🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Refractory Metals Market

Refractory Metals Market Global Industry Analysis and Forecast (2024-2032) By Type(Tungsten, Molybdenum, Tantalum, Niobium, Rhenium), By Form(Powder, Bar, Sheet, Plate, Wire), By Application(Aerospace & Defense, Electronics, Automotive, Industrial, Energy & Power, Medical), By End-Use Industry( Manufacturing, Chemical Processing, Electronics, Mining, Healthcare) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1634

Refractory Metals Market Synopsis

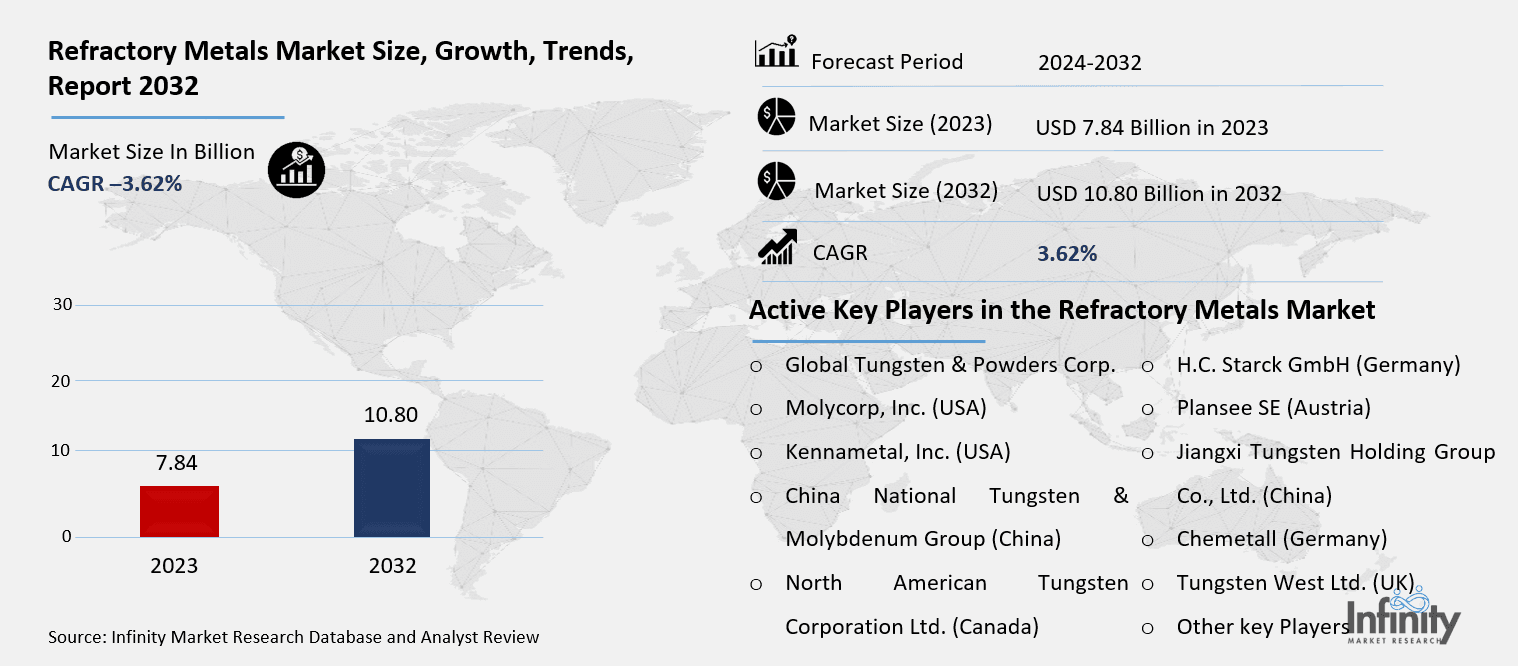

Refractory Metals Market Size Was Valued at USD 7.84 Billion in 2023, and is Projected to Reach USD 10.80 Billion by 2032, Growing at a CAGR of 3.62% From 2024-2032.

Refractory metals are a class of metals including those which have high melting point over 3000 oC and which possess great resistance to heat and wear. These metals can withstand great loads in buildings as well as the forces proposed by weather, temperature, pressure, and other forces that the construction undergoes following erection. The primary classes of refractory metals are tungsten, molybdenum, tantalum, niobium, and rhenium, that finds necessary uses in aerospace, electronics, and energy sector. Because of their properties, they are used in heat areas where the other metals cannot be used due to high temperatures.

The global refractory metals market has been expanding over the years because of rising demand for material that is resistant against high temperatures and wear in versatile industry fields like aerospace and electronics industries, energy and automobile industries. They are used in the manufacturing of high-strength metal components demanded in engines, turbines and other demanding machinery. W by its high MP and density sells most, seconded by molybdenum, famed for strength and heat endurance. Tantalum and niobium are also considered due to their main properties such as corrosion resistance and high melting point, thus can be used in electronics and aerospace industry. Similarly, though not as frequently used as molybdenum, has rhenium has significant uses in niche space such as jet engines and turbines.

In aerospace and defense, refractory metals used in spacecraft shielding, rocket motors, and in aerospace construction parts with high thermal and mechanical requirements. In the electronics industry, they are also employed in the manufacture of semiconductors, capacitors, electrical contacts because of the prospects of withstanding high voltage and temperatures. As well, the automotive industry uses such metals for building high-strength engines and brake systems that require the use of reliable materials that can withstand high temperatures. The modern tendencies towards increasing efficiency and the application of high technology in different fields additionally stimulates the use of refractory metals and contributes to the development of the market in the future.

Refractory Metals Market Outlook, 2023 and 2032: Future Outlook

Refractory Metals Market Trend Analysis

Trend: Increasing Demand for High-Performance Materials

One of the main trends that affect the refractory metals’ market is the constantly escalating requirement to develop materials that would be stable and effective at high temperatures and mechanical stresses. Manufacturing sectors particularly aerospace, automotive, and electronics continue to seek lightweight and stronger parts. Steels of high performance that have such desirable characteristics as heat, strength, and wear resistance are now acquiring greater importance in satisfying these demands and refractory metals now play a significant role. The augment in demands of such sectors can be envisaged owing to the on-going advancement of new-generation technologies in these domains, namely electric vehicles, next-generation aircraft, and efficient power system.

This is also reflected in trends in increased application of refractories metals in the high technology manufacturing applications. Industries such as aerospace, automotive and energy rely on materials that are capable of performing optimally in harsh environments, and such technologies as 3D printing and additive manufacturing are propelling the demand for these metals even higher. Refractory metals’ useful characteristics to remain unimpaired and are able to effectively endure high temperatures coupled with the mechanical stress the helps it become an ideal to be used in the next generation of industrial and specific group of consumer products. As industries drive advances in material capabilities, the tipping point towards employing refractory metals in high demanding applications is predicted to steadily increase.

Opportunity: Growth in Aerospace and Defense Applications

The aerospace and defense industries hold a great potential for growth to the refractory metals market. The further progression of aircraft and defense technologies requires new composites designed for high-temperature applications including rocket engines, turbine blades and heat shields. It turns out that refractory metals, including tungsten, molybdenum, and tantalum, are the metals providing the necessary thermal stability and high strength for these applications, and they play an important role in the creation of new technologies for military and civilian aerospace industries.

In addition, with increased interest in space exploration, and the use of space shuttles-which are reusable- also offers other opportunities for refractory metals. Due to their heat and pressure resistant capabilities as experienced during reentry, or high speed flights, these metals are greatly significant in manufacturing space crafts and satellites. The global refractory metal market in the aerospace and defense segments expands due to the growth in money scarce countries and private companies investing in AS space exploration.

Driver: Technological Advancements in High-Temperature Applications

Technological innovation in diverse areas involving high-temperature uses has been cited as the biggest factor for the exponential growth in the demand for refractory metals. Some of the industries like aerospace, automotive and energy often need materials that can undergo high temperature without affecting their mechanical properties. With the advancement of technology in future especially in areas of jet propulsion, power production and high performance automotive engineering the demand for refractory metals will increase. These metals’ durability to high temperatures as well as mechanical forces extends the prospect of their application in creating new generations of technology and equipment.

In addition, the growth of precision casting and additive manufacturing is making it possible to optimize refractory metals utilisation in complex high performance components. These advance produce light weight, high strength, high durability parts that fuel the need for refractory metals. With the advancement and diversification of these technology applications, needs for such material that can address these new challenges are expected to sustain market growth.

Restraints: High Cost of Refractory Metals

However one of the most significant threats hindering growth of refractory metals market is the cost of extraction and purification of these metals. Tungsten and rhenium, for example, are mainly used in refractory metals, which could be defined as rare metals that are hard to mine due to this, they are expensive. Aso, their processing into utilizes special equipment/technologies leading to higher costs of production of these metals. This make refractory metals costly than the common material which in turn hinders it wider use in areas that have strict cost control measures.

The high cost can also restrict the utility of refractory metals to applications that are costly to the extent that only their properties suffice for their purpose. For instance, car and electronics producers may use cheaper material unless, there are great gaining advantages by using refractory metals. Therefore, this high cost continues to prevent the wider application of these metals in various applications.

Refractory Metals Market Segment Analysis:

Refractory Metals Market Segmented on the basis of type, form, application and end user.

By Type

o Tungsten

o Molybdenum

o Tantalum

o Niobium

o Rhenium

By Application

o Aerospace & Defense

o Electronics

o Automotive

o Industrial

o Energy & Power

o Medical

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Tungsten segment is expected to dominate the market during the forecast period

The refractory metals market is categorized based on different forms of materials such as Tungsten, molybdenum, tantalum, niobium and rhenium. It is scattered market and tungsten controls the largest market share, due to its very high melting point and high strength applications in aerospace, defense, and industries. Next is molybdenum, which shows high melting point, good conditions of strength, it is used as contacts, filaments and in aerospace industry. Tantalum, mainly used in electronics, medical equipment applications and other high requirements for the corrosion-resistance and high melting point of industrial applications;Niobium mostly subjected to electronic components, chemical and metallurgical industries and aerospace applications.

Rhenium is used not as often as other metals yet is indispensable in turboshaft engines and solid-propellant rocket motors since it possesses high-temperature characteristics. Every single one of these metals is unique with characteristics that qualify it for certain applications hence supporting the growth of the market. In each of these applications the requirement placed on materials increases and as a result the market for each of these metals is expected to grow.

By Application, Aerospace & Defense segment expected to held the largest share

A wide variety of industries require refractory metals including aerospace and defense, electronics, automobile, industrial, energy and power, and health-care. Besides aerospace and defense, these metals are used to make jet engine parts, rocket nozzles and heat shields that have to be made from materials that can withstand high temperatures. Currently, tantalum and niobium that are found in capacitors, semiconductors and connectors are some of the most valued refractory metals as a result of their ability to withstand corrosion and their conductivity properties.

Refractory metals are applied in high performance engines and in the brake system of automobiles among others, and usage in turbines, reactors and heat exchangers among others by the energy and power sector. Most of the refractory metals have a special application in the medical industry especially in the manufacturing of related devices and implants where conditions are usually tough. The versatility of the product shows the relevance of refractory metals in the contemporary world, where each branch adds in the market development.

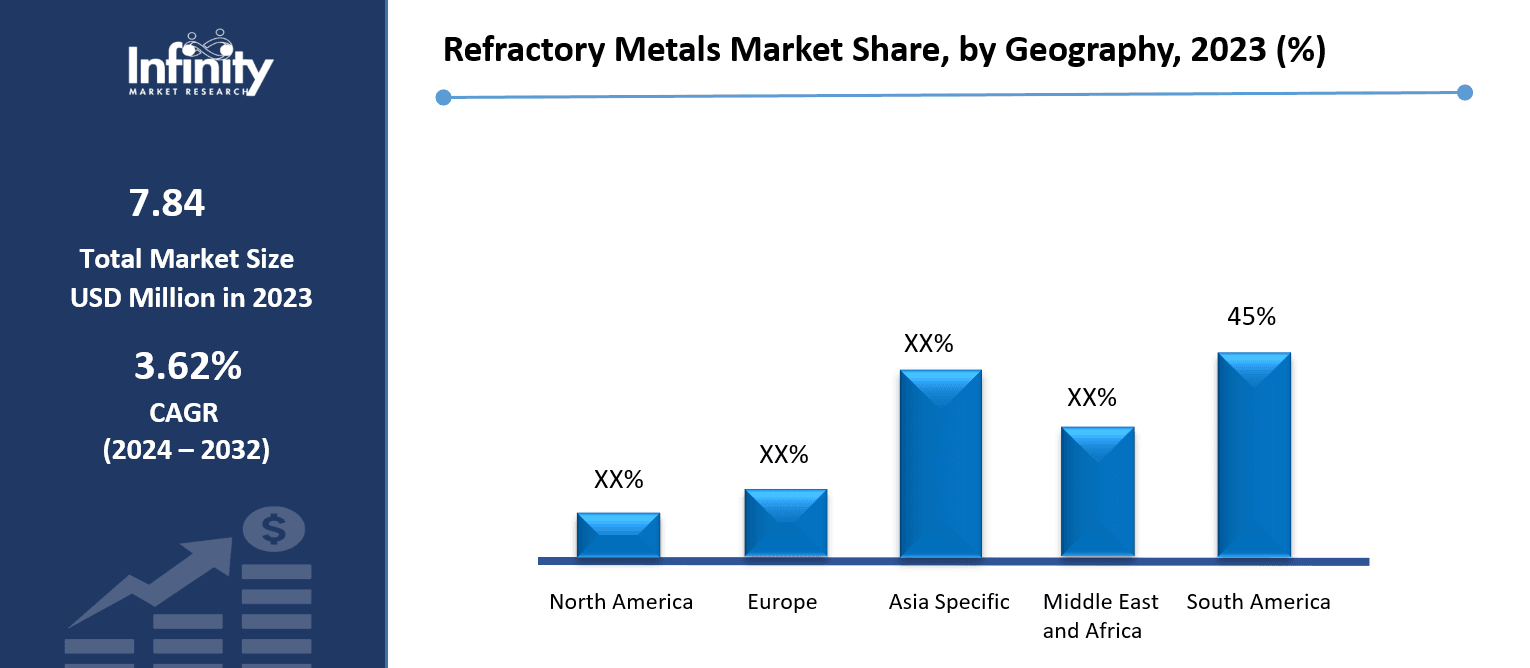

Refractory Metals Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

North America: North America controls the overall refractory metals market because of the growing requirement for such materials in the technological sectors including aerospace, defense, and electronics. Many of this world’s top aerospace and defense companies are sited in the region and they employ these refractory metals for the manufacture of their superior performing parts. Moreover, the large numbers of automotive and energy industries in the area also contribute to the use of refractory metals especially where high temperature is necessary.

In addition, strong manufacturing industry, technological advancement, and high investment in research and development across North America also support the growth in the refractory metals market. Refractory metals, such as Tantalum, are used heavily in the United States and currently, many industries are still straining to reach higher levels of efficiency and performance in their products.

Refractory Metals Market Share, by Geography, 2023 (%)

Active Key Players in the Refractory Metals Market

o Global Tungsten & Powders Corp. (USA)

o Molycorp, Inc. (USA)

o TANCO (Canada)

o Kennametal, Inc. (USA)

o China National Tungsten & Molybdenum Group (China)

o North American Tungsten Corporation Ltd. (Canada)

o Globe Specialty Metals, Inc. (USA)

o H.C. Starck GmbH (Germany)

o Plansee SE (Austria)

o Jiangxi Tungsten Holding Group Co., Ltd. (China)

o Chemetall (Germany)

o Tungsten West Ltd. (UK)

o Other key Players

Global Refractory Metals Market Scope

|

Global Refractory Metals Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 7.84 Billion |

|

Forecast Period 2024-32 CAGR: |

3.62% |

Market Size in 2032: |

USD 10.80 Billion |

|

Segments Covered: |

By Type |

· Tungsten · Molybdenum · Tantalum · Niobium · Rhenium | |

|

By Application |

· Aerospace & Defense · Electronics · Automotive · Industrial · Energy & Power · Medical | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Technological Advancements in High-Temperature Applications | ||

|

Key Market Restraints: |

· High Cost of Refractory Metals | ||

|

Key Opportunities: |

· Growth in Aerospace and Defense Applications | ||

|

Companies Covered in the report: |

· Global Tungsten & Powders Corp. (USA), Molycorp, Inc. (USA), TANCO (Canada), Kennametal, Inc. (USA), China National Tungsten & Molybdenum Group (China), North American Tungsten Corporation Ltd. (Canada), Globe Specialty Metals, Inc. (USA), and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Refractory Metals Market research report?

Answer: The forecast period in the Refractory Metals Market research report is 2024-2032.

2. Who are the key players in the Refractory Metals Market?

Answer: Global Tungsten & Powders Corp. (USA), Molycorp, Inc. (USA), TANCO (Canada), Kennametal, Inc. (USA), China National Tungsten & Molybdenum Group (China), North American Tungsten Corporation Ltd. (Canada), Globe Specialty Metals, Inc. (USA), and Other Major Players.

3. What are the segments of the Refractory Metals Market?

Answer: The Refractory Metals Market is segmented into Type, Form, Application, End User and region. By Type, the market is categorized into Tungsten, Molybdenum, Tantalum, Niobium, Rhenium. By Form, the market is categorized into Powder, Bar, Sheet, Plate, Wire. By Application, the market is categorized into Aerospace & Defense, Electronics, Automotive, Industrial, Energy & Power, Medical. By End-Use Industry, the market is categorized into Manufacturing, Chemical Processing, Electronics, Mining, Healthcare. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Refractory Metals Market?

Answer: Refractory metals are a class of metals including those which have high melting point over 3000 oC and which possess great resistance to heat and wear. These metals can withstand great loads in buildings as well as the forces proposed by weather, temperature, pressure, and other forces that the construction undergoes following erection. The primary classes of refractory metals are tungsten, molybdenum, tantalum, niobium, and rhenium, that finds necessary uses in aerospace, electronics, and energy sector. Because of their properties, they are used in heat areas where the other metals cannot be used due to high temperatures.

5. How big is the Refractory Metals Market?

Answer: Refractory Metals Market Size Was Valued at USD 7.84 Billion in 2023, and is Projected to Reach USD 10.80 Billion by 2032, Growing at a CAGR of 3.62% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.