🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

MBS Impact Modifier for PVC Market

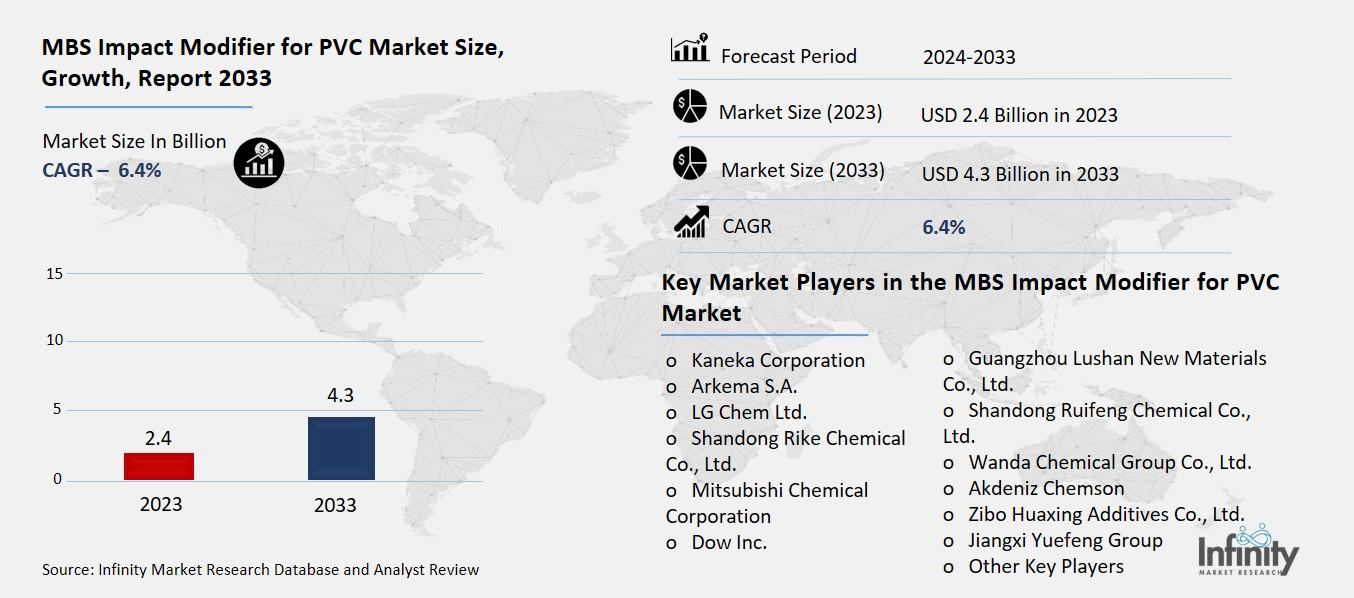

Global MBS Impact Modifier for PVC Market (By Type, PVC, PTB, Nylon, Engineering Plastics, and Other Types; By Application, Rigid Sheets & Panels, Profiles & Tubing, Pipes & Fittings, and Other Applications; By End-Use Industry, Automotive, Building & Construction, Packaging, Electrical & Electronics, and Other End-Use Industries, By Region and Companies), 2024-2033

Dec 2024

Chemicals and Materials

Pages: 138

ID: IMR1346

MBS Impact Modifier for PVC Market Overview

Global MBS Impact Modifier for PVC Market acquired the significant revenue of 2.4 Billion in 2023 and expected to be worth around USD 4.3 Billion by 2033 with the CAGR of 6.4% during the forecast period of 2024 to 2033. MBS (Methyl Methacrylate Butadiene Styrene) Impact modifiers are widely used to add to the PVC (Polyvinyl Chloride) to improve the substance’s impact strength, flexibility and resistance to impact force. Such modifiers are required to enhance the performance of PVC use in industries which requires high strength including window frames, pipes and flooring. When MBS is compounded with PVC, the inherent brittleness of PVC material is improved by the making it more capable of handling stress or an impact which otherwise would cause the material to crack.

It appears that MBS impact modifiers enhance processing attributes of the material so that manufacturers can attain improved dimensional stability and smoothness of surface. There is demand for MBS impact modifiers in PVC from sectors, which need PVC materials with greater impact strength including construction, automotive, and packaging.

Drivers for the MBS Impact Modifier for PVC Market

Advancement in PVC Processing Technologies

The advances in the PVC processing technologies have greatly advanced the incorporation of the MBS impact modifiers to provide improved physical properties of the resultant PVC based products as well as improvements in cost effectiveness of the products. Improved technologies in extrusion and compounding make it easier to introduce MBS uniformly into the PVC resin and other components of the plastic. This leads to enhanced mechanical characteristics such as increase in impact strength, flexibility and toughness of PVC end – products without necessarily affecting the overall strength and stability of the end products. Also, new technologies of the equipment for the processing of the dispersion of MBS, including the high-shear mixers and temperature control systems, are improving to allow the manufacturers to produce high-quality gemstones without the problem of variance in consistency or surface blemishes.

Restraints for the MBS Impact Modifier for PVC Market

Availability of Substitutes

The presence of alternative impact modifiers, such as Ethylene Vinyl Acetate (EVA) and acrylic-based modifiers, creates competition in the MBS (Methyl Methacrylate-Butadiene-Styrene) impact modifier market for PVC applications. EVA is widely used in PVC formulations due to its excellent flexibility, low-temperature impact resistance, and enhanced clarity, making it particularly popular in applications like films, wires, and cables. Its ability to improve the low-temperature performance of PVC, while also offering a cost-effective solution, makes it a strong competitor to MBS, particularly in sectors where performance requirements are less demanding or when cost is a critical factor.

Opportunity in the MBS Impact Modifier for PVC Market

Development of High-Performance PVC Products

The growing trend for high-performance PVC materials in specialized applications, such as medical devices and advanced packaging, presents a significant opportunity for MBS (Methyl Methacrylate-Butadiene-Styrene) impact modifiers. As industries continue to demand materials that offer superior durability, flexibility, and resistance to environmental stress, MBS-modified PVC has become a preferred choice for these specialized applications.

In the medical device sector, for instance, PVC is widely used in the production of items like blood bags, medical tubing, and surgical gloves, where flexibility and impact resistance are crucial. MBS modifiers enhance the toughness and flexibility of PVC, making it more suitable for the stringent requirements of medical devices, which must withstand physical stress and retain structural integrity over time.

Trends for the MBS Impact Modifier for PVC Market

Customization and Product Development

Manufacturers are increasingly focusing on developing customized MBS (Methyl Methacrylate-Butadiene-Styrene) impact modifiers to meet the specific needs of different industries, such as high-temperature resistance, improved UV stability, and enhanced durability. This trend is driven by the growing demand for PVC products that can perform under extreme environmental conditions or in specialized applications. By tailoring the chemical composition and structure of MBS modifiers, manufacturers can enhance PVC's properties to suit the exact requirements of sectors like automotive, construction, medical devices, and packaging.

For instance, high-temperature resistance is crucial in industries like automotive and electronics, where PVC components are often exposed to elevated temperatures. Customized MBS impact modifiers with enhanced thermal stability can ensure that PVC maintains its structural integrity and performance, even in challenging conditions.

Segments Covered in the Report

By Type

o PVC

o PTB

o Nylon

o Engineering Plastics

o Other Types

By Application

o Rigid Sheets & Panels

o Profiles & Tubing

o Pipes & Fittings

o Other Applications

By End-Use Industry

o Automotive

o Building & Construction

o Packaging

o Electrical & Electronics

o Other End-Use Industries

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into PVC, PTB, nylon, engineering plastics, and other types. Among these, PVC segment acquired the significant share in the market. PVC is extensively used in construction materials such as pipes, window profiles, flooring, and roofing, as well as in packaging and automotive components. The widespread adoption of PVC in these sectors is driven by its cost-effectiveness, versatility, and ease of processing. To enhance its impact resistance and durability, especially in outdoor applications, MBS (Methyl Methacrylate-Butadiene-Styrene) impact modifiers are commonly incorporated into PVC formulations. This integration improves the material's toughness making it suitable for demanding applications.

By Application Analysis

On the basis of application, the market is divided into rigid sheets & panels, profiles & tubing, pipes & fittings, and other applications. Among these, pipes and fittings segment held the prominent share of the market due to the extensive use of PVC pipes in construction, plumbing, and infrastructure projects, where durability and impact resistance are crucial. The incorporation of impact modifiers enhances the toughness and flexibility of PVC pipes, making them more resistant to cracking and damage during installation and use. This improvement is essential for ensuring the longevity and reliability of piping systems in demanding environments.

By End-Use Industry Analysis

On the basis of end-use industry, the market is divided into automotive, building & construction, packaging, electrical & electronics, and other end-use industries. Among these, automotive industry held the prominent share of the market. This prominence is driven by the increasing demand for lightweight and high-performance materials in automotive components. Impact modifiers enhance properties such as impact resistance and toughness in automotive parts, contributing to vehicle safety, durability, and overall performance. The automotive industry's focus on reducing vehicle weight to improve fuel efficiency and meet environmental standards further propels the adoption of impact-modified materials.

Regional Analysis

Asia Pacific Dominated the Market with the Highest Revenue Share

Asia Pacific held the most of the share of 32.1% of the market, driven by the region's rapid industrialization, expanding manufacturing sectors, and growing demand for advanced materials in key industries such as automotive, construction, packaging, and electronics. Countries like China, India, Japan, and South Korea are leading the way in adopting impact modifiers for PVC and other polymers, fueled by strong infrastructure development and urbanization trends.

Additionally, the automotive and construction industries in the region continue to grow, further boosting the demand for durable and high-performance materials. The availability of cost-effective raw materials, along with a robust manufacturing base, makes Asia Pacific an attractive hub for the production and consumption of impact modifiers.

Competitive Analysis

The competitive landscape of the impact modifiers market is characterized by the presence of several key players, each striving to capture a larger share by offering innovative solutions tailored to diverse industry needs. Major companies such as BASF, Dow Chemical, Evonik Industries, and Mitsubishi Chemical are at the forefront, leveraging their extensive research and development capabilities to produce high-quality, customized impact modifiers for various applications. These companies focus on enhancing product performance by developing modifiers that offer improved toughness, flexibility, UV stability, and high-temperature resistance, catering to growing demands in sectors like automotive, building & construction, packaging, and electrical & electronics.

Key Market Players in the MBS Impact Modifier for PVC Market

o Kaneka Corporation

o Arkema S.A.

o LG Chem Ltd.

o Shandong Rike Chemical Co., Ltd.

o Mitsubishi Chemical Corporation

o Dow Inc.

o Guangzhou Lushan New Materials Co., Ltd.

o Shandong Ruifeng Chemical Co., Ltd.

o Wanda Chemical Group Co., Ltd.

o Akdeniz Chemson

o Zibo Huaxing Additives Co., Ltd.

o Jiangxi Yuefeng Group

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 2.4 Billion |

|

Market Size 2033 |

USD 4.3 Billion |

|

Compound Annual Growth Rate (CAGR) |

6.4% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, End-Use Industry, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Kaneka Corporation, Arkema S.A., LG Chem Ltd., Shandong Rike Chemical Co., Ltd., Mitsubishi Chemical Corporation, Dow Inc., Guangzhou Lushan New Materials Co., Ltd., Shandong Ruifeng Chemical Co., Ltd., Wanda Chemical Group Co., Ltd., Akdeniz Chemson, Zibo Huaxing Additives Co., Ltd., Jiangxi Yuefeng Group, and Other Key Players. |

|

Key Market Opportunities |

Development of High-Performance PVC Products |

|

Key Market Dynamics |

Advancement in PVC Processing Technologies |

📘 Frequently Asked Questions

1. Who are the key players in the MBS Impact Modifier for PVC Market?

Answer: Kaneka Corporation, Arkema S.A., LG Chem Ltd., Shandong Rike Chemical Co., Ltd., Mitsubishi Chemical Corporation, Dow Inc., Guangzhou Lushan New Materials Co., Ltd., Shandong Ruifeng Chemical Co., Ltd., Wanda Chemical Group Co., Ltd., Akdeniz Chemson, Zibo Huaxing Additives Co., Ltd., Jiangxi Yuefeng Group, and Other Key Players.

2. How much is the MBS Impact Modifier for PVC Market in 2023?

Answer: The MBS Impact Modifier for PVC Market size was valued at USD 2.4 Billion in 2023.

3. What would be the forecast period in the MBS Impact Modifier for PVC Market?

Answer: The forecast period in the MBS Impact Modifier for PVC Market report is 2024-2033.

4. What is the growth rate of the MBS Impact Modifier for PVC Market?

Answer: MBS Impact Modifier for PVC Market is growing at a CAGR of 6.4% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.