🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Mechanical Device Diamond Market

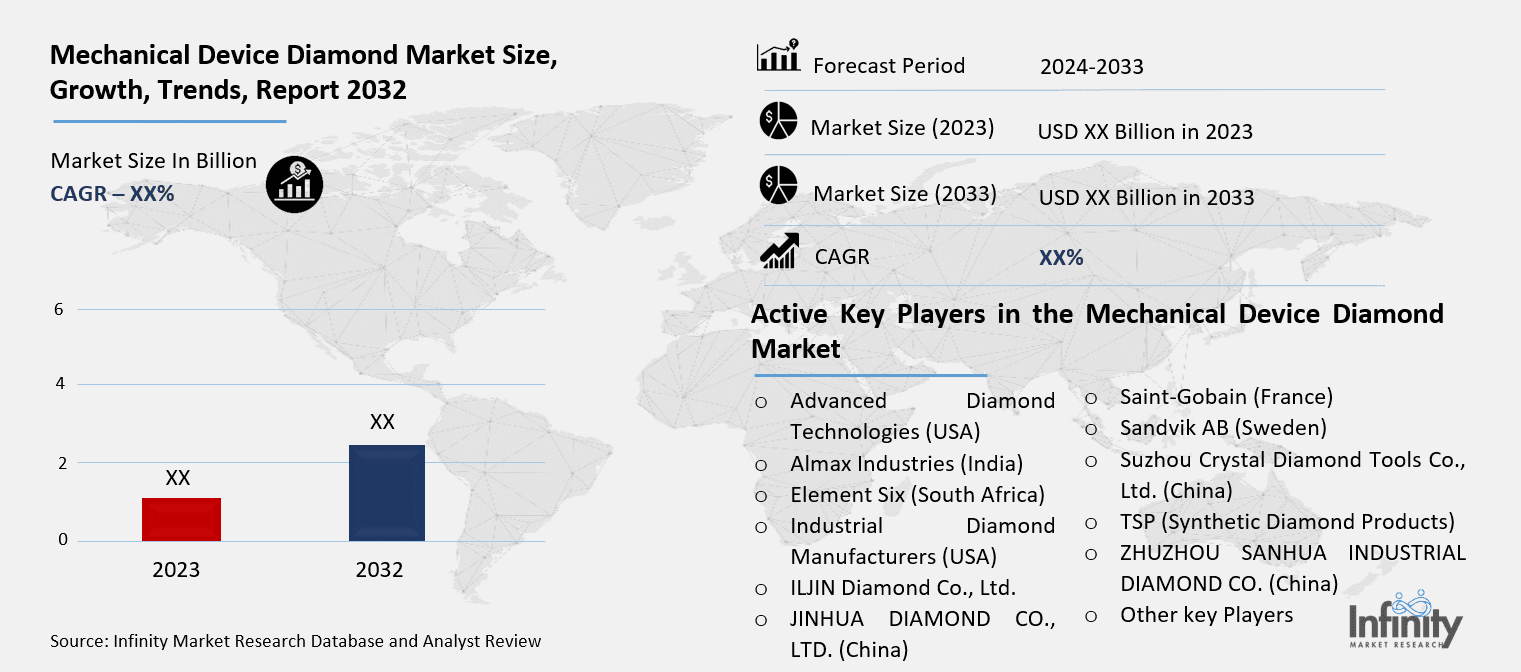

Mechanical Device Diamond Market Global Industry Analysis and Forecast (2024-2032) by Type (HPHT, CVD), Application (Circular Saw Slicing, Frame Saw Slicing, Geological Drill) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1576

Mechanical Device Diamond Market Synopsis

Mechanical Device Diamond Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

The Mechanical Device Diamonds Market is the industry that deals with the manufacture, sales and use of Diamond for mechanical use mainly in industries. These diamonds are specially synthesized and used because of there appropriateness in terms of hardness and accuracy when used in several cutting, grinding, and polishing exercises. Mechanical device diamonds are important components in various products including circular saws, drilling tools, lapping machines and any machinery that demands high wearing capacity material for cutting operations. As there is knowledge development in the field of material science and synthetic diamond technology the market of application of the mechanical device diamonds is growing vigorously because the device helps in enhancing the efficiency, performance, and cost control in manufacturing industrial segments of Auto-Mobile Industry, Electronics & Telescoping, Aerospace, and Mining & Minerals.

In view of this the world mechanical device diamond market has expanded in recent years due to its application in enhanced cutting and grinding processes in a number of industries. Toughness makes diamonds to be used in areas that require very fine workmanship and high degree of wear resistance. As the technologies of industrial machineries are developed, there is an increased market for high quality and specialized diamond tools. Currently the market is characterized by a high amount of synthetic diamonds especially High Pressure High Temperature (HPHT) as they are of better quality and cheaper than natural diamonds. Moreover, the increased demand for better and more effective manufacturing solutions is forcing industries to use diamonds in as many fields as it can be applied, cars, airplanes and similar vehicles.

The market is projected to sustain its upward trend as diamond technological advancements stay continuous and as diamonds tend to establish themselves in even more applications mechanically. One market trend that has especially emerged is the use of HPHT diamonds which are grown under certain pressures and temperatures to mirror the earth’s method of diamond formation. These grade diamonds have attracted this attention because of their relatively cheaper to produce and noted for their first rate performance in mechanical functions. In addition, mechanical device diamonds to increase precision and effectiveness of automation in manufacturing advances as a result continued importance in the market can still be also postulated. The application of the diamond tools in the electronics industry especially the ultra-modern semiconductor’s manufacturing line is also a factor towards the market’s growth.

Mechanical Device Diamond Market Trend Analysis

Trend: Growing Demand for Synthetic Diamonds in Industrial Applications

The largest trend that can be observed within the mechanical device diamond market is the shift towards using synthetic diamonds, produced through HPHT and CVD technologies. These diamonds are cheaper than the natural diamonds and are therefore preferred for industrial use because they are eco-friendly. New synthetic diamond products have actually located application in engineering procedures that require crushing, cutting and polishing tools where improved efficiency and decreased cost are desirable. The advancements with the synthetic diamond manufacturing are making the material better, more efficient and more cost effective compared to the natural diamonds making the material a preferred one in the market.

Driver: Technological Advancements in Diamond Production

The rising technologies in the creation of diamonds are in essence the key factors driving the mechanical device diamonds market. Techniques that are currently being used for synthetic diamond production include HPHT and CVD have greatly reduced price of the diamonds as they can be utilized for industrial purposes. Besides, these technologies have introduced the idea of creating diamonds with certain characteristics that can be useful in some applications, for instance, increased hardness or thermal conductivity. The setting of these diamonds to suit high application technological needs is enhancing the demand of diamonds in aerospace, automobiles, and electronics companies. Also, the level of mechanization and computerization within production lines has amplified the need for enhanced and compact tools that are likely to endure the pressure, hence fueling the uptake of mechanical device diamonds within the market segments under discussion.

Restraint: High Initial Cost of Diamond Tools

Even though mechanical devices have the advantage of better performance and durability still the major disadvantage in market for diamond tool is high initial cost of diamond tools. Although the cost of manufacture of synthetic diamonds has plummeted, the initial outlay coupled with subsequent maintenance and use for acquiring, maintaining and operating, the diamond based cutting tools can still be considerably high. This can often be a problem for SMEs because if the overall cost of such equipment is too high then it may not be feasible to make the investment. Also, the fact that machinery required for manufacturing or processing diamonds is necessarily very specific adds to the initial costs. For that reason, some industries applied cheaper tools such as carbide and ceramic tools even though these are not as accurate or long-lasting.

Opportunity: Growing Adoption of Diamond Tools in Emerging Markets

The increasing level of industrialization within the emerging economies proves to be a massive opportunity within the mechanical device diamond marketplace. Because of growing investments in manufacturing and infrastructure in Asia-Pacific, Latin America, and the Middle East, there remains strong demand for cutting and grinding tools that are excellent in quality and durability. This holds a great prospect for companies in the diamond sector to break into new horizons of consumption by taking their products to serve in varied sectors such as automotive, construction and electronics among others. Further, increase in awareness level about diamond tools and tools advantages to save more time and money along with the increased life expectancy of tools that will foster more demand to these products in other growth areas are also contributing to the growth of global diamond tools market in emerging regions.

Mechanical Device Diamond Market Segment Analysis

Mechanical Device Diamond Market Segmented on the basis of type, application.

By Type

o HPHT

o CVD

By Application

o Circular Saw Slicing

o Frame Saw Slicing

o Geological Drill

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, HPHT segment is expected to dominate the market during the forecast period

The mechanical device diamond market is expected to be led by the high pressure high temperature segment over the course of the forecast period. HPHT diamonds are grown under specified high pressure and high temperature environment, are synthetically formed like natural diamonds. In return, these diamonds come with unique qualities such as low production cost and higher hardness than the other diamond brands. Industries everywhere now look for a material that is resistant to wear and tear that costs less, and this is where the HPHT diamonds come in handy. Because they are widely available, offer cost savings and superior performance they are a major player in the mechanical device diamond market.

This is the case with the HPHT segment which the company continues to dominate due to constant enhancements in production technologies that increase the affordability of HPHT diamonds across various industries. In addition, using them in precision manufacturing like automotive, Aerospace & Electronics industries drive their adoption further. It is believed that due to the ever growing efforts of companies to increase the effectiveness and accuracy of their procedures, HPHT diamonds will retain their market domination.

By Application, Circular Saw Slicing segment expected to held the largest share

The market size of mechanical device diamonds for the Circular Saw Slicing segment is anticipated to dominate the market throughout the given period. Diamond saws mounted on circular saws are widely used cutting and slicing tools utilized in construction, automobile and manufacturing sectors. The ever growing need for using circular saws in cutting of hard materials including concrete, stone, and metal has seen an advanced use of diamond blades. Diamonds providing high hardness, has better performance and durability as compared to the conventional cutting tools widely used, thereby finding wide application in industries.

This is also coupled with the demand for high precision slicing equipment mostly occasioned by the construction and automobile markets. Industry players seeking to make their products better and accurate then before are estimated to keep demanding diamond-enhanced circular saw blades. Currently the application segment of the circular saw slicing application is likely to have a large market share owing to growth in industrial uses as well as the constant need for higher productivity and lower cost for industrial processes.

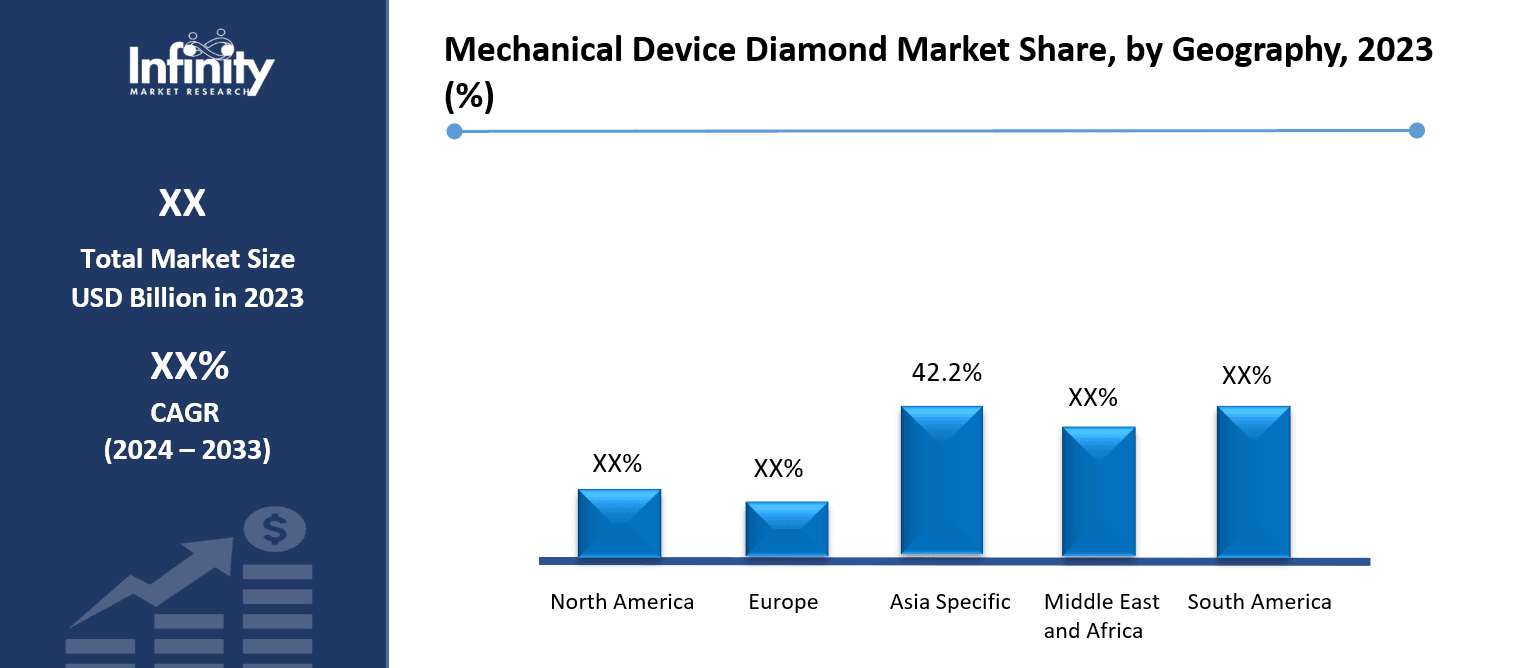

Mechanical Device Diamond Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

Expected in 2023, mechanical device diamond production will be primarily led by the Asia-Pacific region. Some of the most popular countries for this market are China, India and Japan due to their strong industrial segment for example manufacturing and construction and also automotive. Another factor that supports Asia-Pacific’s dominance is continuing urbanization, increased infrastructure investment and the growing use of intelligent manufacturing technology. As per the analysis made in BASESSENSE, it has been considered that with estimated 45% of market share in year 2023, Asia-Pacific region has a high growth prospect typically because of demand for cutting and grinding tools in emerging countries.

Mechanical Device Diamond Market Share, by Geography, 2023 (%)

Active Key Players in the Mechanical Device Diamond Market

o Advanced Diamond Technologies (USA)

o Almax Industries (India)

o Element Six (South Africa)

o Henan Huanghe Whirlwind Co., Ltd. (China)

o Industrial Diamond Manufacturers (USA)

o ILJIN Diamond Co., Ltd. (South Korea)

o JINHUA DIAMOND CO., LTD. (China)

o Laser Diamond Tools Pvt. Ltd. (India)

o Morgan Advanced Materials (UK)

o Noritake Co., Ltd. (Japan)

o Saint-Gobain (France)

o Sandvik AB (Sweden)

o Suzhou Crystal Diamond Tools Co., Ltd. (China)

o TSP (Synthetic Diamond Products) (USA)

o ZHUZHOU SANHUA INDUSTRIAL DIAMOND CO. (China)

o Other key Players

Global Mechanical Device Diamond Market Scope

|

Global Mechanical Device Diamond Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Segments Covered: |

By Type |

· HPHT · CVD | |

|

By Application |

· Circular Saw Slicing · Frame Saw Slicing · Geological Drill | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements in Diamond Production | ||

|

Key Market Restraints: |

· High Initial Cost of Diamond Tools | ||

|

Key Opportunities: |

· Growing Adoption of Diamond Tools in Emerging Markets | ||

|

Companies Covered in the report: |

· Advanced Diamond Technologies (USA), Almax Industries (India), Element Six (South Africa), Henan Huanghe Whirlwind Co., Ltd. (China), Industrial Diamond Manufacturers (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Mechanical Device Diamond Market research report?

Answer: The forecast period in the Mechanical Device Diamond Market research report is 2024-2032.

2. Who are the key players in the Mechanical Device Diamond Market?

Answer: Advanced Diamond Technologies (USA), Almax Industries (India), Element Six (South Africa), Henan Huanghe Whirlwind Co., Ltd. (China), Industrial Diamond Manufacturers (USA) and Other Major Players.

3. What are the segments of the Mechanical Device Diamond Market?

Answer: The Mechanical Device Diamond Market is segmented into Type, Application, and region. By Type, the market is categorized into HPHT, CVD. By Application, the market is categorized into Circular Saw Slicing, Frame Saw Slicing, Geological Drill. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Mechanical Device Diamond Market?

Answer: The Mechanical Device Diamonds Market is the industry that deals with the manufacture, sales and use of Diamond for mechanical use mainly in industries. These diamonds are specially synthesized and used because of there appropriateness in terms of hardness and accuracy when used in several cutting, grinding, and polishing exercises. Mechanical device diamonds are important components in various products including circular saws, drilling tools, lapping machines and any machinery that demands high wearing capacity material for cutting operations. As there is knowledge development in the field of material science and synthetic diamond technology the market of application of the mechanical device diamonds is growing vigorously because the device helps in enhancing the efficiency, performance, and cost control in manufacturing industrial segments of Auto-Mobile Industry, Electronics & Telescoping, Aerospace, and Mining & Minerals.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.