🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Non-Phthalate Plasticizers Market

Non-Phthalate Plasticizers Market Global Industry Analysis and Forecast (2024-2032) By Type (Adipates, Terephthalates, Trimellitates, Epoxidized Soybean Oil (ESBO), Benzoates, Citrates, Others.), By Application (Flooring & Wall Coverings, Wires & Cables, Films & Sheets, Coated Fabrics, Consumer Goods, Medical Products, Others.), By End-Use Industry (Building & Construction, Automotive, Packaging, Electronics, Healthcare, Others.) and Region

Mar 2025

Chemicals and Materials

Pages: 138

ID: IMR1864

Non-Phthalate Plasticizers Market Synopsis

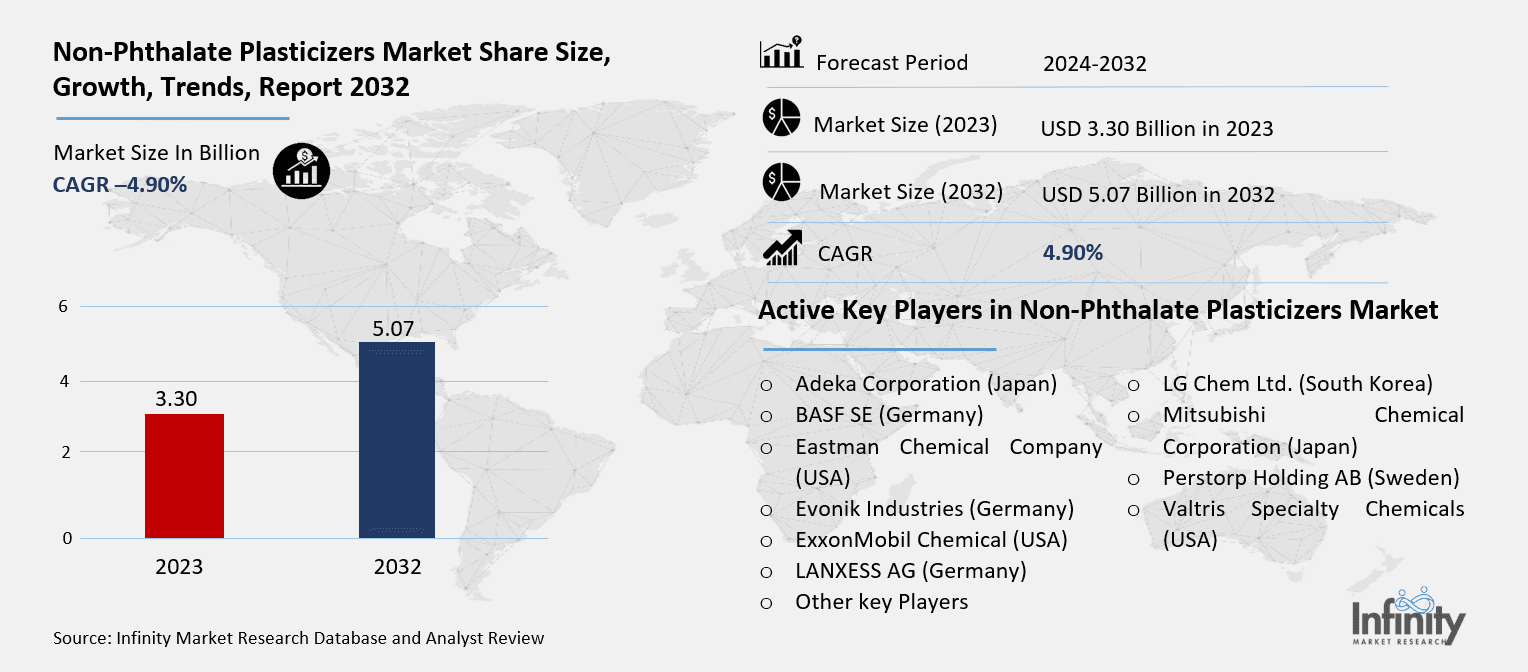

Non-Phthalate Plasticizers Market Size Was Valued at USD 3.30 Billion in 2023, and is Projected to Reach USD 5.07 Billion by 2032, Growing at a CAGR of 4.90 % From 2024-2032.

Mostly polyvinyl chloride (PVC), non-phthalate plasticizers are chemical additions used to improve the flexibility, durability, and processability of polymers without resorting to dangerous phthalues. Ideal for uses in building, automotive, medical, consumer goods, and packaging sectors, these plasticizers provide better environmental and health advantages. Their compliance with strict regulations and customer desire for sustainable materials help them to be more and more preferred.

Rising environmental issues and legislative limitations on conventional phthalates are driving strong worldwide non-phthalate plasticizer market growth. Strict rules implemented by governments and companies all around are meant to lower the usage of dangerous chemicals in plastic products, so promoting the acceptance of better substitutes. Further increasing demand are sectors including construction, automotive, and healthcare which are turning to sustainable materials. Thanks in large part to its fast urbanization and strong manufacturing base, the Asia-Pacific area rules the industry.

Product breakthroughs include bio-based plasticizers and technological developments are opening fresh paths of business. Leading producers are funding R&D to create reasonably priced, high-performance plasticizers meeting strict industry criteria. High production costs and little awareness in underdeveloped areas, however, could restrict the growth of the market. Notwithstanding these challenges, market participants have great chances since non-toxic plasticizers are becoming more and more used in many different applications.

Non-Phthalate Plasticizers Market Outlook, 2023 and 2032: Future Outlook

Non-Phthalate Plasticizers Market Trend Analysis

The Rise of Bio-Based Plasticizers, A Green Revolution in Plastics

An important development in the non-phthalate plasticizers market is growing inclination for renewable substitutes based on bio-based materials. Manufacturers are concentrating on creating plant-derived plasticizers that provide either similar or better performance than synthetic alternatives as sustainability projects grow. Companies are looking at substitutes with improved biodegradability and less carbon footprints including citrates and epoxidized soybean oil (ESBO). This change fits customer knowledge of environmentally friendly products.

Growing acceptance of non-phthalate plasticizers in the medical and healthcare industries is another important development. Concerns about the toxicity of conventional plasticizers have hospitals and makers of medical equipment switching to safer substitutes in IV bags, tubing, and blood storage systems. By establishing rigorous restrictions on phthalate use in medicinal applications, regulatory agencies such the FDA and the European Chemicals Agency (ECHA) are further underlining this change.

Regulations Paving the Way for Non-Toxic Plastic Solutions

The strict regulatory scene is one of the main forces behind the market. Phthalate plasticizer bans in North America and Europe have driven manufacturers to switch to non-phthalate substitutes. Strict policies enforced by regulatory bodies as the Environmental Protection Agency (EPA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) are reducing the usage of dangerous chemicals, therefore driving the need for safer plasticizers.

Rising consumer desire for sustainable and non-toxic plastic materials is another important influence. Rising knowledge of the health hazards connected to phthalates, especially in food packaging and toys for children, has changed buying behavior. Customers are aggressively looking for goods produced using environmentally friendly, compliant materials, therefore motivating producers to make non-phthalate solutions investments.

High Production Costs, A Barrier to Widespread Adoption

Though non-phthalate plasticizers have great growth potential, producers have great difficulty due to their high production costs. These substitutes sometimes call for specific raw materials and sophisticated production methods, which drives higher general costs. For sectors including consumer goods and packaging that are price conscious, this cost element can prevent general acceptance.

Restraints include also limited awareness and sluggish regulatory implementation in several developing countries. Although affluent nations have strict rules against phthalates, many developing nations still lack clear policies which slows down market expansion. Because of their economic benefits and regulatory flexibility, companies running in these areas sometimes keep utilizing traditional plasticizers.

Bio-Based Innovations, The Next Frontier for Non-Phthalate Plasticizers

For market players, the growing need for bio-based plasticizers offers a major potential. Companies investing in renewable and biodegradable substitutes can get a competitive edge as global sustainability projects get steam. Manufacturers are finding fresh income sources from innovations in bio-derived adipates and citrates, which have comparable performance to conventional plasticizers.

Furthermore, the spread of non-phthalate plasticizers in the automotive and electronics industries has rich development possibilities. Flexible and durable polymer components are becoming more important as electric vehicles (EVs) and sophisticated electronic devices become more well-known. Adoption of non-phthalate plasticizers in wire coatings, insulating materials, and automobile interiors is likely to propel significant market expansion in the next years.

Non-Phthalate Plasticizers Market Segment Analysis

Non-Phthalate Plasticizers Market Segmented on the basis of By Type, By Application and By End-Use Industry.

By Type

o Adipates

o Terephthalates

o Trimellitates

o Epoxidized Soybean Oil (ESBO)

o Benzoates

o Citrates

o Others.

By Application

o Flooring & Wall Coverings

o Wires & Cables

o Films & Sheets

o Coated Fabrics

o Consumer Goods

o Medical Products

o Others.

By End Use

o Building & Construction

o Automotive

o Packaging

o Electronics

o Healthcare

o Others.

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Adipates segment is expected to dominate the market during the forecast period

Widely employed throughout many different sectors are adipates, terephthalates, trimellitates, epoxidized soybean oil (ESBO), benzoates, citrates, and other non-phthalate plasticizers. Perfect for automotive and building uses, adipates and terephthalates are selected for their great flexibility and heat resistance. High-performance uses needing great longevity call for trimellites. While benzoates and citrates are widely utilized in consumer products and medical applications because their non-toxic character, ESBO is becoming more and more popular as a bio-based substitute.

By Application, Flooring & Wall Coverings segment expected to held the largest share

Flooring and wall coverings, wires and cables, films and sheets, coated fabrics, consumer goods, medical devices, and other uses all make great use of non-phthalate plasticizers. The demand for flexible and long-lasting materials drives the flooring and construction industries front and foremost. Excellent electrical insulating characteristics of non-phthalate plasticizers help wires and cables. Thanks to regulatory compliance, films and sheets especially in packaging are seeing more acceptance. Another important application area is the medical one since safe plasticizers are increasingly used in tubing and medical equipment.

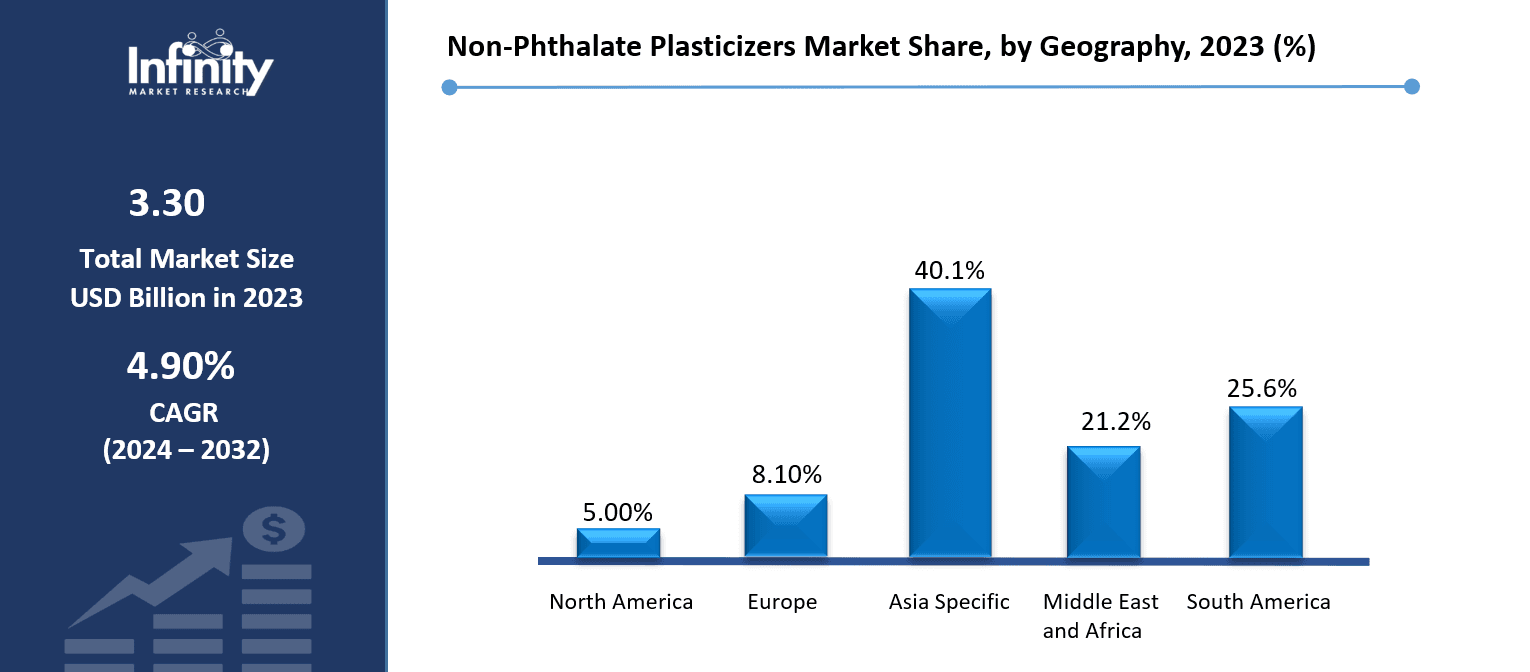

Non-Phthalate Plasticizers Market Regional Insights

Asia pacific is Expected to Dominate the Market Over the Forecast period

Asia-Pacific dominates the non-phthalate plasticizers market because of its strong manufacturing environment, fast industrialization, and great demand from important sectors including consumer goods, automotive, and construction. Leading contributors are nations like China, India, and Japan, whose large-scale manufacturing capability supports safer plasticizers by means of strengthened laws. The demand for non-toxic and sustainable plastic solutions is further driven by the middle-class population of the area and tendencies of urbanization.

Asia-Pacific also gains from a developed supply network and availability of raw materials, therefore guaranteeing manufacturers' competitive prices. Government regulations in China and India pushing the use of environmentally friendly products help to increase market penetration even more. Rising infrastructure and automotive industry developments mean that non-phthalate plasticizers will be more in demand steadily in the area.

Non-Phthalate Plasticizers Market Share, by Geography, 2023 (%)

Active Key Players in the Non-Phthalate Plasticizers Market

o Adeka Corporation (Japan)

o BASF SE (Germany)

o Eastman Chemical Company (USA)

o Evonik Industries (Germany)

o ExxonMobil Chemical (USA)

o LANXESS AG (Germany)

o LG Chem Ltd. (South Korea)

o Mitsubishi Chemical Corporation (Japan)

o Perstorp Holding AB (Sweden)

o Valtris Specialty Chemicals (USA)

o Other key Players

Global Non-Phthalate Plasticizers Market Scope

|

Global Non-Phthalate Plasticizers Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 3.30 Billion |

|

Forecast Period 2024-32 CAGR: |

4.90 % |

Market Size in 2032: |

USD 5.07 Billion |

|

Segments Covered: |

By Type |

· Adipates · Terephthalates · Trimellitates · Epoxidized Soybean Oil (ESBO) · Benzoates · Citrates · Others. | |

|

By Application |

· Flooring & Wall Coverings · Wires & Cables · Films & Sheets · Coated Fabrics · Consumer Goods · Medical Products · Others. | ||

|

By End-Use Industry |

· Building & Construction · Automotive · Packaging · Electronics · Healthcare · Others. | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Consumer Awareness Driving the Surge in Sustainable Plasticizers | ||

|

Key Market Restraints: |

· Slow Market Penetration in Developing Regions, A Growth Challenge | ||

|

Key Opportunities: |

· Expanding Applications in EVs and Electronics, A Market on the Move | ||

|

Companies Covered in the report: |

· BASF SE (Germany), Eastman Chemical Company (USA), Evonik Industries (Germany), LANXESS AG (Germany), ExxonMobil Chemical (USA), LG Chem Ltd. (South Korea), Adeka Corporation (Japan), Perstorp Holding AB (Sweden), Valtris Specialty Chemicals (USA), Mitsubishi Chemical Corporation (Japan). and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Non-Phthalate Plasticizers Market research report?

Answer: The forecast period in the Non-Phthalate Plasticizers Market research report is 2024-2032.

2. Who are the key players in the Non-Phthalate Plasticizers Market?

Answer: BASF SE (Germany), Eastman Chemical Company (USA), Evonik Industries (Germany), LANXESS AG (Germany), ExxonMobil Chemical (USA), LG Chem Ltd. (South Korea), Adeka Corporation (Japan), Perstorp Holding AB (Sweden), Valtris Specialty Chemicals (USA), Mitsubishi Chemical Corporation (Japan). and Other Major Players.

3. What are the segments of the Non-Phthalate Plasticizers Market?

Answer: The Non-Phthalate Plasticizers Market is segmented into By Type, By Application, By End-Use Industry and region. By Type, the market is categorized into Adipates, Terephthalates, Trimellitates, Epoxidized Soybean Oil (ESBO), Benzoates, Citrates, Others. By Application, the market is categorized into Flooring & Wall Coverings, Wires & Cables, Films & Sheets, Coated Fabrics, Consumer Goods, Medical Products, Others. By End-Use Industry, the market is categorized into Building & Construction, Automotive, Packaging, Electronics, Healthcare, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Non-Phthalate Plasticizers Market?

Answer: Mostly polyvinyl chloride (PVC), non-phthalate plasticizers are chemical additions used to improve the flexibility, durability, and processability of polymers without resorting to dangerous phthalues. Ideal for uses in building, automotive, medical, consumer goods, and packaging sectors, these plasticizers provide better environmental and health advantages. Their compliance with strict regulations and customer desire for sustainable materials help them to be more and more preferred.

5. How big is the Non-Phthalate Plasticizers Market?

Answer: Non-Phthalate Plasticizers Market Size Was Valued at USD 3.30 Billion in 2023, and is Projected to Reach USD 5.07 Billion by 2032, Growing at a CAGR of 4.90 % From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.