🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Magnet Market

Magnet Market (By Type (Ferrite, Neodymium Iron Boron (NdFeB), Aluminium Nickel Cobalt (AlNiCo), Samarium Cobalt (SmCo)), By Application (Computer Hard Disk Drives (HDD), CD, DVD, Hybrid Electric Vehicles, Electric Bicycles, Heating, Ventilating, and Air Conditioners (HVAC), Wind Turbines, Other Applications), By Region and Companies)

Jun 2024

Chemicals and Materials

Pages: 132

ID: IMR1089

Magnet Market Overview

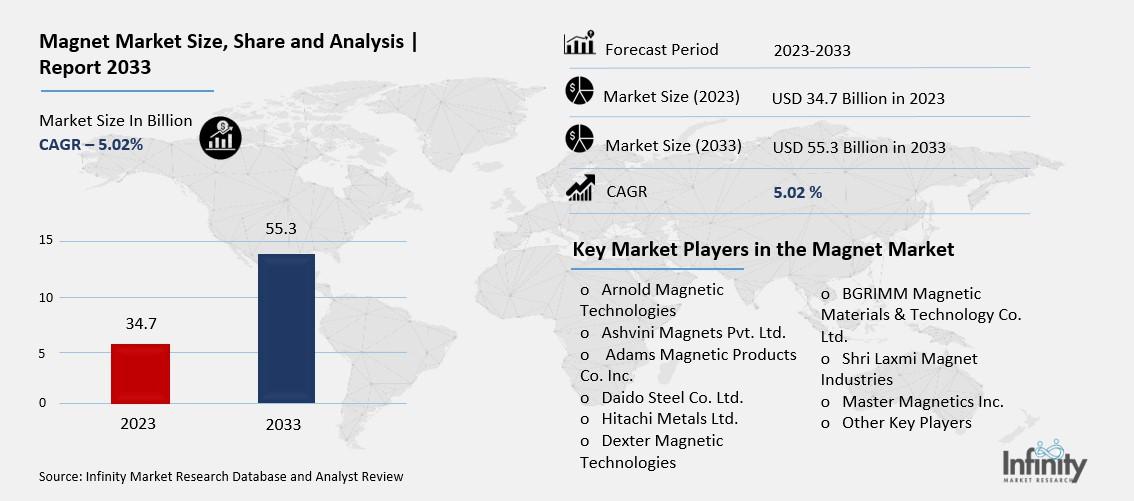

Global Magnet Market size is expected to be worth around USD 55.3 Billion by 2033 from USD 34.7 Billion in 2023, growing at a CAGR of 5.02% during the forecast period from 2023 to 2033.

Many household products, including vacuum cleaners, lawnmowers, garden tractors, and refrigerators, employ magnets. Additionally, they are essential to the operation of many medical devices, including MRI scanners, hearing aids, and ventricular assist devices (VAD). In addition, their high magnetic strength enables significant product performance improvements, production cost reductions, and product downsizing.

Aside from this, reducing greenhouse gas emissions following the Kyoto Protocol is quickly becoming a top priority on the international agenda. Because of this, governments throughout the world are concentrating on utilizing energy-saving tools and technology that might assist them in lowering their carbon footprints.

Additionally, manufacturers have unveiled magnetic levitation, or maglev, a relatively new transportation technology that allows non-contacting vehicles to be securely propelled, guided, and suspended above a guideway by magnetic fields at speeds of 250 to 300 miles per hour or more. Magnet demand is expected to be high shortly due to the potential growth of this technology.

Drivers for the Magnet Market

Increasing Demand in Electronics and Consumer Goods:

One of the primary drivers for the magnet market is the increasing demand for magnets in electronics and consumer goods. Magnets are essential components in a wide range of electronic devices, including smartphones, computers, and home appliances. They are used in speakers, hard drives, electric motors, and sensors, among other applications. As the electronics industry continues to grow and innovate, the demand for smaller, more powerful magnets that can deliver better performance in compact devices is on the rise. According to a report by Grand View Research, the global market for magnets in electronics was valued at over $12 billion in 2020 and is projected to grow significantly in the coming years.

Rising Adoption of Electric Vehicles (EVs):

The adoption of electric vehicles (EVs) is another major driver for the magnet market, particularly neodymium-based magnets. Neodymium magnets are critical components in the motors and generators used in electric vehicles, providing high efficiency and compact size. With the global push towards reducing carbon emissions and increasing environmental sustainability, the demand for electric vehicles is expected to rise significantly. This, in turn, will drive the demand for neodymium magnets. According to Research and Markets, the global market for magnets in electric vehicles was valued at $2.8 billion in 2020 and is anticipated to grow at a compound annual growth rate (CAGR) of over 15% from 2021 to 2028.

Expansion in Renewable Energy Applications:

Renewable energy technologies such as wind turbines and hydropower systems are also driving the demand for magnets, particularly for direct-drive generators. Neodymium magnets are used in the direct-drive generators of wind turbines due to their high magnetic strength and efficiency, which helps in maximizing electricity generation. The increasing focus on renewable energy sources to meet global energy demands and reduce reliance on fossil fuels is expected to further boost the demand for magnets in this sector. According to the Global Wind Energy Council (GWEC), the global wind energy market is expected to reach over 1,200 GW of installed capacity by 2030, which will drive the demand for neodymium magnets.

Technological Advancements and Innovations:

Technological advancements and innovations in magnet materials and manufacturing processes are driving the growth of the magnet market. Researchers and manufacturers are continuously developing new magnet alloys and improving production techniques to enhance performance and reduce the cost of magnets. For instance, advancements in rare earth magnet recycling and the development of alternative magnet materials are addressing concerns related to the supply chain and environmental sustainability. These innovations are expected to expand the application of magnets across industries and drive market growth.

Restraints for the Magnet Market

Supply Chain Disruptions and Raw Material Costs:

One of the primary restraints for the magnet market is supply chain disruptions and fluctuations in raw material costs. The production of magnets, particularly rare earth magnets such as neodymium, dysprosium, and samarium cobalt, heavily relies on a secure supply of rare earth elements. China dominates the global supply of rare earth elements, accounting for over 80% of global production. Geopolitical tensions and trade disputes can disrupt the supply chain, leading to fluctuations in raw material prices and availability. For example, the price of neodymium, a key raw material for magnets used in electric vehicles and renewable energy applications, has experienced significant volatility in recent years. These supply chain disruptions and cost fluctuations can impact the profitability and stability of magnet manufacturers and suppliers.

Environmental and Sustainability Concerns:

Environmental and sustainability concerns related to the mining and processing of rare earth elements used in magnets pose another significant restraint for the magnet market. The mining and extraction of rare earth elements can have negative environmental impacts, including habitat destruction, soil and water contamination, and greenhouse gas emissions. Additionally, the refining processes required to produce high-purity rare earth metals are energy-intensive and can generate hazardous waste. These environmental concerns have led to increased regulatory scrutiny and pressure for more sustainable practices within the magnet industry. As a result, there is a growing focus on developing alternative magnet materials and improving recycling technologies to reduce reliance on newly mined rare earth elements and minimize environmental impacts.

High Cost of Magnet Materials:

The high cost of rare earth and other magnet materials is a significant restraint for the magnet market, particularly for neodymium-based magnets. Neodymium magnets are valued for their high magnetic strength and efficiency but are also expensive to produce due to the cost of raw materials and manufacturing processes. This high cost can limit their adoption in certain applications and industries where cost-effectiveness is a critical factor. Moreover, fluctuations in raw material prices can lead to uncertainty in pricing and profitability for magnet manufacturers and suppliers, affecting their competitiveness in the market.

Regulatory Challenges and Trade Barriers:

Regulatory challenges and trade barriers related to the export and import of rare earth elements and magnet products can hinder market growth. Some countries impose export restrictions on rare earth elements to protect domestic supply or for geopolitical reasons, which can create supply chain disruptions and limit market access for magnet manufacturers outside of dominant producing regions. Additionally, compliance with environmental regulations and standards for hazardous materials can increase operational costs and administrative burdens for magnet manufacturers, particularly in regions with stringent regulatory frameworks.

Opportunity in the Magnet Market

Emerging Technologies and Applications:

One of the primary opportunities for the magnet market lies in emerging technologies and applications that require magnets with specific properties and performance characteristics. For instance, the growing trend towards miniaturization and increased functionality in electronic devices, such as smartphones and wearable technology, requires smaller and more powerful magnets. Additionally, the rise of new technologies like 5G networks, the Internet of Things (IoT), and artificial intelligence (AI) will create opportunities for magnets in communication devices, sensors, and robotics.

Electric Vehicles (EVs) and Renewable Energy:

The transition towards electric vehicles (EVs) and renewable energy sources presents a significant opportunity for the magnet market, particularly neodymium-based magnets. Neodymium magnets are essential components in the motors and generators used in EVs, providing high efficiency and compact size. Similarly, the expansion of renewable energy technologies such as wind turbines and hydropower systems is driving the demand for magnets in direct-drive generators. The Global Wind Energy Council (GWEC) forecasts that the global wind energy market will continue to expand, providing further opportunities for magnets in renewable energy applications.

Investment in Research and Development (R&D):

Investment in research and development (R&D) presents opportunities for innovation and advancement in magnet materials and technologies. Researchers and manufacturers are focusing on developing new magnet alloys, enhancing manufacturing processes, and improving magnet performance to meet the evolving demands of various industries. For example, advancements in rare earth magnet recycling and the development of alternative magnet materials are addressing concerns related to the supply chain and environmental sustainability. The U.S. Department of Energy has invested in R&D initiatives aimed at reducing the reliance on critical materials and developing sustainable magnet technologies.

Global Infrastructure Development:

Global infrastructure development, particularly in emerging economies, offers opportunities for the magnet market. The construction of smart cities, transportation networks, and energy infrastructure requires magnets for various applications such as motors, sensors, and actuators. According to the International Energy Agency (IEA), global investment in energy infrastructure is expected to reach $2.6 trillion per year through 2030, which will drive the demand for magnets in energy-efficient technologies and systems.

Trends for the Magnet Market

Rise of Permanent Magnets in Various Applications:

A significant trend in the magnet market is the increasing adoption of permanent magnets in various applications, driven by their superior magnetic properties and efficiency. Permanent magnets, such as neodymium-iron-boron (NdFeB) magnets, are widely used in electronics, automotive, renewable energy, and industrial applications due to their high magnetic strength and stability. This growth is fueled by increasing demand for energy-efficient technologies, miniaturization of electronic devices, and advancements in magnet manufacturing processes.

Technological Advancements in Magnet Materials:

Technological advancements in magnet materials are driving innovation and expanding the application potential of magnets. Researchers and manufacturers are developing new magnet alloys and enhancing manufacturing processes to improve the performance, reliability, and cost-effectiveness of magnets. For instance, advancements in sintering techniques, powder metallurgy, and magnetic domain engineering are enabling the production of magnets with higher energy densities and improved temperature stability. These advancements are crucial for meeting the evolving demands of industries such as electronics, automotive, and renewable energy, where magnets play a critical role in enhancing product efficiency and performance.

Shift Towards Rare Earth-Free and Alternative Magnet Materials:

There is a growing trend towards the development and adoption of rare earth-free and alternative magnet materials as a response to supply chain vulnerabilities and environmental concerns associated with traditional rare earth magnets. For example, researchers are exploring the use of ferrite magnets, which are based on abundant raw materials like iron oxide and strontium carbonate, as alternatives to neodymium magnets in certain applications. Additionally, advancements in magnet recycling technologies are enabling the recovery and reuse of magnet materials, reducing dependence on newly mined resources, and minimizing environmental impacts. These trends are expected to reshape the magnet market landscape and contribute to the sustainability and resilience of magnet supply chains.

Increasing Demand for Magnets in Electric Vehicles (EVs):

The global shift towards electric mobility is driving significant demand for magnets in electric vehicles (EVs), particularly neodymium-based magnets for traction motors. This growth is driven by government initiatives promoting electric vehicle adoption, advancements in battery technology, and increasing consumer awareness of environmental sustainability. Magnets play a critical role in improving the efficiency and performance of EVs, contributing to their widespread adoption globally.

Segments Covered in the Report

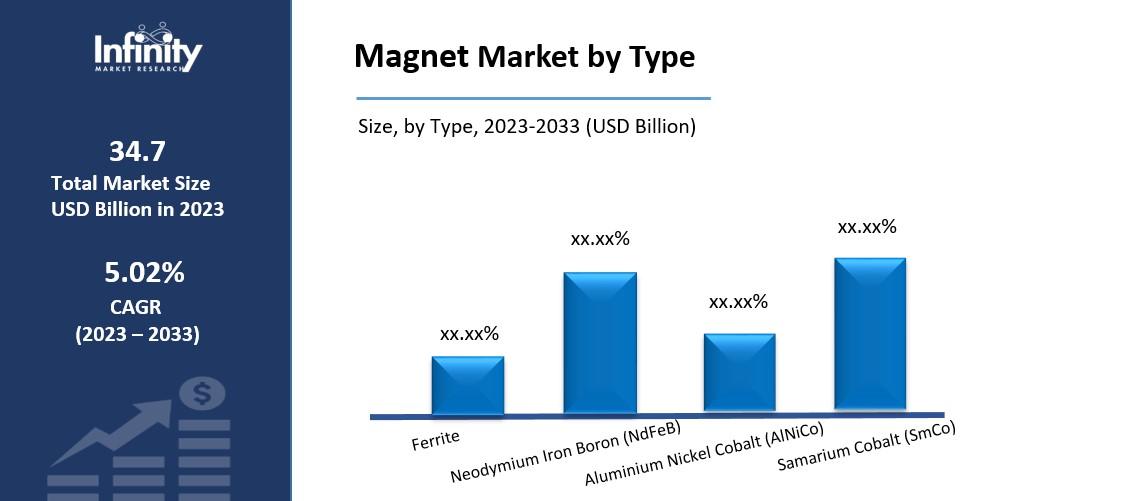

By Type

o Ferrite

o Neodymium Iron Boron (NdFeB)

o Aluminium Nickel Cobalt (AlNiCo)

o Samarium Cobalt (SmCo)

By Application

o Computer Hard Disk Drives (HDD), CD, DVD

o Hybrid Electric Vehicles

o Electric Bicycles

o Heating, Ventilating, and Air Conditioners (HVAC)

o Wind Turbines

o Other Applications

Segment Analysis

By Type Analysis

Because of its remarkable magnetic performance and strength, Neodymium Iron Boron (NdFeB) magnets currently account for the largest share of the market. They are a particular type of rare earth magnet composed of an iron, boron, and neodymium alloy. Because NdFeB magnets offer the highest magnetic field strength and energy product of any permanent magnet, they are perfect for applications where strong magnetic fields and compact dimensions are required, including hard disk drives, wind turbines, and electric cars. Moreover, their exceptional qualities are what propel their broad use in cutting-edge technological applications. In addition, the growing demand for small, strong, and high-efficiency magnetic solutions across a range of industries is fostering market expansion.

The moderate magnetic strength and affordability of ferrite magnets, commonly referred to as ceramic magnets, make them a popular choice. Their composition, which includes barium or strontium carbonate and iron oxide, provides them with good resistance to corrosion and demagnetization. In devices like tiny motors, speakers, and magnetic resonance imaging (MRI) equipment, when a large magnetic field is not required, ferrite magnets are widely used.

Magnets made of aluminum, nickel, and cobalt (AlNiCo) are renowned for having exceptional temperature stability and demagnetization resistance. They are frequently utilized in applications, such as aerospace, military, and automotive sensors, where a steady performance over a broad temperature range is crucial. Because of their distinct magnetic field properties, AlNiCo magnets are also widely used in the production of electric guitar pickups.

The remarkable thermal stability and high magnetic strength of samarium cobalt (SmCo) magnets are well-known. They are especially well-suited for use in spaces with restricted space or extremely hot environments. Because of their exceptional oxidation resistance, SmCo magnets usually don't need to be coated. High-performance motors, the military, and the aerospace industry all frequently use them.

By Application Analysis

Since magnets are essential to the operation of computer hard disk drives (HDD), CDs, and DVDs, they account for the largest portion of the market. They are frequently found in HDD actuators, which move the read/write head across the rotating disks. Magnets are essential components of the drives used in optical media, including CDs and DVDs, which read and write data. For these kinds of applications, magnets need to be accurate, dependable, and able to hold their magnetic qualities for extended periods. Additionally, several industries' increasing need for dependable data storage devices—like HDDs, CDs, and DVDs is driving the market's expansion.

Magnets are used in the electric motors and generators that make up the hybrid electric vehicle (HEV) core. Furthermore, the increasing requirement for small, powerful, and effective motors in these cars is driving up demand for high-performance magnets like NdFeB. In addition, the growing use of hybrid electric vehicles (HEVs) and the worldwide movement towards eco-friendly transportation alternatives are driving the market expansion.

Electric motors with magnets provide the essential thrust for electric bicycles. Furthermore, the growing demand for efficient and small magnet-based motors is being aided by the increasing popularity of e-bikes for recreational and urban commuting purposes, which is being driven by a growing awareness of the benefits to health and the environment.

Magnets are used in a variety of HVAC (heating, ventilation, and air conditioning) system components, such as fans, actuators, and compressors. Furthermore, the need for high-quality magnets is being driven by the increase in energy-efficient and dependable HVAC systems in residential, commercial, and industrial settings, which is supporting the market expansion. Additionally, by enhancing HVAC systems' functionality and energy efficiency, these magnets help lower costs and protect the environment.

One important market for magnets is wind turbines, especially when it comes to the production of renewable energy. Wind turbine generators employ high-performance magnets to effectively convert kinetic wind energy into electrical energy. These magnets need to be able to endure severe weather and continue to function for extended periods.

Regional Analysis

APAC is expected to contribute 44% of the growth of the global market over the forecast period. The region's fast industrialization and notable growth in the automotive, industrial, energy, and consumer electronics sectors have led to a rise in demand for magnets. The rising disposable incomes and improving standards of life in Asia-Pacific are predicted to drive up demand for permanent magnets in the consumer electronics sector. In the consumer electronics market, permanent magnets are found in the motors of peripheral devices including printers, fax machines, scanners, and photocopiers, as well as in the magnetic heads of CDs and hard disk drives (HDDs). There is a growing need for data centers to store enormous volumes of data due to the growing use of cloud computing and related developments.

Furthermore, the need for permanent magnets is being driven by the data centers' increasing demand for hard drives. In addition, these magnets are utilized in computers, fans, microwaves, air conditioners, washing machines, dryers, and loudspeakers. These appliances' increased efficiency thanks to permanent magnets will increase local demand for magnets. therefore, fostering the area market's expansion over the projected period.

Competitive Analysis

The top players are utilizing a range of tactical approaches to fortify their positions and take advantage of the expanding market need. They are spending a lot of money on research and development (R&D) to create and enhance magnetic material performance. Furthermore, several businesses are concentrating on improving the environmental sustainability of magnets through improved recycling and manufacturing techniques. In addition, several significant firms are purchasing smaller businesses or establishing strategic alliances to get access to new markets and technology, especially in developing nations and industries like electric cars and renewable energy.

Key Market Players in the Magnet Market

o Arnold Magnetic Technologies

o Ashvini Magnets Pvt. Ltd.

o Adams Magnetic Products Co. Inc.

o Hitachi Metals Ltd.

o Dexter Magnetic Technologies

o BGRIMM Magnetic Materials & Technology Co. Ltd.

o Shri Laxmi Magnet Industries

o Master Magnetics Inc.

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 55.3 Billion |

|

Market Size 2033 |

USD 34.7 Billion |

|

Compound Annual Growth Rate (CAGR) |

5.02% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

- |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Arnold Magnetic Technologies, Ashvini Magnets Pvt. Ltd., Adams Magnetic Products Co. Inc., Daido Steel Co. Ltd., Hitachi Metals Ltd., Dexter Magnetic Technologies, BGRIMM Magnetic Materials & Technology Co. Ltd., Shri Laxmi Magnet Industries, Master Magnetics Inc., Other Key Players, |

|

Key Market Opportunities |

Emerging Technologies and Applications |

|

Key Market Dynamics |

Increasing Demand in Electronics and Consumer Goods |

📘 Frequently Asked Questions

1. How much is the Magnet Market in 2023?

Answer: The Magnet Market size was valued at USD 34.7 Billion in 2023.

2. What would be the forecast period in the Magnet Market?

Answer: The forecast period in the Magnet Market report is 2023-2033.

3. Who are the key players in the Magnet Market?

Answer: Arnold Magnetic Technologies, Ashvini Magnets Pvt. Ltd., Adams Magnetic Products Co. Inc., Daido Steel Co. Ltd., Hitachi Metals Ltd., Dexter Magnetic Technologies, BGRIMM Magnetic Materials & Technology Co. Ltd., Shri Laxmi Magnet Industries, Master Magnetics Inc., Other Key Players,

4. What is the growth rate of the Magnet Market?

Answer: Magnet Market is growing at a CAGR of 5.02% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.