🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Prepregs Market

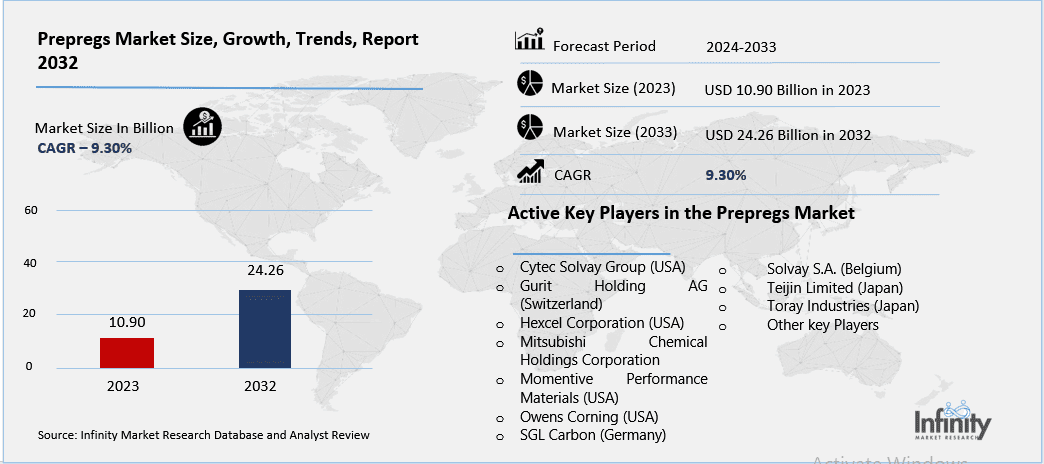

Prepregs Market Global Industry Analysis and Forecast (2024-2032) Resin Type (Epoxy, Phenolic, Bismaleimide (BMI), Polyimide, Others), Fiber Type (Carbon Fiber, Glass Fiber, Aramid Fiber, Others), End-Use Industry (Aerospace & Defense, Automotive, Wind Energy, Electronics, Sports & Leisure, Marine, Others, Manufacturing Process: Lay-Up, Filament Winding, Pultrusion, Compression Molding, Others) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1454

Prepregs Market Synopsis

Prepregs Market Size Was Valued at USD 10.90 Billion in 2023, and is Projected to Reach USD 24.26 Billion by 2032, Growing at a CAGR of 9.30 % From 2024-2032.

The prepregs market means the global market of pre-impregnated composites where fibers including carbon, glass, aramid, are impregnated with resin systems. These materials are ideal for application as materials in high-tech manufacturing businesses for instance aerospace, automotive, and wind power industries. The preg s have many benefits such as high strength, reliability, and light weighted which are significant for high performance elements used in difficult conditions.

The prepregs market is forecasted to have a good growth as there is a high demand for lightweight, higher performance in aerospace, automobile, and wind energy industries. The global trend to adopt fuel efficient and eco-friendly products in industries especially aerospace and automotive industries has been a major driving force towards the use of prepregs in manufacturing. Still, it is worth viewing further growth in the consumption of such materials as a result of increased attention to efficient power generation, including wind turbines for producing electricity, on sustainable materials.

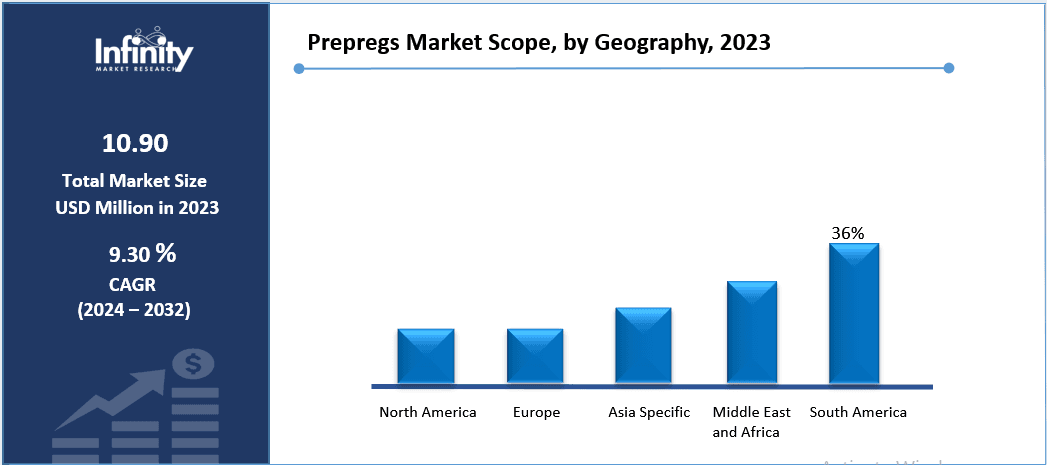

On a regional basis, North America is the largest consumer of prepregs followed next by Europe because of its advanced aerospace as well as automotive sectors. Europe represents another significant market area stimulated by aerospace, automotive, wind energy industries demand. Asia-Pacific is expected to grow at the fastest rate over the forecast period owing to high industrialization rate especially in China and India and the relentless use of composite material in the automobile and wind power industries.

Prepregs Market Outlook, 2023 and 2032: Future Outlook

Prepregs Market Trend Analysis

Technological Innovations in Prepreg Materials

As one of the latest trends in the prepregs market, the increasing application of the advanced composites-based material in the automotive industry is significant. Promising high strength weight balance manufacturers are using pre-preg for weight balance and better per from ounce fuel efficiency and reduction of emissions. Furthermore, there is further development made in terms of new resin systems that are able to enhance the characteristics of prepregs as well as curing methods which in their turn make prepregs more suitable for practical application.

Another of the trends is defined as the increasing popularity of the prepregs that are environmentally friendly and recyclable. The prepreg market, growing in importance as sustainability becomes a factor in production, is now focusing on bio-based resins, and recycling composites. These are being initiated to cater for the increasing preference by consumers of environmentally friendly products and the subsequent drive by organizations in aerospace and automotive to adhere to carbon limits.

Growing Demand for Lightweight Materials in Aerospace and Automotive

The main force behind the growth of the prepregs market is the need for lightweight strong material for operations in the aerospace and automotive sectors. In aerospace, prepregs are applied on the structural parts including fuselages, wings and others in which strength to weight ratio is very much important. Equally, in the automotive industry, application of prepregs has been on the rise due to need to cut down on the vehicle weight to increase fuel efficiency more in the electric and hybrid cars.

The other key factor is the increasing need for clean technologies and specifically for wind blade applications. The prepregs are used in the production of large, high performance and lightweight components required for commercial blades to be used in harsh environment. The demand for use of prepregs in wind energy segment is expected to grow further as countries intensify their investment in renewable energy and carbon reduction targets.

High Cost of Prepreg Materials and Manufacturing Processes

Another factor that may significantly slowdown the growth of prepregs market is its relatively high cost which directly and heavily depends only on the main components such as fiber and resin. Preg materials and processes involved in their preparation are costly, thus their use has not gained much attention especially in automotive industry. Higher cost of prepreg as compared to metals and plastics traditionally used in the fabrication of parts is one of the concerns due to cost of high-performance fibers and resins and the manufacturing processes used in the fabrication of prepregs.

Also, the requirement of additional storage and handling conditions also creates a problem. Regreased samples must be used as early as possible because of its short shelf life and storage conditions should also be kept within certain temperature and humidity. These storage and handling requirements may push up the cost of goods and make prepreg sourcing and usage challenging by raising barriers to entry, especially for SMEs.

Emerging Applications in Electric Vehicles and Renewable Energy

The prepregs market comprises ample prospect for growth in growing markets like EVs and renewable energy systems. Prepregs meet the increasing demand of lightweight materials for manufacturing EVs with battery enclosures, body panels and many others. Also, the wind energy sector can be considered as one of the perspectives as the movement to the use of clean energy sources is constant and the demand for greater and more efficient wind turbine blades increases.

The second opportunity is the innovation of advanced next generation resins: biodegradable and recyclable resins. Due to the push for sustainability, there is an emerging demand for the green prepregs that companies need for production. Shell Chemicals believes manufacturers who invest in research and development of sustainable resin solutions are likely to capture market share since there is an increasing shift by industries such as aerospace, automotive and construction from conventional to environment friendly products.

Prepregs Market Segment Analysis:

Prepregs Market Segmented on the basis of Resin Type, Fiber Type and End-Use Industry.

By Resin Type

o Epoxy

o Phenolic

o Bismaleimide (BMI)

o Polyimide

o Others

By Fiber Type

o Carbon Fiber

o Glass Fiber

o Aramid Fiber

o Others

By End Use Industry

o Aerospace & Defense

o Automotive

o Wind Energy

o Electronics

o Sports & Leisure

o Marine

o Others

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

Resin Type, Epoxy segment is expected to dominate the market during the forecast period

Prepregs are available in different kinds of resin that has specific characteristics ideal for particular use. Epoxy resins are the most commonly used because of their good mechanical properties, resistance to chemicals and good adhesion to fibers, and matted vapor, which serves well in aerospace and automotive industries. Thermosetting phenolic resins are particularly suitable for high temperature use because of its ability to withstand heat. Bismaleimide (BMI) resins are well suited to harsh environments and have particularly good application in aerospace structures. Polyimide resins, the chemical structures of which provide the highest level of thermal stability and environmental durability are also rising in demand. Other resins include thermoplastic and vinyl ester and both have special characteristics based on the intended application.

Fiber Type, Carbon Fiber segment expected to held the largest share

Through the selection of the fiber type, prepregs can be made to have various properties such as high strength/ stiffness ratios and ratios. Carbon fiber prepregs are something of a wonder material, as they boast strength-to-weight ratios that make them excellent for aerospace and automotive industries as well as for sports equipment. Glass fiber prepregs slightly cheaper and have satisfactory characteristics for strengthening, for example, in construction and shipbuilding. Aramid fibre prepregs are used in military and ballistic applications having impact resistance and perfect measure of toughness. Other fibre types are natural- fibres and blended- combinations needed for specialized requirements.

Prepregs Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

The North American prepregs market is currently the biggest market worldwide and it is mainly due to the presence of aerospace, automotive and wind energy industries. The aerospace industry of the region is fairly mature, and well-established giants like Boeing and Lockheed Martin’s requirements for lightweight, high-performance materials are served by prepregs for applications including fuselages, wings, and other structural assemblies. Light automotive is also adding to the growth as more automobile makers use prepregs for vehicle weighting to enhance fuel efficiency owing to stringent emission standards. In addition, the increasing need for renewable sources of energy with an emphasis on wind power turbine blade serves to boost the market.

North America’s prepregs market has expanded due to trends in composites materials and resin systems. The region has impressive base for research and new development with top manufacturers focusing on the improvement of properties of prepreg materials. Also, the enviro-consciousness of using low-carbon lifestyle by the countries in North America has led to buying of more environmentally friendly prepregs with bio-resin and recyclable fiber materials. These trends, coupled with the large investments in research and development, and productivity of manufacturing techniques will help North America remain an important consumer in the preparation resins market in the years to come.

Prepregs Market Share, by Geography, 2023 (%)

Active Key Players in the Prepregs Market

o Cytec Solvay Group (USA)

o Gurit Holding AG (Switzerland)

o Hexcel Corporation (USA)

o Mitsubishi Chemical Holdings Corporation (Japan)

o Momentive Performance Materials (USA)

o Owens Corning (USA)

o SGL Carbon (Germany)

o Solvay S.A. (Belgium)

o Teijin Limited (Japan)

o Toray Industries (Japan)

o Other key Players

Global Prepregs Market Scope:

|

Global Prepregs Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 10.90 Billion |

|

Forecast Period 2024-32 CAGR: |

9.30 % |

Market Size in 2032: |

USD 24.26 Billion |

|

Segments Covered: |

Resin Type |

· Epoxy · Phenolic · Bismaleimide (BMI) · Polyimide · Others | |

|

Fiber Type |

· Carbon Fiber · Glass Fiber · Aramid Fiber · Others | ||

|

End-Use Industry |

· Aerospace & Defense · Automotive · Wind Energy · Electronics · Sports & Leisure · Marine · Others | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements and Performance Improvements in Prepregs | ||

|

Key Market Restraints: |

· Challenges in Scaling Production for Mass Adoption | ||

|

Key Opportunities: |

· Innovation in Prepregs for High-Performance and Niche Applications | ||

|

Companies Covered in the report: |

· Toray Industries (Japan), Hexcel Corporation (USA), Mitsubishi Chemical Holdings Corporation (Japan), Teijin Limited (Japan), SGL Carbon (Germany), Gurit Holding AG (Switzerland), Solvay S.A. (Belgium), Owens Corning (USA), Cytec Solvay Group (USA), Momentive Performance Materials (USA). and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Prepregs Market research report?

Answer: The forecast period in the Prepregs Market research report is 2024-2032.

2. Who are the key players in the Prepregs Market?

Answer: Toray Industries (Japan), Hexcel Corporation (USA), Mitsubishi Chemical Holdings Corporation (Japan), Teijin Limited (Japan), SGL Carbon (Germany), Gurit Holding AG (Switzerland), Solvay S.A. (Belgium), Owens Corning (USA), Cytec Solvay Group (USA), Momentive Performance Materials (USA). and Other Major Players.

3. What are the segments of the Prepregs Market?

Answer: The Prepregs Market is segmented into Resin Type, Fiber Type, End-Use Industry and region. Resin Type, the market is categorized into Epoxy, Phenolic, Bismaleimide (BMI), Polyimide, Others. Fiber Type, the market is categorized into Carbon Fiber, Glass Fiber, Aramid Fiber, Others. End-Use Industry, the market is categorized into Aerospace & Defense, Automotive, Wind Energy, Electronics, Sports & Leisure, Marine, Others, Manufacturing Process: Lay-Up, Filament Winding, Pultrusion, Compression Molding, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Prepregs Market?

Answer: The prepregs market means the global market of pre-impregnated composites where fibers including carbon, glass, aramid, are impregnated with resin systems. These materials are ideal for application as materials in high-tech manufacturing businesses for instance aerospace, automotive, and wind power industries. The preg s have many benefits such as high strength, reliability, and light weighted which are significant for high performance elements used in difficult conditions.

5. How big is the Prepregs Market?

Answer: Prepregs Market Size Was Valued at USD 10.90 Billion in 2023, and is Projected to Reach USD 24.26 Billion by 2032, Growing at a CAGR of 9.30 % From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.