🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Polyurethane Foam Market

Polyurethane Foam Market Global Industry Analysis and Forecast (2024-2032) By Type (Flexible Foam, Rigid Foam, Spray Foam, Integral Skin Foam) By Application (Furniture and Mattresses, Construction, Automotive, Packaging, Electronics and Appliances) By End-User Industry (Building and Construction, Automotive, Consumer Goods, Electronics and Electrical, Packaging) By Function (Building and Construction, Automotive, Consumer Goods, Electronics and Electrical, Packaging) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1626

Polyurethane Foam Market Synopsis

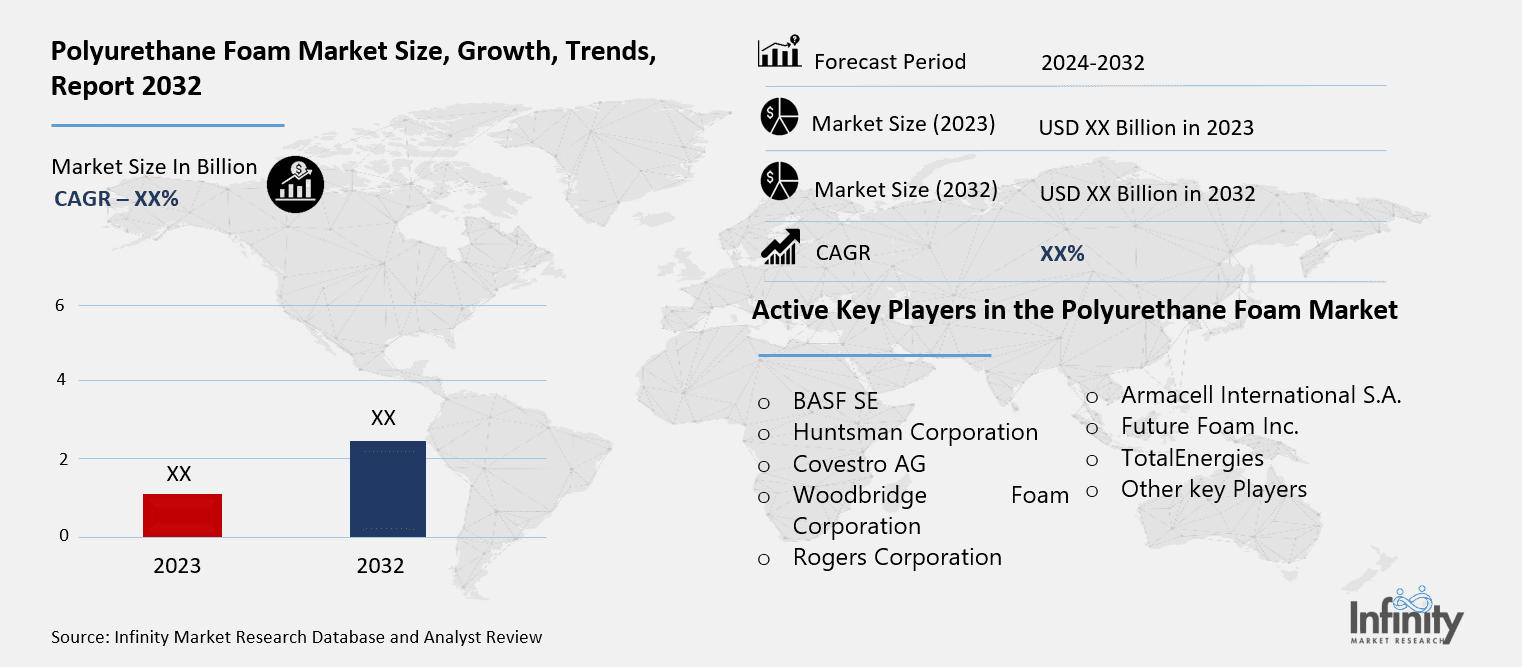

Polyurethane Foam Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

Polyurethane foam industry signifies the segment of the economy involved in production and distribution of polyurethane foam products that are versatile flexible polymer based materials possessing features such as insulation, cushioning, and toughness. These foams are chiefly intended for use in various applications varying from furniture, automobiles, constructions, packaging to bedding industries. The driving forces include higher energy saving requirements for the construction materials, preference towards comfortable products, and advancement in technologies for manufacturing foams. Polyurethane foams are classified into flexible PU foam, rigid PU foam and spray PU foam as per their application and usage in industrial sectors due to their structural nature and functions.

The Polyurethane Foam Market has grown at a relatively high pace due to flexibility of the foam in its use by different industries. Polyurethane foam, a versatile and light weight, high durability, and excellent insulating material, is an essential material in automotive, construction, furniture, packaging, and electronics industries. Examples of polyurethane foam uses includes interior cushioning, insulation and sound absorbing features in automotive parts which make cars comfortable and energy wise. In the same way, construction sector uses polyurethane foam to insulate buildings so as to save energy and also enhance environmental friendly practices. Further, polyurethane foam is used in furniture industry as well as bedding sector due to its flexibility and the strength offered it. There is increasing consumer trend towards using anything that would ensure them get functions of a material as well as comfort and this has made polyurethane foam to be so essential to manufacturers. Also, the constant increase in the global estimates of energy conservation encouraged the creation of environmentally friendly and bio-based polyurethane foam, which also opened new opportunities for the market’s growth. These technologies not only help to satisfy the customer needs in using eco-friendly products but also provide new opportunities for further market expansion, especially in terms of green construction materials and products and ecological packaging.

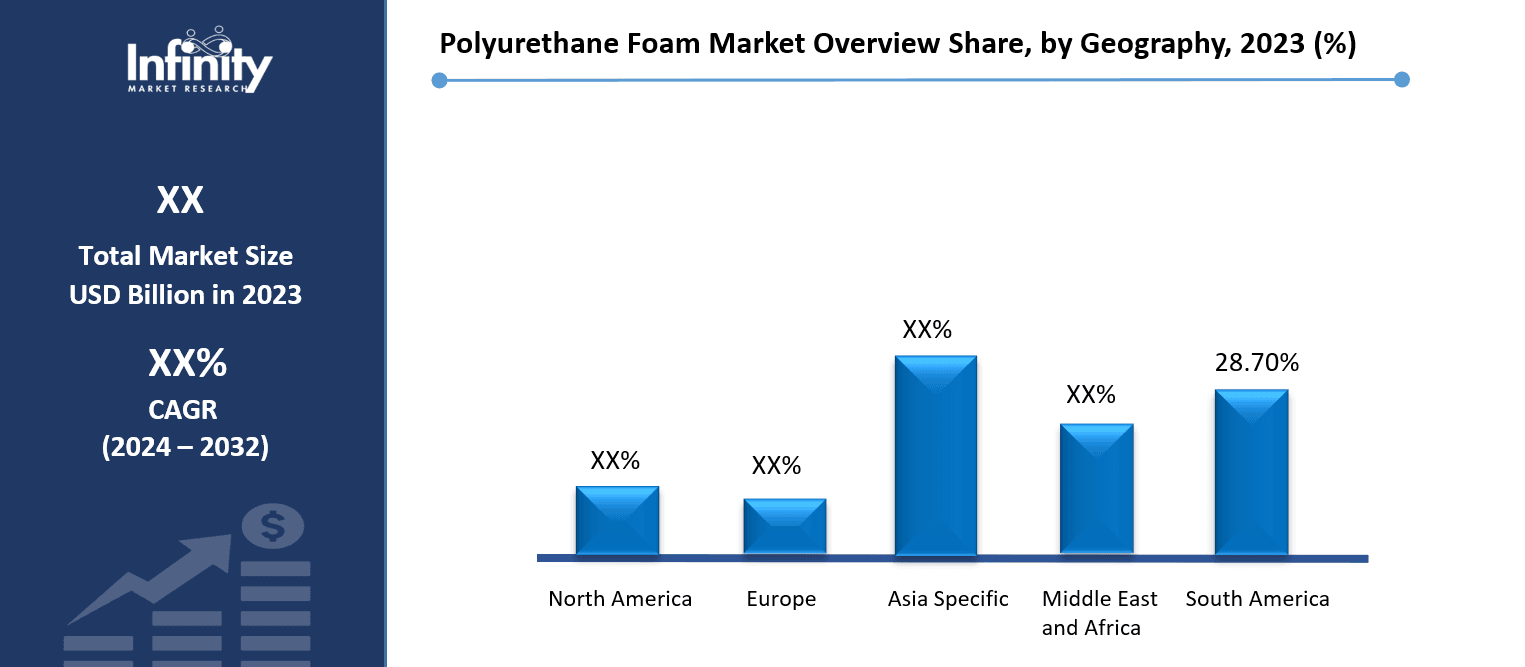

Regionally, the Polyurethane Foam Market is dominated by North America and Europe as automotive, construction, furniture industries remain numeral and continue to indulge in the market. Application of polyurethane foam has been on the rise in North America through energy efficient building and automotive industry needs of weight and comfort enhancement. In Europe timely and strict environmental concerns and focus on efficiency of energy have accelerated demand of polyurethane foam products in construction and automotive sectors. However, in the Asia-Pacific region is expected to attract the highest growth rate in the same forecast period due to the increasing urbanization, industrialization, and automotive and construction segments. Countries within emerging economy like China and India show signs if more infrastructure development in construction industries including residential and commercial buildings where polyurethane foam’s insulation and other uses are on high demand. However, the increase in the per capita income and shift of consumers from low quality products to better quality products in these regions has also helped the growth in polyurethane foam requirements for furniture and bedding. It is believed that more or less these regions will gravitate towards urbanization and industrialization where the market is again expected to rally in automotive application being a crucial area where the material is significantly utilized. In addition, the changes in polyurethane foam production will continue, for instance, the modernisation of high performance and recyclable foam types, trigger the new opportunities for market players to fit the consumers needs and requirements together with the regulations. The focus on new products and growing regional demand will possibly define further development of the polyurethane foam market.

Polyurethane Foam Market Trend Analysis

Trend

Role of Polyurethane Foams in the Automotive Sector

In automobile industry, PU foam is a great priority by providing vehicle comfort, performance, and safety. Their potential uses include: automobile seatings, car headrests and acoustical packs where they offer low weight, excellent damping properties which are advantageous within the searching for of enhanced fuel economy and other automotive performances. Also, these foams assist in increasing efficiency of passengers by enabling provision of better cushioning and sound insulation. The steady growth in the importance of automotive applications in cutting vehicle weight for energy use and minimizing greenhouse gas emissions has increased the necessity for polyurethane foam. According to these virtues, polyurethane foams could not be lacking from modern vehicles during their design or production to meet demands for sustainability and advanced technology.

The construction industry is also another application area that is driving polyurethane foam market especially because of the insulating nature of the foam. Styrene foam is prominently used for insulation purpose in both residential and commercial structures to decrease energy demand and increase thermal performance. That is why foam performs the functions of heat and cold insulation, does not allow air to pass through, and is valued for energy savings while heating or cooling a home. Polyurethane foams are also rapidly becoming a crucial element in green building because of new concerns about energy conservation in buildings and the use of environmentally friendly construction materials. In addition, there is a continuously rising demand for comfortable furniture with high durability and energy efficiency, especially application of polyurethane foams that furnitures are equipped with provide not only comfort but also durability of the furniture products.

Drivers

Growing Demand for Lightweight, High-Performance Materials

The demand for lightweight high-performance material remains one of the most important factors that fuels growth in the polyurethane foam market especially in auto, construction and furniture industries. Since these sectors tend to emphasise on such issues as efficiency, weight reduction, and the general enhancement of performance, polyurethane foam has become a versatile product for the following reasons. It has recently been employed more commonly in cars at the interior trims, particularly the seats, the headliners, and door panels because of its light nature and high comfort level. The material is also used in constructions for thermal insulating panels and since thermal insulation is key in cutting down the energy use the panels are also considered to have enhanced on the building’s energy efficiency. As energy conservation becomes an issue of concern, polyurethane foam is suitable to meet this standards besides providing comfort to the users.

Also, the rising need for insulating the building structures to reduce energy consumption and the need to enhance automotive fuel economy push the use the polyurethane foam. The properties in construction industry make it to better in transmitting less heat thereby making constructions to be energy conserving hence cheap to cater for in terms of heating. Taking this into consideration, there is an increasing concern for the use of green material and construction techniques in an attempt to fulfill the green goals of the society. As in any other industry, weight is a critical factor for improvement in fuel efficiency and emissions in the automotive industry. Due to the important role which polyurethane foam can make to fulfil these objectives, demand for it increases in both industries. With the use of energy concerns emerging a topical priority for consumers as well as producers, then polyurethane foam remains an important material to serve these objectives.

Restraints

Environmental Impact of Polyurethane Foam Production

There is the problem of environmental pollution of the polyurethane foam market, which results from the production process. The production of polyurethane foam creates pollutants such as volatile organic compounds (VOCs) hence affecting environment polluting substances. These substances are known to have adverse impacts on environment and health of people and that has made regulators and environmental non-governmental organizations to express worry. Consequently, it is becoming imperative that regulating the industry to use production methods that discharge fewer pollutants into the environment.

This change is particularly due to the strengthening of emission and environmental standards around the world. To tackle climate change, governments globally put stringent measures in place to curb industrial pollution; manufacturers face pressure to adapt. Switching to green technologies is costly because it involves spending on research, technology development and acquisition of new appropriate equipment. Such an additional cost challenge also poses a threat to the growth of the market and may limit the access to credit by new entrant manufacturers with limited capital. Further, the cost associated with sustainable production methodology might entail higher costs in production hence increase the cost of polyurethane foam products, thus making them less competitive to buyers.

Opportunities

Growing Demand for Lightweight and High-Performance Materials

Quite arguably, one of the biggest threats in the polyurethane foam market is a result of increasing weight consciousness in end user industries such as automotive, construction and furniture where polyurethane foam can offer the much needed lightweight, high-performance material. The defensive of polyurethane foam characteristic is that it is versatile due to properties such as heat insulating, shock absorbing, flexible and durable. Another major industrial application of the now advancing polyurethane foam is in the automobile industry where car makers are trying to look for ways to make their cars lighter to improve energy conservation. It helps enhance the fuel/energy consumption rates thus lowering emissions; a factor that has received emphasis in the green cars development. The automotive sector remains a key consumer of polyurethane foam since consumers and governments seek ways of cutting down carbon emissions hence realising growth prospects.

The construction industry is another key segment where polyurethane foam is increasing its prominence because of higher demand for energy efficient system, especially for insulation. The foam’s high performance in temperature control is an essential aspect of energy saving because it makes it easy for buildings to control their temperatures without necessarily installing heating and cooling gadgets. This demand is keenly so in developing countries as more and more individuals embrace urban lifestyle coupled with increasing energy costs making people demand better building materials. Besides, the application of polyurethane foam in the furniture sector, particularly in bedding product such as mattresses and cushioning is also increasing because of the comfort and durability it provides. Such trends exhibited across several industries help to create different opportunities for the further development of the polyurethane foam market, including in developed and developing countries.

Polyurethane Foam Market Segment Analysis:

Polyurethane Foam Market Segmented on the basis of By Type, By Application, By End-User Industry, By Function.

By Type

o Flexible Foam

o Rigid Foam

o Spray Foam

o Integral Skin Foam

By End User

o Building and Construction

o Automotive

o Consumer Goods

o Electronics and Electrical

o Packaging

By Application

o Furniture and Mattresses

o Construction

o Automotive

o Packaging

o Electronics and Appliances

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Flexible Foam segment is expected to dominate the market during the forecast period

Flexible foam is mainly used in products which need cushioning and supporting qualities, such as furniture, mattresses, auto interiors and protective packaging. Its capacity to conform to different shapes and offer both comfort and sturdiness have established permanent position of this material in industries that value ergonomic aspects and shield against impact. Consumption of flexible foam in bedding and furniture is highly important as it contributes to the increasing market for fine, comfortable, durable products. Consequently, this market has remained relatively healthy and what improvements and developments are being made are aimed at improving the performance of the foam.

Flexible foam is projected to experience a growing demand because consumers are now more inclined towards using more comfortable and ergonomic products from different industriesBUS322, Flexible foam is projected to experience a growing demand because consumers are now more inclined towards using more comfortable and ergonomic products from different industries. Also, the increase in memory foam mattresses and cushions in the furniture industry privately increases the rate of the market’s growth. Market of flexible foam in 2023 was forecasted to show a high value and was expected to grow further in the following years. In particular, they are expected to rise in the near future due to the widespread use of foam in various industries, growth of demand for comfort, constant technological improvements in the material’s production, and popularization of industries such as bedding and furniture production.

By Function, Thermal Insulation segment expected to held the largest share

Thermal insulation foam is significant in every production area that requires the regulation of temperature, mainly in construction, and engineering, refrigeration, automotive, and electronics industries.. Low density rigid foams are mainly cherished for their best thermal resistance characteristics and thus are used in applications such as building insulation and refrigeration and industrial applications. Thus with the increase in energy efficiency consciousness worldwide, there is growing need for efficient thermal insulation more apparent in construction industry where foam material aid in the reduction of energy utilization while adding to the overall sustainability of structures. The increase in green technologies together with increased pressure towards resource friendly building materials increases demand for elaborated thermal insulation foams in the residential as well as commercial areas.• Furthermore, thermal insulation foam is more and more essential in construction but also in electronics and automotive industries.onstruction, refrigeration, automotive, and electronics. Rigid foams are particularly valued for their superior insulating properties, making them ideal for applications such as insulating buildings, refrigeration units, and industrial equipment. As energy efficiency becomes a key focus globally, the demand for effective thermal insulation is rising, particularly in the construction sector, where foam materials help reduce energy consumption and improve the overall sustainability of buildings. The growth in green technologies, alongside the push for sustainable building materials, further fuels the demand for thermal insulation foam in both residential and commercial applications.

In addition to construction, thermal insulation foam is increasingly critical in the electronics and automotive sectors. As the client demanded cooler products like refrigerators, air conditioners, and appliances foam is being used in larger amounts to avoid overheating of the product and for optimising its performance. In the similar fashion in automotive, foam is used to enhance thermal control of components within automobile, and in general to make automobiles to be energy efficient and comfortable. With industries focusing more and more on energy saving and sustainability, the thermal insulation foam market will continue to grow rapidly, thanks to technological innovations and increased consciousness of energy conservation technologies.

Polyurethane Foam Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

The polyurethane foam market in North America has been exhibiting a fairly good growth due to its appreciable demand throughout various application sectors including automotive, furniture, and construction industries. The region possesses a well-developed manufacturing base and a highly developed technology and therefore occupies one of the leading positions in the production of both flexible and rigid foam materials. Automotive application has witnessed a surge in the application of polyurethane foam as it is lightweight, strong, resilient, acoustically soft, thus helping the fuel economy, and performance of automobiles. Likewise, the furniture industry has benefit from the flexibility of polyurethane foams for comfort and padding in items like furniture and furniture’s such as mattresses, to office chairs. The construction industry has also boosted the growth of market because polyurethane foam materials are widely used in the insulating application to improve energy efficiency in homes, offices, and other building.

In addition, there has been a rising concern in environmental issues and the trend towards more environment-friendly construction leading to the use of polyurethane foams that provides extra insulation. Pressure towards green building and efficient-utilization policy on energy efficient constructions has greatly contributed to the increased usage of polyurethane foams in the insulation systems. The biggest market in North America is still the United States, then followed by Canada and Mexico. These countries are gradually adopting sustainable construction solutions, in addition to modern automotive applications materials implying on reduced contribution of carbon footprint as well as environmentally sustainable manufacturing processes. Therefore, the North American polyurethane foam market appears to remain a dynamic market that will further diversify and expand depending on new environmentally friendly and energy-efficient products that will be developed in future.

Polyurethane Foam Market Share, by Geography, 2023 (%)

Active Key Players in the Polyurethane Foam Market

o BASF SE

o Huntsman Corporation

o Covestro AG

o Woodbridge Foam Corporation

o Rogers Corporation

o Armacell International S.A.

o Future Foam Inc.

o TotalEnergies

o Other key Players

Global Polyurethane Foam Market Scope

|

Global Polyurethane Foam Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Type |

· Flexible Foam · Rigid Foam · Spray Foam · Integral Skin Foam | |

|

By Application |

· Furniture and Mattresses · Construction · Automotive · Packaging · Electronics and Appliances | ||

|

By End-User Industry |

· Building and Construction · Automotive · Consumer Goods · Electronics and Electrical · Packaging | ||

|

By Function |

· Thermal Insulation · Acoustic Insulation · Cushioning · Structural Integrity | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Demand for Lightweight, High-Performance Materials | ||

|

Key Market Restraints: |

· Environmental Impact of Polyurethane Foam Production | ||

|

Key Opportunities: |

· Growing Demand for Lightweight and High-Performance Materials | ||

|

Companies Covered in the report: |

· BASF SE, Huntsman Corporation, Covestro AG, Woodbridge Foam Corporation, Rogers Corporation,Armacell International S.A., Future Foam Inc., TotalEnergies and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Polyurethane Foam Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Polyurethane Foam Market?

Answer: BASF SE, Huntsman Corporation, Covestro AG, Woodbridge Foam Corporation, Rogers Corporation, Armacell International S.A., Future Foam Inc., TotalEnergies and Other Major Players.

3. What are the segments of the Polyurethane Foam Market?

Answer: The Polyurethane Foam Market is segmented into By Type, By Application, By End-User Industry, By Function and region. By Type, the market is categorized into Flexible Foam, Rigid Foam, Spray Foam, Integral Skin Foam. By Application, the market is categorized into Furniture and Mattresses, Construction, Automotive, Packaging, Electronics and Appliances. By End-User Industry, the market is categorized into Building and Construction, Automotive, Consumer Goods, Electronics and Electrical, Packaging. By Function, the market is categorized into Building and Construction, Automotive, Consumer Goods, Electronics and Electrical, Packaging. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Polyurethane Foam Market?

Answer: Polyurethane foam industry signifies the segment of the economy involved in production and distribution of polyurethane foam products that are versatile flexible polymer based materials possessing features such as insulation, cushioning, and toughness. These foams are chiefly intended for use in various applications varying from furniture, automobiles, constructions, packaging to bedding industries. The driving forces include higher energy saving requirements for the construction materials, preference towards comfortable products, and advancement in technologies for manufacturing foams. Polyurethane foams are classified into flexible PU foam, rigid PU foam and spray PU foam as per their application and usage in industrial sectors due to their structural nature and functions.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.