🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Insulation Coating Market

Insulation Coating Market Global Industry Analysis and Forecast (2024-2032) By type (Acrylic, Epoxy, Polyurethane, YSZ, Mullite, Others) By End Use Industry (Aerospace, Automotive, Marine, Industrial, Building & Construction, Others) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1705

Insulation Coating Market Synopsis

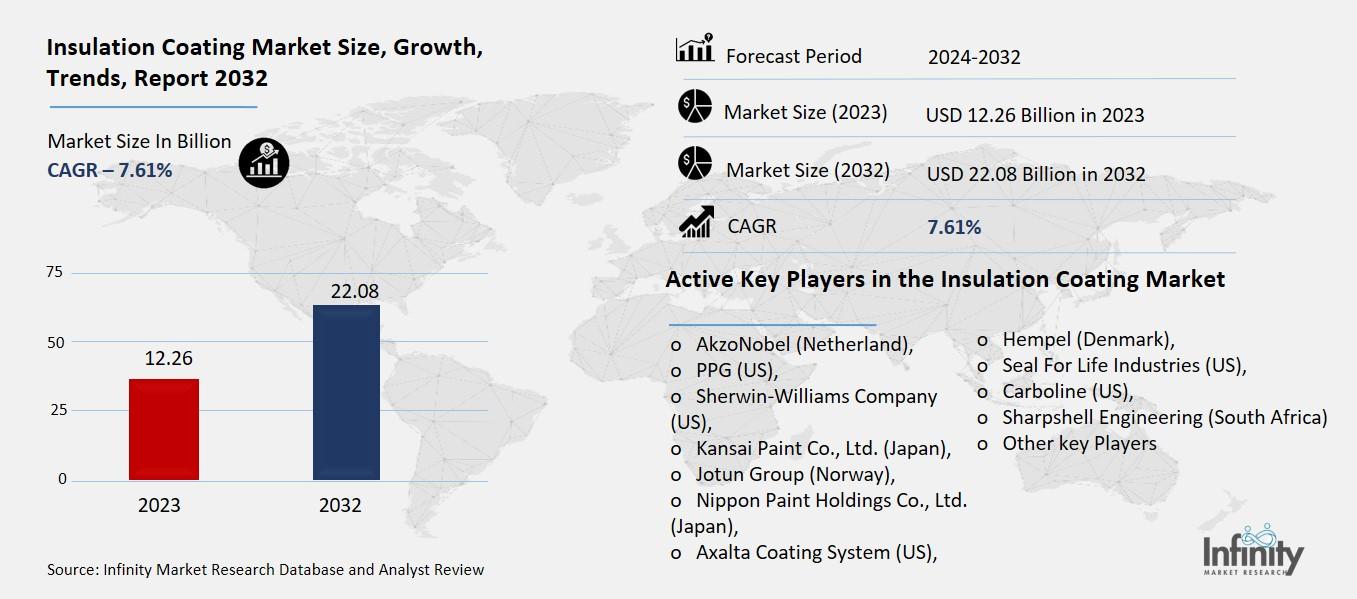

Insulation Coating Market Size Was Valued at USD 12.26 Billion in 2023, and is Projected to Reach USD 22.08 Billion by 2032, Growing at a CAGR of 7.61% From 2024-2032.

Insulation coating industry is a term used to describe the business involving in the manufacturing and supplying of modern high-performance coatings used on different surfaces to offer heat insulation, protection against corrosion and energy absorption. These coatings are developed from materials like acrylic, epoxy, polyurethane and ceramic based to inhibit heat transfer loss and militate against on-setting environmental degradation on substrates. They are used in a variety of industries, such as industrial, automotive, aerospace and construction industries where they help to improve the functionality of operations, increase equipment’s durability, and make positive changes to environmentally friendly practices. The market expansion is due to, rising energy conservation activities, higher standards in environmental legislation, and improved coating techniques.

There is vast growth recognized with the insulation coating market across the globe owing to the rise of energy consumption and environmental conservation consciousness. Thermal insulation coatings used due to thermal properties of anti-condensation and corrosion resistance are in high demand in automotive, oil and gas, marine and construction industries. These coatings are a barrier that optimizes energy use while at the same time increasing safety levels and equipment durability, cutting maintenance expenses. The need to meet escalated environmental requirements and energy requirements make the applications of insulation coatings more popular in industries. Also, growing requirements for non-interference and thin layer solutions in manufacturing and construction create extra demand for these coatings.

In construction industries, insulation coatings are emerging as the most vital components in achieving green building and energy saving in house and office buildings. Also in oil & gas and marine industry, these coatings play vital roles for safeguarding of pipe line, storage tanks and other machineries against temperature condition and natural attacks. Automotive science is also using insulation coatings to enhance the performance and efficiency of energy of automobiles. The global insulation coating market is hence being driven by polices and incentives for using energy efficient materials that are being adopted by governments and other regulatory bodies. New development in the material science concepts and environmental concern reduces hazardous material affecting floor coatings and expanding the opportunities for the market players.

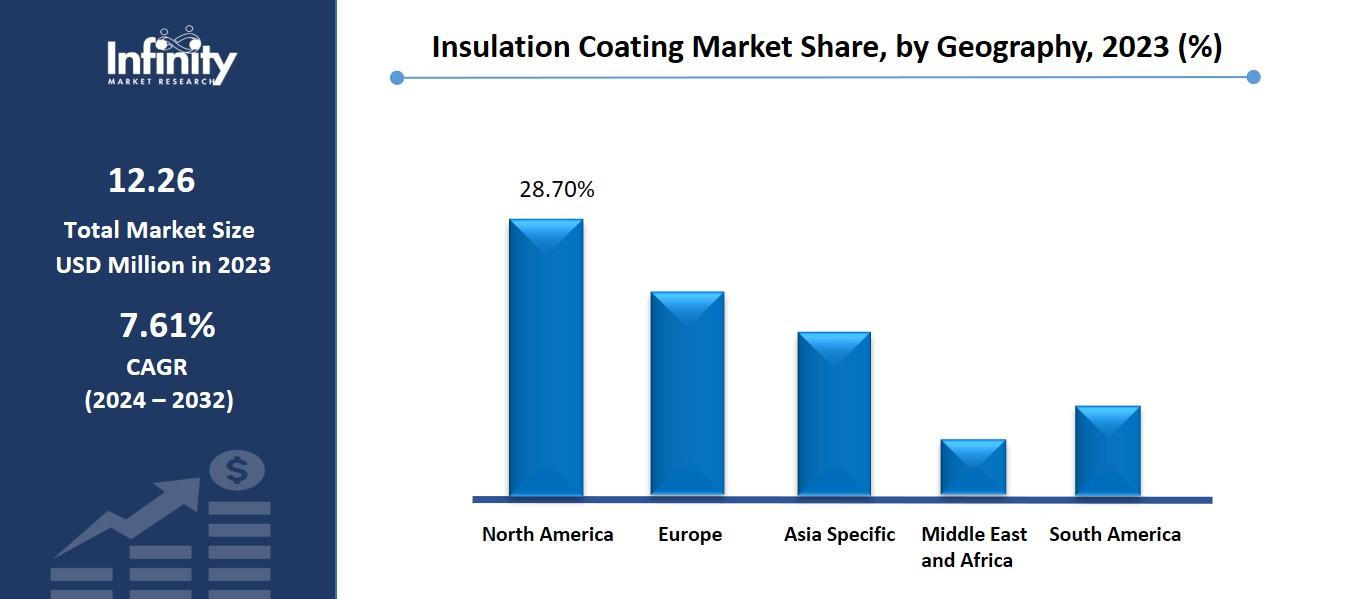

Initially, on a regional level, North America and Europe are dominating the insulation coating market due to increasing concern for advanced technology, enhanced industrial growing base, and increasing environmental regulation standards. The strong market of automotive and construction sectors in these countries has also benefited the market significantly. However, the Asia-Pacific region is pretty much on the rise and can become a large market for due to the increased rate of industrialization and urbanization as well as growing investments into the infrastructure. China and India are examples of the growing market for insulation coatings, boosted by construction activities and government emphasis for energy saving. With wind/solar/other renewable power sectors emerging across the region, there are emerging opportunities for insulation coating manufacturers too.

This means that it is a highly competitive market in which key players aim at the development of innovative products, strategic partnerships, and geographical diversification to enhance their standings in the market). With the increasing understanding of insulation coatings dependability and added value, and due to the continuous development of new technology, researchers predict increased market expansion in the next decade. Owing to the increase in environmental-consciousness and search for energy-saving products across sectors, insulation coating market has a favorable forecast for growth and development in the long term.

Insulation Coating Market Trend Analysis

Trend: Growing Adoption of Energy-Efficient Solutions in Industrial Applications

The insulation coating market is experiencing robust growth due to the increasing adoption of energy-efficient solutions across various industrial sectors. As industries aim to minimize energy consumption and reduce carbon emissions, insulation coatings are becoming a preferred choice for their exceptional thermal management capabilities. These coatings effectively minimize heat loss, improve operational efficiency, and extend the lifespan of equipment, making them indispensable in high-energy environments such as manufacturing and power plants. Their ability to deliver cost savings and enhance performance is further driving their widespread adoption, particularly in energy-intensive industries.

Moreover, the growing emphasis on sustainability and green building initiatives has significantly boosted the demand for insulation coatings. In developed regions, stringent environmental regulations and policies encouraging the use of eco-friendly materials are propelling the adoption of these coatings in construction and infrastructure projects. Insulation coatings not only contribute to energy efficiency but also align with global efforts to reduce carbon footprints. As governments and organizations prioritize sustainable development, the role of insulation coatings in achieving environmental goals continues to expand, solidifying their position as a critical component in modern industrial and construction applications.

Drivers:Growing Emphasis on Energy Efficiency and Environmental Sustainability

The increasing trend towards energy conservation and efforts to minimize emissions of greenhouse gases is a primary factor in the insulation coating business. Industries like oil & gas, automotive, construction and manufacturing have made energy conservation their topmost priority, for which insulation coatings being vital for thermal control and improved operations are now an imperative. These coatings prove especially useful in curtailing energy usage by limiting conductive heat loss and controlling temperature within devices and buildings. Further, insulation coatings are perfectly compatible with sustainable development requirements and enable industries to meet environmental standards that regulate emissions of dangerous gases and substances into the atmosphere.

Also, the applications of lightweight and friendly-on-environment materials such as aerospace, automobile industries have also pushed the need for superior insulation coatings forward. These coatings are used due to the ability to act as insulators, and protect them from moisture and corrosion making the lifespan of the material and equipment longer. Today’s industries are turning more and more to new coating which are not only functional but also more effective in terms of cost, and durability. Therefore, the use of insulation coatings is receiving a lot of attention in organizations from different industries that aim at increasing energy efficiency and enhancing sustainability standards.

Restraints: High Cost of Advanced Insulation Coatings

The main problem in today’s insulation coating is the cost of high end coatings which is relatively expensive for both the producer and the end user. The auxetic properties are normally acquired through the use of high-performance polymers and resins in their production processes as well as employing complex deposition methods all of which increase the overall cost of fabrication. In the case of small businesses or industries with rather fewer resources to invest, the relatively high costs associated with implementing these solutions such as quality reliability or performance testing may reduce the extent of demand for such services hence slowing down the overall advancement and development of the market. Another reason for high costs of these coatings is the complexity of the application process which requires training of experts and use of special equipment to apply the surface coatings which again tends to increase the expense of such formulations.

Further, professional installation of these technologies and costs which are needed for the initial investment in insulation coatings may be serious limitations to its adoption. From the viewpoint of many potential users, the acquisition cost of the material and installation far outweighs this perceived value especially in industries which are accustomed to using other conventional insulation materials such as fiberglass or foam. The resistance to switch to new, higher performing but higher cost products can also hinder the potential of advanced insulation coatings, particularly in price-sensitive environments. These all things put together form a huge barrier that slows the growth of the market and minimize chances of rapid growth.

Opportunities: Global Energy Efficiency and Sustainability Drive Market Growth

A shift to energy efficiency and sustainability is accelerating across the world, and this is the major factor that is propelling the insulation coating market, with construction, automotive and manufacturing industry leading the way. Insulation coatings have been cited to be an inexpensive solution to the power problem since they enhance thermal insulation that makes energy to be saved as well as the environment to be protected. With the prospect of higher standards being implemented by governments and regulatory authorities worldwide for energy efficient, especially in commercial developments, there exists a growing need for systems to increase energy performance of existing buildings. This regulatory pressure is a potent opportunity for insulation coating producers to deliver products that do not violate any burgeoning guidelines but allow investors and building owners to address their sustainable performance concerns without extensive, costly overhauls.

Automotive and manufacturing industries are also emerging as key players in the development of the market in question. In automotive sector these coating enhance heat to mass transfer ratio which enhances energy efficiency of vehicle In manufacturing sector, insulation coatings minimize energy utilization throughout the operational process. Continuing interest in adhering to green building certifications like LEED then increases the need for the provision of energy efficient solutions since developers and builders have to adhere to the provisions of these certifications. The technological change and availability of new nanomaterials for insulation coating make a chance for manufacturers to develop new, efficient and improved solutions for a wider range of applications in various industries.

Insulation Coating Market Segment Analysis

Insulation Coating Market Segmented on the basis of By type, By End Use Industry.

By type, Acrylic segment is expected to dominate the market during the forecast period

Making acrylic incredibly prized for their applications since it is tremendously transparent, safe against weathers and have overall flexibility.. Acrylic coatings are widely applied in automotive and Building & construction industry because of its UV ray resistance and clarity. Such characteristics explain why acrylic can be used both internal and external parts of cars and other vehicles, roofs, and signs. The stability of the material to adverse environmental factors make it desirable for use in making items that should retain their aesthetic values and functionality of shields for a long duration.• Furthermore, acrylic serves as a material of choice for structures, exhibits, and advertising where high visibility of visual message is paramount.ons. In industries such as automotive and building & construction, acrylic coatings are frequently used due to their ability to withstand UV rays and maintain clarity over time. This durability makes acrylic a preferred choice for both exterior and interior applications, including vehicle windows, roofing, and signage. The material’s strength against environmental factors contributes to its popularity in the production of items that require long-lasting visual appeal and protective features.

Moreover, acrylic is extensively used in the creation of architectural elements, displays, and signage, where its ability to offer clear, sharp visuals is essential. Because of such characteristics as versatility in design and better fabrication suitability it is becoming popular in decorative application including windows and facade as well as for the retail display. Due to growing trends for shinning appearance and functionality of the products, the usage of the acrylic-based products remains highly active, while the above mentioned benefits like the ability to prevent impact and keeping relatively light weight are other driving forces.

By End Use Industry, Aerospace segment expected to held the largest share

The aerospace industry has long been associated with very high expectations for materials that are light, strong, durable and resistant to heat. Some aircraft subsystems like the turbine engines, thermal barrier and some structural parts call for material that can endure harsh operating conditions, high pressure and temperatures, and undergo continuous vibration. Some of these materials are epoxy, YSZ (yttria-stabilized zirconia) and mullite because they can be used effectively in high-performance applications. PVD technology, epoxy, YSZ and mullite are widely applied for their high bonding strength, heat resistance, thermal insulation, and thermal shock resistance used in turbine engines and other heat sensitive parts.

The steady stream of investment in new high-performance materials for aerospace applications is due to the understandable commercial requirements of making airframes and their operation safer, more efficient and longer-lasting. As the aerospace industry strives for better fuel efficiency and durability, therefore requiring better and stronger lean materials for construction, the market for high performance materials improves. These materials have to withstand these performance criteria and also provide the safety and durability of the aircraft under operational conditions. These needs and new capabilities make the constant developments in material science necessary in order to meet them and improve aerospace engineering.

Insulation Coating Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Currently, insulating painting is being sold most in the United States and Canada because of growth in demand among commercial and industrial businesses. Its primary sectors are largely about energy saving and minimizing costs of operation, which have contributed to the market’s expansion. As the general public becomes more environmentally conscious about climate change and the conservation of energy energies, companies are seeking cost-effective solutions to improve building energy standards by purchasing better quality insulation materials. As well, the energy which is provided by the green building certifications like LEED, is also urging the use of energy efficient insulations.

New developments in insulating material have been instrumental in the development the insulation coating market in the U.S and Canada. Advancements in high efficiency laminates, and aerogel and spray foam insulations are providing improved thermal characteristics and increased overall effectiveness. What appeared particularly useful was the fact that these materials not only minimize energy heat loss but also regulate temperature and minimize noise pollution in buildings. For these commercial and industrial segment, these new age solutions will further be implemented in coming years and used for insulation coating driving the market growth of both the countries along with growing energy proficient technologies in construction business in the region.

Insulation Coating Market Share, by Geography, 2023 (%)

Active Key Players in the Insulation Coating Market

o AkzoNobel (Netherland),

o PPG (US),

o Sherwin-Williams Company (US),

o Kansai Paint Co., Ltd. (Japan),

o Jotun Group (Norway),

o Nippon Paint Holdings Co., Ltd. (Japan),

o Axalta Coating System (US),

o Hempel (Denmark),

o Seal For Life Industries (US),

o Carboline (US),

o Sharpshell Engineering (South Africa)

o Other key Players

Global Insulation Coating Market Scope

|

Global Insulation Coating Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 12.26 Billion |

|

Forecast Period 2024-32 CAGR: |

7.61% |

Market Size in 2032: |

USD 22.08 Billion |

|

|

By type |

· Acrylic · Epoxy · Polyurethane · YSZ · Mullite · Others | |

|

By End Use Industry |

· Aerospace · Automotive · Marine · Industrial · Building & Construction · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Emphasis on Energy Efficiency and Environmental Sustainability | ||

|

Key Market Restraints: |

· High Cost of Advanced Insulation Coatings | ||

|

Key Opportunities: |

· Global Energy Efficiency and Sustainability Drive Market Growth | ||

|

Companies Covered in the report: |

· AkzoNobel (Netherland), PPG (US), Sherwin-Williams Company (US), Kansai Paint Co., Ltd. (Japan), Jotun Group (Norway), Nippon Paint Holdings Co., Ltd. (Japan), Axalta Coating System (US), Hempel (Denmark), Seal For Life Industries (US), Carboline (US), Sharpshell Engineering (South Africa) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Insulation Coating Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Insulation Coating Market?

Answer: AkzoNobel (Netherland), PPG (US), Sherwin-Williams Company (US), Kansai Paint Co., Ltd. (Japan), Jotun Group (Norway), Nippon Paint Holdings Co., Ltd. (Japan), Axalta Coating System (US), Hempel (Denmark), Seal For Life Industries (US), Carboline (US), Sharpshell Engineering (South Africa) and Other Major Players.

3. What are the segments of the Insulation Coating Market?

Answer: The Insulation Coating Market is segmented into By type, By End Use Industry and region. By type, the market is categorized into Acrylic, Epoxy, Polyurethane, YSZ, Mullite, Others. By End Use Industry, the market is categorized into Aerospace, Automotive, Marine, Industrial, Building & Construction, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Insulation Coating Market?

Answer: The insulation coating market refers to the industry focused on the production and distribution of advanced coatings designed to provide thermal insulation, corrosion resistance, and energy efficiency for various surfaces. These coatings are formulated with materials such as acrylic, epoxy, polyurethane, and ceramic-based compounds to reduce heat transfer, minimize energy loss, and protect substrates from environmental damage. They find applications across diverse sectors, including industrial, automotive, aerospace, and construction, where they enhance operational efficiency, extend equipment lifespan, and contribute to sustainable practices. The market's growth is driven by increasing energy conservation initiatives, stringent environmental regulations, and advancements in coating technologies.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.