its importance, coal faces growing environmental challenges due to its contribution to carbon emissions and air pollution. As global efforts to reduce greenhouse gas emissions intensify, many countries are seeking to transition away from coal to cleaner sources of energy. However, in regions where fossil fuels are still a primary energy source, the demand for coal remains robust, especially in developing economies and industrial sectors that depend on it for energy and production processes. This ongoing demand underscores the complex balancing act between economic development and environmental sustainability, with coal continuing to be a cornerstone of industrial growth despite the increasing push for greener alternatives.

By End-use, Mining and Metallurgy segment expected to held the largest share

The mining and metallurgy sector is integral to the global industrial ecosystem, driving demand for a wide array of raw materials, including coal, coke, graphite, and sulfide ores. Coal and coke are vital in the production of steel, where coal is used as a fuel source and coke acts as a reducing agent in the extraction of iron from ore. Graphite, with its excellent conductivity and heat resistance, is crucial for manufacturing electrodes used in electric arc furnaces, which are essential in steel production. Sulfide ores, containing valuable metals such as copper, zinc, and lead, are processed through smelting to extract these metals, which are foundational in industries such as electronics, construction, and automotive manufacturing.

In addition to traditional metal industries, mining and metallurgy are also key drivers for the development of renewable energy technologies. For instance, metals like copper and rare earth elements are vital in the manufacturing of solar panels, wind turbines, and electric vehicle batteries. As demand for green technologies grows, the mining and metallurgy sectors are under pressure to meet the increasing demand for these critical raw materials. This sector, therefore, not only supports traditional industries but is also at the forefront of enabling the transition to a more sustainable, low-carbon global economy.

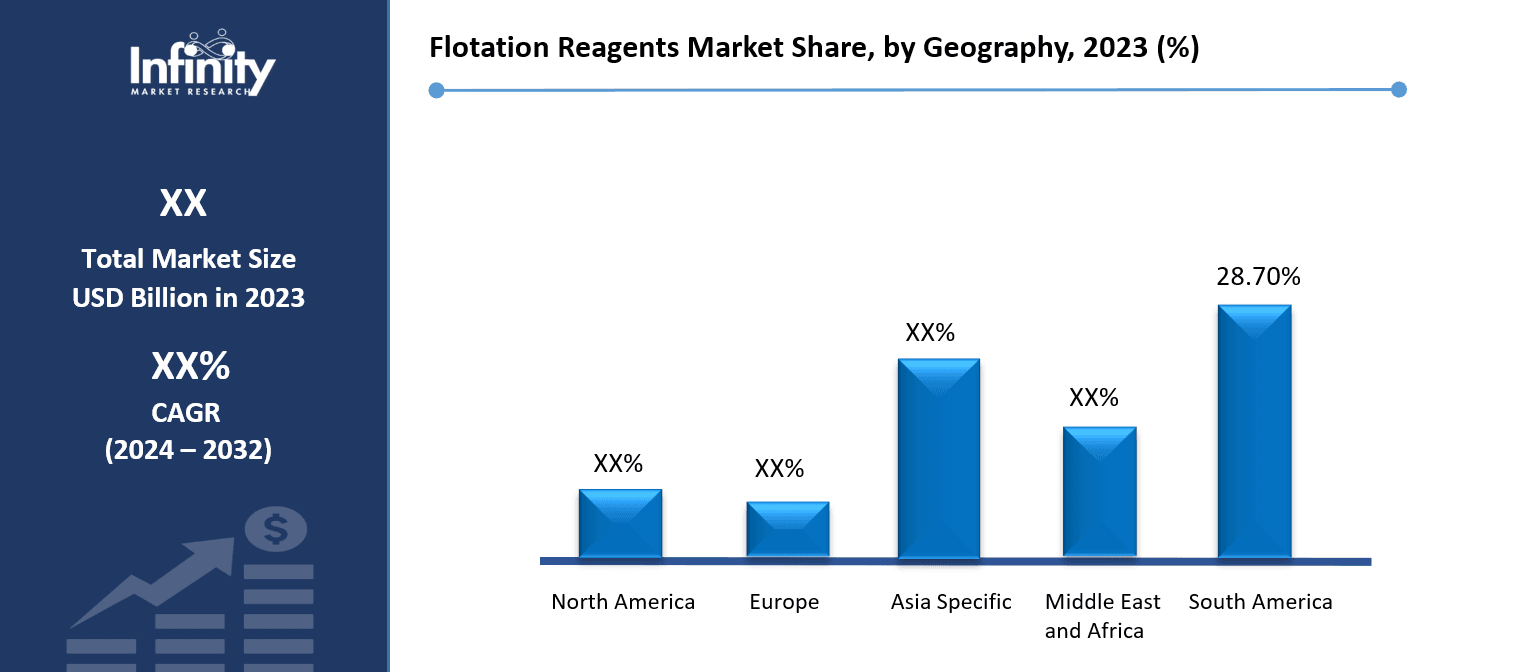

Flotation Reagents Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Increased Demand for Efficient Flotation Reagents in Asia-Pacific and Latin America

The growth of the mining sector presents one of the most interesting prospects for the flotation reagents market, especially in developing areas like Asia-Pacific and Latin America. Resource exploration and exploitation are rising significantly as these areas keep undergoing fast development. Major actors in the worldwide mining industry are nations including China, India, Brazil, and Chile; the need for flotation reagents is resulting from the rising need for precious metals, minerals, and other natural resources. Essential in nature, these compounds help to separate precious minerals from ores during the beneficiation process, therefore enabling mineral processing activities. Manufacturers of flotation reagents thus have lots of chances to become rather prominent in these developing countries.

Another main driver of the need for flotation reagents in these areas is growing attention on more affordable and effective mining techniques. Innovative chemicals that improve the flotation process are in more demand as mining companies try to maximize recovery rates and cut running expenses. Manufacturers have the chance to provide cutting-edge reagents that not only enhance performance but also fit with sustainability objectives by lowering environmental effects. For example, highly sought after reagents are those that cut the usage of dangerous compounds or minimize water consumption. Flotation reagent suppliers clearly have a chance to offer customized solutions that fit the particular needs of these fast growing markets as mining activities in Asia-Pacific and Latin America get underway.

Flotation Reagents Market Share, by Geography, 2023 (%)

Active Key Players in the Flotation Reagents Market

o BASF SE

o Clariant AG

o Cytec Solvay Group

o Kemira Oyj

o Akzo Nobel N.V.

o SNF Group

o Orica Limited

o Huntsman Corporation

o Chevron Phillips Chemical Company

o Evonik Industries AG

o CP Kelco

o Nalco Water (Ecolab Inc.)

o Senmin International

o AECI Ltd

o Other key Players

Global Flotation Reagents Market Scope

|

Global Flotation Reagents Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Type |

· Coal · Graphite · Coke · Non-Sulfhide-Ores · Sulfhide Ores · Phosphate · Others | |

|

By Application |

· Coal · Graphite · Coke · Non-Sulfhide-Ores · Sulfhide Ores · Phosphate · Others | ||

|

By End-use |

· Mining and Metallurgy · Water Treatment Plants · Oil and Gas Industry · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Increasing Global Industrialization and Demand for Mineral Extraction | ||

|

Key Market Restraints: |

· Environmental Concerns and Regulatory Pressure | ||

|

Key Opportunities: |

· Increased Demand for Efficient Flotation Reagents in Asia-Pacific and Latin America | ||

|

Companies Covered in the report: |

· BASF SE, Clariant AG, Cytec Solvay Group, Kemira Oyj, Akzo Nobel N.V., SNF Group, Orica Limited, Huntsman Corporation, Chevron Phillips Chemical Company, Evonik Industries AG, CP Kelco, Nalco Water (Ecolab Inc.), Senmin International, AECI Ltd, and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Flotation Reagents Market research report?

Answer: The forecast period in the Flotation Reagents Market research report is 2024-2032.

2. Who are the key players in the Flotation Reagents Market?

Answer: BASF SE, Clariant AG, Cytec Solvay Group, Kemira Oyj, Akzo Nobel N.V., SNF Group, Orica Limited, Huntsman Corporation, Chevron Phillips Chemical Company, Evonik Industries AG, CP Kelco, Nalco Water (Ecolab Inc.), Senmin International, AECI Ltd, and Other Major Players.

3. What are the segments of the Flotation Reagents Market?

Answer: The Flotation Reagents Market is segmented into By Type, By Application, By End-use Band region. By Type, the market is categorized into Coal, Graphite, Coke, Non-Sulfhide-Ores, Sulfhide Ores, Phosphate, Others. By Application, the market is categorized into Coal, Graphite, Coke, Non-Sulfhide-Ores, Sulfhide Ores, Phosphate, Others. By End-use Band, the market is categorized into Mining and Metallurgy, Water Treatment Plants, Oil and Gas Industry, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Flotation Reagents Market?

Answer: In the mining and mineral processing industries, the flotation reagents market is the industry engaged in the manufacturing and distribution of chemical compounds used in the flotation process. Added to flotation cells, these chemicals help to separate precious minerals from ores so enhancing the recovery and concentration of minerals including coal, copper, and gold. Collectors, frothers, modifiers, and activators are among the several reagents used in the market; each one helps to maximize flotation efficiency and mineral recovery by providing a different use. Rising demand for mineral resources, developments in mining technology, and the necessity of more ecologically friendly and effective mineral processing methods are driving the expansion of this market.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.