🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

High-Temperature Coatings Market

High-Temperature Coatings Market Global Industry Analysis and Forecast (2024-2032) Type (Ceramic Coatings, Metallic Coatings, Intermetallic Coatings), Material (Silicone, Epoxy, Polyurethane, Fluoropolymer), Technology (Liquid Coating, Powder Coating) Application (Aerospace & Defense, Automotive, Industrial Equipment, Power Generation, Marine) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1559

High-Temperature Coatings Market Synopsis

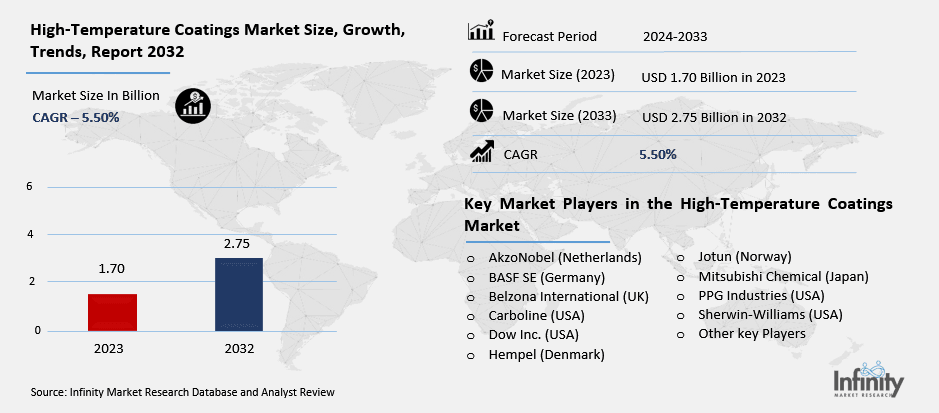

High-Temperature Coatings Market Size Was Valued at USD 1.70 Billion in 2023, and is Projected to Reach USD 2.75 Billion by 2032, Growing at a CAGR of 5.50 % From 2024-2032.

High temperature coatings market can be defined as the demand for specific coating that has been designed to work at high temperature and in severe conditions. These coatings are used on high temperature material applicable in aerospace, automotive, industrial machine, and power generation to provide heat, corrosion, oxidation, and wear resistance. These coatings not only increase the durability and reliability of essential parts, but also enhance the working parameters of application areas which operate at higher thermal stresses.

The high-temperature coatings market is on the rise due to the increased usage across multiple sectors including aerospace, automotive, and power. These coatings are critical to safeguard the material against conditions of the public domain and afford added reliability with enhanced performance. Industries require higher performance materials and high temperature coatings which market has displayed increased growth in areas of high industrialization.

The tenor of the market’s growth is supported by the innovation of technology that covers coating materials and application techniques. Advancements in technologies associated with forming the coatings ranging from ceramics to metals and intermetal coatings have improved on thermal stability and general protection from corrosion and oxidation within the system. High-temperature coatings have a significant demand in the Asia-Pacific region, because of the fast-growing industrialization and a need for efficient power consumption.

High-Temperature Coatings Market Outlook, 2023 and 2032: Future Outlook

High-Temperature Coatings Market Trend Analysis

Advancements in Coating Technologies and Materials

Recent developments in coating material has enabled the development of various coating that can with stand much higher temperatures and as such give long use and high performance of parts. Of these, ceramic coatings are increasingly being used owing to their excellent thermal expansion and corrosion resistant properties. This development is likely to persist since industries always look for measures on how to enhance productivity and minimize the expenses on maintenance of high work output machines.

The other trend is the increasing call to create and use high-temperature coatings that contain no harm to the environment. The chemical industry is paying increasing attention to the eco-friendliness of its coatings by excluding dangerous elements such as lead and chromates for its manufacturers. Concern for the environment is expected to foster the growth of eco coatings that’d be in compliance with strict environmental standards while having the same properties as conventional coatings.

Demand for High-Performance Materials in Extreme Conditions

The increasing demand for different products that require enhanced performance and efficiency in high temperature environment is one of the most significant factors for the high-temperature coatings market. For automotive, aerospace, energy sector and many other industries, materials for producing parts, particularly high-temperature targeted services such as heat resistance, pressure or chemicals call for coatings. It is critical in these sectors since the coatings are used to decrease downtime, enhance its operation life and contribute to energy efficiency.

Another driver is the rising use of high-tech production processes that include three-dimensional printing and additive manufacturing techniques, which need extra layers of coating to guarantee they endure high temperature and are operational. Prospects for these advanced technologies are likely to accelerate in the future, effectively presenting the need for corresponding coating to promote the high-temperature coatings market.

High Costs of Coating Materials and Application Processes

They also recognize that one of the most significant challenges in the high-temperature coatings market is the relatively high cost put on these coatings and related application processes. The types of materials used on high-temperature coatings are costly and the related processes, for instances thermal spraying, chemical vapor deposition among others the expensive. This presents small and medium-sized enterprises with difficulties in the implementation of these coatings constraining their market uptake.

Also, the issues can be arisen from selection of the appropriate high-temperature coating type for particular application, which can also be a limiting factor. The coatings have to be designed depending on the material the coatings are going to be used on, temperature range and environment, which speaks of a lot of experience and knowledge. This leads to longer lead times and higher development cost, which are the factors that may slow down the growth of market in some of the regions.

Growth in Renewable Energy and Sustainable Technologies

The one trend within the high-temperature coatings market is that the market has a high growth potential in applications related to the renewable energy sector. With the increasing focus on the use of renewable resources for energy production, high temperature coatings are critical for maintaining performance of equipment, including solar, wind, and geothermal. This trend is absolutely beneficial for the growth in the established market, since rivals do not race in offering ultra-modern products.

Another opportunity lies in the efforts of automotive industry upon fuel efficient and low emission technologies in the High-temperature coatings market. Since car manufacturers are working towards unveiling new sophisticated engines and fine exhaust systems, the market for satisfactory thermal barrier and anti-corrosive coatings will remain highly active. This emerging demand for high performance coatings in automotive industry is identified as a market opportunity.

High-Temperature Coatings Market Segment Analysis:

High-Temperature Coatings Market Segmented on the basis of Type, Material, Technology and Application

By Type

o Ceramic Coatings

o Metallic Coatings

o Intermetallic Coatings

By Material

o Silicone

o Epoxy

o Polyurethane

o Fluoropolymer

By Application

o Aerospace & Defense

o Automotive

o Industrial Equipment

o Power Generation

o Marine

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

Type, Ceramic Coatings segment is expected to dominate the market during the forecast period

The high-temperature coatings market can be divided by coatings type; ceramic coatings, metallic coatings and intermetallic coatings. Ceramic coatings are popular due to their high heat and wear resistant properties are of great importance in aerospace and power generation industries. It is well known that for thermal protection and for a great number of applications rated to industrial use the best metallic coatings are used. Intermetallic coatings are made to be heat resistant and are applied in applications including those in aerospace and energy production sectors.

Material, Silicone segment expected to held the largest share

A breakdown of high-temperature coatings by material is then provided, including silicone, epoxy, polyurethane, and fluoropolymer Coatings. Silicone based coatings also show high heat resistance and hence it is prominently used in industrial sectors. It is thus chosen for its good adhesion properties to substrates, and heat resistance of epoxy coatings. As far as the flexibility and durability of the material, polyurethane coatings have their special popularity among the automotive and aerospace industries. Fluoropolymer coatings are most suited to high temperature applications and are often applied in chemical-based industries and power generation.

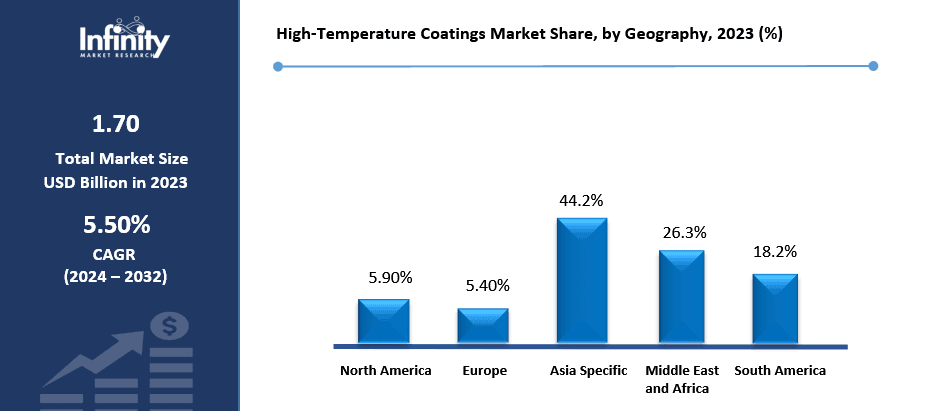

High-Temperature Coatings Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast period

High-Temperature Coatings Market by Type, End-User Industry, and Region Asia-Pacific is the biggest market for high-temperature coatings due to industrial growth and rising energy conservation demands. Hailing from APAC, countries like China, India, and Japan constitute the most active users of advanced manufacturing technologies and plan to boost the manufacturing industries especially the automotive, aerospace, and power generation industries. A rising interest in enhancing productivity and cutting expenses linked to maintenance and operating temperatures has catalyzed this region’s growth of high-temperature coatings.

also there is a strong bench of manufacturing industries across the Asia-Pacific region along with availability of cheap labour and hence creating a good demand for high temperature coatings. The growth of the automotive as well as aerospace industries in this region is expected to increase the demand of high temperature resistant and performance enhancing coatings making this region dominate the market.

High-Temperature Coatings Market Share, by Geography, 2023 (%)

Active Key Players in the High-Temperature Coatings Market

o AkzoNobel (Netherlands)

o BASF SE (Germany)

o Belzona International (UK)

o Carboline (USA)

o Dow Inc. (USA)

o Hempel (Denmark)

o Jotun (Norway)

o Mitsubishi Chemical (Japan)

o PPG Industries (USA)

o Sherwin-Williams (USA)

o Other key Players

Global High-Temperature Coatings Market Scope

|

Global High-Temperature Coatings Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 1.70 Billion |

|

Forecast Period 2024-32 CAGR: |

5.50 % |

Market Size in 2032: |

USD 2.75 Billion |

|

Segments Covered: |

Type |

· Ceramic Coatings · Metallic Coatings · Intermetallic Coatings | |

|

Material |

· Silicone · Epoxy · Polyurethane · Fluoropolymer | ||

|

Technology |

· Liquid Coating · Powder Coating | ||

|

Application |

· Aerospace & Defense · Automotive · Industrial Equipment · Power Generation · Marine | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements in Manufacturing and Coating Applications | ||

|

Key Market Restraints: |

· Complexity in Tailored Coating Selection for Specific Applications | ||

|

Key Opportunities: |

· Rising Demand in the Automotive Sector for High-Temperature Coatings | ||

|

Companies Covered in the report: |

· Hempel (Denmark), AkzoNobel (Netherlands), PPG Industries (USA), BASF SE (Germany), Sherwin-Williams (USA), Jotun (Norway), Mitsubishi Chemical (Japan), Carboline (USA), Dow Inc. (USA), Belzona International (UK) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the High-Temperature Coatings Market research report?

Answer: The forecast period in the High-Temperature Coatings Market research report is 2024-2032.

2. Who are the key players in the High-Temperature Coatings Market?

Answer: Hempel (Denmark), AkzoNobel (Netherlands), PPG Industries (USA), BASF SE (Germany), Sherwin-Williams (USA), Jotun (Norway), Mitsubishi Chemical (Japan), Carboline (USA), Dow Inc. (USA), Belzona International (UK) and Other Major Players.

3. What are the segments of the High-Temperature Coatings Market?

Answer: The High-Temperature Coatings Market is segmented into Type, Material, Technology, Application and region. Type, the market is categorized into Ceramic Coatings, Metallic Coatings, Intermetallic Coatings. Material, the market is categorized into Silicone, Epoxy, Polyurethane, Fluoropolymer. Technology, the market is categorized into Liquid Coating, Powder Coating. Application the market is categorized into Aerospace & Defense, Automotive, Industrial Equipment, Power Generation, Marine. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the High-Temperature Coatings Market?

Answer: High temperature coatings market can be defined as the demand for specific coating that has been designed to work at high temperature and in severe conditions. These coatings are used on high temperature material applicable in aerospace, automotive, industrial machine, and power generation to provide heat, corrosion, oxidation, and wear resistance. These coatings not only increase the durability and reliability of essential parts, but also enhance the working parameters of application areas which operate at higher thermal stresses.

5. How big is the High-Temperature Coatings Market?

Answer: High-Temperature Coatings Market Size Was Valued at USD 1.70 Billion in 2023, and is Projected to Reach USD 2.75 Billion by 2032, Growing at a CAGR of 5.50 % From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.