🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Metallurgical Silicon (Mg-Si) Market

Metallurgical Silicon (Mg-Si) Market Global Industry Analysis and Forecast (2024-2032) By Product Type(High-Purity Silicon, Low-Purity Silicon), By Application(Solar Cells, Semiconductor Industry, Aluminum Alloys, Others ), By End-User Industry(Electronics & Electrical, Automotive, Energy & Power, Chemicals, Others) and Region

Jan 2025

Semiconductor and Electronics

Pages: 138

ID: IMR1581

Metallurgical Silicon (Mg-Si) Market Synopsis

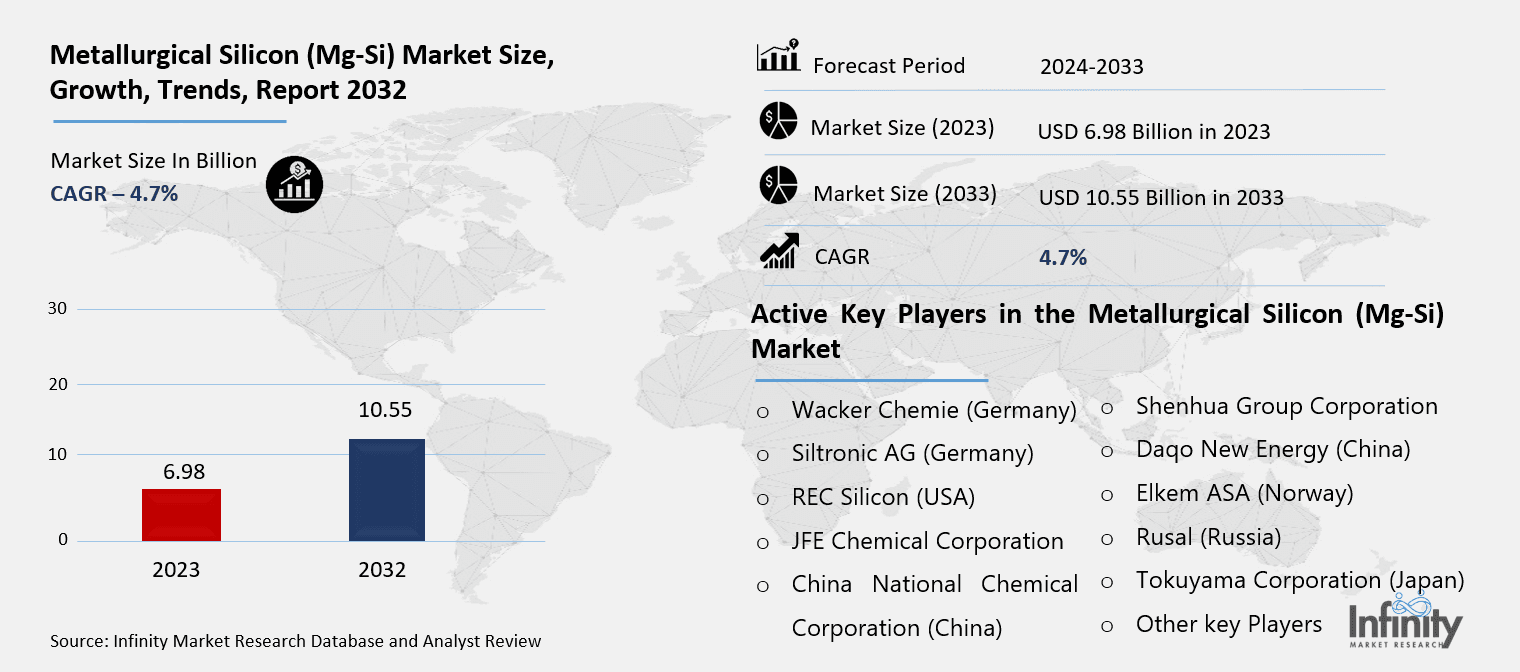

Metallurgical Silicon (Mg-Si) Market Size Was Valued at USD 6.98 Billion in 2023, and is Projected to Reach USD 10.55 Billion by 2032, Growing at a CAGR of 4.7% From 2024-2032.

Metallurgical Silicon (Mg·Si) is an essential material in the refining of high-purity silicon and production of aluminum alloys, photovoltaic cells, semiconductors and many other applications. Mg-Si originates from silicon oxide majorly obtained through a high temperature reduction process. This form of silicon is often employed as a method of strengthening aluminium; used in manufacture of PV cells and electronics due to its electrical conductivity.

The Metallurgical Silicon (Mg-Si) target market comprises of renewable energy sector, electronics and the transport sector. The increasing need for clean energy and in particular the solar energy has seen the utilization of high purity Silicon in the cells used. In semiconductor industry, Mg-Si plays a basic role as a component because of its semiconductivity. This market is, therefore, demanding for higher technology especially in the fields of sun power and electronics hence a development towards increasing production of high purity silicon.

The market is presumed to be on the rise to great height with the technological means and adaptation of renewable energy all over the world. This is because of the growing interest in decreasing difficult and increasing energy saving that has led to increased demand for solar cells and therefore metallurgical silicon. Finally, the constant advancement in electric vehicles production and consumer electronics has resulted in a higher rate of integration of better performing silicon-based parts. The market is rather saturated and the key companies account for most of the production and supply of metallurgical silicon all around the world.

Also, here, external factors pertaining to the availability of raw material essential for the development of clean energies, along with government policies encouraging the production of green energy, and consumers’ increasing concern towards technological solutions. The synthesis and usage of Mg-Si have been further strengthened by more focus being placed on research and development in material science. But it also has problems: unpredictable changes in the prices of the main raw material and the difficulty of producing chemically pure silicon. With global emphasis on renewable energy, the Metallurgical silicon market is set for a constant upward trend driven by these various uses and technological advancements.

Metallurgical Silicon (Mg-Si) Market Outlook, 2023 and 2032: Future Outlook

Metallurgical Silicon (Mg-Si) Market Trend Analysis

Trend: Increasing Demand for Solar Cells

There are some underlying trends that can be used to understand the metallurgical silicon markets and one of these is the adoption of renewable energy. These include Mg-Si alloy which is used as feedstock in preparing high pure silicon that is used in fabrication of solar cells. As more people turn towards using solar energy owing to environment friendly features it becomes apparent that the use of metallurgical silicon will only increase in the future. Solar energy is thought to be one of the most effective and readily available renewable sources, and thus, all countries are actively working to step up their solar facilities in an attempt to decrease CO2 emissions.

As the human demand for clean energy sources rises, solar energy companies themselves seek to develop and integrate new technologies in the manufacturing of solar panels that require high purity silicon materials. This trend is also expected to endure the growth of the metallurgical silicon market since it is an important ingredient for cost-effective and energy dense next generation solar cells. Therefore, due to an increasing demand based on the commitment of many countries to invest in clean energy targets as well as rise in demand for solar energy, the growth of metallurgical silicon will be constant.

Opportunity: Growth in Electric Vehicle (EV) Manufacturing

One of the key drivers in the metallurgical silicon market is connected with the development of the electric vehicles (EV) market. As the global consumer market for electric vehicles continues to expand, so does that of high-performance semiconductor and electronics, which necessary high purity silicon. The automotive industry in particular, as new investor in EVs has emerged as a significant player in demand for metallurgical silicon.

The use of electricity in electric cars demands high tech electronics for power control software, battery capability and communications that all involve the use high purity silicon. With constant growth in the EV market, there has been an increasing call for metallurgical silicon hence a huge market that manufacturers can explore. As the manufacturers of the required raw material for semiconductors and power electronics, the metallurgical silicon industry will benefit from this shift towards cleaner means of transport.

Driver: Technological Advancements in Semiconductor Manufacturing

The production technology of semiconductor is constantly developing and this has a positive impact on the Metallurgical silicon market. As the semiconductors mature there appears a demand for materials that could meet the high performance electronics today. Mainly Metallurgical silicon is used in the production of semiconductors because silicon possesses excellent conduct electrical properties. With the advancement in technology, the semiconductor industries are depending upon the high purity of silicon for manufacturing chips of computer, smartphones and other electronics materials.

Some of these new inventions in the semiconductors such as manufacturing of small more efficient chip are the major factors that have boosted the consumption of metallurgical silicon. The demand for a highly advanced semiconductor remains high across applications as varied as the consumer electronics market and telecommunications, with steadily increasing requirements, and the metallurgical silicon market is set for strong growth accordingly.

Restraints: High Production Costs

Agreeing, the market has good growth prospects however high costs of production of metallurgical silicon is a major pull back. To produce silicon that has a high purity level, the extraction and the refinement processes are laborious and involve high technological input in terms of energy. Apart from the costs of capital equipment, production costs for metallurgical silicon are high because of high cost of raw materials such as silicon dioxide that is used in the primary production. Such cost challenges can be channelled to the end consumers by making it hard for manufacturers to operate in price-sensitive markets.

However, frequent changes in price of raw materials and energy may pose a challenge for the metallurgical silicon producer in respect of their cost structure. The cost shocks on these necessities could prove difficult for firms in the market and those that cannot afford to take a hit on the increased costs. Therefore high cost of production has remained a major factor checked growth in the metallurgical silicon industry making it necessitate the need to either invent ways of reducing its cost or expand the production scale.

Metallurgical Silicon (Mg-Si) Market Segment Analysis

Metallurgical Silicon (Mg-Si) Market Segmented on the basis of product type, application and end user.

By Type

o High-Purity Silicon

o Low-Purity Silicon

By Application

o Solar Cells

o Semiconductor Industry

o Aluminum Alloys

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Product Type, High-Purity Silicon segment is expected to dominate the market during the forecast period

Metallurgical silicon of high purity is a high-grade type of metallurgical silicon and is used mainly in fabrication of semiconductors, solar cells and other novel applications. There has been an increased demand for high purity silicon because of increasing demand of excellent solar energy systems and high power electronic devices. Thus the market for this segment of the high-purity silicon is expected to do well due to rising global demand on renewable source of energy and the enhancement of technology on electronics products.

The low purity silicon can be applied in the industries such as aluminum alloys, construction materials and others. However, it does not contain the features of high purity silicon; its flexibility and lower costs makes it perfect for industries that require products in large scales at lower prices. Thus, the demand for low-purity silicon will remain quite stable over long term due to broad application potential in various industries which, however, will not grow as rapidly as demand on high-pure silicon.

By Application, Solar Cells segment expected to held the largest share

The solar cell application is currently the biggest driving force of Metallurgical silicon market. Silicon of high purity is critical for creating photovoltaic cells that which are the core of the solar energy products. With governments and organizations worldwide especially promoting cleaner sources of energy, the use of solar energy that in turn comes with metallurgical silicon is expected to shoot up steeply.

Thus, splendid improvements of metallurgical silicon, especially high-purity silicon, are urgently in demand for application in the semiconductor industry. The consumer electronics, telecommunications industries and cars, in general, all use silicon chips and as technology advances, the demand will grow even further. The semiconductor industry is therefore a large user of metallurgical silicon for making chips, micro chips and transistors that are widely used in today’s electronics.

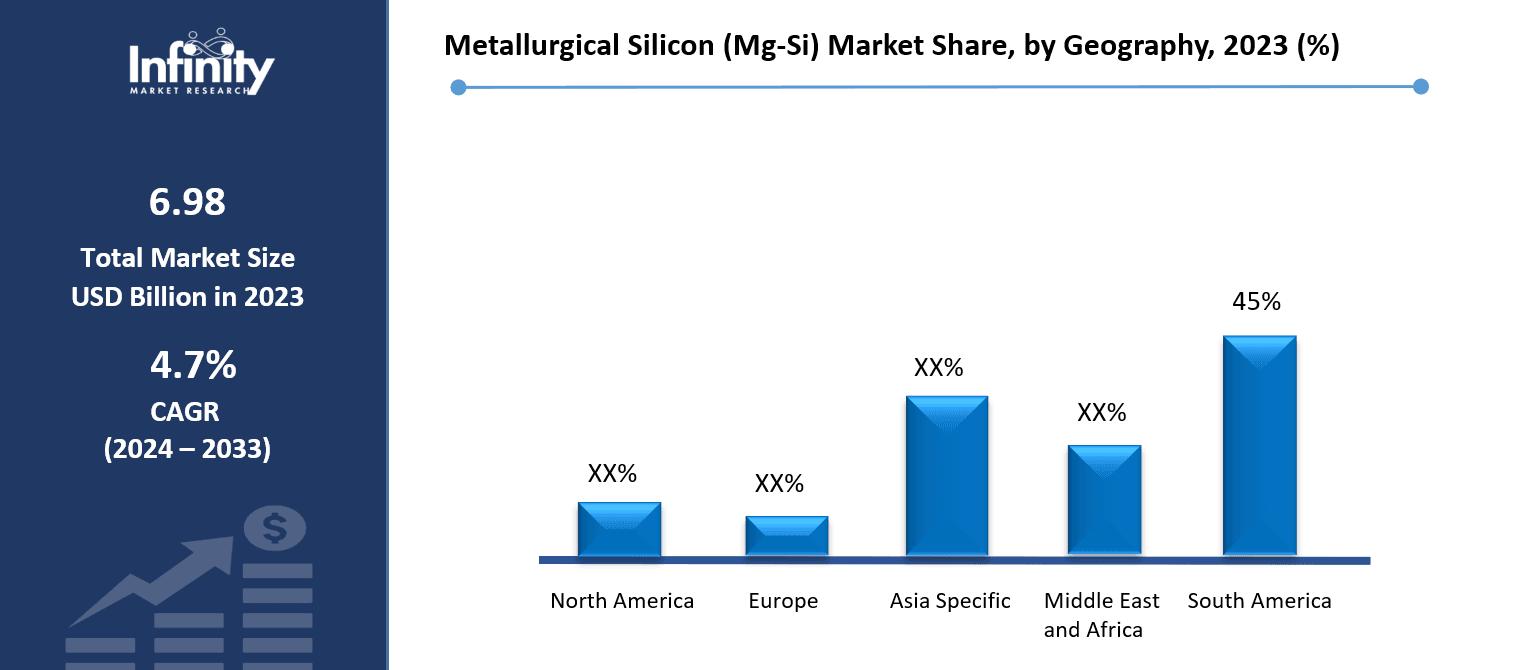

Metallurgical Silicon (Mg-Si) Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Currently, the demand for metallurgical silicon in North American countries is comparatively high, especially from solar energy as well as semiconductor sector. Advanced technology companies and semiconductor manufacturing companies are located in this region and, therefore, exert a considerable impact on the buying behaviour of high-purity silicon. Moreover, rising concerns of renewable energy in the United States, Canada, and Mexico and strict implementation of cleaner technology polices have enhanced the number of demands for metallurgical silicon especially on the solar application.

North American market enjoys strong supporting infrastructure, robust research and development facilities, and supportive governments’ policies to booster clean energy and technologies. Due to increased investment in various aspect of solar energy technologies as well as semiconductor manufacturing North America remains a significant influential region in metallurgical silicon markets and hence remains a leading world region.

Metallurgical Silicon (Mg-Si) Market Share, by Geography, 2023 (%)

Active Key Players in the Metallurgical Silicon (Mg-Si) Market

o Wacker Chemie (Germany)

o Siltronic AG (Germany)

o REC Silicon (USA)

o JFE Chemical Corporation (Japan)

o Ferroglobe (Spain)

o China National Chemical Corporation (China)

o GCL-Poly Energy Holdings Limited (China)

o Shenhua Group Corporation (China)

o Daqo New Energy (China)

o Elkem ASA (Norway)

o Rusal (Russia)

o Tokuyama Corporation (Japan)

o Other key Players

Global Metallurgical Silicon (Mg-Si) Market Scope

|

Global Metallurgical Silicon (Mg-Si) Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 6.98 Billion |

|

Forecast Period 2024-32 CAGR: |

4.7% |

Market Size in 2032: |

USD 10.55 Billion |

|

Segments Covered: |

By Product Type |

· Low-Purity Silicon | |

|

By Application |

· Semiconductor Industry · Aluminum Alloys · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements in Semiconductor Manufacturing | ||

|

Key Market Restraints: |

· High Production Costs | ||

|

Key Opportunities: |

· Growth in Electric Vehicle (EV) Manufacturing | ||

|

Companies Covered in the report: |

· Wacker Chemie (Germany), Siltronic AG (Germany), REC Silicon (USA), JFE Chemical Corporation (Japan), Ferroglobe (Spain), China National Chemical Corporation (China), GCL-Poly Energy Holdings Limited (China)and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Metallurgical Silicon (Mg-Si) Market research report?

Answer: The forecast period in the Metallurgical Silicon (Mg-Si) Market research report is 2024-2032.

2. Who are the key players in the Metallurgical Silicon (Mg-Si) Market?

Answer: Wacker Chemie (Germany), Siltronic AG (Germany), REC Silicon (USA), JFE Chemical Corporation (Japan), Ferroglobe (Spain), China National Chemical Corporation (China), GCL-Poly Energy Holdings Limited (China)and Other Major Players.

3. What are the segments of the Metallurgical Silicon (Mg-Si) Market?

Answer: The Metallurgical Silicon (Mg-Si) Market is segmented into Product Type, Application, End User and region. By Product Type, the market is categorized into High-Purity Silicon, Low-Purity Silicon), By Application, the market is categorized into Solar Cells, Semiconductor Industry, Aluminum Alloys, Other. By End-User Industry, the market is categorized into Electronics & Electrical, Automotive, Energy & Power, Chemicals, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Metallurgical Silicon (Mg-Si) Market?

Answer: Metallurgical Silicon (Mg·Si) is an essential material in the refining of high-purity silicon and production of aluminum alloys, photovoltaic cells, semiconductors and many other applications. Mg-Si originates from silicon oxide majorly obtained through a high temperature reduction process. This form of silicon is often employed as a method of strengthening aluminium; used in manufacture of PV cells and electronics due to its electrical conductivity.

5. How big is the Metallurgical Silicon (Mg-Si) Market?

Answer: Metallurgical Silicon (Mg-Si) Market Size Was Valued at USD 6.98 Billion in 2023, and is Projected to Reach USD 10.55 Billion by 2032, Growing at a CAGR of 4.7% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.