🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

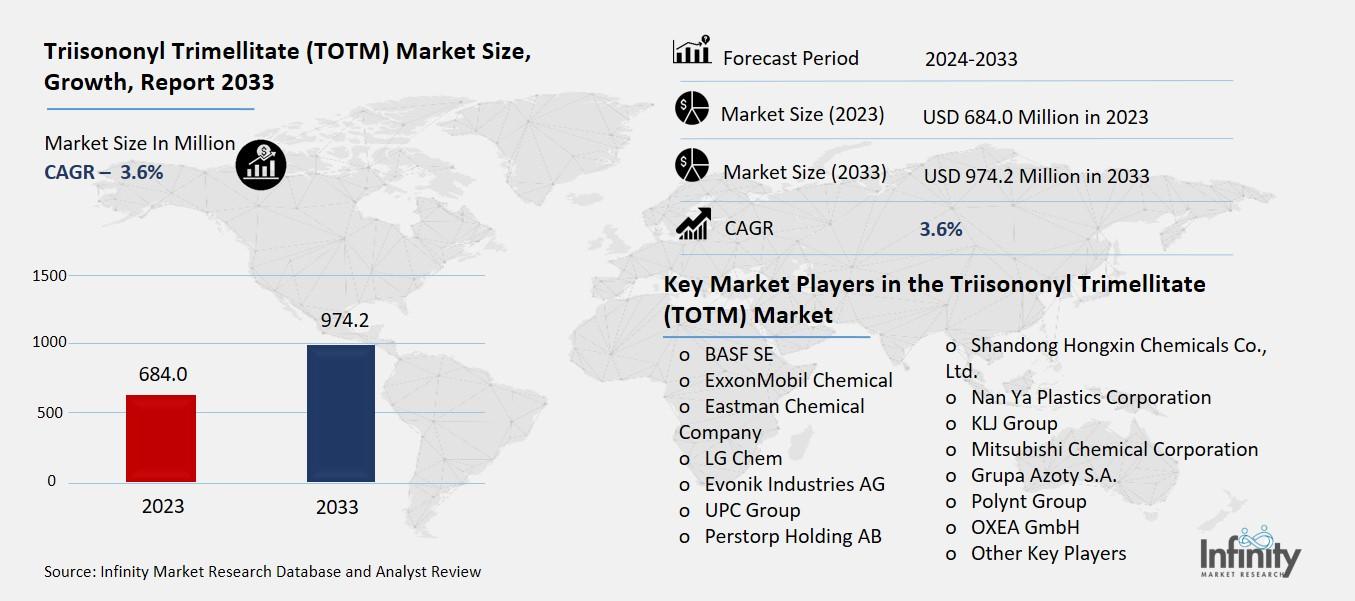

Triisononyl Trimellitate (TOTM) Market

Global Triisononyl Trimellitate (TOTM) Market (By Type, 99% Purity and 98% Purity; By Application, Automobile, Film & Sheet, Flooring & Wall Coverings, Wire & Cable, Coated Fabric, Consumer Goods, and Other Applications; By Region and Companies), 2024-2033

Dec 2024

Chemicals and Materials

Pages: 138

ID: IMR1366

Triisononyl Trimellitate (TOTM) Market Overview

Global Triisononyl Trimellitate (TOTM) Market acquired the significant revenue of 684.0 Million in 2023 and expected to be worth around USD 974.2 Million by 2033 with the CAGR of 3.6% during the forecast period of 2024 to 2033. The demand for Triisononyl Trimellitate (TOTM) is mainly for plasticizers to be used in flexible plastics especially in automotive, construction, and wire and cable industries. TOTM is preferred because of its high heat stability, low volatility, and it improves durability and elasticity characteristics of materials used in high performance. In its white paper, it is widely used in polyvinyl chloride (PVC) products since it increases the products’ thermal stability at high temperatures. The market for TOTM is also conditioned by a higher demand for quality non-toxic and environmentally friendly plasticizers and by developing a tendency toward sustainability in the manufacturing industry.

Drivers for the Triisononyl Trimellitate (TOTM) Market

Increased Demand for Durable and Flexible Plastics

Triisononyl Trimellitate (TOTM) is well preferred in the manufacturing of durable flexible PVC products notably because of high heat resistance and low valuable vapor. These properties help PVC products to have continued performance even under high temperature conditions hence make TOTM suitable for use in areas where malleable material is required for use. TOTM has another advantage in resisting high temperatures, as a result it is heat stable and does not degrade with time due to the high temperatures that cause the degradation of other materials. This is especially the case in the automotive manufacturing sector where parts such as the cables’ insulation, dashboard among others and interior panels may undergo great fluctuations in temperatures. Likewise, TOTM does not display any tendency to evaporate or degrade therefore keeping PVC product flexible and resilient for long term use.

Restraints for the Triisononyl Trimellitate (TOTM) Market

Volatility in Raw Material Prices

The costs of raw materials used in the production of Triisononyl Trimellitate (TOTM) are subject to fluctuations, which can significantly impact both the pricing of the product and the profitability of manufacturers. TOTM is derived from various petrochemical products, including trimellitic anhydride (TMA) and isononyl alcohol, which are sensitive to changes in the prices of crude oil and other raw materials. As global supply chains experience disruptions, such as shifts in oil prices or shortages of key chemicals, the cost of these raw materials can rise, leading to increased production expenses. Manufacturers may face challenges in maintaining consistent pricing for TOTM, as they need to adjust for the rising input costs, potentially passing those increases onto consumers.

Opportunity in the Triisononyl Trimellitate (TOTM) Market

Growing Demand for Environmentally Friendly Products

With increasing global attention on sustainability and the reduction of harmful chemicals, Triisononyl Trimellitate (TOTM) offers significant growth opportunities due to its non-toxic and eco-friendly properties. Unlike many traditional plasticizers, which can contain phthalates and other harmful substances, TOTM is considered a safer alternative, making it more appealing to industries that are prioritizing environmental responsibility and consumer health.

As regulatory frameworks become more stringent, especially in the European Union and North America, there is a growing demand for non-toxic plasticizers in products like medical devices, children's toys, food packaging, and consumer goods, where safety is paramount. TOTM's eco-friendly profile, which includes low volatility and reduced potential for leaching into the environment, aligns well with these regulatory requirements and sustainability goals.

Trends for the Triisononyl Trimellitate (TOTM) Market

Shift Towards High-Performance Plasticizers

A significant trend in the materials industry is the growing demand for high-performance, long-lasting plasticizers, which is driving the increased adoption of Triisononyl Trimellitate (TOTM). This trend is particularly evident in specialized applications such as automotive and construction, where durability, flexibility, and resistance to extreme conditions are critical. In the automotive sector, components like wiring, dashboard materials, and flexible interior parts require plasticizers that not only provide excellent flexibility but also maintain performance over the lifetime of the vehicle, often under exposure to heat, UV radiation, and mechanical stress. TOTM's superior heat stability and low volatility make it ideal for these demanding automotive environments, where conventional plasticizers may degrade or lose their effectiveness.

Segments Covered in the Report

By Type

o 99% Purity

o 98% Purity

By Application

o Automobile

o Film & Sheet

o Flooring & Wall Coverings

o Wire & Cable

o Coated Fabric

o Consumer Goods

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into 99% purity and 98% purity. Among these, 99% purity segment acquired the significant share in the market owing to its superior quality and performance characteristics. Higher purity levels in TOTM enhance its effectiveness as a plasticizer, making it particularly suitable for demanding applications in industries such as automotive, construction, and pharmaceuticals. The increased demand for high-performance materials in these sectors has contributed to the dominance of the 99% purity segment in the market.

By Application Analysis

On the basis of application, the market is divided into automobile, film & sheet, flooring & wall coverings, wire & cable, coated fabric, consumer goods, and other applications. Among these, automobile segment held the prominent share of the market due to the increasing demand for durable and high-performance materials in automotive manufacturing. TOTM is widely used in the automotive industry for applications like interior components, wiring, cables, dashboards, and other flexible PVC parts. Its superior heat stability, low volatility, and long-lasting flexibility make it ideal for automotive environments, where components must withstand extreme temperatures, UV exposure, and mechanical stress over time.

Regional Analysis

Asia Pacific Dominated the Market with the Highest Revenue Share

Asia Pacific held the most of the share of 37.2% of the market owing to the rapid industrialization and growing demand for high-performance plasticizers across key sectors such as automotive, construction, and electrical industries. Countries like China, India, and Japan are experiencing significant growth in infrastructure development, automotive production, and electronics manufacturing, which has directly increased the demand for materials like TOTM that offer durability, heat stability, and flexibility.

Additionally, the region’s cost-effective manufacturing processes and the availability of raw materials have further fueled the growth of the TOTM market. The Asia-Pacific market is also driven by the increasing focus on producing safer and more sustainable plasticizers, aligning with global trends toward eco-friendly products.

Competitive Analysis

The competitive landscape of the Triisononyl Trimellitate (TOTM) market is characterized by a mix of established multinational corporations and regional players, all striving to capture a share of the growing demand for high-performance plasticizers. Major players such as BASF SE, ExxonMobil Chemical, Eastman Chemical Company, and Evonik Industries dominate the market, leveraging their extensive global networks, strong brand reputation, and advanced technological capabilities. These companies have significant research and development investments, focusing on improving the performance and environmental footprint of their products to meet evolving industry standards and consumer preferences.

Recent Developments

In November 2022, Evonik entered into a memorandum of understanding with the Czech chemical company DEZA to collaborate on the production of the plasticizer tri-isononyl trimellitate (TINTM).

Key Market Players in the Triisononyl Trimellitate (TOTM) Market

o BASF SE

o ExxonMobil Chemical

o Eastman Chemical Company

o LG Chem

o Evonik Industries AG

o UPC Group

o Perstorp Holding AB

o Shandong Hongxin Chemicals Co., Ltd.

o Nan Ya Plastics Corporation

o KLJ Group

o Mitsubishi Chemical Corporation

o Grupa Azoty S.A.

o Polynt Group

o OXEA GmbH

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 684.0 Million |

|

Market Size 2033 |

USD 974.2 Million |

|

Compound Annual Growth Rate (CAGR) |

3.6% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Million) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

BASF SE, ExxonMobil Chemical, Eastman Chemical Company, LG Chem, Evonik Industries AG, UPC Group, Perstorp Holding AB, Shandong Hongxin Chemicals Co., Ltd., Nan Ya Plastics Corporation, KLJ Group, Mitsubishi Chemical Corporation, Grupa Azoty S.A., Polynt Group, and OXEA GmbH, and Other Key Players |

|

Key Market Opportunities |

Growing Demand for Environmentally Friendly Products |

|

Key Market Dynamics |

Increased Demand for Durable and Flexible Plastics |

📘 Frequently Asked Questions

1. Who are the key players in the Triisononyl Trimellitate (TOTM) Market?

Answer: BASF SE, ExxonMobil Chemical, Eastman Chemical Company, LG Chem, Evonik Industries AG, UPC Group, Perstorp Holding AB, Shandong Hongxin Chemicals Co., Ltd., Nan Ya Plastics Corporation, KLJ Group, Mitsubishi Chemical Corporation, Grupa Azoty S.A., Polynt Group, and OXEA GmbH, and Other Key Players

2. How much is the Triisononyl Trimellitate (TOTM) Market in 2023?

Answer: The Triisononyl Trimellitate (TOTM) Market size was valued at USD 684.0 Million in 2023.

3. What would be the forecast period in the Triisononyl Trimellitate (TOTM) Market?

Answer: The forecast period in the Triisononyl Trimellitate (TOTM) Market report is 2024-2033.

4. What is the growth rate of the Triisononyl Trimellitate (TOTM) Market?

Answer: Triisononyl Trimellitate (TOTM) Market is growing at a CAGR of 3.6% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.