🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Solar Cell Metal Paste Market

Solar Cell Metal Paste Market Global Industry Analysis and Forecast (2024-2032) By Type(Silver Paste, Aluminium Paste, Other Metal Pastes),By Application( Crystalline Silicon Solar Cells, Thin-Film Solar Cells, Other Solar Cells),By End-User Industry( Residential, Commercial, Industrial) and Region

Jan 2025

Energy and Power

Pages: 138

ID: IMR1651

Solar Cell Metal Paste Market Synopsis

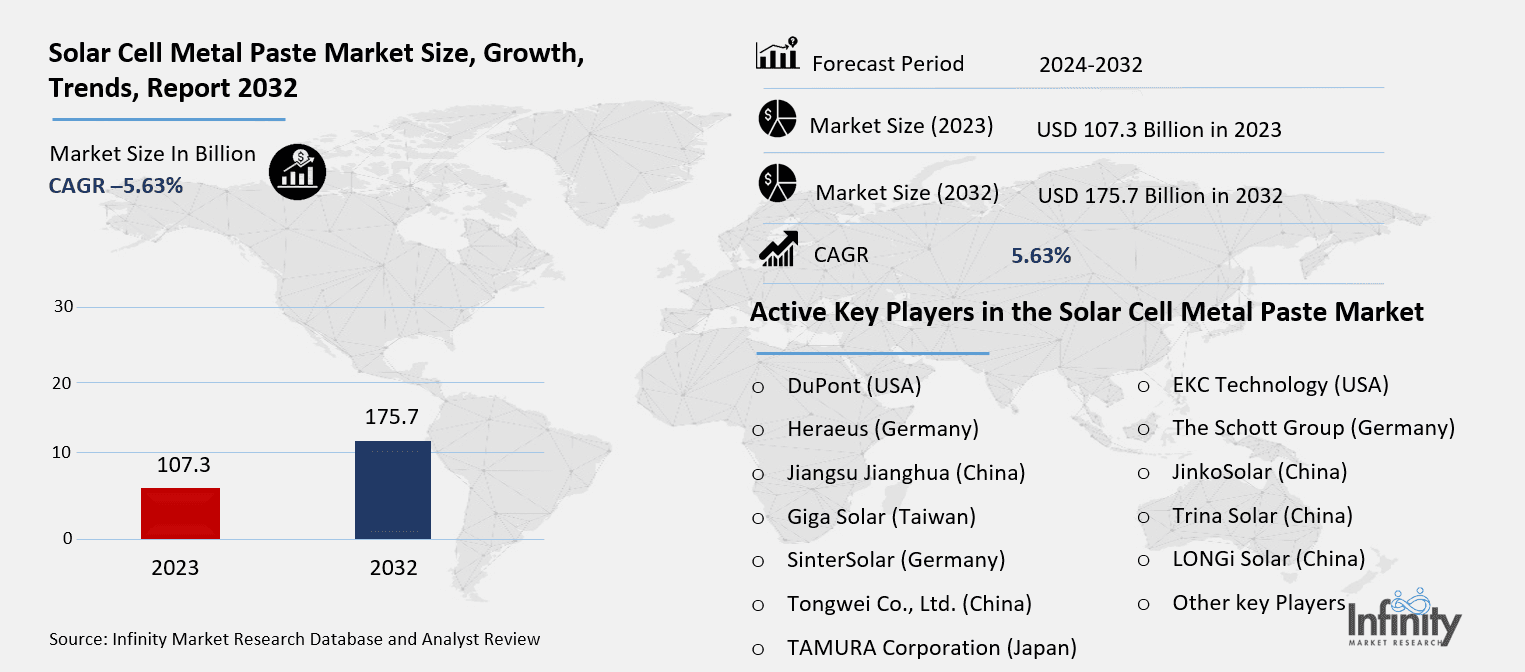

Solar Cell Metal Paste Market Size Was Valued at USD 107.3 Billion in 2023, and is Projected to Reach USD 175.7 Billion by 2032, Growing at a CAGR of 5.63% From 2024-2032.

Solar Cell Metal Paste means the metal paste materials especially designed for preparing solar cell for photovoltaic (PV) systems. These metal pastes normally include silver or aluminum or any other substances, and their primary function is to develop electrical connections and brighten the cell surface to make better solar power conversion. Some metal pastes are printed on the cells in order to form electrodes through which the current can flow.

The Solar Cell Metal Paste market has experience elevated growth rates due to the increasingly demand for solar energy in the world as the effective substitution of the traditional sources of energy – the fossil fuels. Solar cells are one of the most essential products of the new energy industry, which is based on transforming solar energy into electricity, and the acceleration of development of metal pastes for producing these cells is directly related to this tendency. Solar cell metal pastes are applied to both crystalline silicon solar cells and thin-film solar cell production, ensuring high conductivity and reliable adhesion properties for energy conversion and for the lifetime of solar panels.

These market dynamics are owed to the following factors Most countries are incorporating renewable energy into their power generation mix due to the ever-pressing global war on climate change. Furthermore, new generations of solar cells – bifacial solar cells and the tandem cells are also driving the need for better metal pastes capable of delivering the increased efficiency and performance requirements that these advancement in solar cell technology are calling for.

Emerging demand for solar power is also driven by several initiatives being undertaken around the world to contain greenhouse emissions and improve energy security. Governments are making policies that aim at increasing the uptake of renewable energy sources and as solar energy gains recognition as a clean energy source, solar cell metal pastes will be in demand once again. Technological advancement and consequent increase in the scale as well as number of solar projects including residential rooftops has encouraged market growth of metal pastes utilized in the production of solar cells.

Nevertheless, the market has challenges in the areas of direct materials’ raw material, fluctuating prices of these materials, and incidents such as disruption of supply which may affect the costs of making high quality of metal pastes. Also, manufacturers are always challenged to produce products that can be efficient and less expensive in order to cope up with other manufacturers and to adequately respond to the continuously rising demand for solar energy.

Solar Cell Metal Paste Market Outlook, 2023 and 2032: Future Outlook

Solar Cell Metal Paste Market Trend Analysis

Trend: Increasing Efficiency in Solar Cells

The factor that has thought to boost the growth of the Solar Cell Metal Paste market is the pressure of making solar cells more efficient for more usage. As the technology of solar advancements increases there has been the constant strive to get better solar cells with improved energy conversion efficiencies which in turn influences the properties of the metal pastes used in fabrication of such solar cells. Technologies like PERC, bifacial, and tandem structures require higher and efficient metal pastes so they can address these new cell technologies.

As a result, global consumption of silver pastes used in power electronics has risen dramatically, particularly for their well-known performance characteristics such as conductivity and stability. Manufacturers are also seeking for substitutes of silver mainly on the arguments of high cost of silver and the increasing concern of price merket on manufactuerers. As more efficient CSPV solar cells are required, further changes in the metal paste industry can be anticipated and more paste recipes are likely to be developed to support the requirements of next generation CSPV solar technologies

One of the on emerging growths in the Solar Cell Metal Paste market, therefore, is the tendency to lower its costs through formulating metal paste with materials other than silver, which is at present material dominants in solar cell paste formulation. ClipboardResearch shows that silver paste has excellent electrical conductivity, but since it is very expensive, there has been research for cheaper materials, such as copper. The change to copper based encapsulant or other low cost material may greatly reduce the cost of solar cell manufacturing, therefore making the solar energy cheaper and accessible to many.

Technological progress in the solar energy industry also provides a basis for the creation of new metal pastes. Unprecedented research on new high conductivity materials which serve the same or even better purpose as silver at a cheaper price is still being conducted. As for this opportunity, it holds a wide potential for growth of the market; on one hand, it will decrease production costs, and on the other hand, it will decrease the price for solar energy systems, thus stimulating wider usage of solar power all over the world.

Drivers: Growing Demand for Solar Energy

The Solar Cell Metal Paste is one of the budding markets in the world due to climate change consciousness and going green for power sources. Due to the presence of state programmes in the sphere of renewable resources and the GL with the requirement of lowering greenhouse gases, the demand for solar power has risen and this straight impacts the need of solar cells and therefore metal pastes needed for the creation of the last.

Generally there is understanding of impact of fossil fuel on the environment and new technology in production of solar panels has ensured that solar energy product is cheaper to install in both residential and commercial places. Bolstering the forecast by such defendable assumptions, the augmenting amount of installation of the solar power plants and the use of solar energy by growing number of countries evidently means higher demand for high quality solar cell metal paste products. This demand should be driven by the shift of the world towards renewable generation and by inclusion of the solar generation as one of the mainstream supplier.

Restraints: Supply Chain Challenges

Another limitation faced in Solar Cell Metal Paste market is supply chain risks of critical materials within value chains. The chief raw materials in the preparation of metal pastes including silver and aluminum it is vulnerable to periodically market forces and geopolitical events, fluctuating prices. High purity silver used in solar cells is scarce and is highly unpredictable which bears the risk of making manufacturing costs high and therefore making solar energy systems expensive.

Moreover, the solar cell manufacturing industry is global particularly for metal pastes, and this implies that changes in supply chain regimes by way of for instance trade policies, natural calamities or pandemics may potentially disrupt the supply of the metal pastes. All these challenges mean that manufacturers must endeavour to source raw materials with more robustness and less reliance on just one source, and the search for materials that will ensure that these risks do not occur is now a paramount consideration for manufacturers.

Solar Cell Metal Paste Market Segment Analysis

Solar Cell Metal Paste Market Segmented on the basis of type, application and end user.

By Type

o Silver Paste

o Aluminium Paste

o Other Metal Pastes

By Application

o Crystalline Silicon Solar Cells

o Thin-Film Solar Cells

o Other Solar Cells

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Type, Silver Paste segment is expected to dominate the market during the forecast period

The Solar Cell Metal Paste Market by type is classified into Silver paste, Aluminum paste, and other Metal paste. Of these, silver paste has found the greatest uses due its good conductivity and ability to perform well in solar cell sector. Silver paste is mainly applied in producing crystalline silicon solar cells, and it can be concluded that the utilization of this solar cell type occupies the largest share in the global market. This silicon based product provides high conductivity of electrons and is very suitable for use in high performance silicon solar cells.

Nevertheless, aluminum paste is also a critically important component of the market, especially the back-surface metamorphism of solar cell. While independently the metallic aluminum and silver pastes are expensive, their combined application with aluminum paste result in considerable reduction of cost with improved functional efficiency of the solar cell. The aluminum and silver pastes are gradually being replaced with copper and other other metals and alloys to fit the requirements of affordable and environmentally friendly products.

By Application, Crystalline Silicon Solar Cells segment expected to held the largest share

The Solar Cell Metal Paste market is primarily divided into three application segments: They include crystalline silicon solar cells, thin-film solar cells and other classification of solar cells. The crystalline silicon solar cells segment is the biggest one that gas the largest share in the market. These cells are applied widely because they are known to have high conversion efficiency and well-developed fabrication. Metal pastes in crystalline silicon cells have to act as efficient conductors and possess high, long-term stability.

Thin-film cells are even thinner and lighter than crystalline silicon cells; they also need special metal pastes. Compared with crystalline silicon cells, thin-film solar cells are less efficient, which is not offset by other benefits such as lower cost of production and portability. Since the requirement for higher efficient and lower expensive photovoltaic devices develops, for thin-film substrates the necessity for metal pastes will also increase.

Solar Cell Metal Paste Market Regional Insights

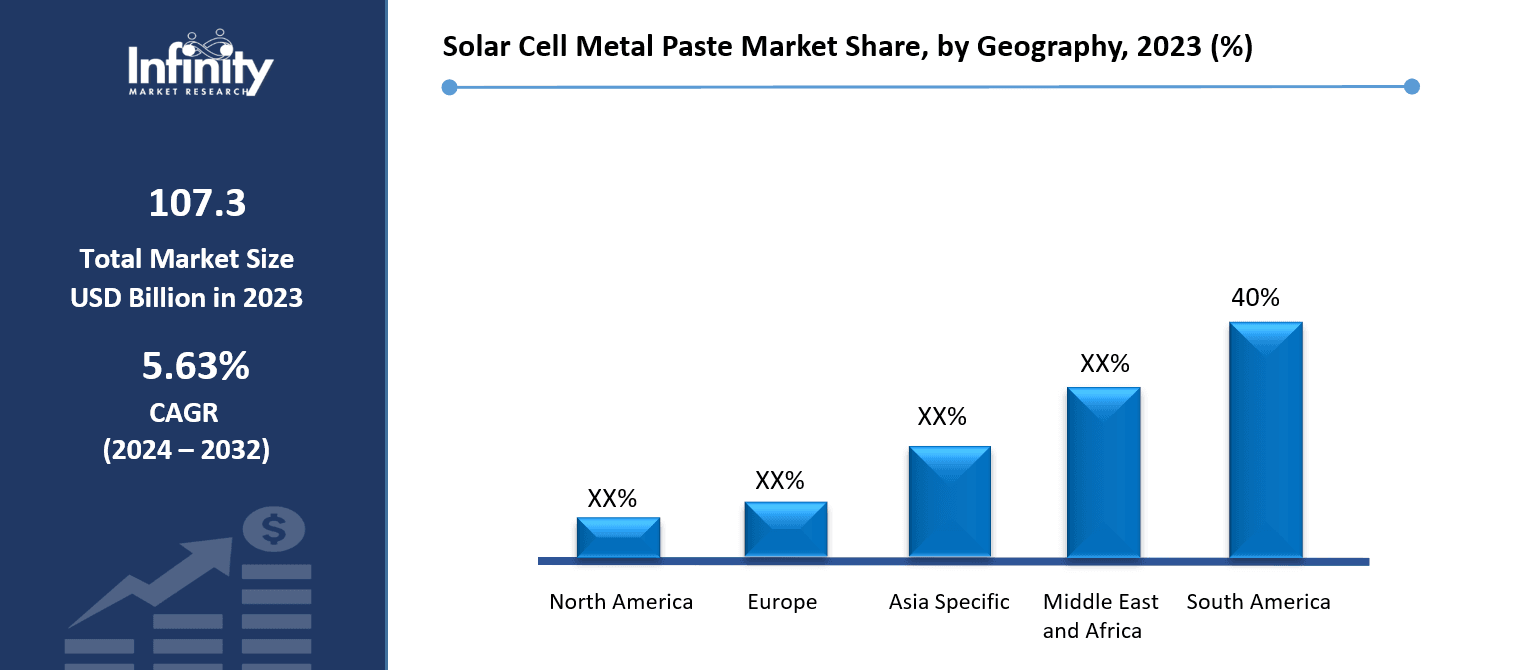

North America is Expected to Dominate the Market Over the Forecast period

Among the regions, North America is commanding the Solar Cell Metal Paste market, thanks to technological development, favourable government policies and inclinations toward solar energy in the United States and Canada. This region has of course witnessed increasing interest in deployment of solar power with many large scale utility solar farms projects and rooftop solar power installations resulting in escalated demand of Solar cells and metal paste used in the manufacture of the same. The U.S. and Canada have set quite aggressive renewable power targets, which will bode well for the solar business.

Besides this, North America is also well supported by players from the solar sector and several governmental policies and subsidies for mastering the usage of solar power. When the region remains much focused on much sustainability, clean energy and kept pushing for minimum green house emission the load for high performance solar cell metal pastes shall continue to be much demanded.

Solar Cell Metal Paste Market Share, by Geography, 2023 (%)

Active Key Players in the Solar Cell Metal Paste Market

o DuPont (USA)

o Heraeus (Germany)

o Jiangsu Jianghua (China)

o Giga Solar (Taiwan)

o SinterSolar (Germany)

o Tongwei Co., Ltd. (China)

o TAMURA Corporation (Japan)

o EKC Technology (USA)

o The Schott Group (Germany)

o JinkoSolar (China)

o Trina Solar (China)

o LONGi Solar (China)

o Other key Players

Global Solar Cell Metal Paste Market Scope

|

Global Solar Cell Metal Paste Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 107.3 Billion |

|

Forecast Period 2024-32 CAGR: |

5.63% |

Market Size in 2032: |

USD 175.7 Billion |

|

Segments Covered: |

By Type |

· Silver Paste · Aluminium Paste · Other Metal Pastes | |

|

By Application |

· Crystalline Silicon Solar Cells · Thin-Film Solar Cells · Other Solar Cells | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Growing Demand for Solar Energy | ||

|

Key Market Restraints: |

· Supply Chain Challenges | ||

|

Key Opportunities: |

· Cost Reduction through Alternative Materials | ||

|

Companies Covered in the report: |

· DuPont (USA), Heraeus (Germany), Jiangsu Jianghua (China), Giga Solar (Taiwan), SinterSolar (Germany), Tongwei Co., Ltd. (China), TAMURA Corporation (Japan), EKC Technology (USA) and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Solar Cell Metal Paste Market research report?

Answer: The forecast period in the Solar Cell Metal Paste Market research report is 2024-2032.

2. Who are the key players in the Solar Cell Metal Paste Market?

Answer: DuPont (USA), Heraeus (Germany), Jiangsu Jianghua (China), Giga Solar (Taiwan), SinterSolar (Germany), Tongwei Co., Ltd. (China), TAMURA Corporation (Japan), EKC Technology (USA) and Other Major Players.

3. What are the segments of the Solar Cell Metal Paste Market?

Answer: The Solar Cell Metal Paste Market is segmented into Type, Application, End User and region. By Type, the market is categorized into Silver Paste, Aluminium Paste, Other Metal Pastes. By Application, the market is categorized into Crystalline Silicon Solar Cells, Thin-Film Solar Cells, Other Solar Cells. By End-User Industry, the market is categorized into Residential, Commercial, Industrial. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Solar Cell Metal Paste Market?

Answer: Solar Cell Metal Paste means the metal paste materials especially designed for preparing solar cell for photovoltaic (PV) systems. These metal pastes normally include silver or aluminum or any other substances, and their primary function is to develop electrical connections and brighten the cell surface to make better solar power conversion. Some metal pastes are printed on the cells in order to form electrodes through which the current can flow.

5. How big is the Solar Cell Metal Paste Market?

Answer: Solar Cell Metal Paste Market Size Was Valued at USD 107.3 Billion in 2023, and is Projected to Reach USD 175.7 Billion by 2032, Growing at a CAGR of 5.63% From 2024-2032.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.