🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Rigid Polyurethane Foam (RPUF) Market

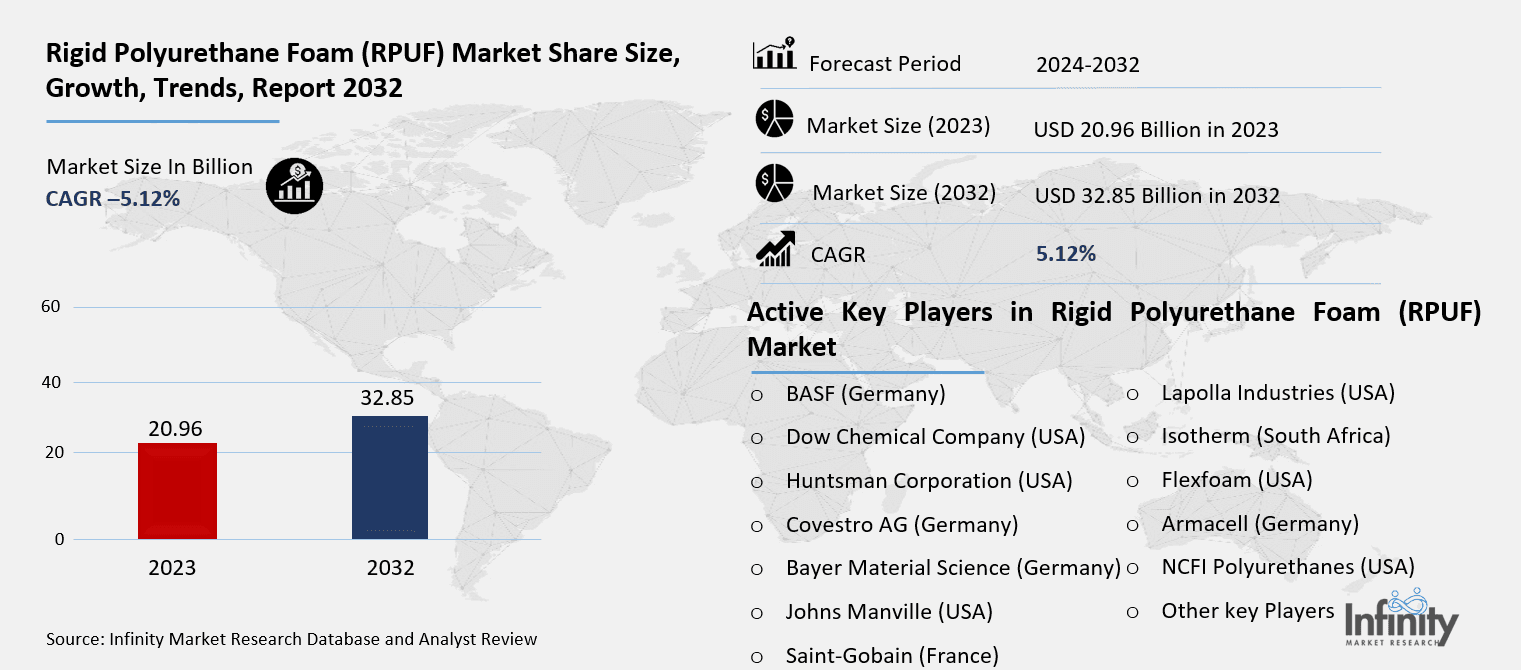

Rigid Polyurethane Foam (RPUF) Market Global Industry Analysis and Forecast (2024-2032) By Type( Conventional RPUF, High-Density RPUF, Spray RPUF),By Application( Building & Construction, Appliances, Automotive, Packaging, Industrial Insulation, Other Applications),By End-Use Industry(Construction Industry, Transportation Industry, Packaging Industry, Electronics Industry, Others) and Region

Feb 2025

Chemicals and Materials

Pages: 138

ID: IMR1774

Rigid Polyurethane Foam (RPUF) Market Synopsis

Rigid Polyurethane Foam (RPUF) Market Size Was Valued at USD 20.96 Billion in 2023, and is Projected to Reach USD 32.85 Billion by 2032, Growing at a CAGR of 5.12% From 2024-2032.

RPUF stands for Rigid Polyurethane Foam which is a kind of rigid closed cell foam that is more made by allowing polyols reacting with isocyanates to yield a tough, light, thermal insulating material. It is widely adopted in different industries for a variety of reasons which include the aforementioned properties: thermal conductivity resistance, sound resistance and structural strength. Today, RPUF finds its use in various forms including on walls , in auto components, packaging material etc.

RPUF is one of the popular of foams distinguished globally since it has special characteristics which include; Polyols and isocyanates are combined to form a solid structure that is light, strong and excellent in thermal insulation. Sometimes the foam is produced by chemically combining these chemicals of which a reaction takes place to form a rigid solid expanded foam. RPUF is most often employed in programs where thermal insulation is particularly critical due to its high heat resistance and energy efficiency.

Global demand for RPUF has risen steadily in the past few years due to the significant uptake of materials with higher energy density in the building and construction, transportation, and numerous industrial applications. It is also equally famous for its ability to lower the rate of energy consumption because it is very insulating. Specifically, in building and construction field, RPUF is further applied to wall and roof insulation, in automotive parts, RPUF is used for seat, dashboard, insulation panels and so on. Also in packaging, RPUF is used due to its nature of providing cushioning to boast the fragile items in case of any transportation.

Regionally, it is evident that RPUF consumption is dominant in North America, Europe and, Asia-Pacific, but with future projections it will see sharp uptake in the developing regions due to enhanced infrastructure development. The need for products with less environmental impact and ones that can save energy is driving the growth of the RPUF market even further. While RPUF has the following advantages, it experiences the following difficulties as well; the cost of raw materials for making RPUF fluctuates, there are environmental issues on the chemicals that make up RPUF and on the regulation of its use, production and disposal.

Rigid Polyurethane Foam (RPUF) Market Outlook, 2023 and 2032: Future Outlook

Rigid Polyurethane Foam (RPUF) Market Trend Analysis

Trend: Adoption of Sustainable Manufacturing Practices

Another one of the major trends in the RPUF market is also the enhancement of the sustainable manufacturing processes. As awareness in the environmental pollution builds up, the use of environmentally sustainable and recyclable materials has expanded. Industry is also concentrating on lowering the emissions intensity and carrying out the supply chain changes on renewable or bio-materials. Such a move has been informed by increased regulatory measures and the customer demand for environmentally friendly products.

In response to these environmental needs, manufacturers are also seeking some alternative raw materials to isocyanates which are produced from fossil fuels. Currently they are focusing on trying to use plant based polyols and other bio based ingredients in the formulation of RPUFs that are more environmentally friendly. Further, there is increasing studies on how to make RPUF products more recyclable with the end-view of repurposing them in other ways at their disposal in order to support the circular economy concept.

Opportunity: Expansion in Emerging Markets

The future has more market sales potential for RPUF in the Asia-Pacific, Latin America, and African regions. These regions are rapidly growing industrially and with increasing urbanization there is much demand for insulation for building , energy efficient materials for construction, and automobile components. As infrastructure projects develop in developing countries and as the demand for energy increases, RPUF is utilized in residential, commercial and industrial sections of buildings to improve their efficiency.

Apart from the construction business, there is industry growth in automotive and packaging industries across these areas. With growing disposable income and enhanced manufacturing production there has been a higher demand for insulation material as well as packaging material. Producers in the emergent countries are also using RPUF to conform to the universal standards of energy saving and heat resistance, which enhance the utilization rate of RPUF in these regions additionally.

Driver: Energy Efficiency Demand

The RPUF is used for constructing energy efficient buildings and also in the transport sector, which is driving the market. RPUF’s superior thermal insulating capability and saving a lot energy in building and vehicles and hence has gained widespread importance as energy saving material. The governments and other regulatory authorities across the world are putting high standards of energy efficient building and that has resulted into high demands in the RPUF in insulation.

RPUF commonly applies to the construction of walls, roofs and floors to minimize heat transfer and strengthen energy saving in the construction line. Automotive industry it find application in light weight, thermal insulation of vehicles. This is inclusive of the energy consumed in residential area majorly felt in the months of winter, homes and vehicles that are being demanded by the consumers for better energy efficiency policies that are equally pushing for the better growth of RPUF in competitive industries.

Restraints: Fluctuating Raw Material Prices

One of the significant factor that check the growth of RPUF market is the volatility of prices of raw material such as polyols and isocyanates, which main raw material in RPUF manufacturing. These are materials that come out of the petrochemicals and their costs are frequently fluctuating with the costs of oil, scarcity of raw materials and political instability. Fluctuation in price also affects the cost of production of RPUF and thus the profits of the manufactures.

Another factor is that the cost of the raw materials used in its production process is unpredictable, which makes it difficult to achieve cost-effective production and determine appropriate price levels on its products. The increase in the cost of its raw material means that manufacturers may be forced to increase the price of RPUF to achieve their targeted profits, meaning that it will be expensive than other types of insulation compounds. This constraint can slow down the market growth, mainly in areas where cost is a main driver when choosing a material.

Rigid Polyurethane Foam (RPUF) Market Segment Analysis

Rigid Polyurethane Foam (RPUF) Market Segmented on the basis of type, application and end user.

By Type

o Conventional RPUF

o High-Density RPUF

o Spray RPUF

By Application

o Building & Construction

o Appliances

o Automotive

o Packaging

o Industrial Insulation

o Other Applications

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Conventional RPUF segment is expected to dominate the market during the forecast period

RPUF is categorized into three main types: As for the general types of RPUF, there are; the conventional RPUF type, the high-density RPUF type and the spray RPUF type. Conventional RPUF is easily the most commonly specified RPUF type because the products are relatively cheap and the uses for RPUF are virtually limitless – from insulation to packaging. It has good thermal resistance to shock and is widely used in construction and refrigerator industries. High-Density RPUF is more compressed RPUF developed for areas requiring extra rigidity including vehicle and industrial insulation. It is especially ideal in more straining conditions as it has a much better load issue capability.

Spray RPUF is more popular now and that is because of its feature that allows to create a material that also insulates perfectly. It is applied in scenarios where accuracy is important as well as applications where the insulation has to be of complex shapes. It can therefore be sprayed on rough surfaces common in roofing systems and to also insulate walls and roof filling cavities. The factors fueling the expansion of the spray RPUF segment include the continuously growing need for high-quality and easy to apply insulating materials especially in building and construction where energy efficiently buildings are emphasis.

By Application, Building & Construction segment expected to held the largest share

RPUF is widely used in a number of industries although very unpopular in some industries it’s most demanded in the building and construction industries and industries that deal with appliances, automobiles, packaging and industries that deal with insulation. In the building construction, RPUF is applied for thermal insulation of walls, roofs and floors. It has relatively high thermal conductivity, can save energy for heating and cooling structures or houses. In the automotive segment, RPUF being lightweight, is employed for manufacturing of seats, dashboards, and insulation panels that can ultimately lower the vehicle weight and optimise the fuel consumption.

RPUF is applied in the packaging industry for protective packaging of delicate goods because it provides good cushioning and shields goods from transport impacts. In the appliances sector it is used in refrigerators freezers and water heaters to enhance efficiency and performance. Versatility, Fire protection, Energy efficiency, Durability of the insulated pipes, tanks and other machineries make the industrial insulation segment advantageous for RPUF. All of these applications are powered by the need for energy density and performance in new construction, automobiles, and packaging materials.

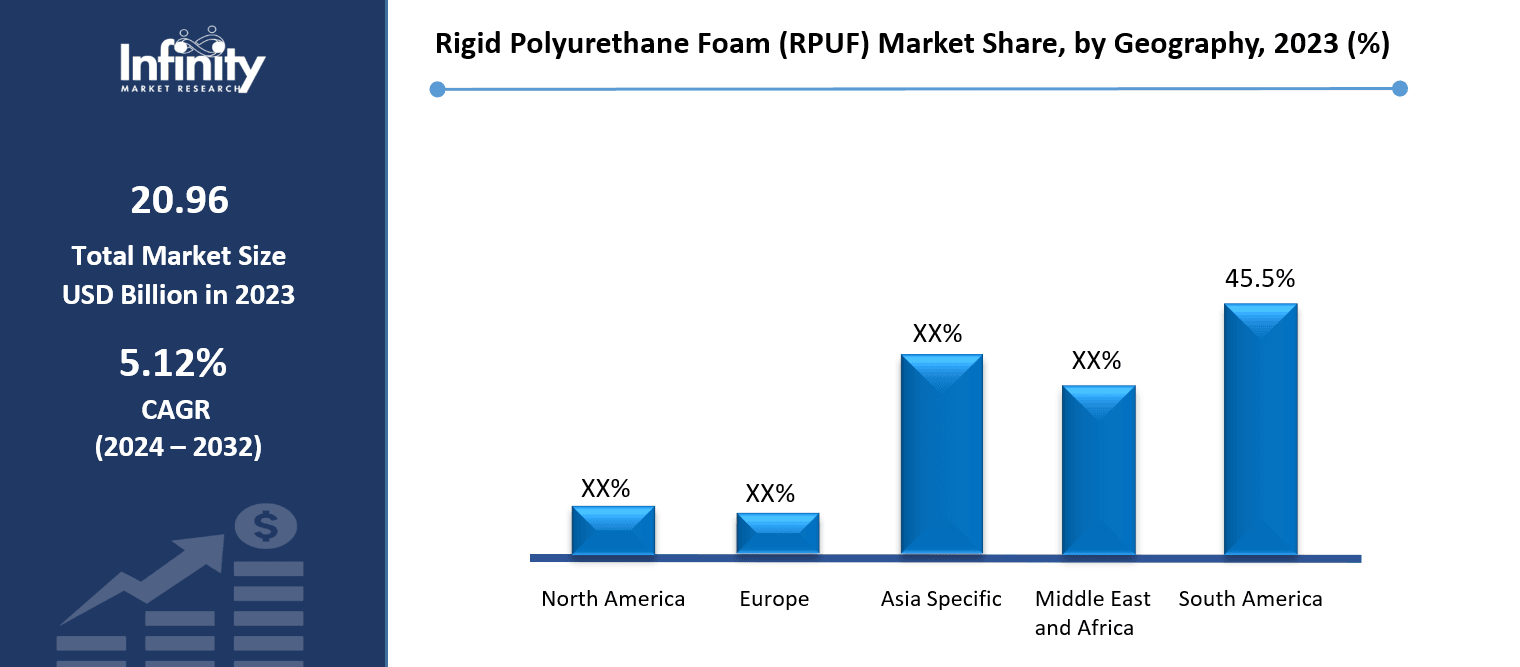

Rigid Polyurethane Foam (RPUF) Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

North America is projected to be the largest RPUF market due to the higher construction regulations, high energy consciousness, and the place of numerous leading manufacturers in the region. The energy conservation regulation in the United States and Canada has restricted the use of thermal insulation material such as RPUF. Moreover, pressure in the region towards sustainable environments as well as advances in green building codes also aids the need for insulation materials that will facilitate energy efficiency.

Automotive is one of the biggest end user markets for RPUF in North America, as both Original Equipment Manufacturers (OEMs) and aftermarket manufacturers use RPUF in vehicle assembly to shave off weight and enhance heat control. Additionally, higher installed base in North America along with rising investment made on energy efficient construction creates additional demand for RPUF. This dominance is expected to continue given the region’s focus to improve energy efficiency especially in both residential and commercial buildings.

Rigid Polyurethane Foam (RPUF) Market Share, by Geography, 2023 (%)

Active Key Players in the Rigid Polyurethane Foam (RPUF) Market

o BASF (Germany)

o Dow Chemical Company (USA)

o Huntsman Corporation (USA)

o Covestro AG (Germany)

o Bayer MaterialScience (Germany)

o Johns Manville (USA)

o Saint-Gobain (France)

o Lapolla Industries (USA)

o Isotherm (South Africa)

o Flexfoam (USA)

o Armacell (Germany)

o NCFI Polyurethanes (USA)

o Other key Players

Global Rigid Polyurethane Foam (RPUF) Market Scope

|

Global Rigid Polyurethane Foam (RPUF) Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 20.96 Billion |

|

Forecast Period 2024-32 CAGR: |

5.12% |

Market Size in 2032: |

USD 32.85 Billion |

|

Segments Covered: |

By Type |

· High-Density RPUF · Spray RPUF | |

|

By Application |

· Appliances · Automotive · Packaging · Industrial Insulation · Other Applications | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Energy Efficiency Demand | ||

|

Key Market Restraints: |

· Fluctuating Raw Material Prices | ||

|

Key Opportunities: |

· Expansion in Emerging Markets | ||

|

Companies Covered in the report: |

· BASF (Germany), Dow Chemical Company (USA), Huntsman Corporation (USA), Covestro AG (Germany), Bayer MaterialScience (Germany), Johns Manville (USA), Saint-Gobain (France), Lapolla Industries (USA), Isotherm (South Africa), Flexfoam (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Rigid Polyurethane Foam (RPUF) Market research report?

Answer: The forecast period in the Rigid Polyurethane Foam (RPUF) Market research report is 2024-2032.

2. Who are the key players in the Rigid Polyurethane Foam (RPUF) Market?

Answer: BASF (Germany), Dow Chemical Company (USA), Huntsman Corporation (USA), Covestro AG (Germany), Bayer MaterialScience (Germany), Johns Manville (USA), Saint-Gobain (France), Lapolla Industries (USA), Isotherm (South Africa), Flexfoam (USA) and Other Major Players.

3. What are the segments of the Rigid Polyurethane Foam (RPUF) Market?

Answer: The Rigid Polyurethane Foam (RPUF) Market is segmented into Type, Application, End User and region. By Type, the market is categorized into Conventional RPUF, High-Density RPUF, Spray RPUF. By Application, the market is categorized into Building & Construction, Appliances, Automotive, Packaging, Industrial Insulation, Other Applications. By End-Use Industry, the market is categorized into Construction Industry, Transportation Industry, Packaging Industry, Electronics Industry, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Rigid Polyurethane Foam (RPUF) Market?

Answer: RPUF stands for Rigid Polyurethane Foam which is a kind of rigid closed cell foam that is more made by allowing polyols reacting with isocyanates to yield a tough, light, thermal insulating material. It is widely adopted in different industries for a variety of reasons which include the aforementioned properties: thermal conductivity resistance, sound resistance and structural strength. Today, RPUF finds its use in various forms including on walls , in auto components, packaging material etc.

5. How big is the Rigid Polyurethane Foam (RPUF) Market?

Answer: Rigid Polyurethane Foam (RPUF) Market Size Was Valued at USD 20.96 Billion in 2023, and is Projected to Reach USD 32.85 Billion by 2032, Growing at a CAGR of 5.12% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.