🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Inline Oil Particle Counters Market

Inline Oil Particle Counters Market Global Industry Analysis and Forecast (2024-2032) By Product Type (Portable, Stationary), By Application (Industrial, Automotive, Aerospace, Energy, Others), By End-User (Manufacturing, Oil & Gas, Pharmaceutical, Food & Beverage, Others) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1704

Inline Oil Particle Counters Market Synopsis

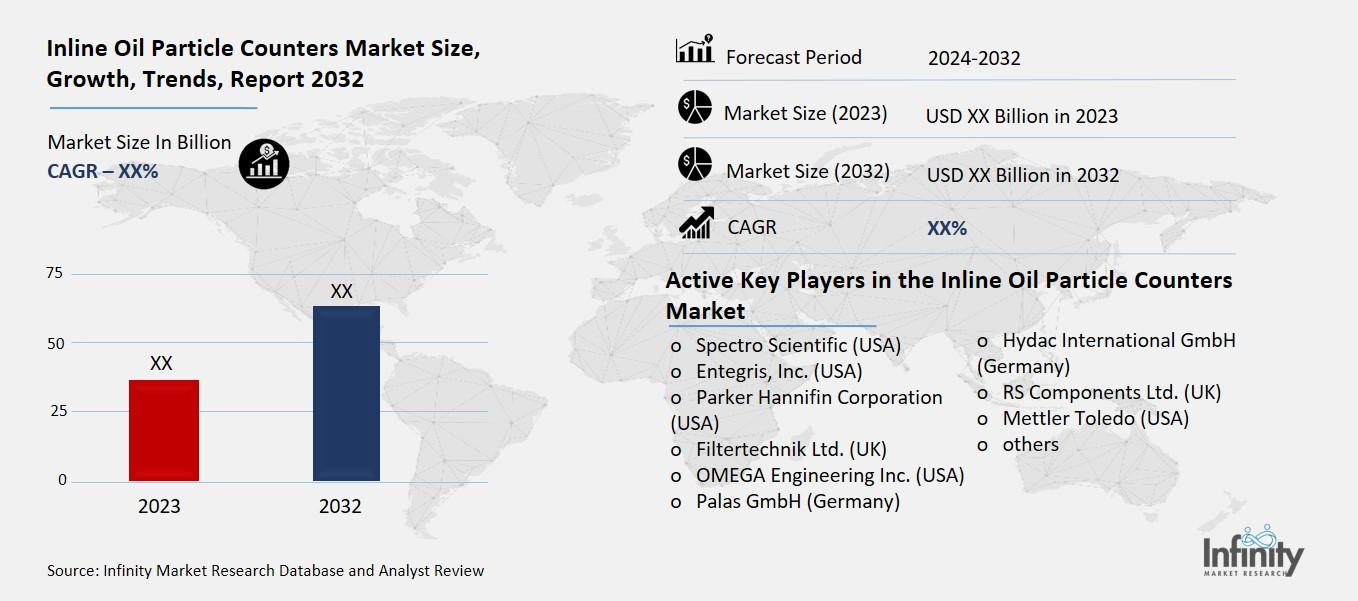

Inline Oil Particle Counters Market Size Was Valued at USD XX Billion in 2023, and is Projected to Reach USD XX Billion by 2032, Growing at a CAGR of XX% From 2024-2032.

This market is currently experiencing considerable growth, thoroughly due to the fact that in many industries the quality of oil is a crucial factor in equipment performance, as well as operations efficiency. Such counters are employed to capture and quantify particle debris in oils utilized in hydraulic, lubricating and other similar industrial applications. It makes it possible to control oil cleanliness and therefore guarantee the durability of equipment, minimize time loss, and increase reliability. Applications of inline oil particle counters include automotive sector, aerospace, energy, and manufacturing industries where high pressure and precision are important.

This market is mainly thriving from the rising need for implementing preventive maintenance solutions in different industries including the oil and gas, automobile, and energy industries. Specifically as industries strive to eliminate additional costs which may be occasioned by equipment failures, there is increasing usage of inline oil particle counters as key real time tools in monitoring as well as filtering the oil systems in an industry. These devices assist in identifying contaminants that could otherwise cause wear and tear in machinery since oil is always clean as well as functional. Moreover, growth of clean industries entails governments and regional environmental standards that encourage adoption of enhanced oil monitoring systems, thus encouraging the growth of the market.

Yet the Inline Oil Particle Counters Market has some threats like the high cost of buying and implementing those systems, especially for firms in the SME category. However, there could also be technological constraints regarding the specific environments such as temperature or pressure fluctuations which complicate the routines of the positioning system. Although there are a number of challenges involved in the implementation of these systems, advances in the hardware technologies for sensors and particle counters, and the miniaturization of these systems, promise to reduce the cost of these systems and make their use more practicable for a wider range of applications. In line with the developments of industries that aim to optimize process, it is comprehensible that inline oil particle counters will gain more market traction, most predominantly in the regions that have recently embarked on industrialization.

Inline Oil Particle Counters Market Outlook, 2023 and 2032: Future Outlook

Inline Oil Particle Counters Market Trend Analysis

Trend: Advancements in Real-Time Monitoring Technology

In choosing the Inline Oil Particle Counters Market trends one of the most pressing is the growth in the real-time monitoring of Inline Oil Particle Counters. In today’s world where there is robotic and diarized operation in industries, the need for an uptime system to inspect the contamination of oil has become relevant. Such innovations make it possible for the companies to be flooded with steady, real-time information, in this case on the spot, which speeds up the have decision making processes especially on the matter of oil maintenance and filtration. Inline oil particle counters used for real time monitoring have higher accuracy in location of equipment which is prone to be damaged by delayed maintenance schedule hence a transition to advanced inline oil particle counters with sensors. These enhancements in technology also inspire the expansion of attaching Inline Oil Particle Counters with the internet and smart production line concepts. It also helps to enable more efficient transmission of information between numerous industrial systems and central command systems to make the industry more efficient and easily managed. As companies develop towards Industry 4.0, the possibility to gather, process, and respond to real-time oil cleanliness data becomes a necessity. This even pushes the usage of inline oil particle counters further as these become more effective, smaller in size and allow the users to get immediate results which leads to effective and efficient prognostication of the machine and equipment health that the inline oil particle counter is tracking.

Driver: Increasing Demand for Preventive Maintenance in Industrial Applications

The Inline Oil Particle Counters Market is competitive and rapidly growing due to the growing emphasis on maintenance techniques in the industry. Sectors including automotive, aerospace, oil and gas, energy industries require high velocity and pressure on the machinery and hence it becomes critical to preserve high levels of oil clarity. Monitoring and analyzing oil particle contamination works hand in hand with other preventive maintenance practices to reduce various challenges to equipment maintenance such as costly hour repair costs, tool wear, and other related downtimes. Inline oil particle counters enable companies to measure oil cleanliness, identify possible contaminants, and intervene when necessary, thus avoiding expensive breakdowns and down time due to machinery losses. While manufacturing companies remain concerned with operational dependability and costs, application of online monitoring devices including inline oil particle counters should remain in demand. The possibility to evaluate the condition of oils in the hydraulic systems, engines and industrial equipment using automated methods is always an advantage for preventing the degradation of the system’s performance with minimal chance of damaging components. The emphasis on the improved schedule of maintenance has been growing, and part and parcel of the current trend towards predictive and condition-based maintenance methods is the use of inline oil particle counters as indicators of early signs of contamination. Such a change is leading to the implementation of these systems especially in industries that have constant and high operating performance demands.

Restraint: High Initial Investment and Maintenance Costs

A major factor that act as a negative driver of Inline Oil Particle Counters Market is the factor of high implementation and maintenance cost which is generally incurred by investing on new instruments. The tools used in accurate particle detection are a bit expensive, especially to the small and medium scale industries. These systems call for capital intensive investments, and people with capital constraints; for instance, small firms might find these systems hard to acquire. Third, calibration and maintenance of these systems are important to guaranteeing the systems’ reliability, but which add to the cost. To many such industries these financial constrains may put a halt, or restrain the use of inline oil particle counters thus restricting the market growth in specific segments. In addition, the level of maintenance which goes into these systems contributes to the continuous cost factor. Because oil particle counters are employed under harsh industrial conditions, they require to stay in the best optimum state for required measurement. This may require staff training, or outsourcing the process to somebody else all of which cost extra money. However, the costs of implementing reliable equipment, including the potential delays in revenue generation, remain a major problem for increased use in the mainstream market. Therefore, understanding the cost factors underlying these systems, and the possibilities for redesigning their basic technology, is critical to extending their applicability across industries.

Opportunity: Growing Industrialization in Emerging Markets

The Inline Oil Particle Counters Market has a huge opportunity due to the ever increasing industrialization in the emerging markets. With more countries in Asia Pacific, Africa and Latin America realizing the need to develop their industrial infrastructure there is always a need for better equipment and systems that will enhance production and minimize on cases of machinery breakdown. Inline oil particle counters that are very important in determination of levels of cleanliness of lubricating oils in large machinery for industries such as automobile manufacturing industries, oil and oil producing industries, and manufacturing of energy producing equipment. Considering the fact that each of these markets is increasingly now industrializing, it is only expected that such technologies which would help prevent disruption of production would also become popular. Also, the escalating concern over sustainability and longer equipment lifespan in these areas may continue to boost inline oil particle counters. Since it is common for companies and factories to seek ways for improving productivity and minimizing maintenance expenses, this is where real time monitoring of oil contaminant is most important. The installed ambient oil particle counters enable proper monitoring of problems that are likely to occur before they cause severe failures and hence can be prevented in the long run. This together with the increasing awareness of the importance of preventive maintenance ought to spur the market on especially as these emerging economies graduate to higher form of industrial practices.

Inline Oil Particle Counters Market Segment Analysis

Inline Oil Particle Counters Market Segmented on the basis of By Product Type, By Application and By End-User.

By Product Type

o Portable

o Stationary

By Application

o Industrial

o Automotive

o Aerospace

o Energy

o Others

By End-User

o Manufacturing

o Oil & Gas

o Pharmaceutical

o Food & Beverage

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

By Product Type, Portable segment is expected to dominate the market during the forecast period

The Inline Oil Particle Counters Market, based on product type, has products classified under two categories namely Portable and Stationary Inline Oil Particle Counters products serving different customer needs. On-the-go oil particle counters are nondirectional and mobile devices that enable operators to measure the cleanliness of oil at different points or in different equipment. These portable devices are gotten high priority in era where equipment is run and installed in different locations like oil & gas industry, automotive industry or aerospace industry and so on. Portability addresses the need of performing analysis on the field or whenever a quick decision is needed, improving operational productivity and minimizing waits. The portable business is again anticipated to rise considerably due to having to monitor various circumstances on the move. Stationary oil particle counters, on the other hand, are intended to be mounted into the production or operational line for uninterrupted monitoring. These systems are real time, without interruption for analysis of oil cleanliness and intended for applications where it is necessary to continuously monitor the cleanliness of the oil to prevent equipment breakdowns, for example in industrial production, generation of power and hydraulic applications. The stationary segment seems to be advantageous from the view that it can present data of higher accuracy and detail with lesser interferences. As for this segment, while then may not be as portable as the above-mentioned devices, it caters to businesses which call for constant maintenance of the quality of the delivered oil as a part of their routine. Both types are essential for maintaining and guaranteeing the functionality and durability of the machinery, and should follow the trend of a growing demand for effective maintenance and functional capacity within the manufacturing industries.

By End-User, Manufacturing segment expected to held the largest share

Inline Oil Particle Counters market is further divided on the basis of end user industry where requirements for oil cleanliness and plant or equipment maintenance vary. In the manufacturing sector these counters are important for monitoring the condition of industrial equipments like CNC machines hydraulic systems compressors and others. Used oil which get into the manufacturing tools bring lots of problems as it causes breakdown and slow processes. In oil & gas, where working conditions are severe, clean oil is vital in order to reduce wear and allow the normal functioning of drilling, pumps and turbines. The growth in demand for minimizing shutdown time as well as avoiding failures in such critical sectors also increases the market for inline oil particle counters. Other industries such as the pharmaceutical and the food and beverage industries also play a great role in fuelling the market for inline oil particle counters. It is because these industries need to keep their oils as clean as possible from contaminants to meet quality standards as well as safety of their products. In pharmaceutical manufacturing, the contamination of oils can result in non-conformance to the standard required by the authorities and quality impact of the drugs. In the same way, in food & beverage industry, the condition of oils in production tools influences food safety and quality of products. Consequently, sustaining oil quality is quite important in meeting both the industry-standard rules and organizational productivity; such demand makes particle counters popular among these industries. A similar trend is expected in the broader industrial applications of these systems because other industries are bound to appreciate the benefits of achieving high levels of oil cleanness.

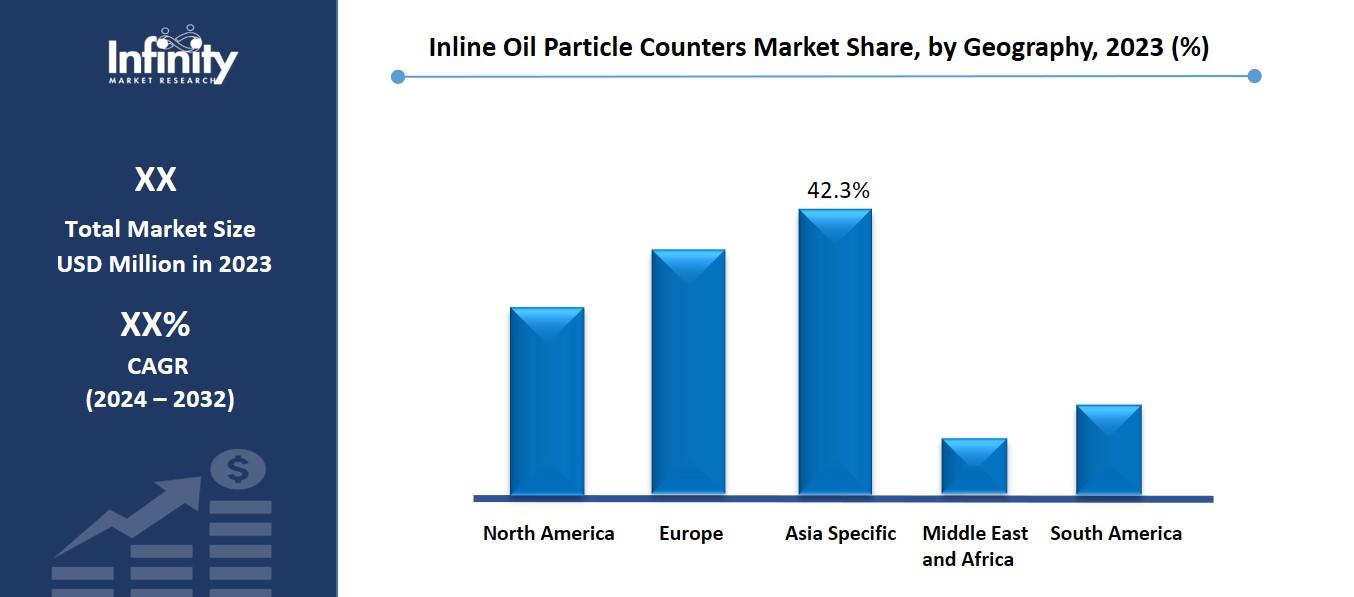

Inline Oil Particle Counters Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period.

The Inline Oil Particle Counters Market is expected to be dominated by the Asia Pacific region during the given period due to factors such as rising industrialization, enhanced manufacturing processes, and rising need for better oil management in emerging countries such as China, India, Japan, and South Korea. With industries in this region growing there is increased usage of technology for equipment maintenance and to minimized time spent on operational downtimes. There is increasing need for inline oil particle counters particularly in the automotive, aerospace and energy industries in order to optimize the performance of machinery and meet environmental standards. The simply fact that the region is already industrialised and hub of manufacturing and automobile industries will further propel the market in the near future. Furthermore, the Asia Pacific market has the added factor in that more attention is being paid to oil cleanliness and preventive maintenance in multiple industries. Ongoing industrialization is set to push up demand for high-tech monitoring devices in oil-borne contamination in hydraulic/lubrication systems. Further, policies being implemented by government aimed at green manufacturing and aim at enhancing operations of these industries will create a market demand for inline oil particle counters. Considering all these elements inserted the inline oil particle counters market’s growth trajectory in the Asia Pacific region and the place makes it among the focus region for the key market participants.

Inline Oil Particle Counters Market Share, by Geography, 2023 (%)

Active Key Players in the Inline Oil Particle Counters Market

o Spectro Scientific (USA)

o Entegris, Inc. (USA)

o Parker Hannifin Corporation (USA)

o Filtertechnik Ltd. (UK)

o OMEGA Engineering Inc. (USA)

o Palas GmbH (Germany)

o Hydac International GmbH (Germany)

o RS Components Ltd. (UK)

o Mettler Toledo (USA)

o others

Global Inline Oil Particle Counters Market Scope

|

Global Inline Oil Particle Counters Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XXX Billion |

|

Forecast Period 2024-32 CAGR: |

XXX% |

Market Size in 2032: |

USD XXX Billion |

|

Segments Covered: |

By Product Type |

· Portable · Stationary | |

|

By Application |

· Industrial · Automotive · Aerospace · Energy · Others | ||

|

By End User |

· Manufacturing · Oil & Gas · Pharmaceutical · Food & Beverage · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Rising Need for Equipment Longevity and Operational Efficiency. | ||

|

Key Market Restraints: |

· Technological Limitations in Extreme Environments. | ||

|

Key Opportunities: |

· Innovation in Compact and Cost-Effective Inline Oil Particle Counters. | ||

|

Companies Covered in the report: |

· Spectro Scientific (USA), Entegris, Inc. (USA), Parker Hannifin Corporation (USA), Filtertechnik Ltd. (UK), OMEGA Engineering Inc. (USA), Palas GmbH (Germany), Hydac International GmbH (Germany), RS Components Ltd. (UK), Mettler Toledo (USA), others. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Inline Oil Particle Counters Market research report?

Answer: The forecast period in the Inline Oil Particle Counters Market research report is 2024-2032.

2. Who are the key players in the Inline Oil Particle Counters Market?

Answer: Spectro Scientific (USA), Entegris, Inc. (USA), Parker Hannifin Corporation (USA), Filtertechnik Ltd. (UK), OMEGA Engineering Inc. (USA), Palas GmbH (Germany), Hydac International GmbH (Germany), RS Components Ltd. (UK), Mettler Toledo (USA), others.

3. What are the segments of the Inline Oil Particle Counters Market?

Answer: The Inline Oil Particle Counters Market is segmented into By Product Type, By Product Type, End User and region. By Product Type (Portable, Stationary), By Application (Industrial, Automotive, Aerospace, Energy, Others), By End-User (Manufacturing, Oil & Gas, Pharmaceutical, Food & Beverage, Others). By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Inline Oil Particle Counters Market?

Answer: Inline Oil Particle Counters are specialized devices used to measure and monitor the concentration of particulate contamination in oil systems, typically in hydraulic, lubrication, and other industrial oils. These counters work by detecting particles of various sizes within the oil flow and providing real-time data on oil cleanliness. By ensuring that oil remains free from harmful contaminants, inline oil particle counters help prevent equipment malfunctions, reduce wear and tear, and optimize the performance of machinery. They are widely used in industries such as automotive, aerospace, manufacturing, and energy, where maintaining the quality of oil is essential for ensuring the longevity and efficiency of equipment.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.