🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Print Mark Sensor Market

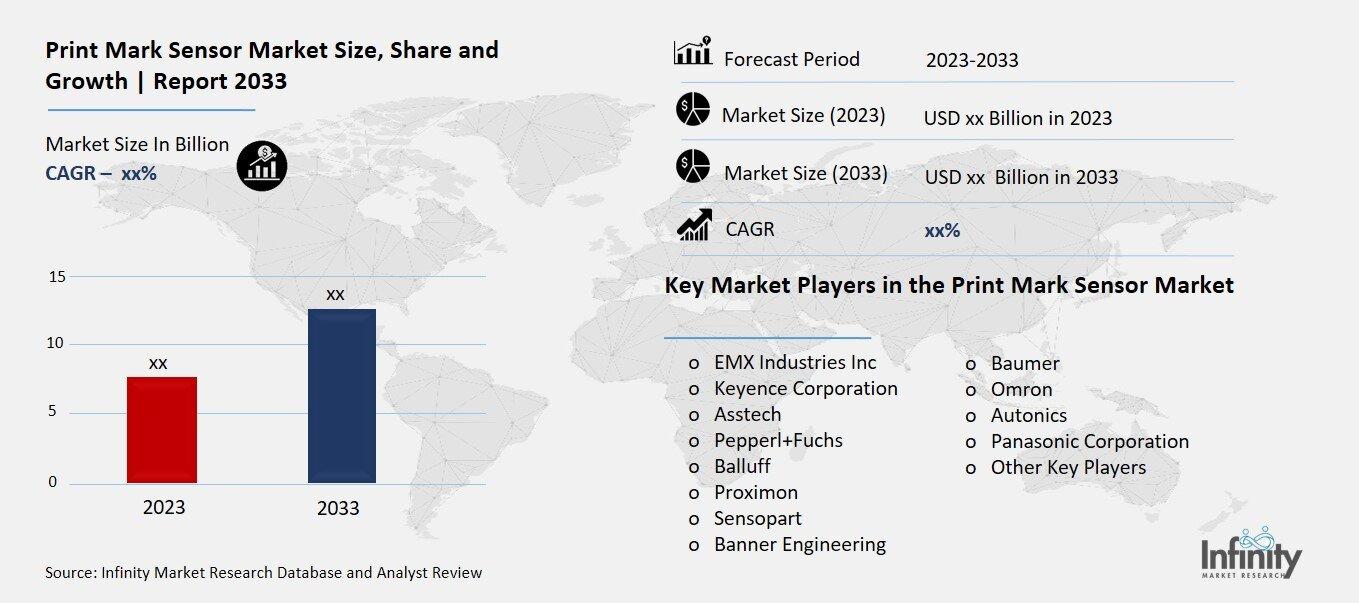

Global Print Mark Sensor Market (By Type, Laser and Modulated Light; By Application, Packaging Industry, Printing Industry, and Other Applications, By Region and Companies), 2024-2033

Sep 2024

Semiconductor and Electronics

Pages: 138

ID: IMR1233

Print Mark Sensor Market Overview

Global Print Mark Sensor Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2033 with the CAGR of XX% during the forecast period of 2024 to 2033. The market has witnessed significant growth driven by advancements in automation and robotics. These sensors are designed to detect and read printed marks, barcodes, and QR codes. The sensors are essential in various industries such as automotive, packaging, electronics, and logistics. Thus, the demand for reliable and accurate mark sensors has surged in the market. With the help of this sensors companies strive to enhance operational efficiency and reduce errors in production lines.

To Get An Overview , Request For Sample

Technological innovations, such as the integration of machine vision and artificial intelligence, are further propelling market expansion. Additionally, the growing trend of Industry 4.0 and the rise of smart factories have increased the need for advanced sensing solutions. This factor makes mark sensors a critical component in the automation landscape.

Drivers for the Print Mark Sensor Market

Growing Demand for Quality Control

Print mark sensors play a pivotal role in minimizing errors during the production process, as industries strive to meet increasingly stringent quality standards. These sensors are designed to detect and interpret various types of marks, such as barcodes, QR codes, and printed labels. This ensures that products are accurately identified and categorized at every stage of the manufacturing cycle. The sensors enable manufacturers to monitor production flows closely by providing real-time feedback. This provides immediate corrective actions if discrepancies are detected. Thus, this capability is crucial in preventing faulty products from reaching consumers and safeguards brand reputation.

Furthermore, by automating the identification and sorting processes, mark sensors enhance operational efficiency, allowing for faster production rates and minimizing human error. The integration of advanced technologies, such as machine vision, further augments the functionality of mark sensors, enabling them to handle complex tasks and adapt to variations in product design and packaging.

Restraints for the Print Mark Sensor Market

Competition from Alternative Technologies

The mark sensor market faces significant competition from other identification and tracking technologies, particularly Radio Frequency Identification (RFID) systems and advanced barcode technologies. RFID offers unique advantages, such as the ability to read multiple tags simultaneously and without line-of-sight, making it particularly appealing for inventory management and asset tracking in environments where speed and efficiency are critical. This capability allows companies to automate processes, streamline operations, and enhance data accuracy, often at a lower operational cost in the long run.

Advanced barcode systems, including 2D barcodes like QR codes, also present formidable competition. These systems benefit from widespread adoption and familiarity across various industries, enabling quick and cost-effective implementation. Barcodes are easily generated and can store more information than traditional 1D barcodes, which enhances their functionality in product identification and tracking.

Opportunity in the Print Mark Sensor Market

Customization and Specialized Solutions

Offering customized mark sensors tailored to specific industry needs opens up significant opportunities for both revenue growth and enhanced customer satisfaction. Different industries have unique operational challenges, whether it's the precision needed in pharmaceuticals for packaging and labeling, the high-speed sorting required in logistics, or the stringent traceability demands in the automotive sector. By developing bespoke mark sensors that address these specific requirements, manufacturers can position themselves as invaluable partners to their clients, offering solutions that not only solve immediate problems but also optimize overall production efficiency.

Customization allows companies to adapt sensor capabilities to varying environmental conditions, product designs, and workflow intricacies, ensuring seamless integration into existing systems. This level of personalization increases the performance and reliability of mark sensors in critical applications, resulting in fewer errors, faster processing times, and greater long-term savings for customers. Additionally, offering tailored solutions allows sensor manufacturers to diversify their product portfolios, creating new revenue streams by meeting niche demands that off-the-shelf solutions cannot satisfy.

Trends for the Print Mark Sensor Market

Increased Use of Machine Learning

The integration of machine learning algorithms into mark sensing systems represents a significant advancement in the ability to enhance accuracy and adaptability in various industrial applications. By employing machine learning, mark sensing systems can analyze vast amounts of data collected during production processes, allowing them to identify patterns and make real-time decisions based on the current operational environment. This capability is particularly valuable in scenarios where products may exhibit variations in labeling, printing quality, or positioning, which can lead to misidentification if traditional algorithms are used.

Machine learning algorithms can continuously learn from the data they process, improving their recognition capabilities over time. This means that as new types of marks or labels are introduced or as production conditions change—such as lighting variations or machine wear—the system can adapt without the need for extensive reprogramming or manual intervention. This adaptability not only minimizes downtime but also reduces the risk of errors, enhancing overall production quality.

Segments Covered in the Report

By Type

o Laser

o Modulated Light

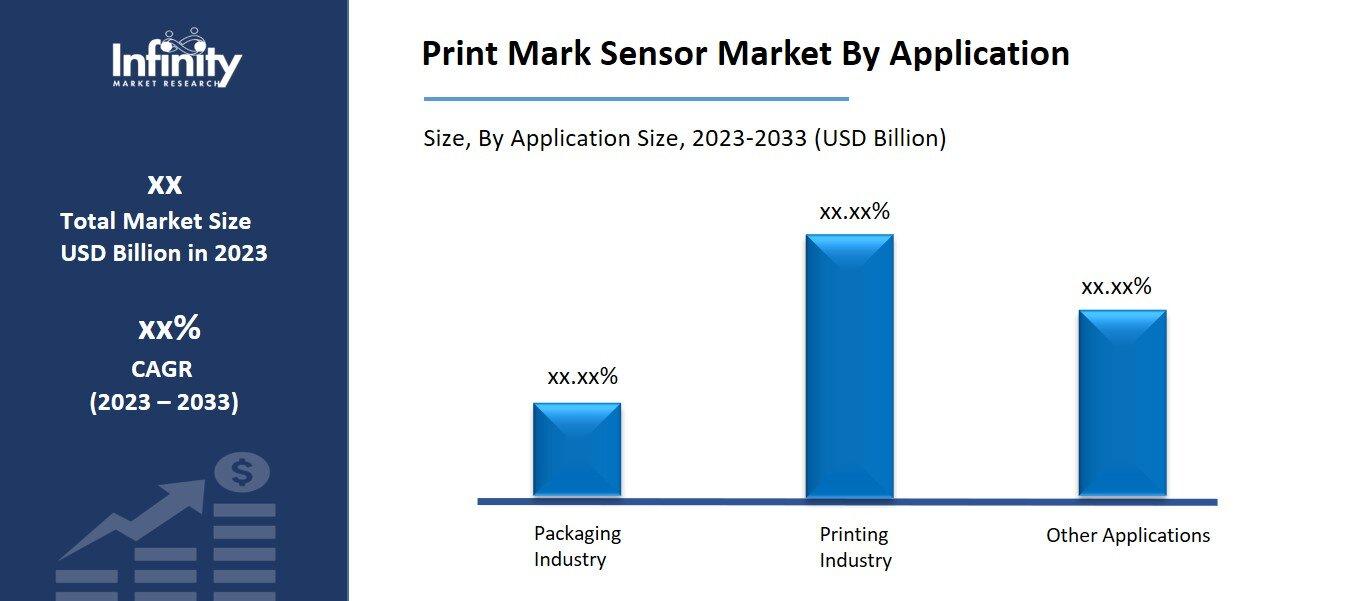

By Application

o Packaging Industry

o Printing Industry

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into laser and modulated light. Among these, buttercream laser segment acquired the significant share in the market owing to its superior accuracy, range, and ability to operate effectively in various conditions. Laser mark sensors utilize focused light beams to detect and read printed marks with high precision, making them ideal for applications that require detailed identification and tracking, such as in high-speed production lines and intricate packaging processes.

By Application Analysis

On the basis of application, the market is divided into packaging industry, printing industry, and other applications. Among these, packaging industry held the prominent share of the market due to the increasing demand for automation, efficiency, and quality control in packaging processes. As consumer preferences evolve towards more complex packaging designs and enhanced traceability, mark sensors play a critical role in ensuring accurate identification and verification of products throughout the packaging lifecycle.

To Learn More About This Report , Request For Sample

In the packaging sector, mark sensors are utilized to read barcodes, QR codes, and printed labels, facilitating seamless inventory management, shipment tracking, and compliance with industry regulations. This capability is vital for ensuring that products are correctly identified and sorted, thus reducing errors and enhancing operational efficiency.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of the market. The adoption of automation and smart manufacturing practices in North American industries has accelerated the demand for mark sensors, as companies seek to enhance operational efficiency, reduce errors, and ensure high-quality output.

Additionally, the presence of leading technology companies and innovators in the mark sensing space has facilitated significant advancements in sensor technologies, such as the integration of machine learning and AI capabilities. These innovations allow for improved performance, adaptability, and data analysis, positioning North American manufacturers at the forefront of the mark sensor market.

Competitive Analysis

The competitive landscape of the mark sensor market is characterized by a diverse array of players, ranging from established multinational corporations to emerging technology startups, all striving to innovate and capture market share. Key industry leaders such as Siemens AG, SICK AG, Keyence Corporation, Cognex Corporation, and Omron Corporation dominate the market by offering a wide range of advanced mark sensors tailored to various applications in manufacturing, packaging, and logistics. These companies focus on technological advancements, incorporating features like machine learning and IoT capabilities to enhance accuracy and efficiency. Strategic partnerships and collaborations are increasingly common as players seek to expand their market reach and improve product offerings, while customization of mark sensors to meet specific industry needs allows for differentiation in a competitive environment.

Key Market Players in the Print Mark Sensor Market

o EMX Industries Inc

o Keyence Corporation

o Asstech

o Pepperl+Fuchs

o Balluff

o Proximon

o Sensopart

o Banner Engineering

o Baumer

o Omron

o Autonics

o Panasonic Corporation

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD XX Billion |

|

Market Size 2033 |

USD XX Billion |

|

Compound Annual Growth Rate (CAGR) |

XX% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

EMX Industries Inc, Keyence Corporation, Asstech, Pepperl+Fuchs, Balluff, Proximon, Sensopart, Banner Engineering, Baumer, Omron, Autonics, Panasonic Corporation, and Other Key Players |

|

Key Market Opportunities |

Customization and Specialized Solutions |

|

Key Market Dynamics |

Growing Demand for Quality Control |

📘 Frequently Asked Questions

1. Who are the key players in the Print Mark Sensor Market?

Answer: EMX Industries Inc, Keyence Corporation, Asstech, Pepperl+Fuchs, Balluff, Proximon, Sensopart, Banner Engineering, Baumer, Omron, Autonics, Panasonic Corporation, and Other Key Players

2. How much is the Print Mark Sensor Market in 2023?

Answer: The Print Mark Sensor Market size was valued at USD xx Billion in 2023.

3. What would be the forecast period in the Print Mark Sensor Market?

Answer: The forecast period in the Print Mark Sensor Market report is 2023-2033.

4. What is the growth rate of the Print Mark Sensor Market?

Answer: Print Mark Sensor Market is growing at a CAGR of xx% during the forecast period, from 2023 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.