🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Methyl Phenyl Silicone Rubber Market

Methyl Phenyl Silicone Rubber Market Global Industry Analysis and Forecast (2024-2032) By Product Type(High Temperature Vulcanized, Room Temperature Vulcanized, Liquid Silicone Rubber),Application(Automotive, Electronics, Construction, Medical, Consumer Goods, Others),End-User(Industrial, Commercial, Residential) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1794

Methyl Phenyl Silicone Rubber Market Synopsis

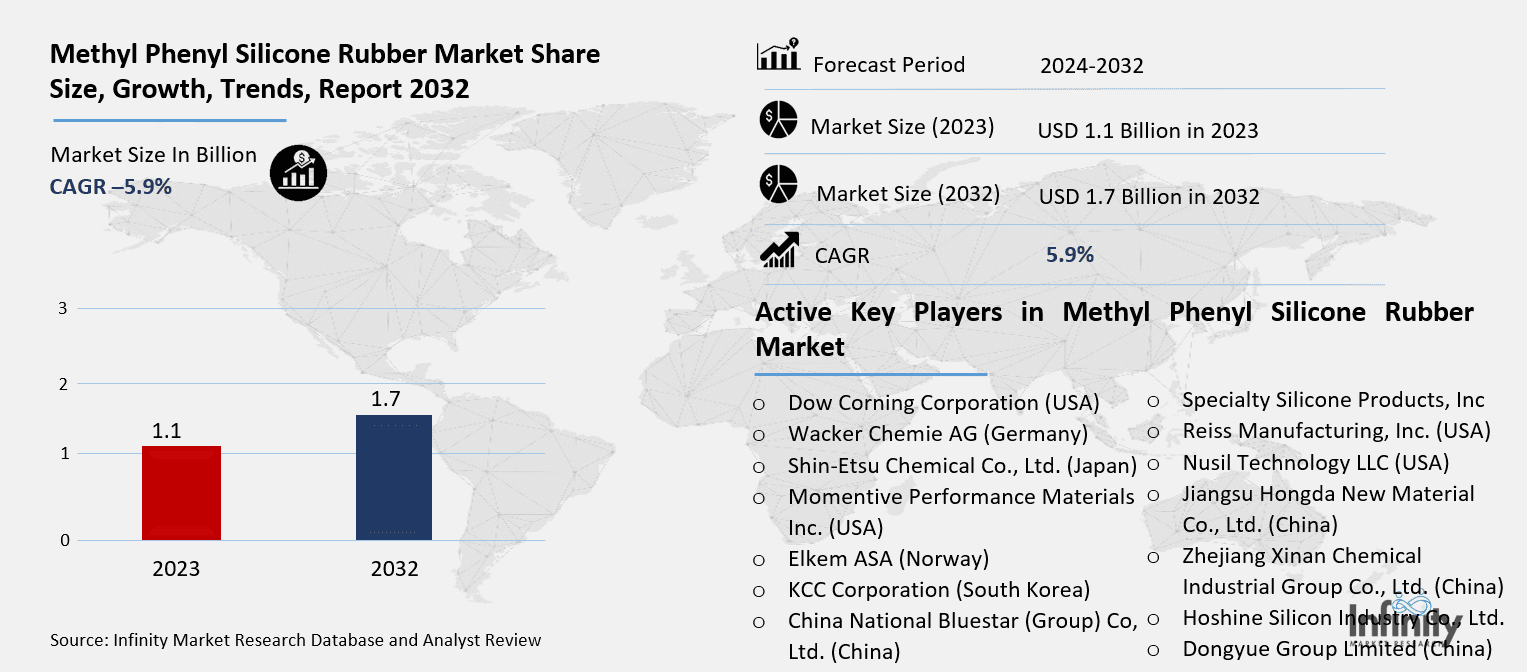

Methyl Phenyl Silicone Rubber Market Size Was Valued at USD 1.1 Billion in 2023, and is Projected to Reach USD 1.7 Billion by 2032, Growing at a CAGR of 5.9% From 2024-2032.

Excellent thermal stability, oxidation resistance, and great electrical insulating qualities make the methyl phenyl silicone rubber market steadily expanding. Applications needing high-temperature resistance—such as aerospace, automotive, and electronics—all find extensive use for this specialist silicone rubber. Its preferred use in industrial sealing, gaskets, and insulation components is based on its capacity to remain flexible and durable under very demanding environmental circumstances. We predict that the market for methyl phenyl silicone rubber will grow as sectors continue to need high-performance elastomers.

Demand from the aerospace and automotive sectors is one of the main forces behind market expansion. The excellent heat resistance of methylphenyl silicone rubber makes it perfect for engine gaskets, O-rings, and protective coatings, which is why it is so extensively employed in these industries. Further boosting market development is the increasing trend toward electric vehicles (EVs), which increases the demand for high-performance materials able to handle thermal stress.

The electronics industry significantly influences the expansion of the methyl phenyl silicone rubber market. This silicone rubber is utilized extensively for insulating and safeguarding semiconductor components, connections, and circuit boards as modern electronic gadgets are becoming more and more adopted. The market is constantly rising in response to consumer electronics, telecommunications, and industrial uses demanding small-sized, high-durability electronic components.

Methyl Phenyl Silicone Rubber Market Outlook, 2023 and 2032: Future Outlook

Methyl Phenyl Silicone Rubber Market Trend Analysis

Trend: Rising Demand for High-Performance Elastomers in Extreme Environments

Rising demand for high-performance elastomers in hostile situations is driving a notable increase in the methyl phenyl silicone rubber market. Aerospace, automotive, and electronics industries, among others, depend on materials that can resist extreme environments, including high temperatures, radiation, and chemical exposure. The excellent dielectric properties, oxidation resistance, and heat stability of methyl phenyl silicone rubber make it useful for sealing, insulation, and protective coatings. The market expansion is being driven even more by the increasing attention on material durability and performance improvement.

Drivers: Growing Applications in Automotive, Aerospace, and Electronics Industries

Expanding uses across the automotive, aerospace, and electronics sectors are driving a notable increase in the methyl phenyl silicone rubber market. This high-performance rubber is extensively utilized in gaskets, seals, and insulating materials in the automobile industry because of its outstanding thermal stability and resilience to hostile surroundings. Because of its exceptional oxidation resistance and flexibility at high temperatures, the aerospace sector benefits from this option for sealing and protective purposes in aircraft components. In high-voltage systems, where resistance to electrical stress is crucial, the electronics sector uses methyl phenyl silicone rubber for coatings, encapsulations, and insulation.

Restraints: High Production Costs and Availability of Alternative Materials

The Methyl Phenyl Silicone Rubber Market faces significant restraints, primarily due to high production costs. The complex manufacturing process, which involves specialized raw materials and stringent quality control measures, drives up the overall expenses. Additionally, energy-intensive production techniques and regulatory compliance further contribute to increased costs. These factors make methyl phenyl silicone rubber less economically viable for certain applications, limiting its widespread adoption across industries such as automotive, aerospace, and electronics.

Opportunities: Advancements in Silicone Rubber Formulations and Expanding Industrial Applications

Continuous developments in silicone rubber compositions are driving notable expansion in the Methyl Phenyl Silicone Rubber Market. High-performance variations with improved thermal stability, flexibility, and tolerance to hostile environmental conditions are under development by manufacturers and researchers. Applications in aerospace, automotive, and electronics sectors, where materials must resist mechanical stress and high temperatures, depend especially on these developments. Low-VOC (volatile organic compound) and recyclable silicone rubber compositions are also growing market opportunities. This is because more people want environmentally friendly alternatives.

Methyl Phenyl Silicone Rubber Market Segment Analysis

Methyl Phenyl Silicone Rubber Market Segmented on the basis of By Product Type, Application and End-User.

By Product

o High Temperature Vulcanized

o Room Temperature Vulcanized

o Liquid Silicone Rubber

By Application

o Automotive

o Electronics

o Construction

o Medical

o Consumer Goods

o Others

By End User

o Industrial

o Commercial

o Residential

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Product Type, High Temperature Vulcanized segment is expected to dominate the market during the forecast period

Perfect for automotive, aerospace, and industrial uses, the High-Temperature Vulcanized (HTV) Silicone Rubber segment rules the market thanks to its outstanding heat resistance, mechanical strength, and durability. High-temperature curing of this kind of silicone rubber produces increased thermal stability and resilience to harsh circumstances. Furthermore, HTV silicone finds extensive application in medical and electronics applications that require high-performance elastomers.

Conversely, Room Temperature Vulcanized (RTV) Silicone Rubber, Liquid Silicone Rubber (LSR), and Methyl Phenyl Silicone Rubber benefit several sectors with different applications. Because RTV silicone rubber easily cures at room temperature, it is often utilized in coatings, adhesives, and mold-making. Medical equipment, baby items, and automotive components all fit LSR because it provides excellent flexibility, biocompatibility, and chemical resistance. Methyl phenyl silicone rubber is the best choice for aerospace and high-performance electrical insulation because it is very flexible at low temperatures and doesn't absorb radiation easily.

End-User, Industrial segment expected to held the largest share

The methyl phenyl silicone rubber market is steadily growing thanks to its excellent thermal stability, resistance to oxidation, and ability to keep electricity from flowing through it. Mostly utilized in automotive applications, it improves seal, gasket, and high-temperature engine component durability. Excellent dielectric qualities of this material make it perfect for insulating semiconductors, circuit boards, and connectors in the electronics sector. Because of its weather-resistant character, the building industry gains from it when applied in coatings and sealants to increase lifetime and performance.

Leveraging its biocompatibility, the medical sector finds it appropriate for surgical tools, tubing, and implants as well. Because of its heat resistance and flexibility, makers of consumer goods, including kitchenware, personal care products, and household appliances, also use methyl phenyl silicone rubber. The other group includes aeronautical and industrial machinery, where severe conditions necessitate the use of high-performance elastomers. Growing applications in developing sectors combined with increasing demand for innovative materials with better thermal and mechanical qualities should propel further growth of the methyl phenyl silicone rubber market in the next years.

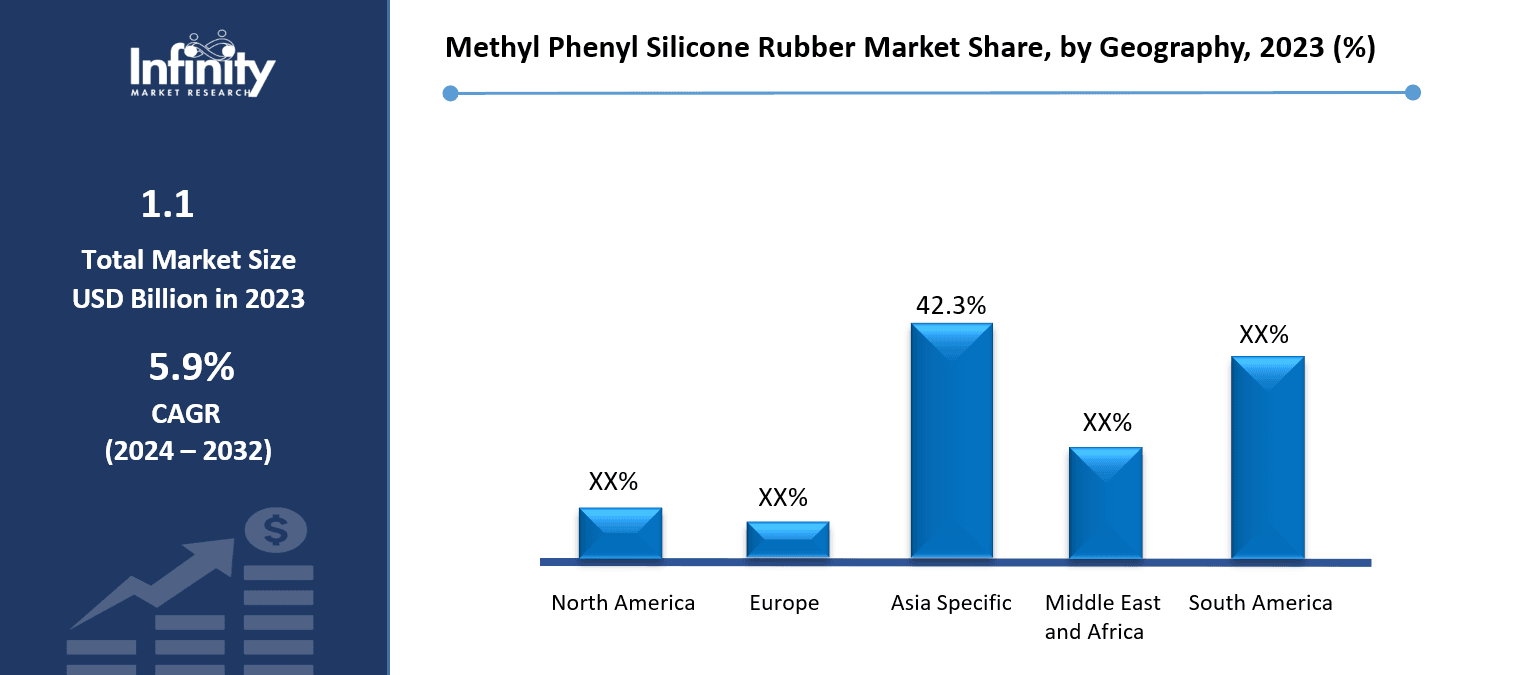

Methyl Phenyl Silicone Rubber Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

Driven by the region's developing industrial sector, rising demand for high-performance materials, and increasing uses in automotive, electronics, and construction sectors, the Asia-Pacific area is predicted to lead the Methyl Phenyl Silicone Rubber Market over the forecast period. Rising leaders in this regard are China, Japan, and South Korea, who gain from strong manufacturing capacity and large R&D expenditures. Methyl phenyl silicone rubber is increasingly finding acceptance in high-temperature-resistant applications, particularly in automotive parts and electrical insulation. This makes the market leader even stronger in this area. Furthermore, the expanding electronics and semiconductor sectors in Asia Pacific generate a significant need for sophisticated silicone materials, therefore supporting the growth of the market.

Methyl Phenyl Silicone Rubber Market Share, by Geography, 2023 (%)

Active Key Players in the Methyl Phenyl Silicone Rubber Market

o Dow Corning Corporation (USA)

o Wacker Chemie AG (Germany)

o Shin-Etsu Chemical Co., Ltd. (Japan)

o Momentive Performance Materials Inc. (USA)

o Elkem ASA (Norway)

o KCC Corporation (South Korea)

o China National Bluestar (Group) Co, Ltd. (China)

o Specialty Silicone Products, Inc. (USA)

o Reiss Manufacturing, Inc. (USA)

o Nusil Technology LLC (USA)

o Jiangsu Hongda New Material Co., Ltd. (China)

o Zhejiang Xinan Chemical Industrial Group Co., Ltd. (China)

o Hoshine Silicon Industry Co., Ltd. (China)

o Dongyue Group Limited (China)

o Shandong Dayi Chemical Co., Ltd. (China)

o Guangzhou Tinci Materials Technology Co., Ltd. (China)

o Shandong Jinling Group Co., Ltd. (China)

o Jiangxi Xinghuo Organic Silicone Plant (China)

o Zhejiang Wynca Chemical Industry Group Co., Ltd. (China)

o Shandong Dongyue Organosilicon Materials Co., Ltd. (China)

o others

Global Methyl Phenyl Silicone Rubber Market Scope

|

Global Methyl Phenyl Silicone Rubber Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 1.1 Billion |

|

Forecast Period 2024-32 CAGR: |

5.9% |

Market Size in 2032: |

USD 1.7 Billion |

|

Segments Covered: |

By Product Type |

· High Temperature Vulcanized · Room Temperature Vulcanized · Liquid Silicone Rubber | |

|

By Application |

· Automotive · Electronics · Construction · Medical · Consumer Goods · Others | ||

|

By End User |

· Industrial · Commercial · Residential | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Applications in Automotive, Aerospace, and Electronics Industries | ||

|

Key Market Restraints: |

· High Production Costs and Availability of Alternative Materials | ||

|

Key Opportunities: |

· Advancements in Silicone Rubber Formulations and Expanding Industrial Applications | ||

|

Companies Covered in the report: |

· Dow Corning Corporation (USA), Wacker Chemie AG (Germany), Shin-Etsu Chemical Co., Ltd. (Japan), Momentive Performance Materials Inc. (USA), Elkem ASA (Norway), KCC Corporation (South Korea), China National Bluestar (Group) Co, Ltd. (China), Specialty Silicone Products, Inc. (USA), Reiss Manufacturing, Inc. (USA), Nusil Technology LLC (USA), Jiangsu Hongda New Material Co., Ltd. (China), Zhejiang Xinan Chemical Industrial Group Co., Ltd. (China), Hoshine Silicon Industry Co., Ltd. (China), Dongyue Group Limited (China), Shandong Dayi Chemical Co., Ltd. (China), Guangzhou Tinci Materials Technology Co., Ltd. (China), Shandong Jinling Group Co., Ltd. (China), Jiangxi Xinghuo Organic Silicone Plant (China), Zhejiang Wynca Chemical Industry Group Co., Ltd. (China), Shandong Dongyue Organosilicon Materials Co., Ltd. (China), others. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Methyl Phenyl Silicone Rubber Market research report?

Answer: The forecast period in the Methyl Phenyl Silicone Rubber Market research report is 2024-2032.

2. Who are the key players in the Methyl Phenyl Silicone Rubber Market?

Answer: Dow Corning Corporation (USA), Wacker Chemie AG (Germany), Shin-Etsu Chemical Co., Ltd. (Japan), Momentive Performance Materials Inc. (USA), Elkem ASA (Norway), KCC Corporation (South Korea), China National Bluestar (Group) Co, Ltd. (China), Specialty Silicone Products, Inc. (USA), Reiss Manufacturing, Inc. (USA), Nusil Technology LLC (USA), Jiangsu Hongda New Material Co., Ltd. (China), Zhejiang Xinan Chemical Industrial Group Co., Ltd. (China), Hoshine Silicon Industry Co., Ltd. (China), Dongyue Group Limited (China), Shandong Dayi Chemical Co., Ltd. (China), Guangzhou Tinci Materials Technology Co., Ltd. (China), Shandong Jinling Group Co., Ltd. (China), Jiangxi Xinghuo Organic Silicone Plant (China), Zhejiang Wynca Chemical Industry Group Co., Ltd. (China), Shandong Dongyue Organosilicon Materials Co., Ltd. (China), others.

3. What are the segments of the Methyl Phenyl Silicone Rubber Market?

Answer: The Methyl Phenyl Silicone Rubber Market is segmented into By Product Type, Application, End User and region. By Product Type (High Temperature Vulcanized, Room Temperature Vulcanized, Liquid Silicone Rubber),Application(Automotive, Electronics, Construction, Medical, Consumer Goods, Others),End-User(Industrial, Commercial, Residential). By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Methyl Phenyl Silicone Rubber Market?

Answer: Methyl Phenyl Silicone Rubber is a specialized type of silicone elastomer that incorporates both methyl and phenyl groups in its molecular structure, enhancing its thermal stability, oxidation resistance, and electrical insulation properties. It is designed to withstand extreme temperatures, ranging from -60°C to over 300°C, making it highly suitable for aerospace, automotive, electronics, and industrial applications. Unlike conventional silicone rubbers, the presence of phenyl groups improves flexibility at low temperatures and enhances radiation resistance, making it an ideal material for sealing, gaskets, coatings, and insulation components in high-performance environments.

5. How big is the Methyl Phenyl Silicone Rubber Market?

Answer: Methyl Phenyl Silicone Rubber Market Size Was Valued at USD 1.1 Billion in 2023, and is Projected to Reach USD 1.7 Billion by 2032, Growing at a CAGR of 5.9% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.