🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Phosphorus-Containing Epoxy Resin Market

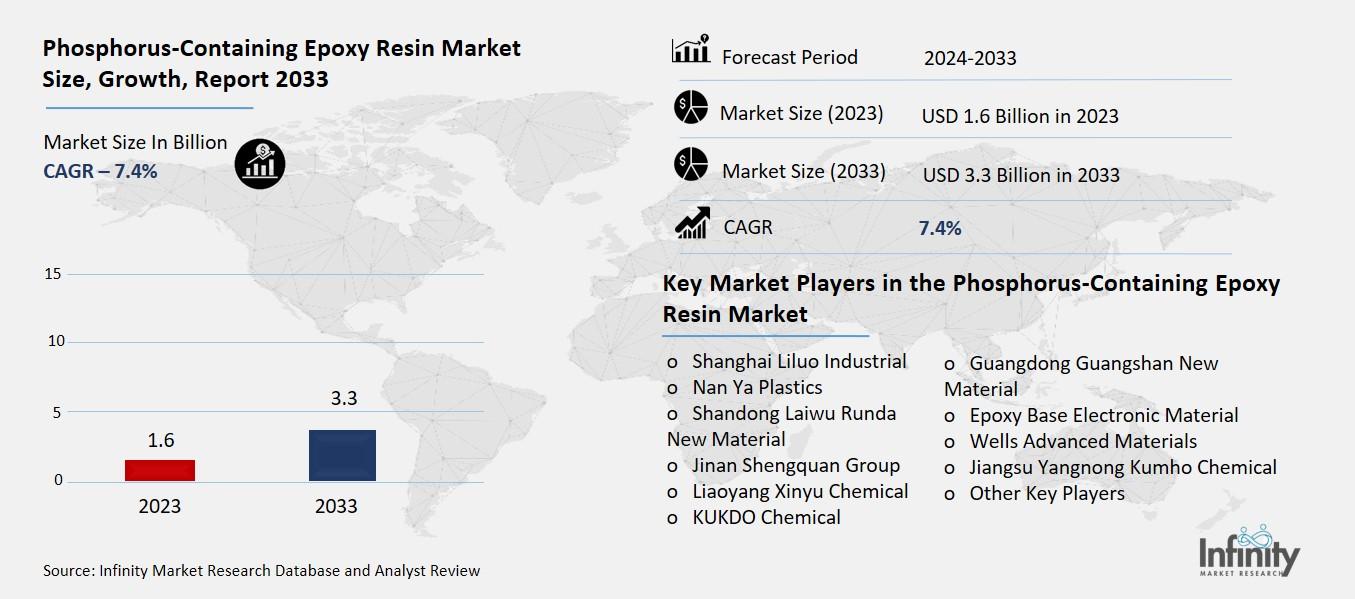

Global Phosphorus-Containing Epoxy Resin Market (By Type, Chemical Reaction and Physical Addition; By Application, Composite Material, Electronic Packaging, Adhesive, Coating, and Other Applications; By Region and Companies), 2024-2033

Dec 2024

Chemicals and Materials

Pages: 138

ID: IMR1388

Phosphorus-Containing Epoxy Resin Market Overview

Global Phosphorus-Containing Epoxy Resin Market acquired the significant revenue of 1.6 Billion in 2023 and expected to be worth around USD 3.3 Billion by 2033 with the CAGR of 7.4% during the forecast period of 2024 to 2033. The global phosphorus containing epoxy resin market is forecasted to grow rapidly as the product finds application in high performance materials in multiple industries. These epoxy resins with phosphorus have superior fire resistance, thermal stability, and mechanical strength, therefore they have been widely used in electronics, automobile, airplanes, and construction.

The rapidly growing need for eco-friendly and halogen-free flame retardants has also promoted a market growth since phosphorus-containing epoxy resins are compatible with higher safety and environmental standards. The factors exhibiting growth are increased production of electronics, such as printed circuit boards and semiconductor encapsulation. Also, as for other sectors, improvements in resin technologies together with increased tendencies towards sustainability are opening up further opportunities for further development in this market. Nonetheless, factors such as variation in the cost of raw material and volatility of rules and regulations can pose a threat to markets.

Drivers for the Phosphorus-Containing Epoxy Resin Market

Rising Demand for Flame-Retardant Materials

Organophosphorus epoxide curable are more widely used in cases where thermal stability is especially important, for example, electric and construction equipment production. In electronics industry, these resins are widely used for the PCBs, semiconductor encapsulations and other high heat performance components in which thermal stability and fire resistant perform are critical. These basic features are due to the incorporation of phosphorus compounds in the fabric, which satisfies essential safety requirements especially in critical uses such as consumer electronics, telecommunications, and auto electronics.

In construction, these resins are used for coatings, adhesives and the composites for fire and structural repair where required for high-rise constructions and infrastructural development. Combined mechanical strength and thermal stability make phosphorus containing epoxy resins as versatile for the end user and able to suit industries where safety comes first, but performance is not compromised.

Restraints for the Phosphorus-Containing Epoxy Resin Market

Stringent Regulatory Compliance

Regulatory requirements in certain regions for chemical production can create significant challenges for market players in the phosphorus-containing epoxy resin industry. Governments and regulatory bodies impose strict guidelines to ensure environmental protection, worker safety, and product quality, particularly for flame-retardant materials that involve potentially hazardous chemicals like phosphorus derivatives. Compliance with these regulations often demands substantial investments in advanced manufacturing technologies, emissions control systems, and detailed reporting mechanisms, which can increase production costs. For example, laws like the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the United States' EPA regulations require rigorous testing and certification of chemical formulations.

Opportunity in the Phosphorus-Containing Epoxy Resin Market

Increased Adoption in Renewable Energy

The use of phosphorus-containing epoxy resins in renewable energy components, such as solar panels and wind turbines, presents promising avenues for market growth. These resins are valued for their exceptional thermal stability, mechanical strength, and flame-retardant properties, which are critical in renewable energy applications exposed to harsh environmental conditions. In solar panels, phosphorus-containing epoxy resins are used in encapsulation materials to protect photovoltaic cells from heat, moisture, and UV radiation, enhancing their efficiency and lifespan.

Similarly, in wind turbines, these resins are employed in rotor blade manufacturing and protective coatings to improve structural integrity and resistance to extreme weather. The global shift toward cleaner energy sources and the rapid expansion of renewable energy projects, driven by government incentives and environmental goals, are expected to fuel demand.

Trends for the Phosphorus-Containing Epoxy Resin Market

Research and Development in Hybrid Materials

The combination of phosphorus-containing epoxy resins with other materials to enhance performance is gaining significant traction across industries. By blending these resins with fillers, fibers, or other advanced materials, manufacturers are developing composites with superior properties tailored to specific applications. For instance, reinforcing epoxy resins with carbon or glass fibers creates lightweight yet durable materials suitable for aerospace and automotive industries, where strength-to-weight ratio is critical. Similarly, integrating nanomaterials such as graphene or silica nanoparticles improves thermal conductivity, flame resistance, and mechanical robustness, making them ideal for high-performance electronics and industrial components. This approach also allows for customization to meet evolving industry standards, such as achieving higher efficiency in electrical insulation or better environmental resistance in outdoor applications like wind turbines.

Segments Covered in the Report

By Type

o Chemical Reaction

o Physical Addition

By Application

o Composite Material

o Electronic Packaging

o Adhesive

o Coating

o Other Applications

Segment Analysis

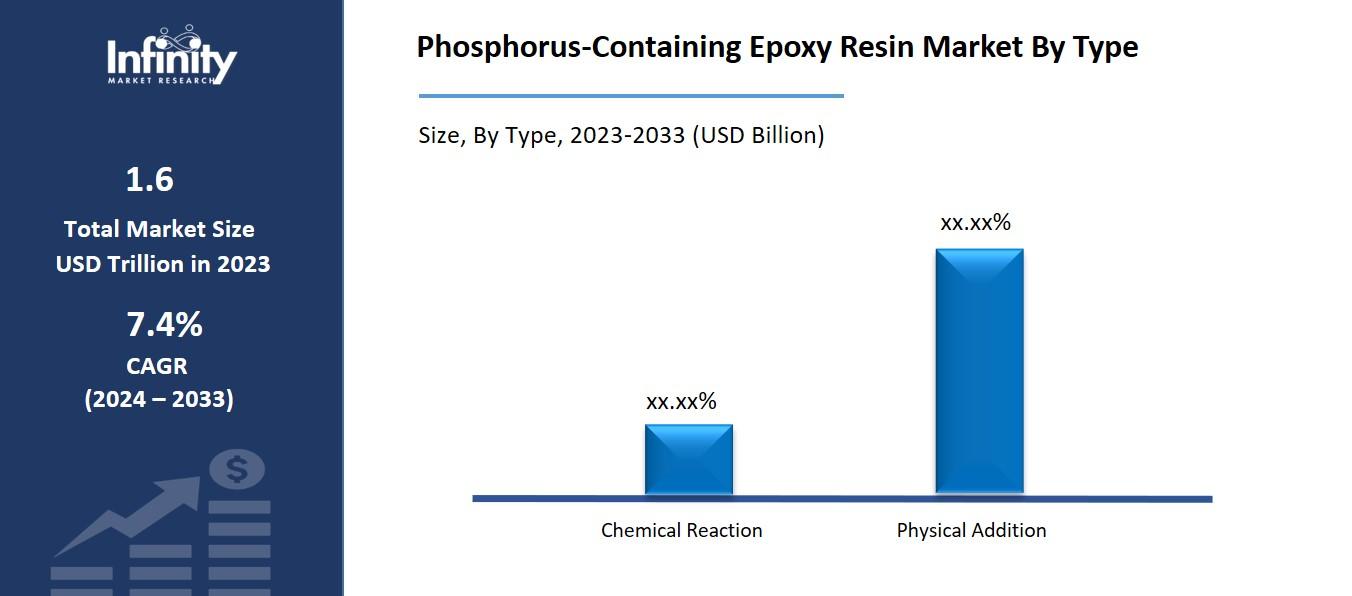

By Type Analysis

On the basis of type, the market is divided into chemical reaction and physical addition. Among these, chemical reaction segment acquired the significant share in the market owing to its superior integration of phosphorus into the epoxy resin matrix. This method ensures a more uniform distribution of phosphorus, resulting in enhanced flame-retardant properties, thermal stability, and mechanical strength. The chemical reaction process also enables the production of tailored resins with specific properties, meeting the stringent requirements of high-performance applications in electronics, aerospace, and construction.

By Application Analysis

On the basis of application, the market is divided into composite material, electronic packaging, adhesive, coating, and other applications. Among these, composite material segment held the prominent share of the market due to its critical role in industries requiring high-performance materials with enhanced mechanical properties and fire resistance. Phosphorus-containing epoxy resins are widely used in the production of composite materials for applications in aerospace, automotive, construction, and marine industries, where lightweight, durable, and fire-resistant materials are essential. The ability of these resins to improve the strength, heat resistance, and flame-retardant properties of composite materials makes them particularly valuable in manufacturing advanced components like aircraft parts, structural components in buildings, and automotive parts.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 34.1% of the market due to the region's robust industrial base, rapid urbanization, and significant growth in key sectors such as electronics, automotive, construction, and renewable energy. Countries like China, India, and Japan are major contributors to this growth, where the demand for high-performance materials, including flame-retardant resins, is increasing rapidly.

The region's leading position is further supported by the growing electronics manufacturing sector, particularly in China, where phosphorus-containing epoxy resins are extensively used in printed circuit boards and semiconductor encapsulations. Additionally, the expansion of the construction industry in countries like India and China, along with increasing infrastructure projects, further boosts the demand for composite materials and coatings incorporating phosphorus-containing epoxy resins.

Competitive Analysis

The competitive landscape of the phosphorus-containing epoxy resin market is characterized by a mix of established global players and regional manufacturers, all vying for market share by leveraging technological advancements, product innovation, and strategic partnerships. Key players in the market are focusing on enhancing their product portfolios by developing resins with improved flame-retardant properties, superior mechanical strength, and greater environmental sustainability to meet the increasing demand from industries such as electronics, automotive, aerospace, and construction. To gain a competitive edge, many companies are investing in research and development (R&D) to formulate more efficient, cost-effective resins and to explore alternative phosphorus sources, which can help mitigate supply chain challenges.

Key Market Players in the Phosphorus-Containing Epoxy Resin Market

o Shanghai Liluo Industrial

o Nan Ya Plastics

o Shandong Laiwu Runda New Material

o Jinan Shengquan Group

o Liaoyang Xinyu Chemical

o KUKDO Chemical

o Guangdong Guangshan New Material

o Epoxy Base Electronic Material

o Wells Advanced Materials

o Jiangsu Yangnong Kumho Chemical

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 1.6 Billion |

|

Market Size 2033 |

USD 3.3 Billion |

|

Compound Annual Growth Rate (CAGR) |

7.4% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Shanghai Liluo Industrial, Nan Ya Plastics, Shandong Laiwu Runda New Material, Jinan Shengquan Group, Liaoyang Xinyu Chemical, KUKDO Chemical, Guangdong Guangshan New Material, Epoxy Base Electronic Material, Wells Advanced Materials, Jiangsu Yangnong Kumho Chemical, and Other Key Players. |

|

Key Market Opportunities |

Increased Adoption in Renewable Energy |

|

Key Market Dynamics |

Rising Demand for Flame-Retardant Materials: |

📘 Frequently Asked Questions

1. Who are the key players in the Phosphorus-Containing Epoxy Resin Market?

Answer: Shanghai Liluo Industrial, Nan Ya Plastics, Shandong Laiwu Runda New Material, Jinan Shengquan Group, Liaoyang Xinyu Chemical, KUKDO Chemical, Guangdong Guangshan New Material, Epoxy Base Electronic Material, Wells Advanced Materials, Jiangsu Yangnong Kumho Chemical, and Other Key Players.

2. How much is the Phosphorus-Containing Epoxy Resin Market in 2023?

Answer: The Phosphorus-Containing Epoxy Resin Market size was valued at USD 1.6 Billion in 2023.

3. What would be the forecast period in the Phosphorus-Containing Epoxy Resin Market?

Answer: The forecast period in the Phosphorus-Containing Epoxy Resin Market report is 2024-2033.

4. What is the growth rate of the Phosphorus-Containing Epoxy Resin Market?

Answer: Phosphorus-Containing Epoxy Resin Market is growing at a CAGR of 7.4% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.