🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Low-Temperature Cofired Ceramics Market

Low-Temperature Cofired Ceramics Market Global Industry Analysis and Forecast (2024-2032) By Type (Standard LTCC and Modified LTCC) By Application (Electronic Components, Telecommunication, Automotive, Medical Devices, Defense and Aerospace) and Region

Jan 2025

Semiconductor and Electronics

Pages: 138

ID: IMR1574

Low-Temperature Cofired Ceramics Market Synopsis

Low-Temperature Cofired Ceramics Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

LTCC stands for Low-Temperature Cofired Ceramics and the market related to this product area is defined as the segment of the industry that deals with ceramics to be fired at a lower temperature than the conventional ceramics. These materials are employed in electronics industry and items including sensors, capacitors, inductors and substrates because of high electrical conductivity, high thermal conductivity and high endurance. LTCC technology has continued to capture the market in the production of HDI’s and miniaturized circuits that reduce size and complexity for applications in telecommunications, automobiles, medical equipment and consumer goods. It has been due to the customers who need smaller sized, more dependable and higher performing electronics products in market.

The Low-Temperature Cofired Ceramics (LTCC) market is continuously growing as more and more electronic industries seek high operating compact electronic devices and instruments. While LTCC materials can be used at comparatively higher temperatures, they are particularly valued for their lower operating temperatures, which is important in heat sensitive circuits. They are widely employed in creation of multi-layer printed circuit boards, semiconductor devices and integrated circuits and various sensors and high-frequency devices. Due to its high thermal stability, low dielectric loss and excellent mechanical strength LTCC is very important in areas such as telecommunication, automobile, aerospace and medical fields. Because LTCC enables high density function integration within small packages, it aligns well with the miniature size situation in electronics where demand continues to rise. Specifically, 5G commercialization, the EV charging facility necessities, constant progress in medical apertures and implants, etc., are scenarios that boost up the LTCC solutions’ demand.

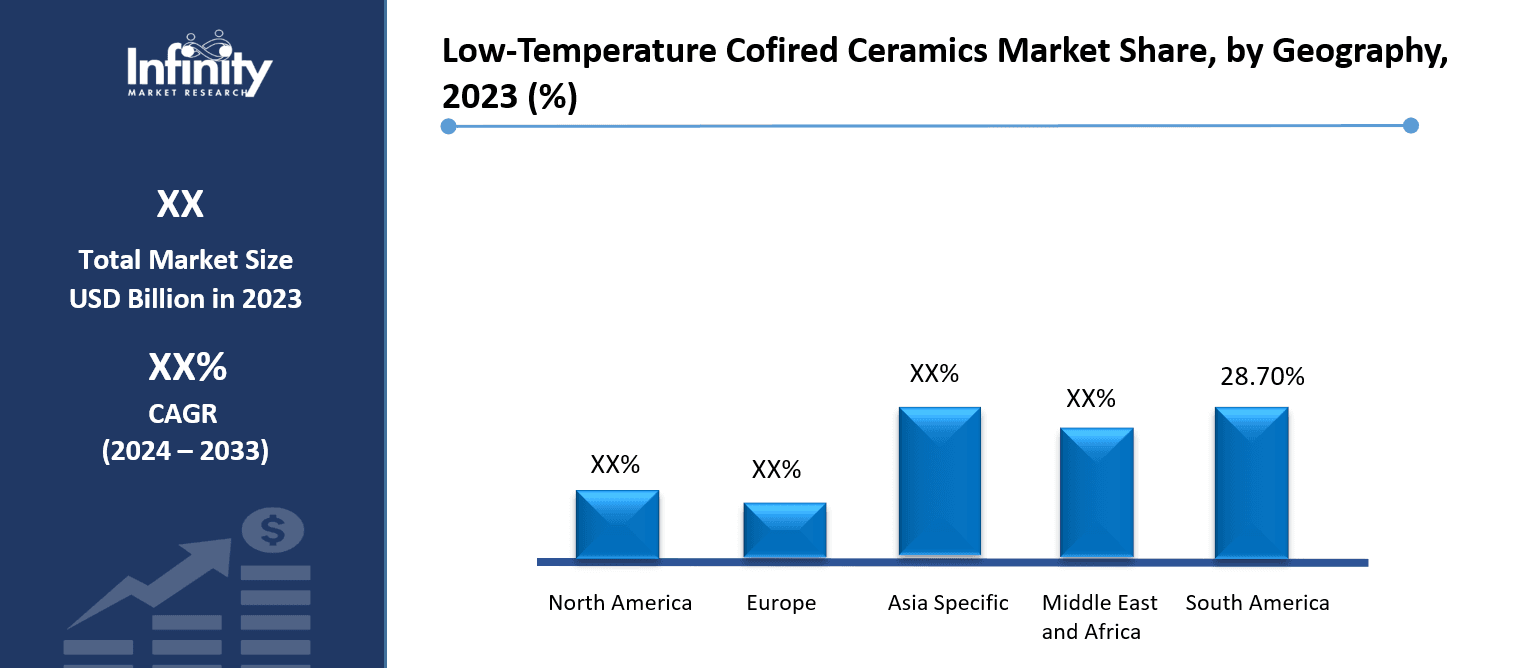

Among the regions, Asia-Pacific region stands at the forefront amongst other regions in relation to the growth of LTCC market which is due to the established electronics manufacturing industries in Asia which include China, Japan and South Korea. In telecommunications, consumer electronics, and electric vehicles the region is most advanced utilizing the LTCC’s properties for creating complex electronic components. 5G infrastructure and IoT devices have created stringent needs for LTCC in the communications segment, at the same time, electric vehicles and ADAS systems in automobiles make the LTCC’s applications broader. In North America and Europe, LTCC materials are also used and being accepted for use in aerospace, defence and medical fields where high reliability of the components is mandatory and can be an issue of life and death. These regions are committed to pour large sums of money into research and development in order to improve on the functions of the LTCC material and also to bring down the manufacturing costs so as to extend its uses. Hence, on-going technological breakthroughs in manufacturing processes make LTCC to penetrate enhanced markets including wearable electronics and smart health systems, with prospects for market stakeholders of high yields. As the need for more multifunctional, reliable and small size electronics components grows, the LTCC market has the potential to remain and become a growth market in the future established in the mature, developing markets as well as developing.

Low-Temperature Cofired Ceramics Market Trend Analysis

Trend

Introduction to the Low-Temperature Cofired Ceramics (LTCC) Market

Piezoelectric ceramic for multilayer ceramic, multilayer ceramic for low-temperature cofired ceramics (LTCC) together are significantly growing market as more and more industries demand various advanced electronics parts in transportation systems, telecommunication, auto- mobiles, medical fields, and home appliances. LTCC materials are desireable for their superior electrical characteristics, high thermal dissipation and the fact that they can be directly integrated with other parts. These features make them ideal for modern electronics were the demand of components of high reliability and performance, together compact in size, continue to rapidly increase. In line with the current trends in electronics toward miniaturization, LTCC materials have also found a useful application in that they can provide condensed circuitry including capacitors, inductors and resistors thus meeting the complexity of denser circuitry design.

In addition, the continual need for compact and power-efficient has enhanced energy usage of LTCC in numerous applications. Newer solutions like 5G, and electric vehicles (EVs) are putting increased pressure on the LTCCs as the call for next-generation technologies get louder. This is the place where high-frequency and low loss dielectric materials are required and LTCCs are perfectly designed to fulfill the 5G technology needs of the telecommunication industry. Likewise, LTCCs are being considered for electric and autonomous cars as the automotive industry adjusts for the new complex electronic systems, in which LTCCs can offer the level of permanence needed for these applications. As there are many opportunities for bettering the properties of the LTCC and cutting the costs of its production, the market is expected to steadily develop and provide improved market opportunities in a broader range of industries.

Drivers

Miniaturization in Electronic Devices Driving LTCC Market Growth

A key factor driving growth of the LTCC market is the need for integration of features of electronic devices. With the catapulted demand for miniaturized, lightweight, efficient electronics, there is a concurrent need for developing innovative and efficient components that are large-scale integrated, but are not compromised for functionality. LTCC material assists in this through the use of multifunction circuit modules on a material package that will help manufacturers to design compact devices. This miniaturization trend is more apparent in industries such as telecommunication, automobile, electronics, etc., where space and optimization of design plays an important role.

In telecommunications technologies where size is minimal, space-saving is essential in automotive and consumer electronics, and as electronics continue to provide diverse functionality in small form factors. These industries can then use the LTCCs to satisfy their space and performance needs because an LTCC has the capability of offering high density interconnection and embedding multiple layers of passive components such as capacitors, resistors and inductors in one ceramic carrier. This in turn causes the overall size and mass of the devices to decrease while at the same keeping the necessary electrical performance. Because of this, the LTCCs have emerged as a critical material in the development of the newer generation electronics which inturn is helping the market to grow in terms of application across industry.

Restraints

High Manufacturing Costs

The major issues affecting the LTCC market currently include the high cost of manufacturing these materials as compared to other more conventional materials. LTCC manufacturing is a complex process that includes micro-co-firing of ceramics with metal electrodes, which requires particular equipment and suitable conditions. By so doing, these technical requirements result in high costs of production in comparison to other materials. However, such specialized machinery require capital investment for the creation of LTCC products and this increases the overall cost of production hence making the LTCC products to be expensive than simple ceramics or other materials used in similar application.

The above increased cost can act as a major disadvantage especially to industries that require efficiency and affordability through implementation of LTCC technology. The key industries that have a large number of consumers and where the price factor is critical to success are telecommunications, automobiles, and mainly electronics with a focus on consumer electronics, may face a problem in making a rational decision of investing in LTCC materials. For this reason, LTCC technology may not penetrate deeply into these markets as firms in these industries look for cheaper solutions. This challenge prevents the use of LTCC in other electronics and automobile systems where LTCC outcompets other Ink-Jet techniques due to its features such as high-frequency performance and miniaturization.

Opportunities

Miniaturization and Integration in Consumer Electronics

Currently, the LTCC market has a number of opportunities attributed to the continuously increasing need for miniaturization and integration of various electronic devices. LTCC materials have a great application in the manufacturing of the RF devices, sensors, automotive electronics, and medical electronics; as these industries demand smaller, compact and reliable components. As the trend for smartphones, wearables, smart home devices grows steadily, the market calls for LTCC solutions that are capable of handling more functions in compact circuits. This trend presents a good chance to manufacturers to optimize and design LTCC components that will be more cheap and effective in meeting the increasing demand from the Electronics industry.

Moreover, materials in LTCC technology are steadily growing in demand in cars especially in newly developed electric vehicles (EVs) and self-driving facilities. These materials are crucial to manufacturing sensors, controllers, and power electronic devices in electric vehicles and smart transport systems, such as ADAS. These changes in the automotive industry represent an opportunity for LTCC manufacturers because the car’s electric and smart technologies will require durable high-performance parts to be integrated into the vehicle. At the same time, growing dependence on sophisticated devices in the healthcare industry for implantable sensors and diagnostics also provides a solid background for the LTCC market, making these materials critically important to create future-focused solutions in healthcare.

Low-Temperature Cofired Ceramics Market Segment Analysis

Low-Temperature Cofired Ceramics Market Segmented on the basis of By Type, By Application.

By Type

o Standard LTCC

o Modified LTCC

By Application

o Electronic Components

o Telecommunication

o Automotive

o Medical Devices

o Defense and Aerospace

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Standard LTCC segment is expected to dominate the market during the forecast period

Conventional LTCC (Low-Temperature Co-fired Ceramics) is a high performance and cost-effective substrate material which is suitable for general electronic applications. Its major properties of electrical conductivity, mechanical strength, and thermal stability qualify its uses in consumer electronics, automotive applications, and telecommunication equipment. Standard LTCC material is made from co-firing process where mixed metal/ceramic powders at low temperature, the above multi-layer substrate substrate with complex circuit design is easily to establish. It makes it ideal for application with high rating density small form factors components requirements. Therefore, LTCC standard remains to be a significant commodity in electronics industries mostly in areas where minimal cost of production is an important aspect.

Standard LTCC offers cost advantages as well as product density and given the increasing trend towards developing compact, high performance electronic systems, there are expected to continue to be demand for it. It is cheap to use in manufacturing and has the added means of being able to accommodate the production of small components that are desired in many industries. As more products incorporate efficient electronics into their designs, including high-powered and smaller devices, the market for standard LTCC will burgeon as well. This is especially the case especially with industries like telecommunication, automotive industry and electronics where high performance and reliable material is needed by virtue of advancing technological needs.

By Application, Electronic Components segment expected to held the largest share

LTCC abbreviated as Low-Temperature Co-fired Ceramics is inevitably used in the fabrication of different kinds of passive parts like capacitors, inductors,& resistors. The characteristic of handling high density multi-layer cont conductive materials with regard to independence of layers makes it useful in portable electronics. This characteristic is especially valuable as the situation with miniaturization and increasing the density of electronics is developing progressively. LTCC substrates can support multilayer and high-density designs that remain challenging to implement with traditional printed circuit board (PCB) techniques, which makes LTCC critical for modern electronics. Additionally, by implication, LTCC material provides that these components meet required thermal and electrical performance under severe operating conditions.

Since electronic systems are smaller with sophisticated functionality the application of LTCC technology is expected to increase significantly. Smartphones, wearable technology products, and smart home devices demand integrated circuits that offer small size, low power consumption and high signal control capabilities. Other areas such as automotive systems involve in electric vehicles (EVs) and self-driving technologies, the application of LTCC which offers capability of handling complex electronics yet exhibit endurance and efficiency at higher operating temperature. Since industries are demanding higher levels of electronic systems integrated in to their products, the LTCC has a immense potential for grown as an essential solution provider for the electronic components to be incorporated in to next generation devices.

Low-Temperature Cofired Ceramics Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Currently, the North American Low-Temperature Cofired Ceramics (LTCC) market is growing sharply based on the considerable investments in the technology advancement, especially in aerospace and defense industries. LTCC materials find a vital application in manufacturing of high reliability components employed in sophisticated systems such as radar, satellite communications, and sensors. These sectors require materials that afford reliability, miniaturization, and frequency and high-temperature features that LTCC materials offer. The incorporation of such key manufacturing companies and numerous research and development centers also contributes to the development of this particular market and the constant advancements made in LTCC technology expand its applicability across numerous sectors.

Further, there is a growing demand for LTCC materials in North America because of the trends towards integration of miniaturized electronic devices and high frequency devices in telecommunications and modern consumer electronics products. Automotive industry, especially the development of electric vehicle and self-driving technology, is another source for this growth because LTCC material is a key component for the miniaturization and performance improvement of automobile parts. Thus, there is steady development of the system in question if talking about the future, where the focus remains on the development of new generation technologies and corresponding infrastructure in the field of LTCC market and their worthy demand throughout the telecommunication, automotive, and consumer electronics industries.

Low-Temperature Cofired Ceramics Market Share, by Geography, 2023 (%)

Active Key Players in the Low-Temperature Cofired Ceramics Market

o Murata Manufacturing Co., Ltd.

o Taiyo Yuden Co., Ltd.

o KOA Corporation

o Kyocera Corporation

o Samsung Electro-Mechanics

o Honda Chemical Co., Ltd.

o Leatec Fine Ceramics Co., Ltd.

o Other key Players

Global Low-Temperature Cofired Ceramics Market Scope

|

Global Low-Temperature Cofired Ceramics Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Type |

· Standard LTCC · Modified LTCC | |

|

By Application |

· Electronic Components · Telecommunication · Automotive · Medical Devices · Defense and Aerospace | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Miniaturization in Electronic Devices Driving LTCC Market Growth | ||

|

Key Market Restraints: |

· High Manufacturing Costs | ||

|

Key Opportunities: |

· Miniaturization and Integration in Consumer Electronics | ||

|

Companies Covered in the report: |

· Murata Manufacturing Co., Ltd., Taiyo Yuden Co., Ltd., KOA Corporation, Kyocera Corporation, Samsung Electro-Mechanics, Honda Chemical Co., Ltd., Leatec Fine Ceramics Co., Ltd. and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Low-Temperature Cofired Ceramics Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Low-Temperature Cofired Ceramics Market?

Answer: Murata Manufacturing Co., Ltd., Taiyo Yuden Co., Ltd., KOA Corporation, Kyocera Corporation, Samsung Electro-Mechanics, Honda Chemical Co., Ltd., Leatec Fine Ceramics Co., Ltd. and Other Major Players.

3. What are the segments of the Low-Temperature Cofired Ceramics Market?

Answer: The Low-Temperature Cofired Ceramics Market is segmented into By Type, By Application and region. By Type, the market is categorized into Standard LTCC and Modified LTCC. By Application, the market is categorized into Electronic Components, Telecommunication, Automotive, Medical Devices, Defense and Aerospace. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Low-Temperature Cofired Ceramics Market?

Answer: The Low-Temperature Cofired Ceramics (LTCC) market refers to the sector that involves the production and application of ceramics designed to be fired at lower temperatures compared to traditional ceramics. These materials are typically used in electronic devices and components, such as sensors, capacitors, inductors, and substrates, due to their excellent electrical properties, high thermal conductivity, and durability. LTCC technology is favored in the manufacturing of high-density interconnects and miniaturized electronic circuits, enabling compact and efficient designs for advanced applications in telecommunications, automotive, medical devices, and consumer electronics. The market is driven by the demand for more compact, reliable, and high-performance electronic products.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.