🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Friction Modifier Additives Market

Friction Modifier Additives Market Global Industry Analysis and Forecast (2024-2032) By Product Type (Organic Friction Modifiers, Inorganic Friction Modifiers, Polymer-based Friction Modifiers) By Application (Automotive, Industrial Lubricants, Marine, Aerospace, Heavy Equipment) By Functionality (Anti-Wear, Extreme Pressure (EP) Friction Modifiers, Energy-saving, Corrosion Resistance) By End-User (Automotive OEM (Original Equipment Manufacturer), Aftermarket) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1805

Friction Modifier Additives Market Synopsis

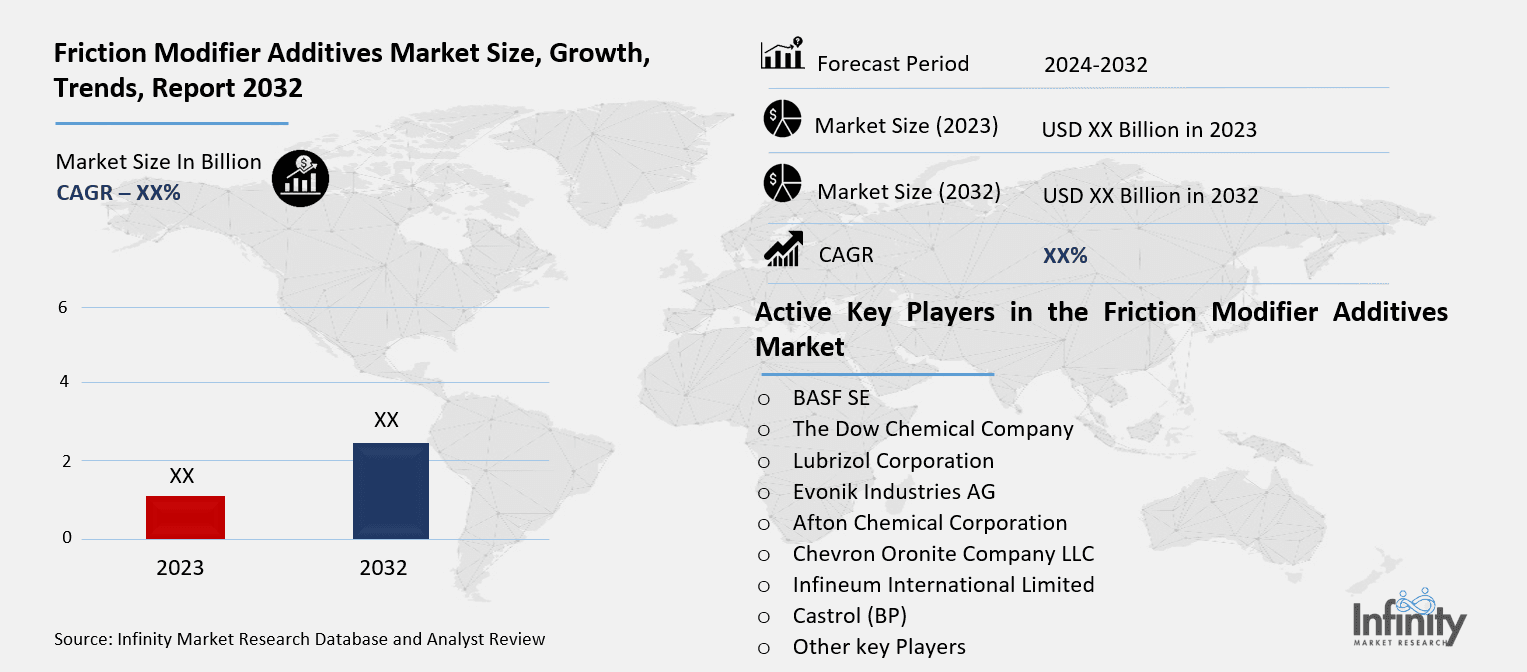

Friction Modifier Additives Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

Usually in lubricants, the market for Friction Modifier Additives is the one driven on the manufacturing and supply of chemical compounds used to lower friction and wear between two surfaces in contact. By reducing energy loss, increasing fuel economy, and extending the lifetime of mechanical components in automotive, industrial, and other machinery uses, these additives improve the performance and efficiency of lubricants. The increased demand for high-performance lubricants in several industries, including automotive, manufacturing, and energy, with an eye toward sustainability and fuel economy, drives the market for friction modifiers.

Increasing need for sophisticated lubrication solutions in sectors including automotive, manufacturing, and industrial machinery is driving notable expansion in the Friction Modifier Additives market. By lowering friction and wear, increasing fuel economy, and extending the lifetime of machinery, these additives are indispensable for optimizing the performance of lubricant. Friction modifying additives are very important in lowering energy consumption and environmental effect as sectors keep emphasizing sustainability and energy efficiency. As more businesses use these solutions to satisfy legal requirements and increase operational effectiveness, the market is predicted to expand.

The Friction Modifier Additives market is driven mostly by the automotive industry since vehicle demand for high-performance lubricants keeps growing. By lowering friction between engine components, friction modifiers aid to increase fuel economy and hence enhance general vehicle performance. Furthermore, the increasing attention on hybrid and electric cars (EVs) is driving the creation of specific friction modifiers that fit the particular requirements of EVs, such enhancing the performance of electric drivetrains and lowering of energy losses. This trend is supposed to support the expansion of the market in next years.

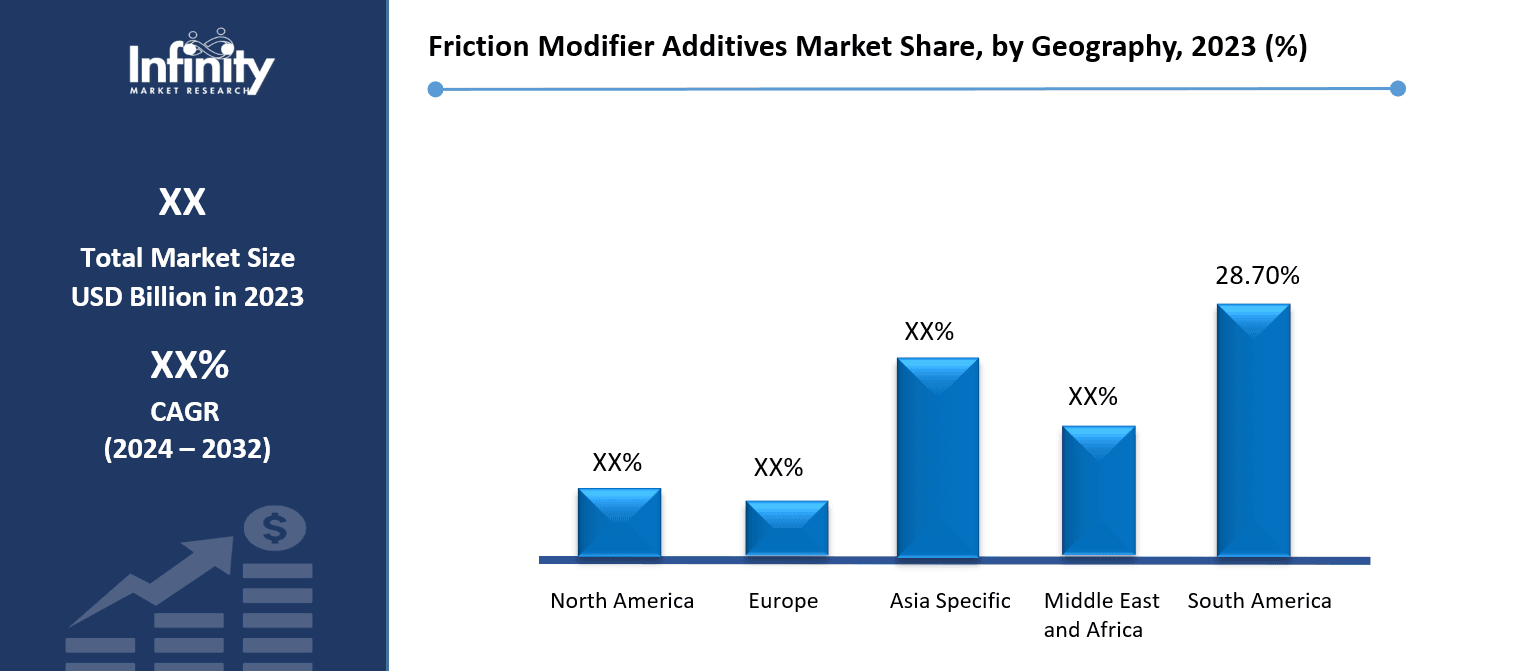

Driven by the presence of large car manufacturers, industrial sectors, and strict environmental rules, geographically North America and Europe rule the Friction Modifier Additives market. Friction modifiers are being adopted in several uses as these areas pay more and more attention on lowering carbon emissions and raising energy efficiency. Due mostly to the fast industrialization in nations like China and India, which are generating demand in the automotive, construction, and manufacturing sectors, Asia-Pacific is also becoming increasingly important as a main market for friction modifiers.

Regarding the several kinds of friction modifiers, the two main ones are organic and inorganic ones. Widely employed in the automotive and industrial sectors, organic friction modifiers including esters and fatty acid derivatives have great lubricating qualities and help to lower friction. High thermal stability and efficacy in extreme pressure applications make inorganic friction modifiers—like molybdenum disulfide—favored. Innovations in additive formulations are likely to keep the market changing and offer more eco-friendly and effective solutions to satisfy the several wants of businesses all around.

Friction Modifier Additives Market Trend Analysis

Trend

Shift Towards Sustainability in the Friction Modifier Additives Market

With an eye toward bio-based solutions especially, the market for friction modifiers shows a notable change toward sustainability. Manufacturers are funding the creation of friction modifiers made from renewable resources as environmental issues are growing in scope worldwide. These bio-based substitutes not only lessen reliance on petroleum-based components but also assist to lower the carbon footprint related to their manufacture. Companies trying to match stronger environmental rules and answer the growing consumer demand for environmentally friendly substitutes are driving the trend toward green products.

Apart from their advantages for the surroundings, bio-based friction modifiers are meant to either preserve or even improve the performance of conventional additives. These products, which use renewable ingredients, provide efficient lubrication, low wear, and effective performance in a variety of uses—including industrial and automotive machinery. Industries are thus progressively using these additives to satisfy consumer tastes for environmentally friendly, high-performance solutions as well as legal criteria. As businesses try to strike a mix between environmental responsibility and operational effectiveness, this trend is predicted to last.

Opportunity

Growing Demand for Friction Modifier Additives in Green Automotive Technologies

Demand for friction modifying compounds in lubricants is fast growing as the automotive sector adopts greener technology more and more. By lowering friction and wear in engine components, these additives greatly help to improve fuel economy and lower emissions. Apart from fulfilling strict environmental rules, this offers producers a great chance to improve the quality of their goods. Friction modifying additives are becoming increasingly important in creating sustainable automotive solutions as consumer demand for environmentally friendly vehicles and higher emissions criteria drive development of these solutions.

Apart from their use in conventional internal combustion engines, the increasing manufacturing of electric vehicles (EV) creates more chances for friction modifying additives. By lowering internal friction and increasing thermal management, these additives are absolutely crucial in extending the lifetime and efficiency of EV drivetrains and batteries. High-performance lubricants and additives become increasingly important as EV usage rises, opening a new path for the market for friction modifying additives. Using this trend toward electrification, manufacturers can innovate and offer solutions tailored especially to the changing needs of electric cars.

Friction Modifier Additives Market Segment Analysis:

Friction Modifier Additives Market Segmented on the basis of By Product Type, By Application, By Functionality, By End-User.

By Product Type

o Organic Friction Modifiers

o Inorganic Friction Modifiers

o Polymer-based Friction Modifiers

By Application

o Automotive

o Industrial Lubricants

o Marine

o Aerospace

o Heavy Equipment

By End User

o Automotive OEM (Original Equipment Manufacturer)

o Aftermarket

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Product Type, Organic Friction Modifiers segment is expected to dominate the market during the forecast period

Organic friction modifiers are primarily derived from natural sources such as fatty acids, esters, and amides, making them an environmentally friendly choice in lubrication applications. These compounds function by forming a protective molecular film on metal surfaces, reducing direct metal-to-metal contact and minimizing friction. As a result, they enhance the overall lubrication performance, improving energy efficiency and reducing wear on mechanical components. Their ability to lower frictional losses makes them particularly beneficial in automotive engine oils, where they contribute to fuel economy improvements and prolonged engine life.

Beyond automotive applications, organic friction modifiers play a crucial role in industrial lubricants, where they help optimize machinery performance and reduce maintenance costs. Industries such as metalworking, manufacturing, and heavy equipment rely on these additives to enhance the efficiency and durability of lubricants under varying operating conditions. Additionally, their biodegradable and non-toxic nature aligns with the growing demand for sustainable lubricant formulations, making them an ideal choice for companies aiming to reduce their environmental impact without compromising performance.

By End-User, Automotive OEM (Original Equipment Manufacturer) segment expected to held the largest share

Automotive OEMs incorporate friction modifiers into factory-fill lubricants to ensure that new vehicles achieve optimal performance from the outset. These additives play a critical role in reducing internal engine friction, which enhances fuel efficiency and minimizes wear on essential components. As global regulatory standards for emissions and fuel economy become increasingly stringent, OEMs rely on friction modifiers to help meet these requirements without compromising engine performance. By reducing mechanical losses, these additives contribute to lower CO₂ emissions, supporting automakers' efforts to develop more environmentally friendly vehicles.

Beyond regulatory compliance, friction modifiers also extend the durability and longevity of engine components, reducing the risk of premature wear and tear. By maintaining a stable lubrication film under varying temperatures and loads, they enhance the overall reliability of factory-fill lubricants. This is especially important for modern engines, which are designed with tighter tolerances and advanced technologies such as turbocharging and direct injection. As a result, friction modifiers help OEMs deliver vehicles that perform efficiently over extended service intervals, providing long-term value to both manufacturers and consumers.

Friction Modifier Additives Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

The demand for friction modifying additives is mostly driven in North America by the expanding automotive and industrial sectors, especially in the United States, where the adoption of advanced lubricants and friction modifiers is necessary to meet the rising demand for improved fuel efficiency and lowered emissions. Friction modifiers are essential in improving the efficiency of internal combustion engines, lowering wear and tear, and therefore optimizing fuel usage as the automotive sector concentrates on strengthening vehicle performance. The strict environmental rules of the area, including those meant to lower vehicle emissions, support the demand even more and drive the development and application of low-emission and ecologically friendly products in lubricants and additives.

Furthermore hastening the acceptance of friction modifiers is the growth in North America of electric cars (EVs). The demand for specific additives improving the performance and energy economy of electric drivetrains becomes crucial as EVs get traction. By helping electric motors maximize their efficiency, friction modifiers lower energy loss and enhance the general EV performance. As manufacturers try to satisfy the demand for greener technologies and innovative materials, the shift towards electric mobility and growing attention on sustainability are also generating fresh market prospects. These patterns make North America a major area of expansion for friction modifying additive demand.

Friction Modifier Additives Market Share, by Geography, 2023 (%)

Active Key Players in the Friction Modifier Additives Market

o BASF SE

o The Dow Chemical Company

o Lubrizol Corporation

o Evonik Industries AG

o Afton Chemical Corporation

o Chevron Oronite Company LLC

o Infineum International Limited

o Castrol (BP)

o Other key Players

Global Friction Modifier Additives Market Scope

|

Global Friction Modifier Additives Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Product Type |

· Organic Friction Modifiers · Inorganic Friction Modifiers · Polymer-based Friction Modifiers | |

|

By Application |

· Automotive · Industrial Lubricants · Marine · Aerospace · Heavy Equipment | ||

|

By Functionality |

· Anti-Wear · Extreme Pressure (EP) Friction Modifiers · Energy-saving · Corrosion Resistance | ||

|

By End-User |

· Automotive OEM (Original Equipment Manufacturer) · Aftermarket | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Advancements in Manufacturing and the Role of Lubricants | ||

|

Key Market Restraints: |

· Regulatory Pressure on Chemical Additives | ||

|

Key Opportunities: |

· Growing Demand for Friction Modifier Additives in Green Automotive Technologies | ||

|

Companies Covered in the report: |

· BASF SE, The Dow Chemical Company, Lubrizol Corporation, Evonik Industries AG, Afton Chemical Corporation, Chevron Oronite Company LLC, Infineum International Limited, Castrol (BP), and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Friction Modifier Additives Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Friction Modifier Additives Market?

Answer: BASF SE, The Dow Chemical Company, Lubrizol Corporation, Evonik Industries AG, Afton Chemical Corporation, Chevron Oronite Company LLC, Infineum International Limited, Castrol (BP), and Other Major Players.

3. What are the segments of the Friction Modifier Additives Market?

Answer: The Friction Modifier Additives Market is segmented into By Product Type, By Application, By Functionality, By End-User and region. By Product Type, the market is categorized into Organic Friction Modifiers, Inorganic Friction Modifiers, Polymer-based Friction Modifiers. By Application, the market is categorized into Automotive, Industrial Lubricants, Marine, Aerospace, Heavy Equipment. By Functionality, the market is categorized into Anti-Wear, Extreme Pressure (EP) Friction Modifiers, Energy-saving, Corrosion Resistance. By End-User, the market is categorized into Automotive OEM (Original Equipment Manufacturer), Aftermarket. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Friction Modifier Additives Market?

Answer: Usually in lubricants, the market for Friction Modifier Additives is the one driven on the manufacturing and supply of chemical compounds used to lower friction and wear between two surfaces in contact. By reducing energy loss, increasing fuel economy, and extending the lifetime of mechanical components in automotive, industrial, and other machinery uses, these additives improve the performance and efficiency of lubricants. The increased demand for high-performance lubricants in several industries, including automotive, manufacturing, and energy, with an eye toward sustainability and fuel economy, drives the market for friction modifiers.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.