🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Prepreg Glass Fiber Market

Prepreg Glass Fiber Market Global Industry Analysis and Forecast (2024-2032) By Fiber Type( E-Glass, S-Glass, Others),By Resin Type( Epoxy, Phenolic, Polyimide, Others),By Manufacturing Process( Hot-Melt Process, Solvent Dip Process),By Application(Aerospace & Defense, Automotive, Wind Energy, Sports & Recreation, Electronics, Others),By End-User Industry(Transportation, Energy, Industrial, Consumer Goods, Others)and Region

Mar 2025

Chemicals and Materials

Pages: 138

ID: IMR1867

Prepreg Glass Fiber Market Synopsis

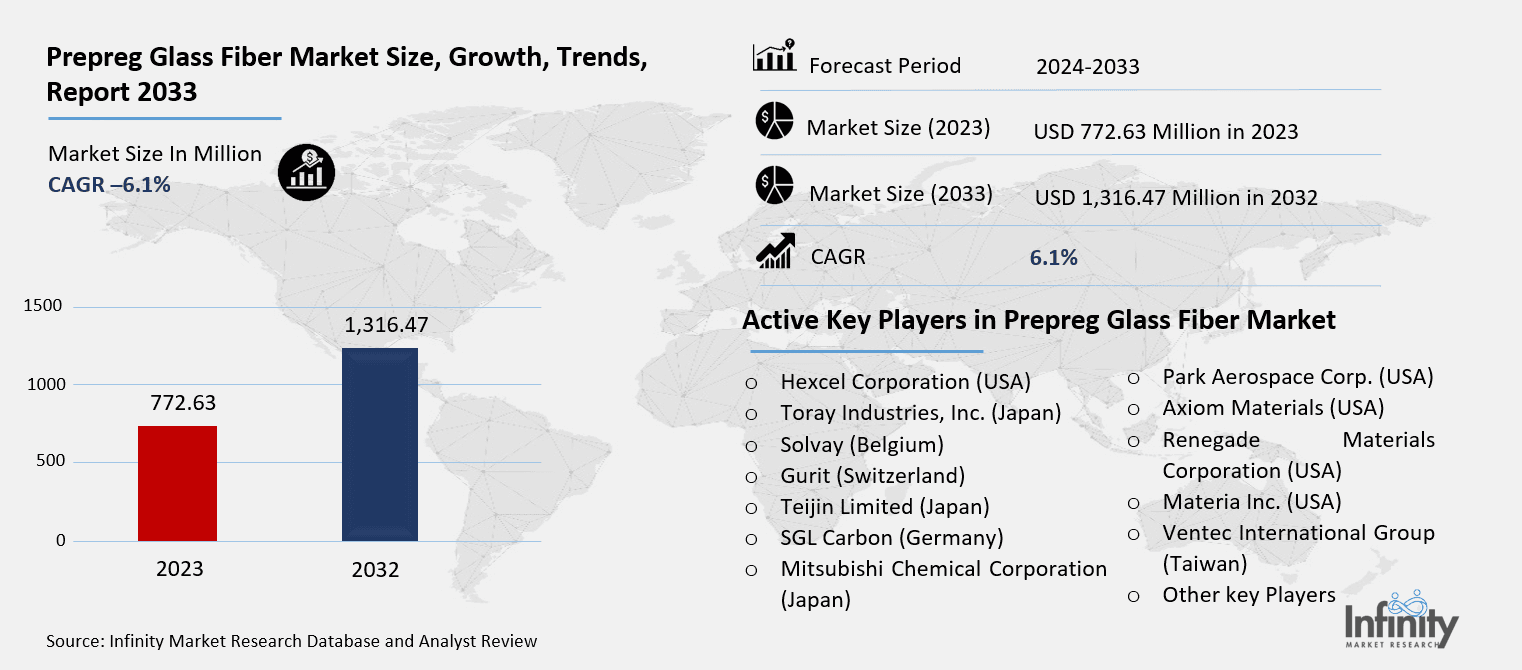

Prepreg Glass Fiber Market Size Was Valued at USD 772.63 Million in 2023, and is Projected to Reach USD 1,316.47 Million by 2032, Growing at a CAGR of 6.1% From 2024-2032.

The prepreg glass fiber market is the sector of industry centered on pre-impregnated glass fiber-reinforced composite materials based on resin matrix. Aerospace, automotive, wind energy, and sports equipment are just a few of the sectors where these materials find great application because of their mechanical strength, lightweight qualities, and durability. Because of their simplicity of processing, consistency in quality, and capacity to satisfy strict performance and environmental criteria, prepreg glass fibers are favored.

Because of its great strength-to---weight ratio, corrosion resistance, and simplicity of use for high-performance applications, prepreg glass fiber composites have become rather popular in many different fields. Mostly employed in areas including aerospace and defense, automotive, wind energy, sports and recreation, and electronics, where structural integrity and lightweight materials are critical, these materials are Growing acceptance of composite materials in manufacturing processes—especially in sectors trying to lower emissions, boost fuel efficiency, and improve product performance—is driving market expansion.

Since aircraft builders are using composites to improve fuel economy and lower total aircraft weight, the aerospace sector continues to be one of the biggest users of prepreg glass fiber. Similar demand for these composites is driven in the car industry by strict fuel economy and pollution control rules. The market also depends much on the wind energy sector since bigger wind turbine blades need lightweight but strong materials to enhance energy output. As sports and leisure as well as electronics applications progressively incorporate advanced composites for better product performance, their expansion helps to drive market growth.

Further inspiring creativity in the Prepreg Glass Fiber Market are technological developments in resin formulas, fiber-reinforced polymer technologies, and automated manufacture procedures. Furthermore, sustainability issues force manufacturers to provide recyclable prepreg materials and bio-based resins, therefore improving the environmental friendliness of the market. Still major limitations, though, are high startup costs and processing difficulties—especially for small-scale producers. Still, government programs to support lightweight and energy-efficient materials along with increasing research and development investment should drive market growth in the next years.

Prepreg Glass Fiber Market Outlook, 2023 and 2032: Future Outlook

Prepreg Glass Fiber Market Trend Analysis

Trend: Growing Demand for Lightweight and High-Performance Materials

One important trend influencing the Prepreg Glass Fiber Market is the growing need for lightweight and high-performance materials in many different sectors. Adoption of prepreg glass fiber composites is rising as sectors including aerospace, automotive, and wind energy keep giving weight reduction a priority for fuel economy and performance enhancement. Ideal for uses where structural integrity is crucial, these materials provide great mechanical strength, resistance to corrosion, and longevity while keeping a low weight.

The move toward electric vehicles (EVs) in the automotive sector has sped the demand for lightweight composite materials to increase battery efficiency and vehicle range. Comparably, in the wind energy industry, the growing scale of wind turbine blades calls for materials with great strength and low weight to guarantee effective energy output. The need for advanced prepreg glass fiber solutions is predicted to keep growing as sectors aim for better performance criteria, so promoting market development in the next years.

Opportunity: Expansion of Prepreg Glass Fiber in Emerging Markets

For the sector, the spread of prepreg glass fiber uses in developing nations offers a major growth potential. Aeronautical, automotive, renewable energy, and infrastructure industries are attracting more investment from nations in Asia-Pacific, Latin America, and the Middle East, thereby opening new paths for prepreg glass fiber producers. Adoption in these areas is driven by fast industrialization together with growing demand for high-performance and energy-efficient materials.

Further increasing demand for lightweight and robust composite materials are governments in developing nations supporting renewable energy projects, electric mobility, and infrastructure modernizing initiatives. Furthermore projected to cut production costs and provide access to innovative prepreg glass fiber materials is the growth of manufacturing facilities in nations such China, India, and Brazil. By means of localized manufacturing and supply chain optimization, this change will help market participants to seize the increasing demand in these highly promising areas.

Driver: Rising Adoption of Composite Materials in Aerospace & Automotive Industries

The prepreg glass fiber market is driven mostly by the growing acceptance of composite materials in the aerospace and automotive industries. Leading manufacturers like Boeing and Airbus are using lightweight composite materials into aircraft constructions in the aerospace sector to increase flying performance, fuel economy, and emissions reduction. Because of its great strength and tolerance to difficult weather conditions, pre-reg glass fiber is extensively utilized in airplane interiors, fuselage panels, and structural components.

Likewise in the vehicle industry, manufacturers are emphasizing lightweighting techniques to satisfy strict fuel economy and pollution standards. The increasing manufacture of electric cars (EVs) has driven demand for composite materials meant to maximize battery life and general vehicle performance even further. Long-term market expansion is predicted to be driven by the integration of prepreg glass fiber composites in aerospace and automotive applications as worldwide regulatory criteria keep stressing sustainability and carbon footprint reduction.

Restraints: High Production Costs and Complex Manufacturing Process

The high production cost and manufacturing process complexity are among the main limitations in the Prepreg Glass Fiber Market. Higher operating expenses result from the advanced processing processes, specialized equipment, and exact resin impregnation methods used in the manufacturing of prepreg glass fiber composites. This increases the cost of prepreg composites relative to conventional metal and polymer-based materials, which limits their use especially in small and medium-sized businesses.

Furthermore aggravating the operating difficulties are the storage and handling needs of prepreg glass fiber supplies. Many times, these products need chilled storage to keep their qualities, which drives more inventory control and logistical expenses. Especially in cost-sensitive industries, the substantial initial investment in manufacturing equipment and trained personnel needs hinders the general acceptance of prepreg glass fiber composites.

Prepreg Glass Fiber Market Segment Analysis:

Prepreg Glass Fiber Market Segmented on the basis of Fiber Type, Resin Type, Manufacturing Process, Application and End User.

By Fiber Type, E-Glass segment is expected to dominate the market during the forecast period

Fiber type defines the three segments of the Prepreg Glass Fiber Market: E-Glass, S-Glass, Others. Ideal for automotive, wind energy, and electronics uses, e-glass fiber is the most often utilized variety because of its cost-effectiveness, great strength, and electrical insulating qualities. Conversely, S-Glass fiber is fit for aerospace and defense uses where performance under demanding conditions is vital since it provides outstanding mechanical qualities, high-temperature resistance, and stronger impact strength.

Specialized high-performance glass fiber materials meant for specialist uses in sectors needing customized reinforcement solutions fall under the others category. The particular mechanical and thermal needs of the end-use application will determine which of E-Glass or S-Glass is best; S-Glass commands a premium price because of its advanced characteristics.

By Application, Aerospace & Defense segment expected to held the largest share

Aerospace and defense, automotive, wind energy, sports and recreation, electronics, and others all find uses for prepreg glass fiber. Because aircraft construction demand lightweight, high-strength materials so highly sought after, the Aerospace & Defense industry rules. Another important customer is the automotive sector, particularly given the growth of electric cars needing lightweight materials to increase energy economy.

Longer, more robust turbine blades made from prepreg glass fibers are produced in the wind energy sector, therefore aiding worldwide attempts to increase the capacity for renewable energy. By including prepreg composites into high-performance athletic gear and electronic components, sports and recreation and electronics sectors are also helping to drive market growth.

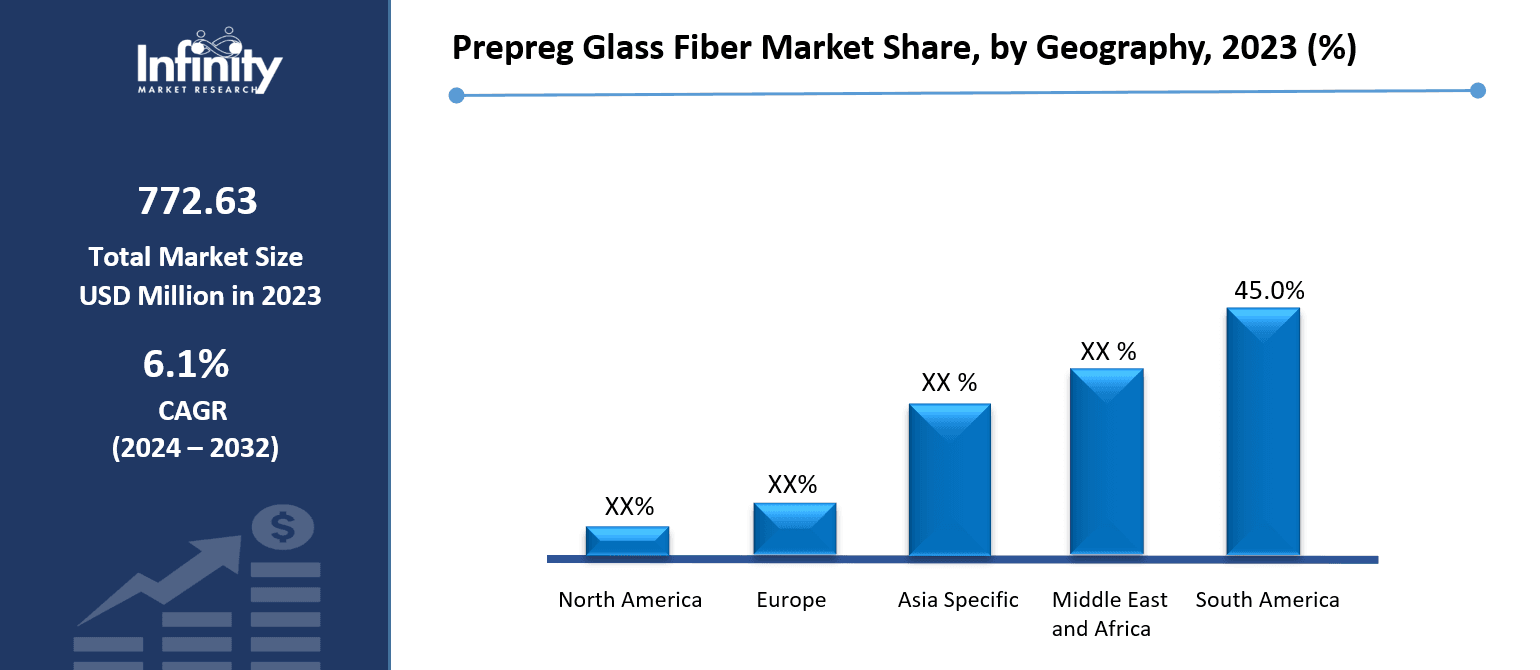

Prepreg Glass Fiber Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

Driven by great demand from the aerospace, automotive, and wind energy sectors, North America is the main area in the Prepreg Glass Fiber Market. Major aerospace companies like Boeing, Lockheed Martin, and Northrop Grumman help to explain the rise in the market.

Further increasing market acceptance is North America's emphasis on renewable energy development and strict car sector fuel economy rules. Still leading with great investments in composite material research and development are the United States and Canada.

Prepreg Glass Fiber Market Share, by Geography, 2023 (%)

Active Key Players in the Prepreg Glass Fiber Market

o Hexcel Corporation (USA)

o Toray Industries, Inc. (Japan)

o Solvay (Belgium)

o Gurit (Switzerland)

o Teijin Limited (Japan)

o SGL Carbon (Germany)

o Mitsubishi Chemical Corporation (Japan)

o Park Aerospace Corp. (USA)

o Axiom Materials (USA)

o Renegade Materials Corporation (USA)

o Materia Inc. (USA)

o Ventec International Group (Taiwan)

o Other key Players

Global Prepreg Glass Fiber Market Scope

|

Global Prepreg Glass Fiber Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 772.63 Million |

|

Forecast Period 2024-32 CAGR: |

6.1% |

Market Size in 2032: |

USD 1,316.47 Million |

|

Segments Covered: |

By Fiber Type |

· E-Glass · S-Glass · Others | |

|

By Application |

· Aerospace & Defense · Automotive · Wind Energy · Sports & Recreation · Electronics · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Rising Adoption of Composite Materials in Aerospace & Automotive Industries | ||

|

Key Market Restraints: |

· High Production Costs and Complex Manufacturing Process | ||

|

Key Opportunities: |

· Expansion of Prepreg Glass Fiber in Emerging Markets | ||

|

Companies Covered in the report: |

· Hexcel Corporation (USA), Toray Industries, Inc. (Japan), Solvay (Belgium), Gurit (Switzerland), Teijin Limited (Japan), SGL Carbon (Germany), Mitsubishi Chemical Corporation (Japan), Park Aerospace Corp. (USA, Axiom Materials (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Prepreg Glass Fiber Market research report?

Answer: The forecast period in the Prepreg Glass Fiber Market research report is 2024-2032.

2. Who are the key players in the Prepreg Glass Fiber Market?

Answer: Hexcel Corporation (USA), Toray Industries, Inc. (Japan), Solvay (Belgium), Gurit (Switzerland), Teijin Limited (Japan), SGL Carbon (Germany), Mitsubishi Chemical Corporation (Japan), Park Aerospace Corp. (USA, Axiom Materials (USA) and Other Major Players.

3. What are the segments of the Prepreg Glass Fiber Market?

Answer: The Prepreg Glass Fiber Market is segmented into Fiber Type, Resin Type, Manufacturing Process, Application, End User and region. By Fiber Type, the market is categorized into E-Glass, S-Glass, Others. By Resin Type, the market is categorized into Epoxy, Phenolic, Polyimide, Others. By Manufacturing Process, the market is categorized into Hot-Melt Process, Solvent Dip Process. By Application, the market is categorized into Aerospace & Defense, Automotive, Wind Energy, Sports & Recreation, Electronics, Others. By End-User Industry, the market is categorized into Transportation, Energy, Industrial, Consumer Goods, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Prepreg Glass Fiber Market?

Answer: The prepreg glass fiber market is the sector of industry centered on pre-impregnated glass fiber-reinforced composite materials based on resin matrix. Aerospace, automotive, wind energy, and sports equipment are just a few of the sectors where these materials find great application because of their mechanical strength, lightweight qualities, and durability. Because of their simplicity of processing, consistency in quality, and capacity to satisfy strict performance and environmental criteria, prepreg glass fibers are favored.

5. How big is the Prepreg Glass Fiber Market?

Answer: Prepreg Glass Fiber Market Size Was Valued at USD 772.63 Million in 2023, and is Projected to Reach USD 1,316.47 Million by 2032, Growing at a CAGR of 6.1% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.