🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

Steel Seamless Pipes Market

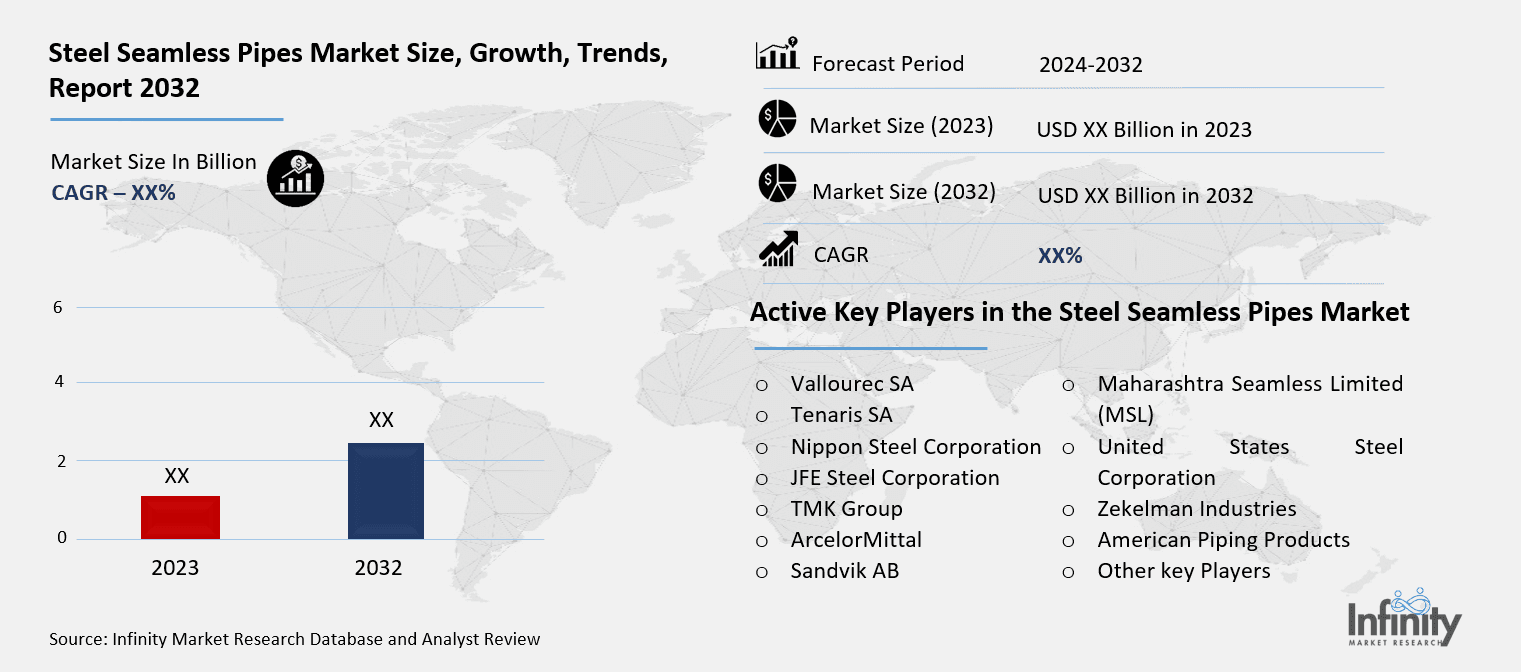

Steel Seamless Pipes Market Global Industry Analysis and Forecast (2024-2032) By Material (Carbon Steel, Alloy Steel, Stainless Steel, Others) By Manufacturing Process (Cold Drawn Seamless Pipes, Hot Rolled Seamless Pipes) By Diameter (Small Diameter Pipes, Large Diameter Pipes) By End-Use Industry (Oil & Gas, Automotive & Transportation, Power Generation, Chemical & Petrochemical, Construction & Infrastructure, Others) By Application (Pressure Applications, Structural Applications, Hydraulic Applications) and Region

Jan 2025

Chemicals and Materials

Pages: 138

ID: IMR1659

Steel Seamless Pipes Market Synopsis

Steel Seamless Pipes Market acquired the significant revenue of XX Billion in 2023 and expected to be worth around USD XX Billion by 2032 with the CAGR of XX% during the forecast period of 2024 to 2032.

The steel seamless pipes market will mean the business of manufacturing and marketing of seamless pipes produced from steel that are widely used in demand sectors such as construction, automobiles, oil and natural gas, and energies segments among others. Seamless pipes are produced without recourse to seams hence; they are stronger, enduring, and more reliable as compared to welded pipes. Such pipes are normally produced by, and through processes such as; extrusion, rotary piercing and elongation to produce a pipe that is seamless and of a homogenous wall thickness. The market rising due to enhanced need of seamless pipes in some averse industries involving high pressure and temperature along with enhanced global infrastructure demands and industrialization.

Currently, the growth rate of the global steel seamless pipes market is firm and the market is likely to grow due to the rising uses in the industries like oil and gas, automobile, construction, and energy. Steel seamless pipes that have fewer flaws and more strength than welded pipes are more suitable when pressure and high tensile temperature are of highest significance. The oil and gas industry particularly in the exploration and drilling of oil and natural gas cannot do without seamless pipes particularly in operation in regions such as offshore and shale. Growing energy demand all over the world and increasing investments in renewable energy necessitate further higher performance seamless pipes. The automotive also has a role in the contribution to market growth where seamless pipes are used for special applications such as fuel injection systems, exhaust systems and hydraulic cylinders. At the same time, these pipes play a significant role in constructing large scales structures with diversified segments of Infrastructure and high rise buildings sector as a result of urbanization and demanding applications for pipes that can bear earthquake or climatically related pressures in certain geographies.

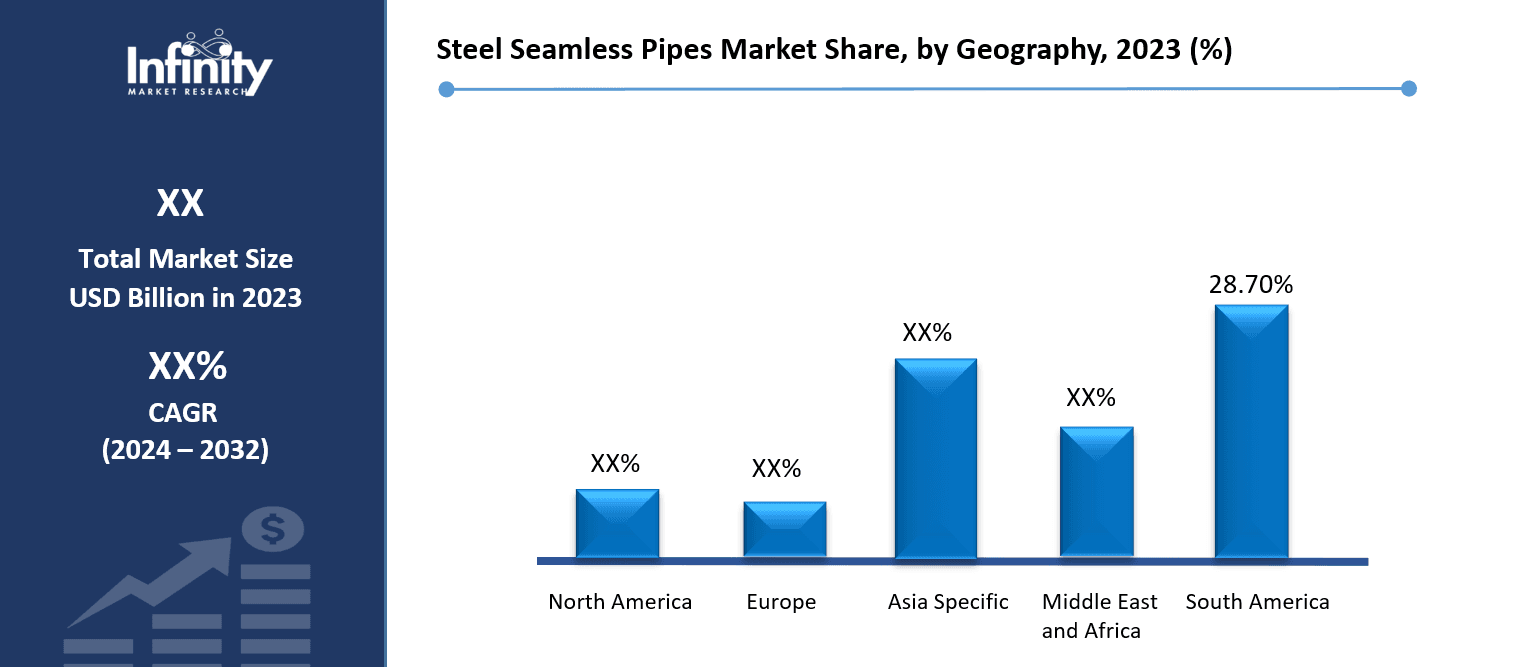

Regionally, Asia-Pacific is considered the market with the most potential because of the increased industrialization rate and tremendous investments across asia in infrastructure, development, and construction. The expanding oil and gas in the region have contributed to the region’s energy industry which in turn supports the growing automotive industry deeply enhancing the need for seamless pipes. North America is next, based on the improvement of energy facilities, such as pipelines and growth in the demand for natural gas. Europe is also a significant market because of its sustainable development and the employments of energy management and efficiency technologies for industrial processes. Of all these regions, Middle East and Africa indicate tremendous growth propelled by existing and new exploration projects in the oil and gas industry, while Latin American region has been recording gradual increase in their investments in structures and energy areas.

Research and development of latest technologies and techniques demarcate the steel seamless pipes market, where the concentration on the creation of stronger alloys and cheaper manufacturing processes to meet requisite market force developments and features is paramount. Nevertheless, the market has threats that include volatile price of raw materials, regulations on emission of poisonous gases and competition from other materials like composite ones. However, there are some challenges that have discouraged investors from investing in this market so much; these challenges include; But all these barriers cannot hold back the market as new opportunities of renewable projects like wind and solar farms are emerging while more exploration is being extended to other unexplored ventures like oil and gas. In addition, the incorporation of the concepts of hot and cold rolling technologies is most likely to enhance the product performance and enlarge market prospects in the years to come.

Steel Seamless Pipes Market Trend Analysis

Trend

Growing Demand for High-Performance Materials in the Steel Seamless Pipes Market

The market of steel seamless pipes is undergoing the transition to high-performance pipe material that is associated with increased durability, high carrying capacity and corrosion resistance. These properties qualify seamless pipes for use in conditions that other types of welded pipes could not adequately serve. Especially in the oil and gas industry reliable pipes called seamless pipes are essential particularly for offshore drilling and ultra-deep water operations as pipes for these applications have to withstand pressure and temperature levels that are unparalleled. This growing percentage is owed to the fact that seamless pipes offer remarkable mechanical characteristics that guarantee safe and effective operations within difficult environments. The oil & gas industry that consumes a significant percentage of seamless pipes will also continue to drive this demand as exploration & production moves deeper into offshore and remote regions.

Apart from the energy sector, the construction industry is applying pressure to increase demand for seamless steel pipes. Subsea structures such as bridges, tunnels and pipes call for long lasting pipes that can handle stress, corrosion and temperature variations. Mainly, seamless pipes are used for such applications since these pipes do not have welded seams that make them less reliable than seamless pipes which also means that they have longer life cycles. This demand of both oil and gas as well as construction industries is drifting the market demonstrating a rising trend for utilizing high-performance seamless steel pipes in projects, especially where quality and safety standards matter.

Drivers

Ideal for High-Pressure and Corrosive Environments

The market for steel seamless pipes is driven by continually rising rates of oil and gas exploration. Sleek steel pipes are major requirements in the conveying of oil and gas in pipelines since they have improved benefits as regards functionality and security. There is also high pressure and corrosion resistant, and as such they are suitable to some vital and highly challenging environments like deep water and offshore drilling. With global energy demand growing steadily, oil and gas industry remains the biggest consumer of these pipes more so in areas where resource exploration and production from more complex locations is becoming inevitable. As exploration of oil and natural gas resources have increased the need for laying down pipeline infrastructure for its extraction, this aspect has directly added up to the demand in the global seamless pipes market.

In addition, the need for seamless steel pipes for the oil and gas segment is carried further by prospects in technology of prospecting processes. The newer type of exploration and production scenarios like ultra-deep water construction calls for materials that are able to withstand the conditions while being employed. Seamless pipes due to their accurate calibre and robustness are capable of fulfilling these requirements but while at the same time promoting operational efficiency and safety. The enhanced extension of the global oil reserves to the difficult and extended areas would require the essential application of the seamless steel pipes for the reinforcement of the projects in question; therefore, the potential demand will be driven further.

Restraints

Specialized Technology and Equipment Requirements

This is however, one of the major factor that threaten the production of steel seamless pipes today – the high cost of production. Fabrication of seamless pipes demands sophisticated equipment and technology than welding pipes thereby making it more costly. It is essential for the pipes to achieve the desired standards of requisite strength and durability, and even accuracy of measurement. Another factor that is partly causing the high cost is the requirements of the highly crafted machineries and highly skilled labor needed to supervise the production. Consequently, operational expenses take a very high number, which puts manufacturers at a disadvantage especially when costs are a very sensitive major factor in markets

There is also the cost of technology, not forgetting that seamless pipes are made from high grade steel which is itself costly. Seamless pipes are Figure out by widespread supply and demand fluctuations, and any variations in the prices of steel can consequently impact the cost of producing seamless pipes. Such an increase in the raw material costs is usually absorbed by increase in product prices and can lower demand mostly in mature markets or countries and sensitive industries. This cost factor may reduce the sales volume or may prevent potential buyers to consider the product as better than the other pipe products, such as welded or fabricated pipes that can be more economical and thus hinders the market growth.

Opportunities

Growing Demand for High-Performance Materials in Deep-Water Drilling

The first major opportunity, therefore, of the steel seamless pipes market lies in the prospects of a steady increase in the need for high-quality and reliable pipes in the oil and gas market. An increase in deep water drilling, exploration and requirement of obtaining resources from high-risk areas has led to the increased pressures for products that can maintain put up with high pressure, corrosion and severe circumstances. Fossil-fuels processing entails demanding physical, chemical, and mechanical stresses by the pipeline materials, and the steel seamless pipes possess the right characteristics to meet these demands. Global demand for seamless pipes is expected to remain strong as upstream operations move to harsher environments, creating a significant market development potential.

Construction sector also supports the use of steel seamless pipes in addition to oil and gas industry it has been identified. The pipes are applied within the construction of bridges, tunnels, and skyscrapers because the foremost characteristic of these structures is the durability of the materials used. They include cement, concrete and asbestos and are occasioned by the growing rates of urbanization especially in the emergent markets to call for durable constructions material that fit safety and aesthetic needs. Large-scale high-performance applications for pipelines include the construction industry, where steel seamless pipes, through their ability to withstand environmental stress and last longer, present a precious market opportunity for reach into this growing industry.

Steel Seamless Pipes Market Segment Analysis

Steel Seamless Pipes Market Segmented on the basis of By Material, By Manufacturing Process, By Diameter, By End-Use Industry, By Application

By Material

o Carbon Steel

o Alloy Steel

o Stainless Steel

o Others

By Manufacturing Process

o Cold Drawn Seamless Pipes

o Hot Rolled Seamless Pipes

By End Use Industry

o Oil & Gas

o Automotive & Transportation

o Power Generation

o Chemical & Petrochemical

o Construction & Infrastructure

o Others

By Application

o Pressure Applications

o Structural Applications

o Hydraulic Applications

By Region

o North America (U.S., Canada, Mexico)

o Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

o Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

o Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC)

o Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

o South America (Brazil, Argentina, Rest of SA)

By Material, Carbon Steel segment is expected to dominate the market during the forecast period

Carbon steel pipes are one of the most used products today since they are is cheap, strong, and durable for use in many industries. They are used in applications where medium to high strength is needed or where high temperatures, as well as pressures, must be tolerated. This is because carbon steel widely used among the oil & gas, automotive and power generation industries where pipes are exposed to high conditions. Their capacity to endure high mechanical loads and resist corrosion besides their suitability for applications in atmospheres such as in off-shore drilling facilities or power stations also adds to their advantage in these sectors.

Other than being employed in stressful environments carbon steel pipes are also used in structural and hydraulic systems. They can thus operate under diverse environmental situations such as moving gases and liquids in the auto industry and being used as parts of structures in infrastructural projects. The strength, durability, and, comparatively, low cost make carbon steel pipes one of the most used and required types of pipes in industry, power supply, construction, and other fields where the key aspect is the materials’ performance.

By Application, Pressure Applications segment expected to held the largest share

Pipes utilized for pressure containing applications are designed to be used where internal and external pressures together with pressure varying from moderate to severe can be well experienced. These pipes are mostly made from metals compounds like alloy steel or stainless steel, making them strong, heat resistant and resistant to corrosive material. For use in such systems as transport of the fluid or gas at high pressure, then the above pipes should have the right quality and workmanship for the best experience of the whole system. The ex-amples of high-pressure piping systems include: pipelines in oil & gas industries where transport of crude oil and natural gas occurs under high pressure; steam lines in power plant industries where steam is transferred at high temperatures.

The other major application areas include oil & gas, power generation, chemical processing including other industries, where containment of pressure is paramount to avoid incidents or catastrophic failure. For example, in chemical plants pipes are exposed to corrosive fluids and they require high pressure containment for safety reasons. In addition to strict designs and testing, the type of materials used helps provide pressure pipes with the necessary safety requirements to maintain in extreme conditions common to industries using pipe systems.

Steel Seamless Pipes Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

In the North American region the steady demand for steel seamless pipes has been largely influenced by the oil and gas sector particularly in the U.S and Canada. Thus, the development of shale gas resources especially in the USA has directly boosted the requirements of smoother pipes for the transportation and drilling which requires these pipes. The move towards ultra deep water and harsh environments again has accentuated the requirement of high-quality seamless pipes as these are critically important for providing safety and efficient production and transportation of hydrocarbons, particularly through explorations of unconventional oil and gas fields. This has led to the gradual rising demand for these pipes, especially in areas with large deposit of shale resources.

Also, there are increasing trends seen in the recent years for infrastructure improvement activities in North America that has boosted the market for seamless pipes even more. Since there has been a strong focus of the companies in the pipeline construction, urbanization and industrialization, the seamless pipes find their application nearly in all types of construction projects and other sectors such as power, manufacturing, etc. Stake holders such as several Key pipe manufacturing companies and technological development in pipe manufacturing industry has facilitated the competitive position of the region in the global market. These developments together with government policy push for energy self-sufficiency and energy infrastructure upgrade have therefore placed North America on a firm foundation on the seamless pipes market.

Steel Seamless Pipes Market Share, by Geography, 2023 (%)

Active Key Players in the Steel Seamless Pipes Market

o Vallourec SA

o Tenaris SA

o Nippon Steel Corporation

o JFE Steel Corporation

o TMK Group

o ArcelorMittal

o Sandvik AB

o Maharashtra Seamless Limited (MSL)

o United States Steel Corporation

o Zekelman Industries

o American Piping Products

o Other key Players

Global Steel Seamless Pipes Market Scope

|

Global Steel Seamless Pipes Market | |||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD XX Billion |

|

Forecast Period 2024-32 CAGR: |

XX% |

Market Size in 2032: |

USD XX Billion |

|

|

By Material |

· Carbon Steel · Alloy Steel · Stainless Steel · Others | |

|

By Manufacturing Process |

· Cold Drawn Seamless Pipes · Hot Rolled Seamless Pipes | ||

|

By Diameter |

· Small Diameter Pipes · Large Diameter Pipes | ||

|

By End-Use Industry |

· Oil & Gas · Automotive & Transportation · Power Generation · Chemical & Petrochemical · Construction & Infrastructure · Others | ||

|

By Application |

· Pressure Applications · Structural Applications · Hydraulic Applications | ||

|

By Region |

· North America (U.S., Canada, Mexico) · Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe) · Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe) · Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC) · Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa) · South America (Brazil, Argentina, Rest of SA) | ||

|

Key Market Drivers: |

· Ideal for High-Pressure and Corrosive Environments | ||

|

Key Market Restraints: |

· Specialized Technology and Equipment Requirements | ||

|

Key Opportunities: |

· Growing Demand for High-Performance Materials in Deep-Water Drilling | ||

|

Companies Covered in the report: |

· Vallourec SA, Tenaris SA, Nippon Steel Corporation, JFE Steel Corporation, TMK Group, ArcelorMittal, Sandvik AB, Maharashtra Seamless Limited (MSL), United States Steel Corporation, Zekelman Industries, American Piping Products and Other Major Players. | ||

📘 Frequently Asked Questions

1. What would be the forecast period in the Steel Seamless Pipes Market research report?

Answer: The forecast period in the Market research report is 2024-2032.

2. Who are the key players in the Steel Seamless Pipes Market?

Answer: Vallourec SA, Tenaris SA, Nippon Steel Corporation, JFE Steel Corporation, TMK Group, ArcelorMittal, Sandvik AB, Maharashtra Seamless Limited (MSL), United States Steel Corporation, Zekelman Industries, American Piping Products and Other Major Players.

3. What are the segments of the Steel Seamless Pipes Market?

Answer: The Steel Seamless Pipes Market is segmented into By Material, By Manufacturing Process, By Diameter, By End-Use Industry, By Application and region. By Material, the market is categorized into Carbon Steel, Alloy Steel, Stainless Steel, Others by Manufacturing Process, the market is categorized into Cold Drawn Seamless Pipes, Hot Rolled Seamless Pipes. By Diameter, the market is categorized into Small Diameter Pipes, Large Diameter Pipes. By End-Use Industry, the market is categorized into Oil & Gas, Automotive & Transportation, Power Generation, Chemical & Petrochemical, Construction & Infrastructure, Others. By Application, the market is categorized into Pressure Applications, Structural Applications, Hydraulic Applications. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

4. What is the Steel Seamless Pipes Market?

Answer: The steel seamless pipes market refers to the industry involved in the production and distribution of seamless pipes made from steel, which are used in a wide range of applications including construction, automotive, oil and gas, and energy industries. Unlike welded pipes, seamless pipes are formed without welding seams, offering superior strength, durability, and reliability. These pipes are typically manufactured through processes such as extrusion or rotary piercing and elongation, which create a continuous pipe with uniform thickness. The market is driven by increasing demand for seamless pipes in industries requiring high-pressure and high-temperature applications, as well as the growing global infrastructure development and industrialization.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.