🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

PET Bottle Recycling Market

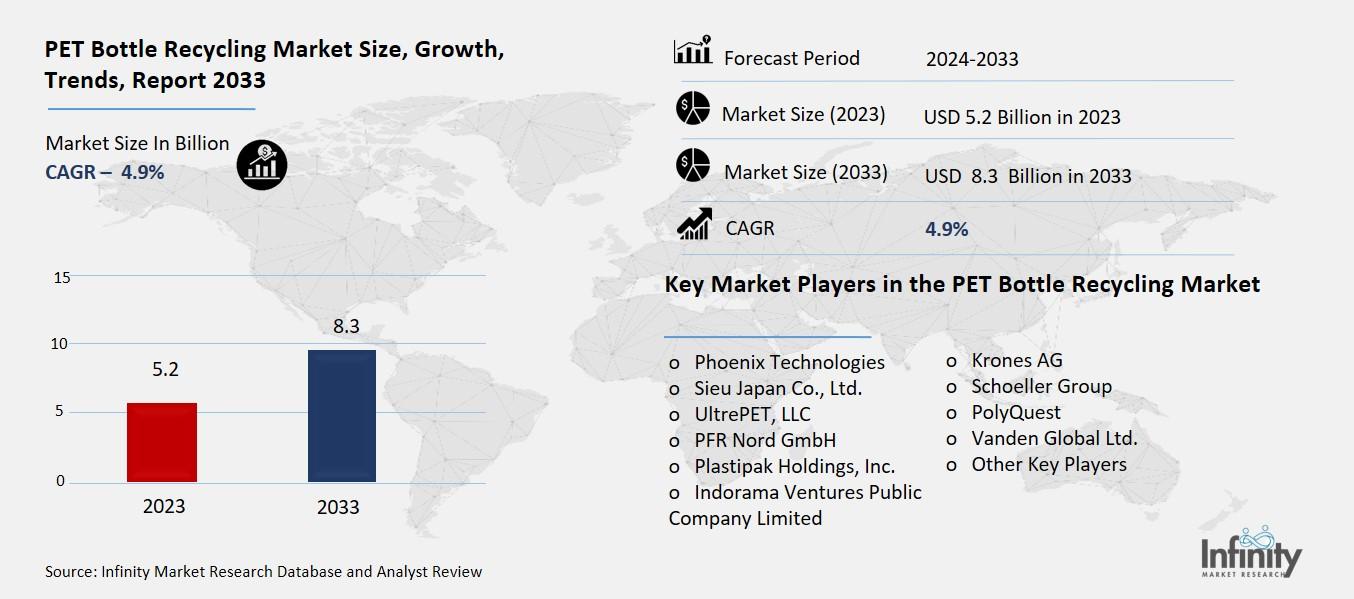

Global PET Bottle Recycling Market (By Process, Chemical and Mechanical; By Application, Beverages, Consumer Goods, Pharmaceuticals, Personal Care, and Other Applications; By Region and Companies), 2024-2033

Nov 2024

Packaging and Transports

Pages: 138

ID: IMR1328

PET Bottle Recycling Market Overview

Global PET Bottle Recycling Market acquired the significant revenue of 5.2 Billion in 2023 and expected to be worth around USD 8.3 Billion by 2033 with the CAGR of 4.9% during the forecast period of 2024 to 2033. The recycled PET bottle market has expanded over the years as consumers become more conscious on the impact of their actions on the environment and the need to adopt sustainable measures such as recycling in packaging. Plastic bottles commonly used in beverages industries especially PVC are a source of plastic wastes. Due to increased environmental consciousness on the increased use of single-use plastics, both the consumers and producers are demanding increased recycling.

The market is stimulated by increasing demand for rPET to replace virgin plastic material in production across various sectors such as food and beverages, textiles, automobiles among others. Governments of the world are coming up with measures to curb plastics use and carbon emission hence increasing the adoption of the product boosting the market.

Drivers for the PET Bottle Recycling Market

Increasing Environmental Awareness

The increasing awareness of the impact of plastics in the environment has become one of the leading social problems in the twenty first century. As plastic waste, particularly PEST bottles, and other single-use plastic wastes continue to fill the world’s landfill sites, seas, oceans and other environments, the search for the best substitutes has become even more crucial. Plastic PET bottles that is used to pack all types of beverages and consumer products were identified as the largest stream of plastic waste. This has in the process brought awareness to the general public of the various negative effects that plastic is causing to animal and plant life, water sources and even health of human beings.

As a result, there is an increasing call for technologies that are able to lower the impact of plastic materials on the environment. rPET is becoming the new black because it creates an opportunity for utilising recycled items in making new products and providing value to waste citizens generate.

Restraints for the PET Bottle Recycling Market

Limited Collection and Sorting Systems

In many regions, inadequate or inefficient collection and sorting systems pose a significant barrier to the effective recycling of PET bottles. The success of recycling programs heavily depends on the ability to efficiently collect and separate recyclable materials from general waste. In regions where waste management infrastructure is underdeveloped or poorly implemented, large volumes of PET bottles end up in landfills or are incinerated instead of being recycled. Without proper collection systems, recyclable PET is often contaminated with other waste, making it difficult or costly to process. Furthermore, the lack of advanced sorting technologies means that PET bottles are frequently mixed with other types of plastics, reducing the quality of the recycled material.

Opportunity in the PET Bottle Recycling Market

Technological Advancements in Recycling

Innovations in chemical and enzymatic recycling processes are revolutionizing the PET recycling industry by significantly improving the efficiency and effectiveness of recycling methods. Traditional mechanical recycling, which involves melting down PET bottles and reusing the material, often results in a decrease in quality and limits the types of PET products that can be recycled. However, chemical and enzymatic recycling technologies offer more advanced solutions by breaking down PET at the molecular level, allowing for a higher-quality, purer form of recycled PET (rPET) to be produced.

Chemical recycling methods involve breaking down PET into its basic building blocks, such as terephthalic acid and ethylene glycol, which can then be repolymerized to form new PET products. This process can handle contaminated or mixed PET waste, making it more versatile and efficient than traditional recycling methods.

Trends for the PET Bottle Recycling Market

Increasing Use of rPET in Packaging

Innovations in chemical and enzymatic recycling processes are transforming the PET recycling landscape by addressing some of the key limitations of traditional recycling methods. In mechanical recycling, PET materials are often degraded by heat and pressure, leading to a decrease in quality and limiting their ability to be reused in high-value products. Chemical recycling, however, involves breaking down PET into its core components monomers like terephthalic acid and ethylene glycol through processes such as glycolysis, hydrolysis, or methanolysis. This method allows for the complete deconstruction of PET, making it possible to produce high-quality recycled PET (rPET) that can be reused in food-grade packaging or other demanding applications.

Segments Covered in the Report

By Process

o Chemical

o Mechanical

By Application

o Beverages

o Consumer goods

o Pharmaceuticals

o Personal Care

o Other Applications

Segment Analysis

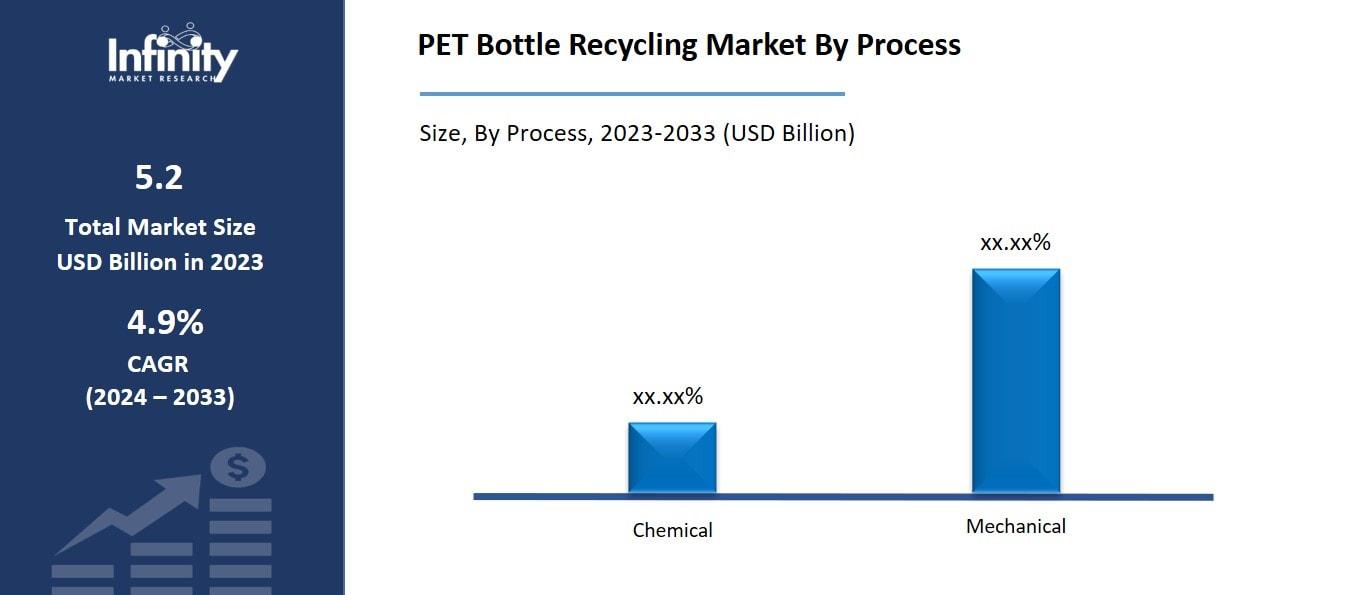

By Process Analysis

On the basis of process, the market is divided into chemical and mechanical. Among these, chemical segment acquired the significant share in the market owing to its ability to handle a wider range of PET waste and produce higher-quality recycled materials. Unlike mechanical recycling, which involves melting and reprocessing PET, chemical recycling breaks down PET into its monomers, such as terephthalic acid and ethylene glycol, allowing for a more complete and efficient recycling process. This method not only enables the recycling of contaminated or mixed PET waste that is typically unsuitable for mechanical recycling but also allows for the production of food-grade recycled PET (rPET), which can be used in applications that require high purity, such as beverage bottles.

By Application Analysis

On the basis of application, the market is divided into beverages, consumer goods, pharmaceuticals, personal care, and other applications. Among these, beverages segment held the prominent share of the market due to the widespread use of PET bottles in beverage packaging, particularly for carbonated drinks, bottled water, juices, and ready-to-drink teas. PET is favored in the beverage industry due to its lightweight, durability, and ability to preserve the contents while maintaining cost-effectiveness in production.

The demand for sustainable packaging solutions in the beverage sector has driven significant adoption of recycled PET (rPET), as both consumers and regulatory bodies push for reductions in plastic waste and greater recycling efforts. Beverage companies are increasingly committed to sustainability targets, such as using higher percentages of rPET in their bottles, to reduce their environmental footprint.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 31.1% of the market. The U.S. and Canada have implemented stringent environmental regulations that encourage the use of recycled materials in manufacturing, particularly in packaging for beverages, consumer goods, and other industries. These regulations, coupled with increased corporate sustainability efforts, have spurred significant investments in PET recycling technologies and infrastructure.

Additionally, North American companies are increasingly adopting recycled PET (rPET) in their packaging to meet sustainability targets and respond to consumer preferences for eco-friendly products. The region also benefits from a well-established recycling infrastructure that enables more efficient collection, sorting, and processing of PET bottles and other plastic waste. This, combined with ongoing advancements in chemical and enzymatic recycling technologies, has further boosted the availability and quality of recycled PET materials.

Competitive Analysis

The PET recycling market is highly competitive, with key players focusing on innovation, sustainability, and expanding their recycling capabilities to meet the growing demand for recycled PET (rPET). Major companies in the market include plastic recycling firms, packaging manufacturers, and beverage producers who are increasingly integrating recycled materials into their products to comply with regulatory standards and address consumer demand for eco-friendly packaging. Key players such as Coca-Cola, PepsiCo, and Nestlé have made significant commitments to incorporating more rPET into their packaging, driving further market growth.

Recent Developments

In November 2022, Plastipak announced the launch of its fifth recycling plant in Toledo, Spain, which boasts a capacity of 20,000 tons of food-grade recycled pellets. This new facility will help reduce resin transport-related emissions, as it is strategically located near its existing preform manufacturing unit.

In October 2021, PolyQuest established Renuva Plastics LLC, a subsidiary of PolyQuest operating as Faith Group USA, following the acquisition of Faith Group Company's U.S. division. Faith Group is a leading distributor of post-industrial thermoplastics, particularly PET. This acquisition grants PolyQuest significant access to virgin, post-industrial, and post-consumer materials used in applications like bottles, sheets, film, textiles, strapping, and more.

Key Market Players in the PET Bottle Recycling Market

o Phoenix Technologies

o Sieu Japan Co., Ltd.

o UltrePET, LLC

o PFR Nord GmbH

o Plastipak Holdings, Inc.

o Indorama Ventures Public Company Limited

o Krones AG

o Schoeller Group

o PolyQuest

o Vanden Global Ltd.

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 5.2 Billion |

|

Market Size 2033 |

USD 8.3 Billion |

|

Compound Annual Growth Rate (CAGR) |

4.9% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Process, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Phoenix Technologies, Sieu Japan Co., Ltd., UltrePET, LLC, PFR Nord GmbH, Plastipak Holdings, Inc., Indorama Ventures Public Company Limited, Krones AG, Schoeller Group, PolyQuest, Vanden Global Ltd., and Other Key Players. |

|

Key Market Opportunities |

Technological Advancements in Recycling |

|

Key Market Dynamics |

Increasing Environmental Awareness |

📘 Frequently Asked Questions

1. Who are the key players in the PET Bottle Recycling Market?

Answer: Phoenix Technologies, Sieu Japan Co., Ltd., UltrePET, LLC, PFR Nord GmbH, Plastipak Holdings, Inc., Indorama Ventures Public Company Limited, Krones AG, Schoeller Group, PolyQuest, Vanden Global Ltd., and Other Key Players.

2. How much is the PET Bottle Recycling Market in 2023?

Answer: The PET Bottle Recycling Market size was valued at USD 5.2 Billion in 2023.

3. What would be the forecast period in the PET Bottle Recycling Market?

Answer: The forecast period in the PET Bottle Recycling Market report is 2024-2033.

4. What is the growth rate of the PET Bottle Recycling Market?

Answer: PET Bottle Recycling Market is growing at a CAGR of 4.9% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.