🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

High Molecular Weight Polyisobutylene Market

High Molecular Weight Polyisobutylene Market Global Industry Analysis and Forecast (2024-2032) By Application (Lubricants, Stretch Films, Adhesives, Sealants), By End Use industry (Transportation, Industrial and Food) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1557

High Molecular Weight Polyisobutylene Market Synopsis

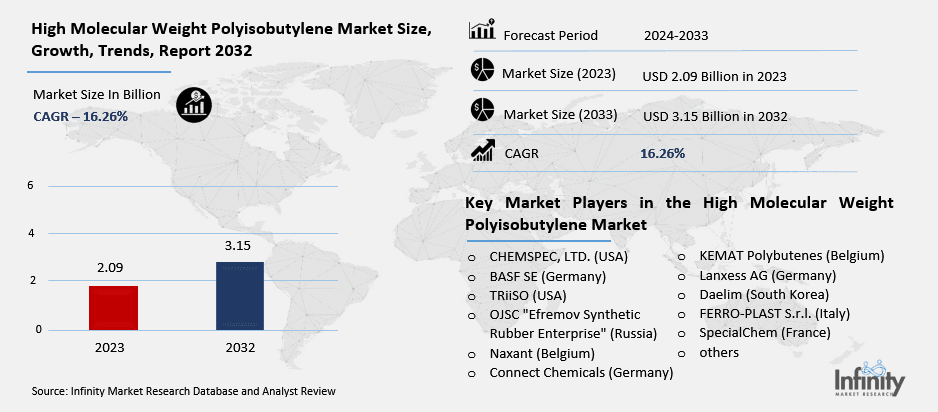

High Molecular Weight Polyisobutylene Market Size Was Valued at USD 2.09 Billion in 2023, and is Projected to Reach USD 3.15 Billion by 2032, Growing at a CAGR of 16.26% From 2024-2032.

The Global High Molecular Weight Polyisobutylene (HMPIB) Market is constantly growing because of the broadening uses of HMPIB across industries like automobile, lubricants and sealants, and adhesives. Polyisobutylene high molecular weight is a synthetic polymer that has very desirable characteristics such as low permeability by gases, chemical inactivity, and extreme longevity. This hub structure also makes it ideal for the production of high performance lubricants, fuel additives and waterproofing materials. The automotive industry is considered to be the market leader, as HMPIB is applied in fuel systems, tyre production, and as a performance-enhancing component of engine oil.

This market is similarly getting a tremendous boost from the continuously increasing need for premium quality and energy conserving lubricants. HMPIB’s property of enhancing the viscosity and stability of lubricants is making it relevant in automobiles as well as industry use. Moreover, Increase in demand for adhesive, sealants and coatings in construction industry and manufacturing industry is a factor that also fuels the market growth. The current quest for sustainable and green chemistry is forcing manufacturers to look for eco- and performance-friendly materials such as HMPIB, with no toxic byproducts that can be incorporated in green formulations.

On a regional basis, Asia-Pacific dominates from the High Molecular Weight Polyisobutylene Market mainly due to increased industrialization, urbanization, and huge manufacturing industries in countries such as China and India. Notably, North America and Europe also belong to core markets, improvement of automobile performance and tightening environmental laws contribute to the growth of synthetic high polymers such as HMPIB demand. With the continuing maturation of the market and further improvement in the HMPIB formulations and its increasing use in new applications, the growth for the next few years is anticipated.

High Molecular Weight Polyisobutylene Market Outlook, 2023 and 2032: Future Outlook

High Molecular Weight Polyisobutylene Market Trend Analysis

Trend: Increasing Demand for High-Performance Lubricants

An emerging development in the HMPIB Market is the increasing application of high-performance lubrication, especially in automobiles and industries. Automotive applications boost/review the efficiency and fuel economy of engines, and hence, HMPIB is applied in engine oils and transmission fluids for viscosity and/with friction. This has been occasioned by the need to embrace high performance lubricants especially in view of extreme conditions but also to enhance product durability for vehicles and a push to economize on fuel thus the essence of HMPIB in the modern auto fluids.

Driver: Growth in Automotive and Industrial Applications

Surge in demand for automotive and industrial application is supporting the high molecular weight polyisobutylene market. Its function of improving the performance of lubricants, fuel additives, sealants, adhesives, makes this product to be widely demanded in these industries. Its application in fuel systems, tires and engine oils in the automotive industry is also growing because manufacturers are in search of material with high strength and low friction. Likewise, the industrial application sectors which demand high performance coatings adhesives and sealant are also the driving force for HMPIB in these segments.

Restraint: High Production Costs

The high costs of manufacturing the polymer form part of the constraints faced in the High Molecular Weight Polyisobutylene Market. The preparation of HMPIB requires elaborate chemical works that are consuming a lot of energy and time as well as money translating to high costs when compared to other materials. This may hinder its use particularly in areas whose demand is cut across by cost as it may be outcompeted by cheaper substitutes that are available in the developing world. However, reliability on raw material costs also makes the costs fluctuate and unreliable for both the manufacture and the consumer.

Opportunity: Eco-Friendly and Sustainable Solutions

There is a chance to raise the High Molecular Weight Polyisobutylene Market due to the increasing focus on the need for environmentally friendly and sustainable products. With the growing environmental consciousness, the need for polymers that are non-toxic, biodegradable polymers with no rise byproducts is getting higher. Due to its relatively low level of environmental compatibility, HMPIB has great potential for some more ecologically sensitive fields such as the automotive and construction industries. Furthermore, the increase in research aimed at developing even more eco-friendly and energy-saving forms of HMPIB provides fresh opportunities for growth at the market level.

High Molecular Weight Polyisobutylene Market Segment Analysis

High Molecular Weight Polyisobutylene Market Segmented on the basis of By Application and By End Use industry.

By Application

o Lubricants

o Stretch Films

o Adhesives

o Sealants

By End Use Industry

o Transportation

o Industrial and Food

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Application, Lubricants segment is expected to dominate the market during the forecast period

The High Molecular Weight Polyisobutylene (HMPIB) market is further category into key applications such as lubricants, stretch films, adhesives and sealants which are also playing a vital role in its growth. Lubricants alone account for the largest proportion because HMPIB has excellent viscosity improving and shear stability properties and is used in engine oils, transmission fluids and industrial lubricants. The demand for high-performance lubricants, energy efficient and its use in automotive and machinery applications will also drive this segment. Further, as a result of excellent gas-barrier properties, HMPIB is widely used for sealants which are applied in automobile and industrial applications, where gas-barrier effectiveness and high stability is needed.

Other HMPIB application segments include stretch films as well as adhesives. The mechanical properties of HMPIB make the stretch films to have better performance in packaging where stretching properties such as tensile strength and elongation guarantees holding power for goods to be conveyed. HMPIB has significance in adhesives for increases tack, coherence and stored energy beneficial to both industrial and consumer use. Rising demand of adhesives and sealants in construction, automobile and packing industries indicates that HMPIB will continued to be more significant in these sectors and prescribing the compound’s market growth.

By End Use industry, Transportation segment expected to held the largest share

Transportation industry is identified as one of the largest end-users in the HMPIB market mile, attributed to its function in automotive and aerospace framework.. HMPIB is employed in manufacturing fuel additives, lubricants, and tires because of its excellent viscosity control, gas impermeability and steam resistance. It finds use in automotive industry as a performance boosting additive to improve characteristics of engine oil and decrease friction thus increase fuel economy and life of automobile engines. In the aerospace industry, applications that include high-performance lubricants and sealants are significant for reliable performance under high temperature and pressure making it an essential component of the current generation of transportation systems.

Together with the automotive sector, the industrial and food sectors remain another major force in the HMPIB market. The major uses of HMPIB are in adhesive, sealant and waterproof industries with emphasis on constructions and heavy equipment manufacturing industries. HMPIB finds application in the food industry where it is used in skilled food-grade lubricants and facets of packaging material given its inert and non toxic characteristics. This characteristic makes it offer good barrier properties in food packaging applications and so helps provide product freshness and longer shelf life. Owing to the rising need for high-performing durable- and efficient, Sustainable material in each of these industries, HMPIB remains to embody exponential growth in multiple areas of use.

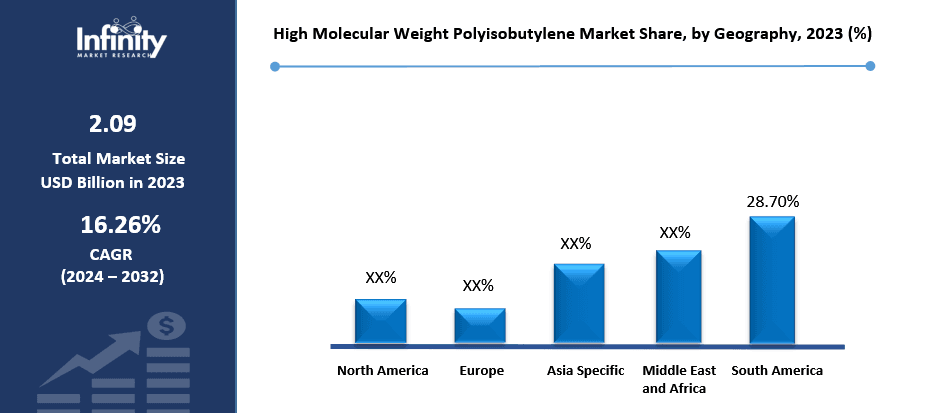

High Molecular Weight Polyisobutylene Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Market in North America is expected to dominate the High Molecular Weight Polyisobutylene (HMPIB) market during the forecast period due to its mature automotive and industrial industries. The increasing use of HMPIB in the global lubricant, adhesive and sealant industries driven by the need for high performance in manufacturing processes across the Asia-Pacific region is developing rapidly. One prime example is the automotive industry which has and will continue to invest more heavily in electric vehicles and energy efficient engines both of which require high quality synthetic polymers such as HMPIB. Furthermore, emphasis on compliance with environmental standards and insisting on enhanced fuel economy in the region has also triggered the employment of HMPIB in fuel and lubricant solutions.

High Molecular Weight Polyisobutylene Market Share, by Geography, 2023 (%)

Active Key Players in the High Molecular Weight Polyisobutylene Market

o CHEMSPEC, LTD. (USA)

o BASF SE (Germany)

o TRiiSO (USA)

o OJSC "Efremov Synthetic Rubber Enterprise" (Russia)

o Naxant (Belgium)

o Connect Chemicals (Germany)

o KEMAT Polybutenes (Belgium)

o Lanxess AG (Germany)

o Daelim (South Korea)

o FERRO-PLAST S.r.l. (Italy)

o SpecialChem (France)

o others

Global High Molecular Weight Polyisobutylene Market Scope

|

Global High Molecular Weight Polyisobutylene Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 2.09 Billion |

|

Forecast Period 2024-32 CAGR: |

16.26% |

Market Size in 2032: |

USD 3.15 Billion |

|

Segments Covered: |

By Application |

· Lubricants · Stretch Films · Adhesives · Sealants | |

|

By End Use industry |

· Transportation · Industrial and Food | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· The high molecular weight polyisobutylene market is driven by automotive and industrial demand for high-performance lubricants and fuel additives. | ||

|

Key Market Restraints: |

· High manufacturing costs and raw material price volatility hinder the adoption of High Molecular Weight Polyisobutylene is hindered in cost-sensitive sectors. | ||

|

Key Opportunities: |

· Sustainable materials are becoming more popular, giving high molecular weight polyisobutylene potential in green technologies and applications. | ||

|

Companies Covered in the report: |

· CHEMSPEC, LTD. (USA), BASF SE (Germany), TRiiSO (USA), OJSC "Efremov Synthetic Rubber Enterprise" (Russia), Naxant (Belgium), Connect Chemicals (Germany), KEMAT Polybutenes (Belgium), Lanxess AG (Germany), Daelim (South Korea), FERRO-PLAST S.r.l. (Italy), SpecialChem (France), others. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the High Molecular Weight Polyisobutylene Market research report?

Answer: The forecast period in the High Molecular Weight Polyisobutylene Market research report is 2024-2032.

2. Who are the key players in the High Molecular Weight Polyisobutylene Market?

Answer: CHEMSPEC, LTD. (USA), BASF SE (Germany), TRiiSO (USA), OJSC "Efremov Synthetic Rubber Enterprise" (Russia), Naxant (Belgium), Connect Chemicals (Germany), KEMAT Polybutenes (Belgium), Lanxess AG (Germany), Daelim (South Korea), FERRO-PLAST S.r.l. (Italy), SpecialChem (France), others.

3. What are the segments of the High Molecular Weight Polyisobutylene Market?

Answer: The High Molecular Weight Polyisobutylene Market is segmented into By Application, End User and region. By Application (Lubricants, Stretch Films, Adhesives, Sealants), By End Use industry (Transportation, Industrial and Food). By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the High Molecular Weight Polyisobutylene Market?

Answer: High Molecular Weight Polyisobutylene (HMPIB) is a synthetic polymer derived from isobutylene, characterized by its high molecular weight and unique physical and chemical properties. Known for its excellent impermeability to gases, thermal stability, and resistance to oxidation, HMPIB is widely used in applications requiring durability and flexibility. These properties make it an essential material in the production of high-performance lubricants, fuel additives, sealants, adhesives, and waterproofing solutions. Its non-toxic nature and compatibility with various formulations further enhance its versatility, enabling its use in industries such as automotive, construction, and packaging.

5. How big is the High Molecular Weight Polyisobutylene Market?

Answer: High Molecular Weight Polyisobutylene Market Size Was Valued at USD 2.09 Billion in 2023, and is Projected to Reach USD 3.15 Billion by 2032, Growing at a CAGR of 16.26% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.