🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Polymer Coatings Market

Polymer Coatings Market Global Industry Analysis and Forecast (2024-2032) By Resin Type( Epoxy, Polyester, Polyurethane, Acrylic, Others (Polyvinylidene Fluoride, Silicone, etc.),By Application( Automotive, Construction, Industrial, Marine, Packaging, Consumer Goods, Others (Electronics, Aerospace, etc.)),By Technology(Solvent-borne, Waterborne, Powder Coatings, UV-cured),By End-User Industry( Automotive & Transportation, Construction, Industrial Equipment, Consumer Goods, Packaging, Electronics) and Region

Jan 2025

Chemicals and Materials

Pages: 1380

ID: IMR1624

Polymer Coatings Market Synopsis

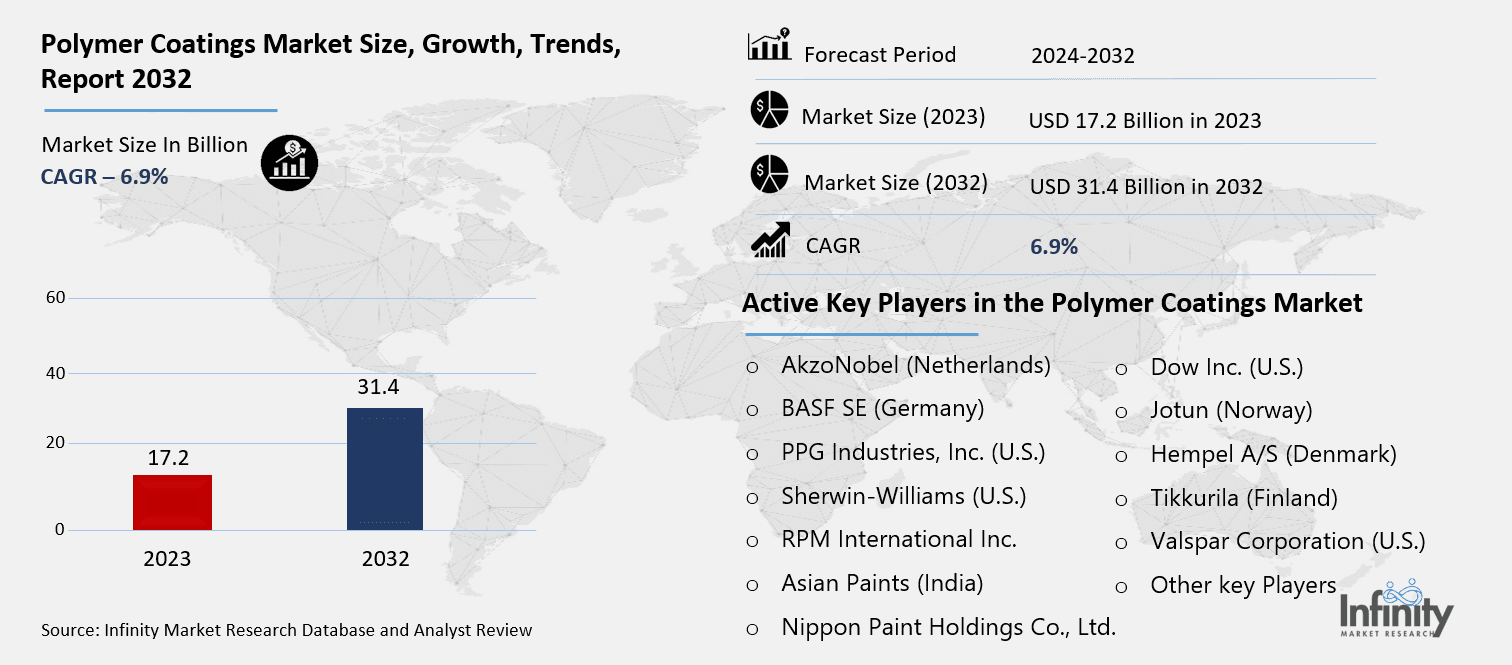

Polymer Coatings Market Size Was Valued at USD 17.2 Billion in 2023, and is Projected to Reach USD 31.4 Billion by 2032, Growing at a CAGR of 6.9% From 2024-2032.

Polymer Coatings Market means the segment that deals with manufacturing and utilizing of protective coatings made of polymer based materials. The uses of these coatings are to offer protection of surfaces, increase the lifespan and beautification of the surface as well as creating resistance against corrosion by formation of a thin layer on the surface, chemicals, and heat. Popular especially in varied types of businesses, polymer coatings are used across different industries on substrates such as metal, plastic, and concrete to deliver durable and protective films.

The Polymer Coatings Market has been rapidly growing in the last few years due to the rising need for high-performance and sustainable coatings in several sectors like automotive, construction, marine, packaging and consumer durable products. It is forecasted that the market will remain growing in the future by the help of new technologies and increasing cognition of the environmental problems. Polymer coatings have unique performances and great wearing, corrosion, moisture and UV light resistance, therefore it can be used in severe conditions. With increasing focus on environmental control and preservation the use of low VOC, and environmentally friendly systems such as water borne and solvent less borne systems have become popular resulting in development of new coatings.

In as much as the applications are concerned the automotive manufactures use the polymer coatings to improve on the looks of the automobiles and their resistance to weathers and corrosion. In construction it plays a role of protecting various products that are used in construction from various wears that they would otherwise undergo in natural conditions, in order to ensure that structures have a longer durability. The use of polymer coating is common in marine applications since it is resistant to saltwater, used in protecting ships as well as offshore structures. The packaging industry also widely uses polymer coatings in guaranteeing the effectiveness of material and packaged products in terms of moisture, oxygen, and other harm causing agents.

The polymer coatings are also used in various specific applications such as in electronics and aerospace industries where its insulating property brings protection for delicate parts. The increased trade and economic growth on the global market together with the resumption of industrial processes after the COVID-19 pandemic increase the demand for polymer coatings. There is a great emphasis on growth in production portfolio while increasing the functionality of the coatings like increased adhesion, scratch resistance and anti fouling characteristics to meet the needs of the expanding market. Moreover, the emphasis will be made on the primary research for the development of new polymer coatings that will stimulate the further market growth.

Polymer Coatings Market Outlook, 2023 and 2032: Future Outlook

Polymer Coatings Market Trend Analysis

Trend: Shift Towards Eco-Friendly and Low-VOC Coatings

The trend that can be seen in the Polymer Coatings Market is the increasing demand for environmentally friendly, as well as low VOC polymer coating. Environmental conservation has forced stake holders in manufacturing industries and consumers to look for coatings that will have minimal effects on air quality and human health. Conventional coatings have been known to contain large proportions of volatile organic compounds (VOCs) that are prejudicial to the generations’ health. As a result, many organizations are formulating, water borne, powder, and other coating systems that have lower VOC emissions.

This trend is expected to continue with increasing speed as laws regulating the emissions of air pollutants become tighter. Also, the improved understanding of the effects of environmental conservation leads to improved industrial implementation, in particular automotive and construction, practices. Due to the rising need for green solutions, manufacturers are searching for new raw materials which include bio-based polymers and recycled content that produce coatings that meet the criteria for sustainability. This change is anticipated to create a new bearing that will enable the market players to unlock themselves by the innovative method they employ in the synthesis of sustainable surface coatings.

Opportunity: Growth in the Automotive and Construction Industries

The two prospective areas in the Polymer Coatings Market are automobile and building industries. Automotive industry today has adopted polymer coatings to enhance the aesthetic value, and the lifespan of cars. These coatings not only add beauty to these surfaces but equally provide barrier against rain, snow and with the ultraviolet radiation. This is because of the emergence of electric vehicles and increased customer interest in highest performing coatings. OEMs are pumping more money into the development of better technologies to produce enhanced surface coatings like scratch-proof, auto-repair, and anti-rust surfaces.

Construction Industry is one of the largest segment of the polymer coatings market especially in developing regions where infrastructure development is on an upscale. They are widely applied in construction activities mainly to prevent structures from environmental threats mainly including moisture, corrosion and UV deterioration. Increasing the focus of sustainable construction, the need for durable low-maintenance polymer coatings with minimal environmental impact is increasing. These coatings enable an improvement of the thermal insulation standard of construction and the useful life of products. So as these two industries progress the polymer coatings market will have a chance to strengthen its position and introduce new solutions.

Driver: Technological Advancements in Coating Formulations

Polymer coatings are regarded as one of the most rapidly growing markets because of constant technological improvements in the coating formulations. With advances in the chemical formulation of resin, additives and techniques of applying the coatings, there has been significant improvements in coatings properties. For instance, advancement in polyurethane and epoxy coatings come with enhancements in abrasion, chemical as well as extreme temperatures resistance. These technological improvements create opportunities for the polymer coatings that cannot be employed in such challenging industries as aeronautics and marine.

Moreover, the emergence of enhanced application techniques, namely the utilization of nanomaterials in coatings, results in further improvement of polymers’ protective properties. Nanoparticles can confer further functionalities including anti-microbial, self-cleaning, scratch-resistance properties that improve coatings’ value in numerous uses. These are new opportunities for the market by presenting new opportunities for manufacturers to deliver products for various industries and uses. As research and development among the key players in the polymer coatings market remain active with constant technological advancement in coating compositions.

Restraints: Raw Material Price Fluctuations

Also one of the probables that act as a restraint in the Polymer Coatings Market is fluctuating crude prices that in turn affects the polymer prices. Polymer coatings depend for their effectiveness on some chemical compounds, resins, and additives that are partially of petrochemical origin. Crude oil and natural gas and other raw materials that go into the making of polymer coatings for their production are subject to frequent changes in their price. These are effects of such price fluctuations which causes the increase cost of production, which in turn could result in increased cost of the coatings to consumers making them less competitive.

The dependency of many manufacturing firms on global sources for their supplies of raw materials only amplifies this problem since events such as geopolitics, natural calamities, and transportation hitches can splits the supply chain’s timeline. Many corporations that operate in the polymer coatings market have to manage such risks, either through long-term agreements, diversified sourcing or through the development of lower-risk materials to which they are heavily dependent. This challenge still persists up to now especially for manufacturers who are in constant look out for ways to ensure they stay profitable while at the same time controlling the cost of raw materials.

Polymer Coatings Market Segment Analysis

Polymer Coatings Market Segmented on the basis of resin type, technology, application and end user.

By Type

o Epoxy

o Polyester

o Polyurethane

o Acrylic

o Others (Polyvinylidene Fluoride, Silicone, etc.)

By Application

o Automotive

o Construction

o Industrial

o Marine

o Packaging

o Consumer Goods

o Others (Electronics, Aerospace, etc.)

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Resin Type, Epoxy segment is expected to dominate the market during the forecast period

According to the type of resin in the Polymer Coatings Market, some of the critical raw materials employed in coating production are epoxy, polyester, polyurethane, acrylic and others. Epoxy resins are among some of the highly popular types on the current market due to their excellent bonding, high resistance to corrosion, and performance. They can be used in Automotive, Construction and Industrial Coatings because of these properties. Epoxy coatings are also preferred because they can create a coat which will act as a shield against moisture, chemicals, and physical abrasion.

Polyurethane and polyester resins are also getting widely used because of enhanced flexibility, good resistance to weathering, and excellent appearance. Polyurethane coatings especially worthwhile for automotive and industrial services mainly because of its abrasion resistant nature. Acrylic coatings used in decorative and protective coatings include consumer goods and packaging application due to the specialty coatings’ easy application and fast-drying ability. There are also newer resins being incorporated such as polyvinylidene fluoride and silicone for high performance and environmental advantages in compliance with green and waterborne coatings requirements.

By Application, Automotive segment expected to held the largest share

The Polymer Coatings Market is extensively applicable across various industries, leading by the automotive, construction, industrial, marine, packaging and consumer goods segments. In the automotive industry, coatings are employed as anticorrosive, weatherproof, and scratch resistant barrier and to give better appearance to the surfaced vehicle. As the demand for electric cars grows and the market expands to find lighter ways, a polymer coating will provide a significant solution to the automotive industry.

In construction industry, polymer coatings is applied to make building materials and structures resistant to moisture, UV deterioration and corrosion. These coatings play a critical role in increasing durability of buildings and thus suited for long term use. This application is common within the marine industry because polymer coatings are used to shield ships, boats, and other offshore structures from corrosion, especially from saltwater. These industries will continue to expand and the subsequent requirement for superior polymer coatings will in turn increase influencing the future advancement of polymer coatings significantly.

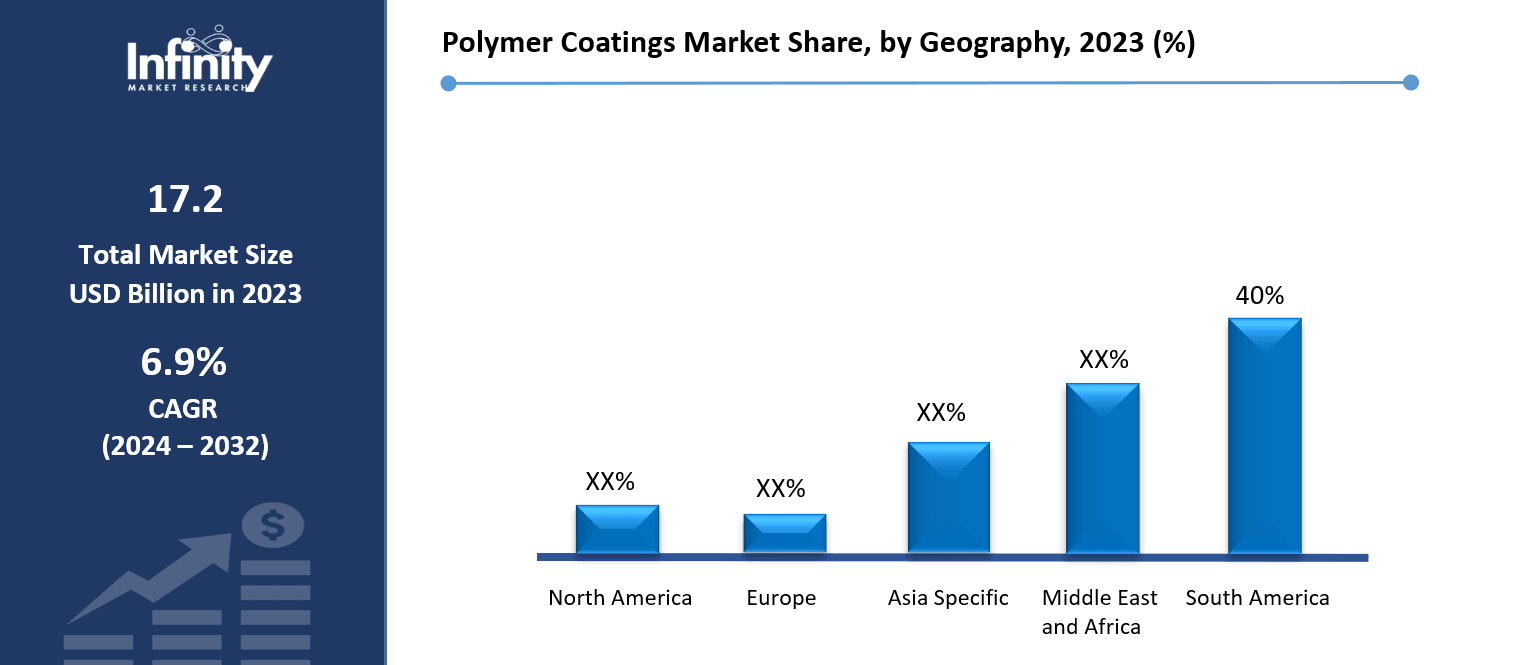

Polymer Coatings Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Currently, the Polymer Coatings Market is highly concentrated in North America due to continued demand for products from sectors such as automotive, construction, and manufacturing. The market is dominated by this region, which has a robust industrial infrastructure and technological developments in the formulation of the coatings. For example, several key players in the polymer coatings market such as the U.S. are never relenting in the discovery of new solutions suited to end users’ needs. The growth in North American polymer coatings market is benefited from the automotive industry demand of long-lasting and ornamental coatings and the construction industry demand for energy efficiency and sustainability coatings.

In addition, North America continues to be protected by environment regulation laws that allow high usage of green and LVOC coatings. This has created a great demand for water and powder coatings as they are thought to be safer than solvent based coatings. The demand for sustainable coatings in North America has grown and there are more funds invested in research and development to sustain the development of polymer coatings market in the region.

Polymer Coatings Market Share, by Geography, 2023 (%)

Active Key Players in the Polymer Coatings Market

o AkzoNobel (Netherlands)

o BASF SE (Germany)

o PPG Industries, Inc. (U.S.)

o Sherwin-Williams (U.S.)

o RPM International Inc. (U.S.)

o Asian Paints (India)

o Nippon Paint Holdings Co., Ltd. (Japan)

o Dow Inc. (U.S.)

o Jotun (Norway)

o Hempel A/S (Denmark)

o Tikkurila (Finland)

o Valspar Corporation (U.S.)

o Other key Players

Global Polymer Coatings Market Scope

|

Global Polymer Coatings Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 17.2 Billion |

|

Forecast Period 2024-32 CAGR: |

6.9% |

Market Size in 2032: |

USD 31.4 Billion |

|

Segments Covered: |

By Resin Type |

· Epoxy · Polyester · Polyurethane · Acrylic · Others (Polyvinylidene Fluoride, Silicone, etc.) | |

|

By Application |

· Automotive · Construction · Industrial · Marine · Packaging · Consumer Goods · Others (Electronics, Aerospace, etc.) | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements in Coating Formulations | ||

|

Key Market Restraints: |

· Raw Material Price Fluctuations | ||

|

Key Opportunities: |

· Growth in the Automotive and Construction Industries | ||

|

Companies Covered in the report: |

· AkzoNobel (Netherlands), BASF SE (Germany), PPG Industries, Inc. (U.S.), Sherwin-Williams (U.S.), RPM International Inc. (U.S.), Asian Paints (India), Nippon Paint Holdings Co., Ltd. (Japan), Dow Inc. (U.S.)m Jotun (Norway) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Polymer Coatings Market research report?

Answer: The forecast period in the Polymer Coatings Market research report is 2024-2032.

2. Who are the key players in the Polymer Coatings Market?

Answer: AkzoNobel (Netherlands), BASF SE (Germany), PPG Industries, Inc. (U.S.), Sherwin-Williams (U.S.), RPM International Inc. (U.S.), Asian Paints (India), Nippon Paint Holdings Co., Ltd. (Japan), Dow Inc. (U.S.)m Jotun (Norway) and Other Major Players.

3. What are the segments of the Polymer Coatings Market?

Answer: The Polymer Coatings Market is segmented into Resin Type, Technology, Application, End User and region. By Resin Type, the market is categorized into Epoxy, Polyester, Polyurethane, Acrylic, Others (Polyvinylidene Fluoride, Silicone, etc.). By Application, the market is categorized into Automotive, Construction, Industrial, Marine, Packaging, Consumer Goods, Others (Electronics, Aerospace, etc.). By Technology, the market is categorized into Solvent-borne, Waterborne, Powder Coatings, UV-cured. By End-User Industry, the market is categorized into Automotive & Transportation, Construction, Industrial Equipment, Consumer Goods, Packaging, Electronics. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Polymer Coatings Market?

Answer: Polymer Coatings Market means the segment that deals with manufacturing and utilizing of protective coatings made of polymer based materials. The uses of these coatings are to offer protection of surfaces, increase the lifespan and beautification of the surface as well as creating resistance against corrosion by formation of a thin layer on the surface, chemicals, and heat. Popular especially in varied types of businesses, polymer coatings are used across different industries on substrates such as metal, plastic, and concrete to deliver durable and protective films.

5. How big is the Polymer Coatings Market?

Answer: Polymer Coatings Market Size Was Valued at USD 17.2 Billion in 2023, and is Projected to Reach USD 31.4 Billion by 2032, Growing at a CAGR of 6.9% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.