🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

PVDC Resins & PVDC Latex Market

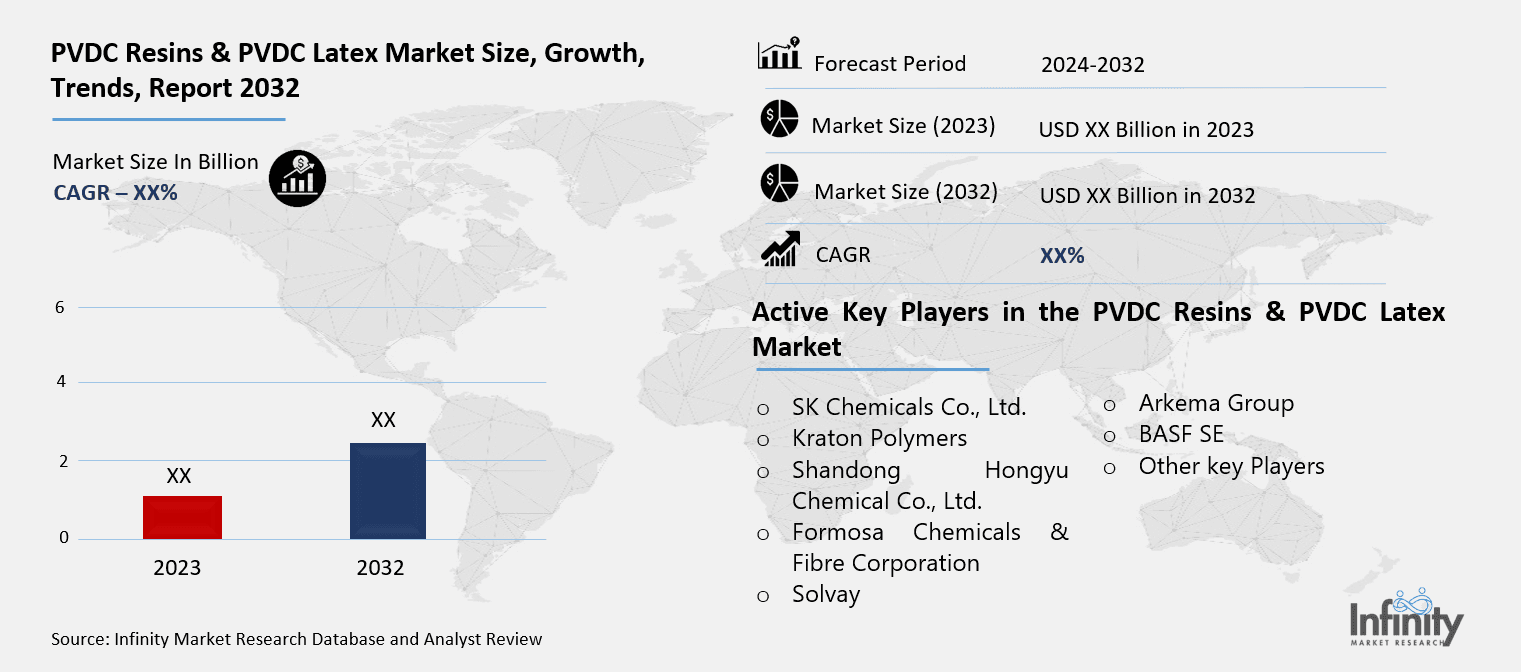

PVDC Resins & PVDC Latex Market Global Industry Analysis and Forecast (2024-2032) By Type (PVDC Resins, PVDC Latex) By Application (Packaging, Coatings, Adhesives) By Distribution Channel (Direct Sales, Online Sales) By Product Form (Solid Resins, Liquid Resins, Latex Emulsions) By End-Use Industry (Food and Beverage Industry, Pharmaceuticals, Textiles, Other Industries) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1632

PVDC Resins & PVDC Latex Market Synopsis

PVDC Resins & PVDC Latex Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

The PVDC (Polyvinylidene Chloride) Resins and PVDC Latex refers to the industry engaged in the manufacturing of products derived from PVDC for its high barrier properties which make them suitable for use in packaging food products, drugs, and cosmetic products. PVDC resins are crystalline polymers, namely, solid polymers of VDC, while PVDC latex is a water-borne dispersion of PVDC employed mostly as coatings and adhesives. These materials are prized for their endurance in moisture, gases or odors, that makes them prolong the shelf life of products. The market is stimulated by the need for effective packaging materials and solutions and there is especially high demand from the food and beverage companies due to concerns of sustainability and preservation.

The PVDC (Polyvinylidene Chloride) resins and PVDC latex has become an essential element in the packaging sector mainly because of their exceptional barrier qualities that guarantee product security and quality of different products particularly in the food and drug industries. PVDC is a high-performance resin with protective characteristic to oxygen, moisture, and also chemicals being a perfect material of packaging films in order to elongate the shelf life of products. Due to growing demand in organized living styles, packaged foods, rising healthcare requirements for pharmaceutical and personal care products, and the concern towards environment sustainable and efficient packaging requirements, the demand for PVDC-based films and coatings has prominently increased. In the food industry, PVDC resins offer protection against spoilage, contamination, and diminution in the shelf-life of the packed products and therefore, finds attractive application in the sector in relation to, wraps, pouches and multilayer films. Likewise, the pharmaceutical industry utilizes PVDC since it provides essential properties for the protection of delicate drugs that easily degrade through transport conveyance or may become compromised during storage.

Burgeoning consumer concern towards food safety, quality retention and hygiene requirements, coupled with rising demand for protective packaging has boosted demand for PVDC resins & latex. Secondly, due to changes in consumers perception of the numerous packaging types being in the market today where they prefer packages that are more durable and tamper proof, flexibility of PVDC as a material has played a major role in increasing market potential of the film. The pharma sector has seen a large increase in demand for the use of PVDC in blister packs as the resin provides a solution to the issues of exposure to moisture, air, and light for sensitive products. This increasing trend in the use of PVDC packaging is however boosted by its qualities in ensuring that more structures in the packaging items are retained and that cases of contamination and spoilage of the products or loss of their effectiveness are greatly minimized.

However, there exist several issues that were experienced by the PVDC resins and latex market, including the availability of environmental hazards and the increased production of substitute packaging material. Although PVDC coated films were widely used in food packaging due to their excellent barrier properties, it has also been on the receiving end of the rising focus on sustainability of products and reduced use of conventional plastics which fall under the same category. As a result, advanced technologies like biodegradable films and recyclable products have surfaced on the market. While PVDC is currently used in various applications such as coatings, films, and adhesives, its producers have been seeking to improve the green performance by modifying the methods of production, integrating the recyclable material in its formulation and minimizing the overall effect of PVDC-based packaging on the environment. Such steps should enhance the general sustainability of PVDC resins making them even more attractive to environmentally conscious customers and firms.

Moreover, there is mounting legal action against the utilization of plastic packaging which is especially eminent in the European Union and in other areas that have implemented strict regulation on emissions onto the environment. However, there are still certain challenges which can be, But the PVDC resins and latex market is expected to further grow in the future with increasing demand of high performance barrier materials and advancing efforts for eco-friendly material solutions. Several players in the industry are also identifying other uses of PVDC across various industries including medical device packaging, agricultural films and industrial coatings giving this material an even broader market opportunity. This indicates PVDC resins and latexs will continue to grow steadily, especially with improvement of production technology and boosting concerns on sustainability that creates promising prospects for the packaging & food, pharmaceuticals and personal care markets.

PVDC Resins & PVDC Latex Market Trend Analysis

Trend

Rising Demand for PVDC Latex in Sustainable Applications

PVDC latex is today more appreciated for its multi-functional nature and usually environmentally sensitive features particularly in the coatings and adhesive types. As organizations and industries begin to move towards the direction of sustainability, this water-borne product is increasingly being used in sectors other than the food industry including textiles, paints, and construction. Compared to the conventional solvent based products, PVDC latex is easily more friendly to the environment as it does not emit VOCs into the atmosphere, thus protecting workers. Its advantage of flexibility, water resistant, and adhesive nature makes it to be widely used in surface treatments, coatings and formulations that require flexibility, and resistance to water. Such advantages give fillip to its deployment across a spectrum of applications and particularly in markets that prefer green and sustainable solutions.

The increasingly important focus on environmental concerns along with proliferation of applications requiring low emission and safe solutions is stimulating the market for PVDC latex. The latter is due to the fact that the green building movement is part of the expansion as more construction projects include the use of the green material. Nonetheless, the market holds criticisms, for example changes in the raw material price and regulatory concerns over the use of chlorines based products that may hamper growth in some part of the globe. Nevertheless, the prevailing tendency of environmental Management and development of innovation in PVDC latex product offers the market potential to progress as the manufacturers attempt to overcome these challenges and enhance latex product’s performance along with making them environmentally friendly.

Drivers

Growing Demand for High-Performance Packaging Materials

The aforementioned resins and latex markets finds its strength on the emerging need for high performance packaging material solutions especially in the food and beverages industries. PVDC-based films are particularly desirable due to the high barrier properties which result from its ability to protect the packed products from moisture, oxygen and light. All these protective attributes are very crucial to help preserves the foods and beverages, and increase their shelf life substantially. In current context stressed on the nutritional value and taste of packaged goods, PVDC resins have emerged as a popular choice in flexible packaging applications as they offer a critical function of extending shelf life.

Besides the improvement of product anti-aging, consumers’ demand for longer and fresher products such as food have posed a major influence towards the use of packaging materials containing PVDC. With consumers today looking for new packaging materials that are more durable and have long shelf life and good preservation features, PVDC films can be used to solve this problem. This is enhanced by the growing aspect of convenience foods and ready to eat foods most of which require the factor of fresh fruits and vegetables to be a determining factor. The fact that PVDC resins offer the characteristics of product protection as well as its preservation and taste preservation has further placed the food and beverage sector as the growth driver in the PVDC market.

Restraints

Environmental Concerns Surrounding PVDC Products

The major issue of concern for the PVDC resins and PVDC latex market is the rapidly increasing environmental issues regarding the sustainability of PVDC products. Various environmental agencies as well as regulatory authorities have had reason to frown at PVDC because the material is not biodegradable. They are campaigning for decrease in utilization of non-biodegradable items most especially with the industries that produce high volumes of wastes such as the packaging industries. Such concerns on the part of the environment on the effect of PVDC and the contribution of this material to the formation of long-term perspectives on the perspectives of ecosystems have inspired the development of stricter regulations concerning the usage of PVDC. Which has led to increased pressure on the manufactures to look for greener options to avoid the impacts of the same.

Due to the increasing problems that people have been facing with their current environment, there has been a rising trend towards the use of bio-degradable and environmentally sound products and this has not been felt only in the food packaging industry. By extension, there are likely to be reduced demands for PVDC resins and latex with this implication that regions sensitive to environmental issues will record lower consumption rates. Currently, some companies in the PVDC market are struggling to address the issue of applying and integrating the high-performance properties of PVDC with the current higher demand for environmental-friendly solutions. An increase in consumer preference and regulatory pressure in a direction away from this kind of plastic could put pressure on manufacturers to heavily invest into researching, designing, and implementing more sustainable replacements, the costs of which would either have to be reflected in the price of the final product or alternatively force PVDC based products out of the market.

Opportunities

Growth of PVDC Latex in High-Performance Coatings

Food packaging is one of the biggest chances for PVDC resins as it has heavy demand in applications which require heat seal and superior barrier properties to prevent product contact with moisture, oxygen and light. These features enhance the shelf life of the packaged goods in a way that makes PVDC particularly popular in the preservation of the quality of foods. In a future, where consumer consciousness in product durability and food packaging is expected to rise, the market for PVDC resins in flexible packaging is predicted to increase. Retail and e-commerce food service market in emerging economies is rapidly growing which means that consumers demand packaging solutions that can effectively seal in the freshness of the product and preserve the overall quality. The rising popularity of convenient foods, ready to eat foods and online grocery purchases also fuel the demand for PVDC in foods and beverages which in turn has immense growth opportunities for its manufacturers in theses regions.

As for the food packaging application, PVDC latex also has broad developing prospect in the coatings market. Specifically, the characteristic of the material which has a high degree of moisture resistance and excellent film forming property makes it the best for high performance coating for a number of applications which may include the constructions, automobile and electronics industries. Since these industries require coatings that are highly resistant and protective of surfaces due to the conditions under which the material will be used, PVDC latex has the opportunity to perform an important function. In construction for instance, PVDC latex is used coated films that are more resistant to water and UV amongst others. For the automotive and electronics industries, the characteristic of the latex of providing smooth protective films adds to the material’s importance to the durability and efficiency of the final product. Thus, these widening areas of application in coatings open up the prospect of growth in sectors requiring extensive PVDC latex usage in demand industries.

PVDC Resins & PVDC Latex Market Segment Analysis

PVDC Resins & PVDC Latex Market Segmented on the basis of By Type, By Application, By Distribution Channel, By Product Form, By End-Use Industry.

By Form

o Solid Resins

o Liquid Resins

o Latex Emulsions

By Application

o Packaging

o Food Packaging

o Pharmaceutical Packaging

o Consumer Goods Packaging

o Coatings

o Adhesives

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, PVDC Resins segment is expected to dominate the market during the forecast period

PVDC (Polyvinylidene Chloride) resins are famous for their very good barrier characteristics, mainly barrier to moisture, gases and aroma thus are very useful in most packaging and related industries. These resins are available in two main types: Homopolymer polivinylacetaat (PVDC) dan Copolymer polivinylacetaat (PVDC) PVDC homopolymer is synthesized using only vinylidene chloride monomer and is acclaimed for its high barrier properties inclusive of an excellent moisture barrier hence applicable for use in packing highly perishable commodities such as food and drugs. Its structure also makes it very stiff and this affords the opportunity to protect fragile products from factors such as humidity and oxygen which in the long run reduce product shelf life.

Nor is Copolymer PVDC which is prepared by copolymerisation of vinylidene chloride with others Monomers improving its properties and having a greater flexibility than homopolymer PVDC. This variant yields enrichment derived from adjustability for targeted characteristics including processability as well as tailored performance profiles. Copolymer PVDC is most effective in relatively sophisticated packaging products where the ductility and the amenability to being formed into different forms is desirable. Both kinds of the PVDC resins are very vital in maintaining the safety, quality, and protection of products for use and that is why their application is paramount in foods, pharmaceuticals and consumer goods packaging.

By End-Use Industry, Food and Beverage Industry segment expected to held the largest share

In the F&B industry PVDC has a vital function of protecting perishable commodities form spoilage due to ease flexibility in packaging that offers excellent barrier capacities.. The moisture, oxygen and light excluding characteristic of this material helps in keeping food products fresh by protecting them from factors that cause the deterioration of the material. Many current applications involve the use of PVDC in packaging films since it acts as a protective barrier to food since it retains its taste, texture and nutritional value. This is especially so for the processed foods, whose packaging need to protect them against changes in the environment during storage and transport.• Moreover, PVDC has great advantages when used for packing fresh products, all kinds of meat products, fruits and vegetables, where a main factor is the preservation of freshness and excluding any bacterial infection.y to block moisture, oxygen, and light ensures that food products remain fresh and protected from external factors that could lead to spoilage. PVDC is widely used in packaging films, providing a protective layer that preserves the quality of food by maintaining its flavor, texture, and nutritional value. This is particularly important for processed foods, which require packaging solutions that can offer long-term protection against environmental changes during storage and transportation.

Additionally, PVDC is highly beneficial for packaging fresh foods, such as meats, fruits, and vegetables, where maintaining freshness and preventing contamination is vital. This characteristic of the material makes it very easy to achieve a hermetic barrier around these perishable items, which minimises the potential for microbial activity and oxidation leading to spoilage. PVDC comes under shrink films, wraps and laminates all of which offer excellent protection and barrier properties. This makes PVDC an essential material especially in the manufacture of food and beverages since the products undergo physical protection that would last until the consumers get hold of the products.

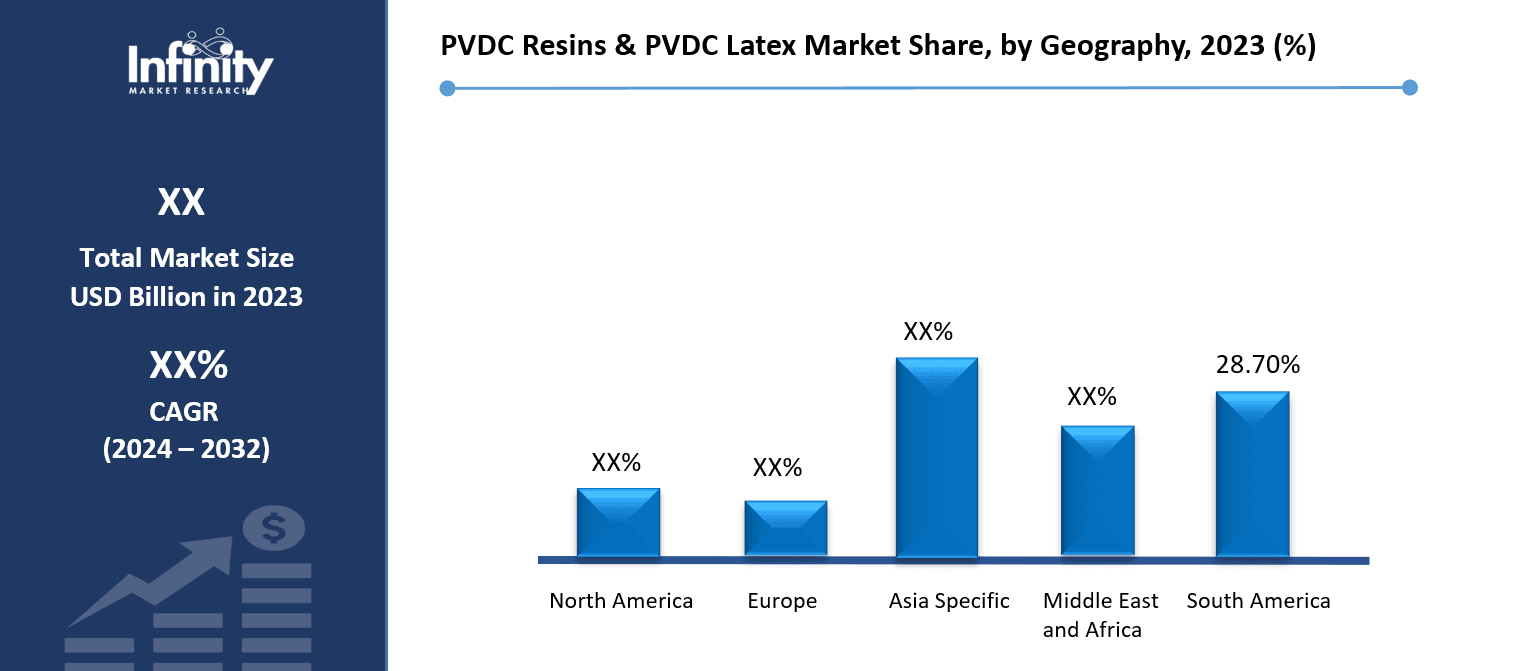

PVDC Resins & PVDC Latex Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

In North America, the demand for PVDC resins and latex is fueled by the growing uptake of higher-barrier packaging application across the food and pharmaceutical industries. These industries are fast embracing the PVDC based materials to increase shelf life and maintain quality of the produce. These factors, namely the increasing focus on increasing aware of food waste and improvements in sustainable packaging facilitate the use of PVDC resins in the packaging sector further. Industry imperative in the global PVDC based packaging market include food safety standards that have prompted the manufacturing of high quality PVDC based packaging to meet set standards. Therefore, these trends are equally responsible for the growth of the PVDC resins market in North America.

The use of PVDC latex in healthcare segment of North America is also growing at a fast pace along with the food and packaging industries. The PVDC latex is widely used in the manufacture of medical device coatings and has considerable improvements on the protective side of medical goods. This growth is contributed to by increasing healthcare needs and increasing concern with the safety and efficacy of medical devices. In the coming years, the growth of the North American health care market is expected to act as a driver of increased demand for PVDC latex in medical coatings. The regional healthcare industry remains well-developed, and the systematic incidence of PVDC resins and latex is likely to grow further.

PVDC Resins & PVDC Latex Market Share, by Geography, 2023 (%)

Active Key Players in the PVDC Resins & PVDC Latex Market

o SK Chemicals Co., Ltd.

o Kraton Polymers

o Shandong Hongyu Chemical Co., Ltd.

o Formosa Chemicals & Fibre Corporation

o Solvay

o Arkema Group

o BASF SE

o Other key Players

Global PVDC Resins & PVDC Latex Market Scope

|

Global M PVDC Resins & PVDC Latex Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Type |

· PVDC Resins o Homopolymer PVDC o Copolymer PVDC · PVDC Latex | |

|

By Application |

· Packaging o Food Packaging o Pharmaceutical Packaging o Consumer Goods Packaging · Coatings · Adhesives | ||

|

By Distribution Channel |

· Direct Sales · Online Sales | ||

|

By Product Form |

· Solid Resins · Liquid Resins · Latex Emulsions | ||

|

By End-Use Industry |

· Food and Beverage Industry · Pharmaceuticals · Textiles · Other Industries | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Demand for High-Performance Packaging Materials | ||

|

Key Market Restraints: |

· Environmental Concerns Surrounding PVDC Products | ||

|

Key Opportunities: |

· Growth of PVDC Latex in High-Performance Coatings | ||

|

Companies Covered in the report: |

· SK Chemicals Co., Ltd., Kraton Polymers, Shandong Hongyu Chemical Co., Ltd., Formosa Chemicals & Fibre Corporation, Solvay, Arkema Group, BASF SE, and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the PVDC Resins & PVDC Latex Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the PVDC Resins & PVDC Latex Market?

Answer: SK Chemicals Co., Ltd., Kraton Polymers, Shandong Hongyu Chemical Co., Ltd., Formosa Chemicals & Fibre Corporation, Solvay, Arkema Group, BASF SE, and Other Major Players.

3. What are the segments of the PVDC Resins & PVDC Latex Market?

Answer: The PVDC Resins & PVDC Latex Market is segmented into By Type, By Application, By Distribution Channel, By Product Form, By End-Use Industry and region. By Type, the market is categorized into PVDC Resins, PVDC Latex. By Application, the market is categorized into Packaging, Coatings, Adhesives. By Distribution Channel, the market is categorized into Direct Sales, Online Sales. By Product Form, the market is categorized into Solid Resins, Liquid Resins, Latex Emulsions. By End-Use Industry, the market is categorized into Food and Beverage Industry, Pharmaceuticals, Textiles, Other Industries. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the PVDC Resins & PVDC Latex Market?

Answer: The PVDC (Polyvinylidene Chloride) Resins and PVDC Latex refers to the industry engaged in the manufacturing of products derived from PVDC for its high barrier properties which make them suitable for use in packaging food products, drugs, and cosmetic products. PVDC resins are crystalline polymers, namely, solid polymers of VDC, while PVDC latex is a water-borne dispersion of PVDC employed mostly as coatings and adhesives. These materials are prized for their endurance in moisture, gases or odors, that makes them prolong the shelf life of products. The market is stimulated by the need for effective packaging materials and solutions and there is especially high demand from the food and beverage companies due to concerns of sustainability and preservation.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.