🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Magnesium-Based Hydrogen Storage Materials Market

Global Magnesium-Based Hydrogen Storage Materials Market (By Type, Pure Magnesium, Magnesium-Based Composite, and Magnesium-Based Alloy; By Application, Fuel Cells, Cooling Devices, Rechargeable Batteries, and Other Applications; By Region and Companies), 2024-2033

Dec 2024

Chemicals and Materials

Pages: 138

ID: IMR1376

Magnesium-Based Hydrogen Storage Materials Market Overview

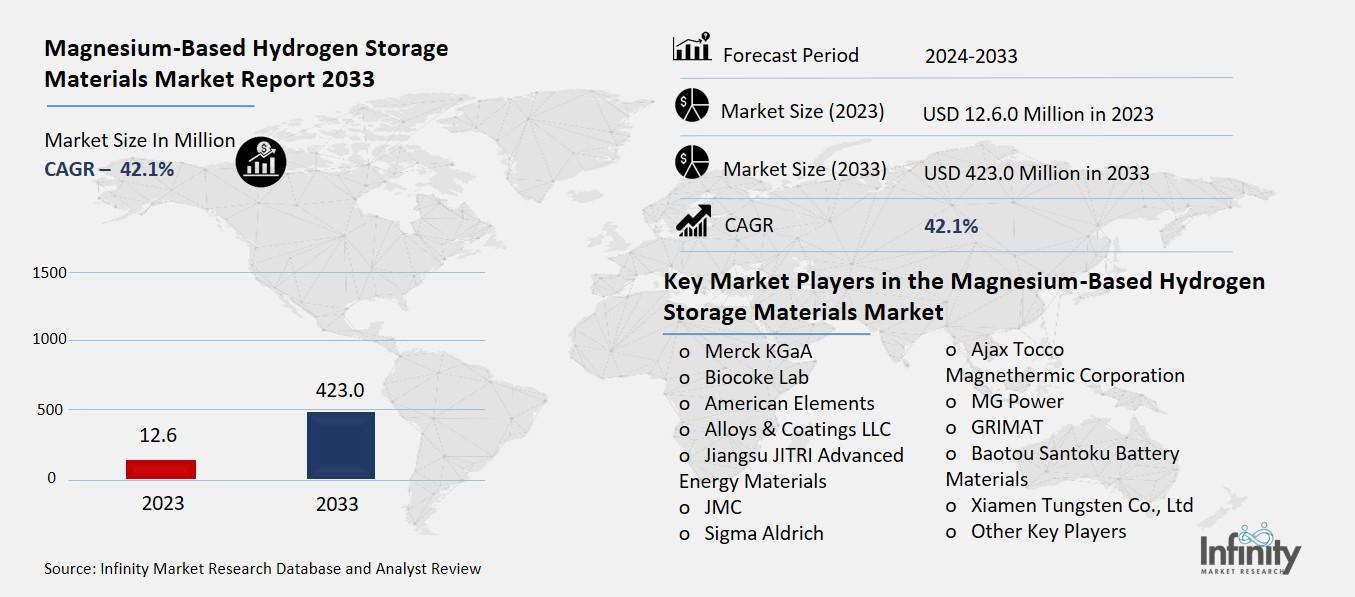

Global Magnesium-Based Hydrogen Storage Materials Market acquired the significant revenue of 12.6 Million in 2023 and expected to be worth around USD 423.0 Million by 2033 with the CAGR of 42.1% during the forecast period of 2024 to 2033. The material for hydrogen storage based on magnesium and its alloy is a rather new branch of the hydrogen market but is necessary due to safety and efficiency necessity in the fuel cell technologies and hydrogen energy. Among these elements, Magnesium (Mg) has recently attract high attention since this element has high hydrogen volumetric density and can absorb and desorb hydrogen reversibly. Out of all the materials in the category of complex hydrides, Magnesium hydride (MgH2) has received the most attention due to its potential for high hydrogen storage capacity that ranges theoretically fourth generation hydrogen storage systems, which makes it appropriate for use in hydrogen powered vehicles and energy storage.

However, several issues are associated with this approach; first, the desorption temperature is relatively high, and second, the kinetics of hydrogen release are not very fast. Current research involves a relentless search of how the efficiency and cost of using magnesium in the creation of storage materials can be enhanced through modifying the composition or the nanostructure of magnesium.

Drivers for the Magnesium-Based Hydrogen Storage Materials Market

Rising Demand for Clean Energy

Energy and carbon reduction remain high on the global agenda as countries work towards decarbonization and a shift to renewable energy, thus the push for efficient storage of hydrogen. Hydrogen has been seen as a potential solution to the problem of climate change and the elimination of fossil fuels from economies’ energy mix, as countries need to move to cleaner sources of energy and hydrogen is suitable for energy storage and transport. For instance, hydrogen fuel cells are viewed as a real solution for energy transportation needs, powering automobile engines, industries and even whole cities, creating mere water vapor as an emission.

Although hydrogen is one of the clean energy sources, it faces the problem of storage and safe storage in particular. Therefore, to develop sufficient and secure stocks of hydrogen particularly for transportation and heavy duty energy applications, advanced storage mechanisms are relevant. Necessary advance in hydrogen storage systems, for instance, magnesium or other high density material based, are being required for Hydrogen to be used effectively as a green energy carrier for a better and sustainable energy solution.

Restraints for the Magnesium-Based Hydrogen Storage Materials Market

Slow Kinetics of Hydrogen Absorption and Desorption

The slow reaction rates for hydrogen absorption and desorption in magnesium-based materials present significant challenges for their practical use in real-time applications. While magnesium hydride (MgH2) offers a high theoretical hydrogen storage capacity, the process of absorbing and releasing hydrogen occurs at a relatively slow pace. This sluggish kinetics limits the material's efficiency, especially in applications that require rapid hydrogen uptake and release, such as in fuel cell vehicles or energy storage systems where performance and responsiveness are critical. The slow release of hydrogen also means that additional time and energy are needed to heat or activate the material, further hindering its efficiency.

Opportunity in the Magnesium-Based Hydrogen Storage Materials Market

Technological Advancements and Research

Ongoing research into improving the performance of magnesium hydride (MgH2) through alloying, nanostructuring, and other methods presents significant opportunities for breakthrough innovations in hydrogen storage efficiency. One of the primary challenges with magnesium hydride is its high desorption temperature and slow hydrogen absorption and release rates. Researchers are exploring various strategies to address these issues. Alloying magnesium with other elements, such as calcium or aluminum, can lower the desorption temperature and improve the kinetics of hydrogen release, making the material more practical for real-world applications. Nanostructuring, on the other hand, involves reducing the size of magnesium particles to enhance their surface area, which can accelerate the hydrogen absorption and desorption processes.

Trends for the Magnesium-Based Hydrogen Storage Materials Market

Research into Magnesium Alloys and Nanostructures

There is a growing trend in enhancing the properties of magnesium-based materials through alloying and nanotechnology to overcome current limitations, such as high desorption temperatures and slow kinetics. Magnesium hydride, while offering high hydrogen storage capacity, suffers from slow hydrogen absorption and release rates, as well as a high temperature requirement for hydrogen desorption. To address these challenges, researchers are increasingly turning to alloying techniques, where magnesium is combined with other elements like calcium, zirconium, or titanium. These alloys can lower the desorption temperature and improve the material's overall kinetics, making hydrogen storage more feasible for practical applications, including fuel cell vehicles and large-scale energy storage. Nanotechnology is also playing a critical role, as reducing the particle size of magnesium and creating nanostructured materials can dramatically increase surface area, enhancing the rate of hydrogen absorption and desorption.

Segments Covered in the Report

By Type

o Pure Magnesium

o Magnesium-Based Composite

o Magnesium-Based Alloy

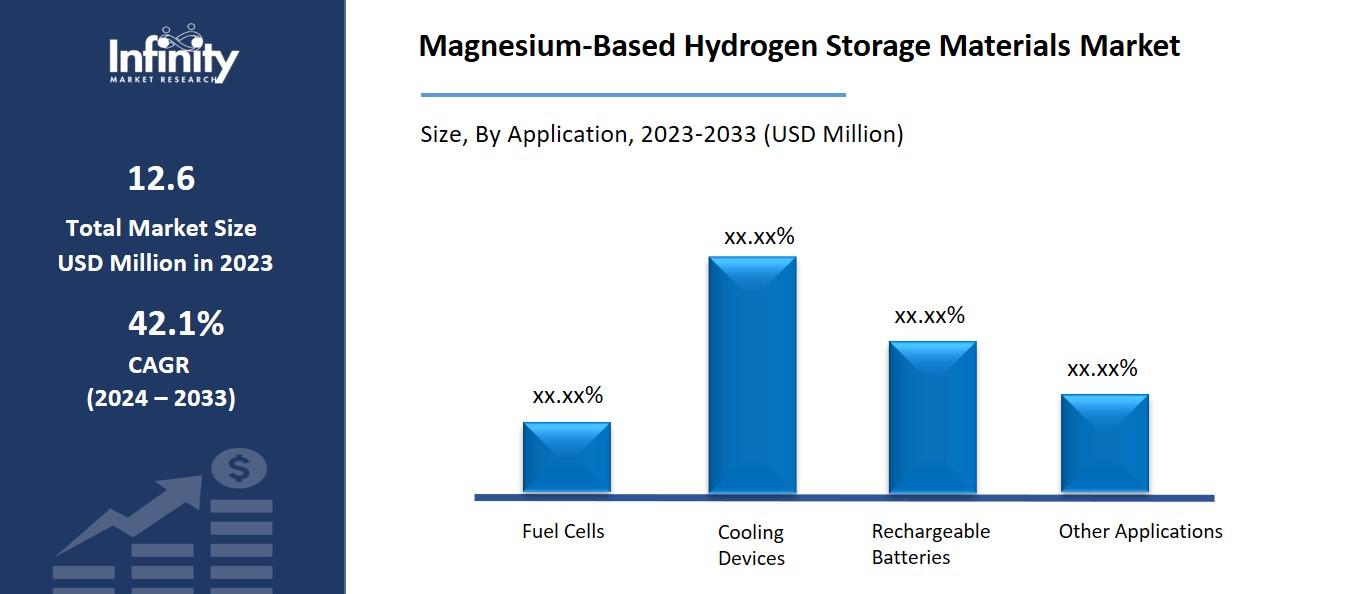

By Application

o Fuel Cells

o Cooling Devices

o Rechargeable Batteries

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into pure magnesium, magnesium-based composite, and magnesium-based alloy. Among these, buttercream frosting segment acquired the significant share in the market due to the enhanced properties that magnesium alloys offer, such as improved hydrogen storage performance and lower desorption temperatures compared to pure magnesium. Magnesium alloys are often combined with other elements like titanium, aluminum, and zirconium, which help optimize the hydrogen absorption and release kinetics, making them more suitable for real-world applications like fuel cell vehicles and large-scale energy storage systems. The ability to enhance the material's performance through alloying makes magnesium-based alloys more attractive for industrial use, driving their dominance in the hydrogen storage market.

By Application Analysis

On the basis of application, the market is divided into fuel cells, cooling devices, rechargeable batteries, and other applications. Among these, commercial held the prominent share of the market due to the growing adoption of hydrogen fuel cell technology in various industries, particularly in transportation (e.g., hydrogen-powered vehicles) and stationary energy systems. Fuel cells rely on hydrogen as a clean energy source, and efficient hydrogen storage is critical for their performance. Magnesium-based materials, especially alloys, offer high volumetric hydrogen storage density, making them an ideal choice for storing the hydrogen required for fuel cells.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 32.1% of the market due to the region's strong focus on developing clean energy technologies, significant government support for hydrogen infrastructure, and rapid adoption of hydrogen-powered vehicles. Countries like Japan, South Korea, and China are at the forefront of hydrogen technology research and development, investing heavily in hydrogen fuel cells, storage solutions, and the broader hydrogen economy.

Japan, for example, has been a pioneer in hydrogen technology, with major automotive manufacturers like Toyota and Honda leading the development of hydrogen fuel cell vehicles, which require efficient storage systems. Furthermore, China’s ambitious goals for reducing carbon emissions and transitioning to renewable energy sources have spurred demand for hydrogen storage solutions, making it a major player in the market.

Competitive Analysis

The competitive landscape of the magnesium-based hydrogen storage materials market is characterized by a mix of established players and innovative startups, all working to develop efficient, scalable, and cost-effective hydrogen storage solutions. Major companies, including Hydrogenious LOHC Technologies, Magnesium Elektron, and General Electric, are at the forefront, leveraging their expertise in materials science and hydrogen technologies to advance magnesium-based storage systems. These players are heavily investing in research and development to improve the hydrogen absorption/desorption rates and reduce the high desorption temperatures associated with magnesium hydride.

Key Market Players in the Magnesium-Based Hydrogen Storage Materials Market

o Merck KGaA

o Biocoke Lab

o American Elements

o Alloys & Coatings LLC

o Jiangsu JITRI Advanced Energy Materials

o JMC

o Sigma Aldrich

o Ajax Tocco Magnethermic Corporation

o MG Power

o GRIMAT

o Baotou Santoku Battery Materials

o Xiamen Tungsten Co., Ltd

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 12.6 Million |

|

Market Size 2033 |

USD 423.0 Million |

|

Compound Annual Growth Rate (CAGR) |

42.1% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Million) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Merck KGaA, Biocoke Lab, American Elements, Alloys & Coatings LLC, Jiangsu JITRI Advanced Energy Materials, JMC, Sigma Aldrich, Ajax Tocco Magnethermic Corporation, MG Power, GRIMAT, Baotou Santoku Battery Materials, Xiamen Tungsten Co., Ltd, and Other Key Players. |

|

Key Market Opportunities |

Technological Advancements and Research |

|

Key Market Dynamics |

Rising Demand for Clean Energy |

📘 Frequently Asked Questions

1. Who are the key players in the Magnesium-Based Hydrogen Storage Materials Market?

Answer: Merck KGaA, Biocoke Lab, American Elements, Alloys & Coatings LLC, Jiangsu JITRI Advanced Energy Materials, JMC, Sigma Aldrich, Ajax Tocco Magnethermic Corporation, MG Power, GRIMAT, Baotou Santoku Battery Materials, Xiamen Tungsten Co., Ltd, and Other Key Players.

2. How much is the Magnesium-Based Hydrogen Storage Materials Market in 2023?

Answer: The Magnesium-Based Hydrogen Storage Materials Market size was valued at USD 12.6 Million in 2023.

3. What would be the forecast period in the Magnesium-Based Hydrogen Storage Materials Market?

Answer: The forecast period in the Magnesium-Based Hydrogen Storage Materials Market report is 2024-2033.

4. What is the growth rate of the Magnesium-Based Hydrogen Storage Materials Market?

Answer: Magnesium-Based Hydrogen Storage Materials Market is growing at a CAGR of 42.1% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.