🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Silicon-Manganese Alloy Market

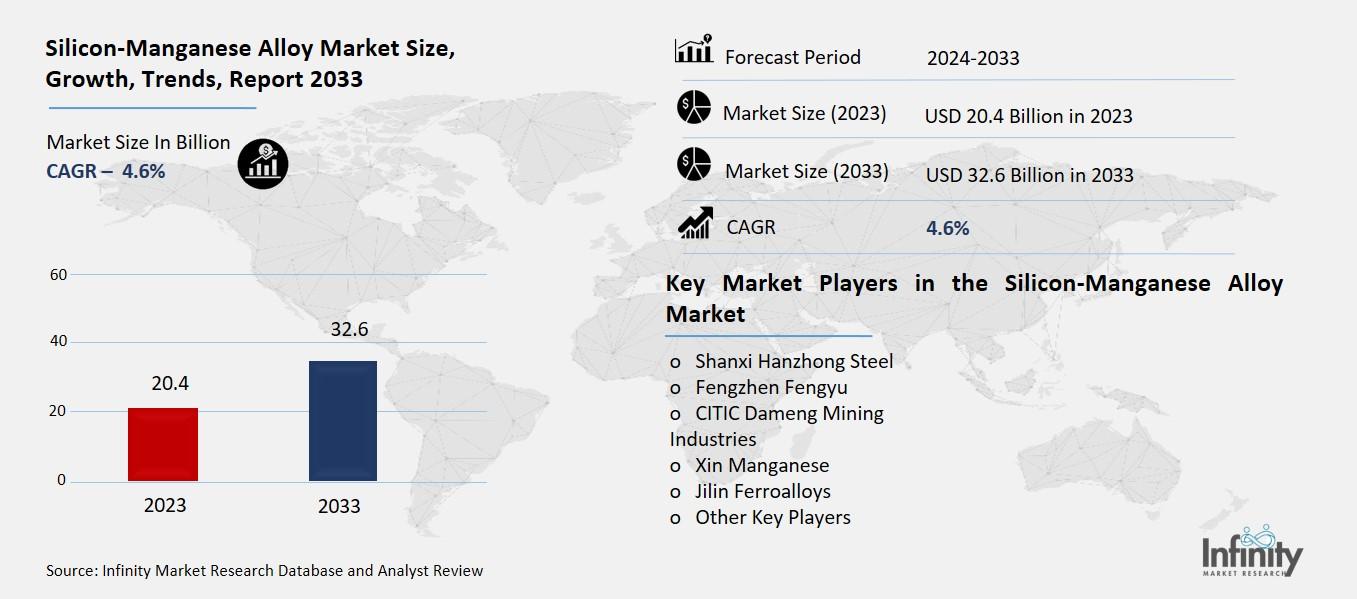

Global Silicon-Manganese Alloy Market (By Type, Mn Content min. 65% and Mn Content below 65%; By Application, Steel Production and Low-carbon Ferromanganese; By Region and Companies), 2024-2033

Dec 2024

Chemicals and Materials

Pages: 138

ID: IMR1340

Silicon-Manganese Alloy Market Overview

Global Silicon-Manganese Alloy Market acquired the significant revenue of 20.4 Billion in 2023 and expected to be worth around USD 32.6 Billion by 2033 with the CAGR of 4.6% during the forecast period of 2024 to 2033. The silicon manganese alloy market is one of the key markets in the global alloy market, due to need for steel and other metals in the construction, automobile, and manufacturing industries. Silicon-manganese alloy contains silicon, manganese and iron is mainly applied in steel making to improve its mechanical properties like strength, and resisting oxidation and corrosion.

There is increasing industrialization and urbanization in many emerging economies such as china and India and the production of steel has increase and so has the demand for silicon manganese alloys. Also, as a material, it finds applications for use in other materials ongoing through the alloying process such as aluminum and castings; this fact fuels the expansion of the market. Increased global consumption of high performance steel and global efforts to improve production methods that are more sustainable including the use of ferroalloys are also driving this market.

Drivers for the Silicon-Manganese Alloy Market

Growing Industrialization in Emerging Economies

Burgeoning economies coupled with growing industrialization in developing countries like China, India, and in Southeast Asia have boosted the demand for silicon-manganese alloy. These regions are already showing an unprecedented urbanization process and development of infrastructure; they have increased significantly the metal consumption especially steel. The steel industry is a crucial sector in construction, manufacturing, and transportation industries, significant improvements in quality and performance of the steel depend on the use of alloys such as silicon manganese.

Specifically, the growth of automotive, and heavy machinery, and infrastructure industries in the emerging economy has created the demand for high strength and durability that increases the consumption of silicon manganese alloys. Further, the application of these countries involves silicon-manganese in steel production to enhance the protective features of steel such as oxidation and corrosion resistance and the ability to resist wear, as is required in the increasing market for superior metal products.

Restraints for the Silicon-Manganese Alloy Market

Competition from Alternative Alloys

The availability and use of alternative alloys, such as ferrochrome and ferrosilicon, pose a significant challenge to the demand for silicon-manganese alloys. These alternatives are often considered more cost-effective or efficient in certain applications, making them attractive options for manufacturers. Ferrochrome, for example, is primarily used in the production of stainless steel and offers high corrosion resistance, which makes it a preferred choice in industries where such properties are critical. Similarly, ferrosilicon, which is produced by combining iron with silicon, is often used in steelmaking and in the production of cast iron, offering better performance in some contexts and being potentially cheaper to produce compared to silicon-manganese alloys.

Opportunity in the Silicon-Manganese Alloy Market

Increasing Demand for High-Performance Alloys

The shift towards advanced materials in the automotive and aerospace industries presents significant opportunities for the silicon-manganese alloy market, as these sectors increasingly demand high-performance, durable materials. In the automotive industry, there is a growing emphasis on lightweight, fuel-efficient, and high-strength materials to improve vehicle performance and meet regulatory standards for emissions and safety. Silicon-manganese alloys, known for their excellent strength-to-weight ratio and resistance to wear and corrosion, are ideal for these applications. They are used in the production of high-strength steels that can withstand harsh conditions, enhancing the durability and safety of automotive components such as structural parts, engine blocks, and chassis.

Trends for the Silicon-Manganese Alloy Market

Focus on Low-Carbon Steel Production

As the steel industry transitions to low-carbon technologies in response to environmental concerns and stringent regulations on carbon emissions, the demand for alloys like silicon-manganese is steadily rising. Traditional steel production methods, which rely heavily on coke and other carbon-intensive materials, are being gradually replaced by more sustainable technologies, such as electric arc furnaces (EAF) and hydrogen-based reduction processes. These low-carbon methods focus on reducing the carbon footprint of steel production while maintaining or improving the quality and performance of the steel.

Silicon-manganese alloys play a critical role in this transition as they are integral to modern steelmaking processes. The combination of silicon and manganese helps improve the strength, durability, and corrosion resistance of steel, allowing manufacturers to meet the high standards required by industries like automotive, construction, and infrastructure.

Segments Covered in the Report

By Type

o Mn Content min. 65%

o Mn Content below 65%

By Application

o Steel Production

o Low-carbon Ferromanganese

Segment Analysis

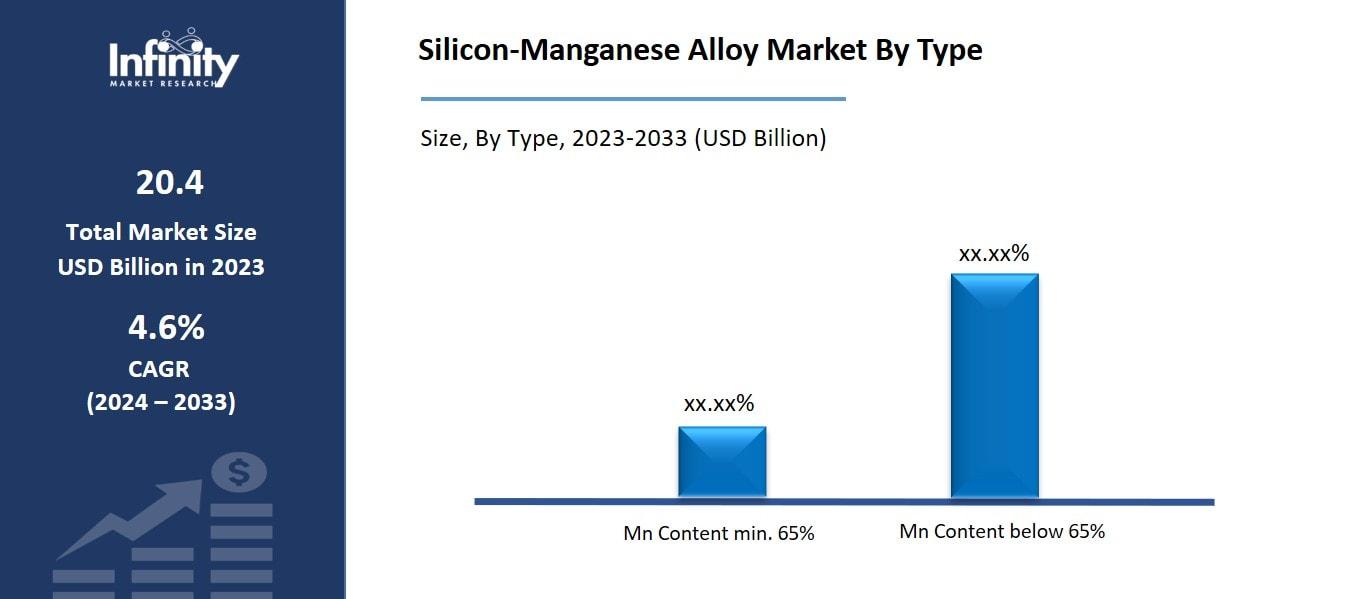

By Type Analysis

On the basis of type, the market is divided into Mn content min. 65% and Mn content below 65%. Among these, manganese content below 65% segment acquired the significant share in the market due to its widespread use in steel production, where it serves as a deoxidizer and alloying agent, enhancing the strength, toughness, and wear resistance of steel. Alloys with lower manganese content are often preferred in applications where precise control over the steel's chemical composition is crucial, as they allow for more flexibility in adjusting the final product's properties.

Additionally, these alloys are commonly used in the production of low-carbon ferromanganese, which is essential for producing high-quality steel grades. The versatility and cost-effectiveness of silicon-manganese alloys with manganese content below 65% have contributed to their dominant position in the market.

By Application Analysis

On the basis of application, the market is divided into steel production and low-carbon ferromanganese. Among these, steel production segment held the prominent share of the market owing to the critical role of silicon-manganese alloys in enhancing the properties of steel. Silicon-manganese is widely used in steelmaking as it improves the strength, durability, and resistance to oxidation and corrosion of steel. As one of the key components in the production of high-quality steel, it helps in the deoxidation of molten steel and enhances the overall performance of the steel, making it suitable for a wide range of industries, including automotive, construction, and manufacturing.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 31.1% of the market, driven by rapid industrialization and urbanization in countries like China and India. These nations are major consumers of steel, which is essential for infrastructure development, manufacturing, and construction. The demand for high-quality steel in these regions has significantly increased the consumption of silicon-manganese alloys, as they enhance the strength, durability, and corrosion resistance of steel.

Additionally, the presence of large steel manufacturing facilities and the adoption of advanced steel production technologies in Asia-Pacific further contribute to the region's leading position in the market. This trend is expected to continue, with Asia-Pacific maintaining its dominance in the global silicon-manganese alloy market.

Competitive Analysis

The competitive landscape of the silicon-manganese alloy market is characterized by a mix of established global players and regional suppliers, all vying for market share through strategic pricing, product differentiation, and technological advancements. Key players in the market include major alloy producers from Asia-Pacific, particularly China and India, where the demand for silicon-manganese is driven by robust steel production industries. These companies often leverage economies of scale and advanced manufacturing capabilities to maintain cost-effectiveness while meeting the growing demand for high-quality alloys.

Key Market Players in the Silicon-Manganese Alloy Market

o Shanxi Hanzhong Steel

o Fengzhen Fengyu

o CITIC Dameng Mining Industries

o Xin Manganese

o Jilin Ferroalloys

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 20.4 Billion |

|

Market Size 2033 |

USD 32.6 Billion |

|

Compound Annual Growth Rate (CAGR) |

4.6% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Billion) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

Shanxi Hanzhong Steel, Fengzhen Fengyu, CITIC Dameng Mining Industries, Xin Manganese, Jilin Ferroalloys, and Other Key Players. |

|

Key Market Opportunities |

Increasing Demand for High-Performance Alloys |

|

Key Market Dynamics |

Growing Industrialization in Emerging Economies |

📘 Frequently Asked Questions

1. Who are the key players in the Silicon-Manganese Alloy Market?

Answer: Shanxi Hanzhong Steel, Fengzhen Fengyu, CITIC Dameng Mining Industries, Xin Manganese, Jilin Ferroalloys, and Other Key Players.

2. How much is the Silicon-Manganese Alloy Market in 2023?

Answer: The Silicon-Manganese Alloy Market size was valued at USD 20.4 Billion in 2023.

3. What would be the forecast period in the Silicon-Manganese Alloy Market?

Answer: The forecast period in the Silicon-Manganese Alloy Market report is 2024-2033.

4. What is the growth rate of the Silicon-Manganese Alloy Market?

Answer: Silicon-Manganese Alloy Market is growing at a CAGR of 4.6% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.