🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Molding Compounds Market

Molding Compounds Market Global Industry Analysis and Forecast (2024-2032) By Type (Thermoset Molding Compounds, Thermoplastic Molding Compounds), By Material (Epoxy, Phenolic, Polyester, Polyurethane, Others), By Application (Automotive, Electrical & Electronics, Aerospace, Consumer Goods, Industrial, Others) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1588

Molding Compounds Market Synopsis

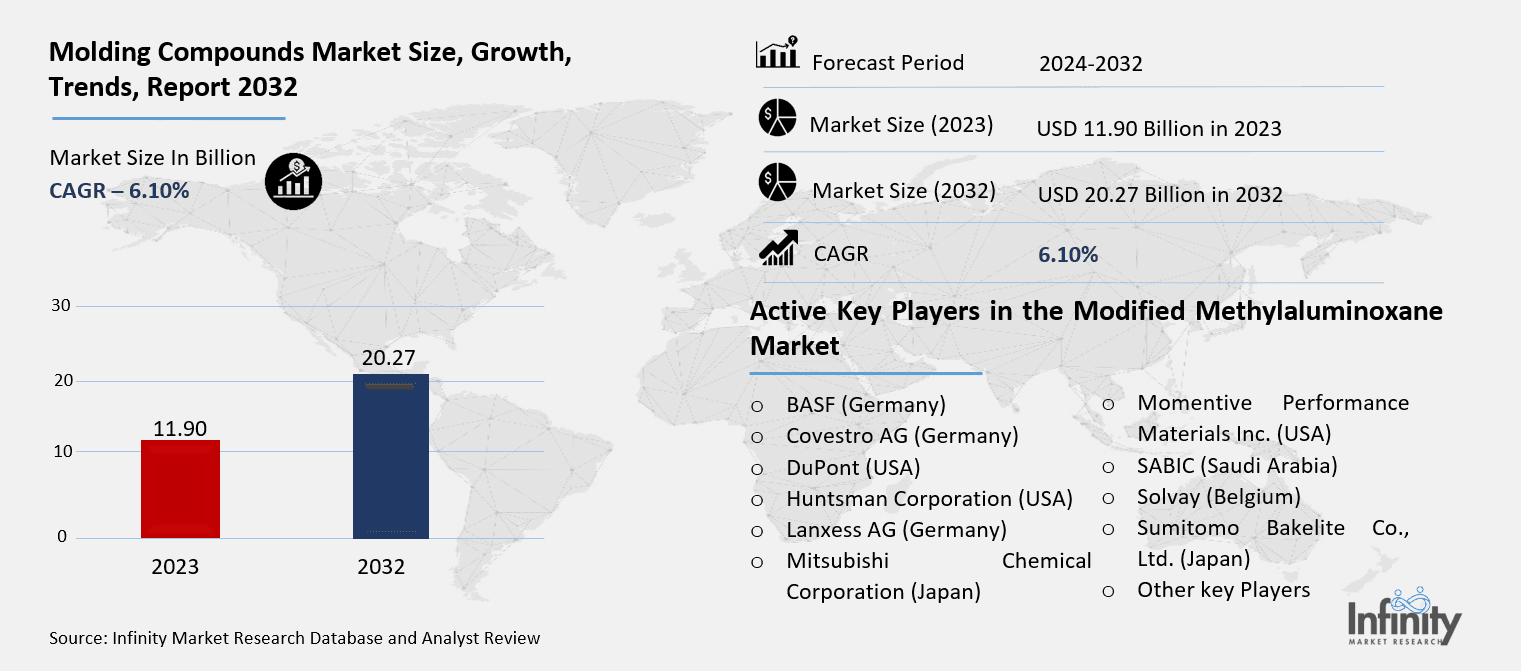

Molding Compounds Market Size Was Valued at USD 11.90 Billion in 2023, and is Projected to Reach USD 20.27 Billion by 2032, Growing at a CAGR of 6.10 % From 2024-2032.

Molding compounds are used for making molded products in several fields of manufacturing. These are thermosetting or thermoplastic materials that are prepared to be given form under heat and pressure for end products. The most frequently applied types of molding compounds include epoxy, polyester and polyurethane resins due to high mechanical characteristics, heat and chemical resistance. Molding compounded are extensively used in automotive, electrical & aerospace industries, as well as in consumer durables due to the capacity of the compound to produce complex, high standard parts.

The Market of Molding Compounds is projected to recover owing to the rising popularity in applications including automotive, electrical and electronics, and consumer goods. The use of lightweight materials in automotive applications as well as increasing trends in the use of molding technologies also lead to market growth. As to the use of thermosetting and thermoplastic compounds, the ability to create more bespoke products for these industries continues to grow as the materials improve in quality.

Regionally, molding compounds market current trends indicates that Asia Pacific will replace North America as the market leader because of its sound manufacturing industry and large end-use industries such as automotive and electronics. North America and Europe are also other key consumers of the product due to advances in technology in the automobiles’ industry. Market is quite saturated due to high density of competition, but all the major players are always trying to come up with new solution to meet the changing requirement in various applications.

Molding Compounds Market Outlook, 2023 and 2032: Future Outlook

Molding Compounds Market Trend Analysis

Shifting Gears, The Rise of Lightweight and Durable Molding Compounds

Evaluations show that the consumers in the molding compounds market are gradually considering lightweight and durables materials needed for automotive industries especially in the electric vehicles (EVs). Automakers are now seeking lightweight materials and new manufacturing technologies to make cars lighter and lighter for greater economy and power. Moreover, molding compounds with High temperature performances and electrical EMI and electrical insulation are increasingly demanded due to electronics industries.

Another new development noted is the rising use of environmental friendly molding compounds. As stakeholders aim to limit their emissions, companies are engineering products with environmentally friendly medium, including the use of compounds that are biodegradable, or that are developed from renewable sources. They expect this trend to continue given the increase in environmental standards around the world that compelled firms to incorporation sustainability into their supply chain.

Fueling Growth, The Automotive Industry’s Push for Molding Compounds

The automotive industry and particularly that of lightweight vehicles is a major driver of demand for molding compounds. Molding compounds find widespread applications in automotive applications including bumpers, dashboards and appliques inside the hood due to their mechanical strength and heat tolerance. While electric vehicles are gaining more popularity in the market, so there is a need for such materials that can perform the required functions for the proper work of these vehicles.

The other factor is the increasing need for electronics products for which molding compounds are employed for electrical insulation or for shielding of electronic circuits. This is evidenced by the sophisticated consumer electronics industry as more consumer devices trend towards the use of smart devices, the molding compounds’ performance requirements in terms of heat property, mechanical strength, and durability are increasingly more demanding. These developments are further fueling the growth of the molding compounds market.

The Price of Progress, Raw Material Costs Impacting Market Dynamics

The molding compounds market is facing several risks one of which is the high cost of the raw materials. It is noteworthy that the creation of some resins, including epoxy and polyurethane, involves the use of expensive chemicals and elaborate processes, constraining the development of markets. Also the volatility in the global supply chain, which has been evidenced by frequent changes in the prices of raw materials, is a factor that has compromised manufacturing costing and hence the ability of producers to compete in terms of prices.

Another restraint is the environmental factors the handling of molding compounds especially on thermosetting compounds which are difficult to dispose. This has led to regulation agencies to set rigid standards to control waste management and recycling which may help the cost structure of business into the market. Actually, manufacturers are now regularly forced to come up with solutions that will help reduce the impact of their products on the environment, but in most cases such options are yet to be evolved.

Green Revolution, Capitalizing on Sustainable Molding Compounds

One of the biggest market drivers in the molding compounds market can be seen into the increased use of green and environment friendly products. As the concentration on sustainability in industries rises, the manufacturers get the opportunity to excite in research of biodegradable or recyclable alloys. It is present in automobile and electronics industries in particular where the companies are very concerned with cutting their environmental footprints.

Another prospect thing that can be avails the molding compounds market is the growing popularity of electric vehicles (EVs). Reinforcement, lightweight and heat endurable material is relevant in the production of EV casings and under hood. This position provides specialized molding compound manufacturers with a chance to develop new specialized molding compounds for the particular requirements of the EV market and thus define the future development of the market.

Molding Compounds Market Segment Analysis:

Molding Compounds Market Segmented on the basis of By Type, By Material and By Application.

By Type

o Thermoset Molding Compounds

o Thermoplastic Molding Compounds

By Application

o Epoxy, Phenolic

o Polyester

o Polyurethane

o Others

By Material

o Epoxy, Phenolic

o Polyester

o Polyurethane

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Thermoset Molding Compounds segment is expected to dominate the market during the forecast period

The molding compounds market can be divided into two key types: thermoset and thermoplastic. Thermoset molding compounds are characterized by high operating temperature, mechanical strength and electrical insulation thus suitable for applications where long useful life is needed, for instance cars and aircrafts. Thermoplastic compounds can be readily processed since they can be re-melted and re-formed Thermoplastic compounds are therefore the most favored for mass production for relatively low volume applications in the consumer goods and electronics industries.

By Material, Epoxy segment expected to held the largest share

Many molding compounds can be made using epoxy, phenolic, polyester and polyurethane; all of which have certain characteristics for certain applications. Epoxy based compound are widely used because of high mechanical performance or chemical corrosion resistance while phenolic based compound are mainly used in electrical items due to their high heat resistance capabilities. It being an elastomeric material it has been used with polyester and polyurethane compounds for flexibility, durability and low cost. Other types of materials in the market include silicone and polyimide materials which are used in applications that require high performing material in rigorous circumstances.

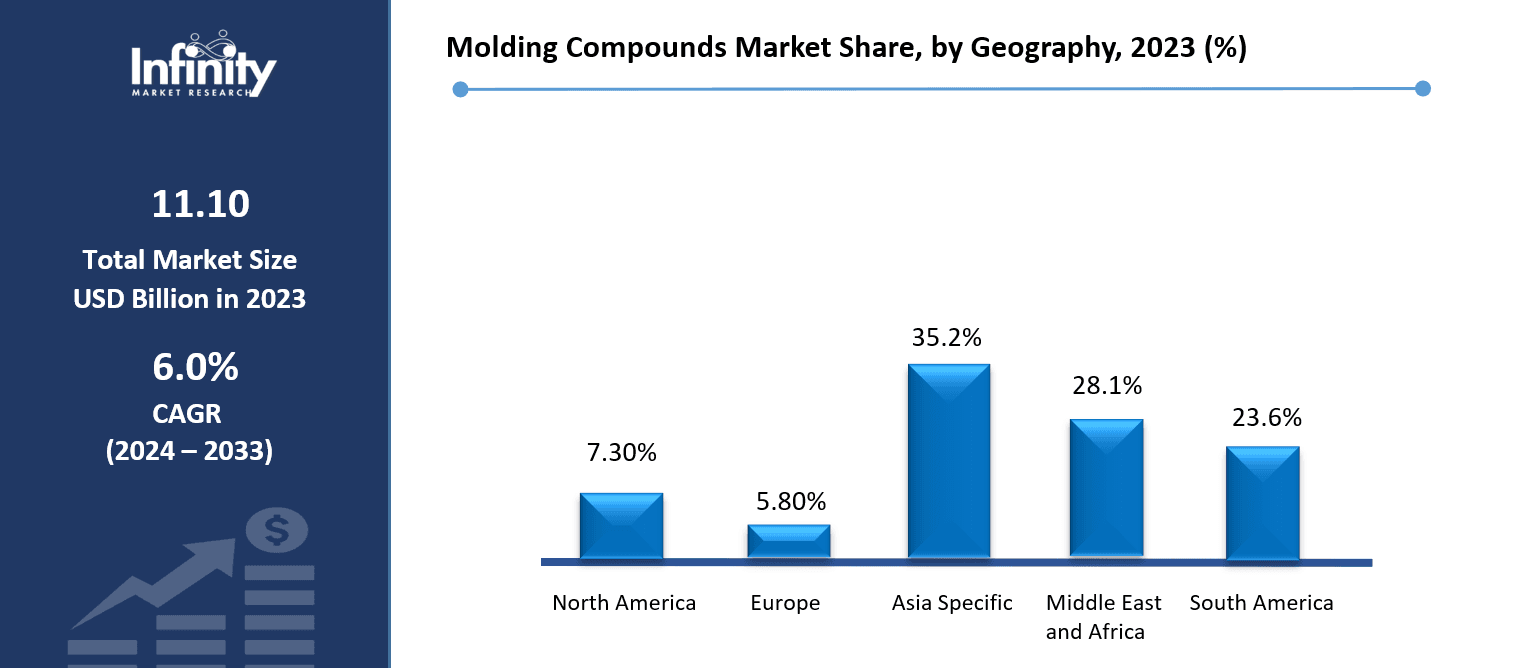

Molding Compounds Market Regional Insights

Asia Pacific is Expected to Dominate the Market Over the Forecast period

The Asia Pacific region is expected to emerge as the largest consumer of molding compounds due to its sound manufacturing structure, affordable production and upcoming industrialization of countries like China and India. The key application areas include automotive, especially in lightweight and high strength electric vehicle (EV) components. In the same regard, the Electronics industry in developed countries like Japan and South Korea is growing strongly, creating need for high performance molding compound materials that provide electrical insulation, heat resistance and mechanical strength. Thus an increasing industrial demand and development mainly the supply line chains is opening up a plethora of possibilities for manufacturers in the region.

Furthermore, Asia Pacific location is experiencing the start of sustainable solutions; the escalating environmental problems cause increased attention to waste management and recycling. This has led to developments in several productions of molding compounds including biodegradable or recyclable products manufacturing, seeing the market offer an opportunity to meet both record and market needs. Thus, the increasing automotive and electronics industries, along with environmental demands for shift towards reduced emissions molding compounds for Asia Pacific is expected to hold significant growth in the near future.

Molding Compounds Market Share, by Geography, 2023 (%)

Active Key Players in the Molding Compounds Market

o BASF (Germany)

o Covestro AG (Germany)

o DuPont (USA)

o Huntsman Corporation (USA)

o Lanxess AG (Germany)

o Mitsubishi Chemical Corporation (Japan)

o Momentive Performance Materials Inc. (USA)

o SABIC (Saudi Arabia)

o Solvay (Belgium)

o Sumitomo Bakelite Co., Ltd. (Japan)

o Other key Players

Global Molding Compounds Market Scope

|

Global Molding Compounds Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 11.90 Billion |

|

Forecast Period 2024-32 CAGR: |

6.10 % |

Market Size in 2032: |

USD 20.27 Billion |

|

Segments Covered: |

By Type |

· Thermoset Molding Compounds · Thermoplastic Molding Compounds | |

|

By Material |

· Epoxy, Phenolic · Polyester · Polyurethane · Others | ||

|

By Application |

· Automotive · Electrical & Electronics · Aerospace · Consumer Goods · Industrial · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Powering Electronics, The Surge in Demand for High-Performance Molding Materials | ||

|

Key Market Restraints: |

· Waste Not, Overcoming Recycling Challenges in Molding Compounds | ||

|

Key Opportunities: |

· Electric Dreams, Seizing Opportunities in the Electric Vehicle Market with Molding Compounds | ||

|

Companies Covered in the report: |

· BASF (Germany), DuPont (USA), Huntsman Corporation (USA), SABIC (Saudi Arabia), Mitsubishi Chemical Corporation (Japan), Lanxess AG (Germany), Solvay (Belgium), Covestro AG (Germany), Momentive Performance Materials Inc. (USA), Sumitomo Bakelite Co., Ltd. (Japan) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Molding Compounds Market research report?

Answer: The forecast period in the Molding Compounds Market research report is 2024-2032.

2. Who are the key players in the Molding Compounds Market?

Answer: BASF (Germany), DuPont (USA), Huntsman Corporation (USA), SABIC (Saudi Arabia), Mitsubishi Chemical Corporation (Japan), Lanxess AG (Germany), Solvay (Belgium), Covestro AG (Germany), Momentive Performance Materials Inc. (USA), Sumitomo Bakelite Co., Ltd. (Japan) and Other Major Players.

3. What are the segments of the Molding Compounds Market?

Answer: The Molding Compounds Market is segmented into By Type, By Material, By Application and region. By Type, the market is categorized into Thermoset Molding Compounds, Thermoplastic Molding Compounds. By Material, the market is categorized into Epoxy, Phenolic, Polyester, Polyurethane, Others. By Application, the market is categorized into Automotive, Electrical & Electronics, Aerospace, Consumer Goods, Industrial, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Molding Compounds Market?

Answer: Molding compounds are used for making molded products in several fields of manufacturing. These are thermosetting or thermoplastic materials that are prepared to be given form under heat and pressure for end products. The most frequently applied types of molding compounds include epoxy, polyester and polyurethane resins due to high mechanical characteristics, heat and chemical resistance. Molding compounded are extensively used in automotive, electrical & aerospace industries, as well as in consumer durables due to the capacity of the compound to produce complex, high standard parts.

5. How big is the Molding Compounds Market?

Answer: Molding Compounds Market Size Was Valued at USD 11.90 Billion in 2023, and is Projected to Reach USD 20.27 Billion by 2032, Growing at a CAGR of 6.10 % From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.