🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

At Infinity Market Research, we dont just deliver data — we deliver clarity, confidence, and competitive edge.

In a world driven by insights, we help businesses unlock the infinite potential of informed decisions.

Here why global brands, startups, and decision-makers choose us:

Industry-Centric Expertise

With deep domain knowledge across sectors — from healthcare and technology to manufacturing and consumer goods — our team delivers insights that matter.

Custom Research, Not Cookie-Cutter Reports

Every business is unique, and so are its challenges. Thats why we tailor our research to your specific goals, offering solutions that are actionable, relevant, and reliable.

Data You Can Trust

Our research methodology is rigorous, transparent, and validated at every step. We believe in delivering not just numbers, but numbers that drive real impact.

Client-Centric Approach

Your success is our priority. From first contact to final delivery, our team is responsive, collaborative, and committed to your goals — because you re more than a client; you re a partner.

Recent Reports

Obesity Management Market

GLP-1 Receptor Agonist Market

UV-resistant Adhesive Tape Market

Global UV-resistant Adhesive Tape Market (By Type, Single-sided and Double-sided; By Application, Automobile, Aerospace, Electronics Industry, Manufacturing Industry, and Other Applications; By Region and Companies), 2024-2033

Nov 2024

Chemicals and Materials

Pages: 138

ID: IMR1318

UV-resistant Adhesive Tape Market Overview

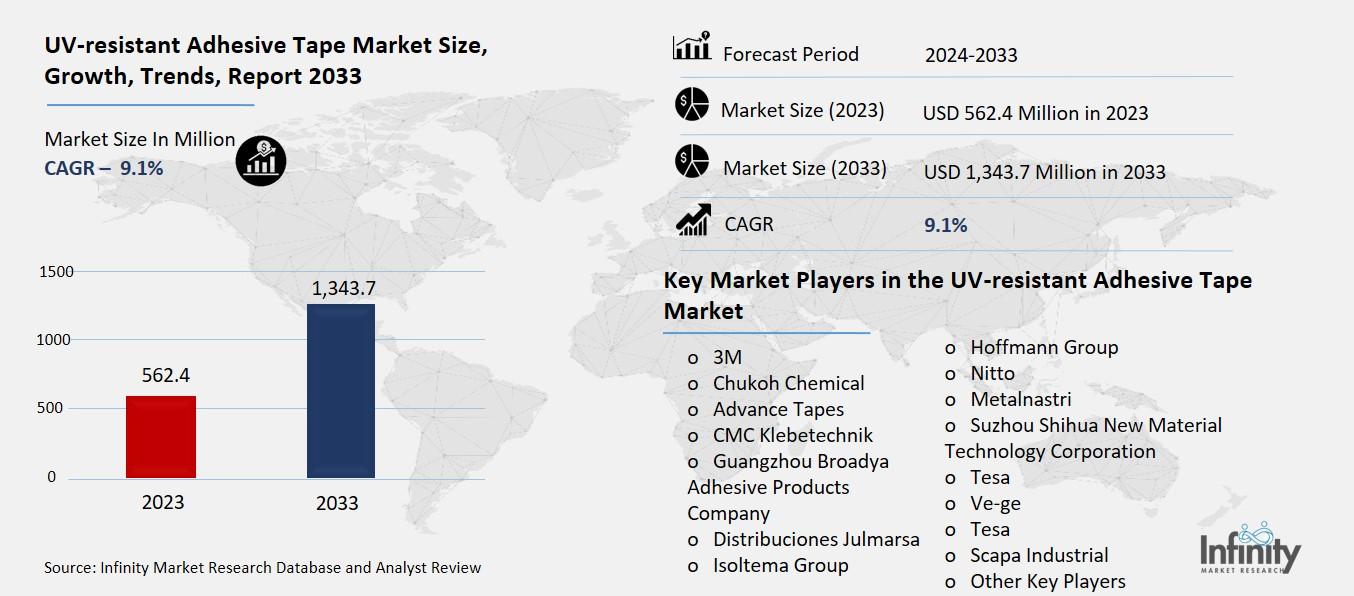

Global UV-resistant Adhesive Tape Market acquired the significant revenue of 562.4 Million in 2023 and expected to be worth around USD 1,343.7 Million by 2033 with the CAGR of 9.1% during the forecast period of 2024 to 2033. UV resistant adhesive tape is on the rise because of the growing application into different industries such as automotive, electronics, construction, and packaging industries. This type of tapes can endure lengthy periods of exposure to ultraviolet radiation or UV thus making perfect for outdoor use. They are not susceptible to degradation from UV light hence they deliver their best when used in areas that require strong adhesives such as solar panel manufacturing, manufacturing of signage and automobiles among other industrial uses. In addition, as sustainability awareness increases, the use of environment friendly and high performance material in adhesive products creates further demand.

Drivers for the UV-resistant Adhesive Tape Market

Rising Demand for Outdoor Applications

UV resistant adhesive tapes are used prominently in numerous industrial application areas such as automotive, constructions, and outdoor signage to those industries, which require tapes that are stable and durable when exposed to ultraviolet radiation. Examples in automotive industry include, use of UV resistant tapes in bonding exterior trims, window sealing and protective films on auto components. These tapes make sure that adhesives still maintain its properties and functionality for it will not fail due to uv degradation caused by sunlight.

These tapes are essential for closing joints, insulating materials and forming weather barriers in constructions and structures that are exposed to different weather conditions in the construction process. UV stable tapes are able to sustain their capabilities and adhesion throughout the UV – exposed areas guaranteeing excellent performance for roofing, facades, and other exterior construction.

Restraints for the UV-resistant Adhesive Tape Market

High Cost of UV-Resistant Materials

UV-resistant adhesive tapes are generally more expensive than standard tapes because they are made with specialized materials and undergo advanced manufacturing processes. These tapes require high-quality polymers and additives that can resist degradation from ultraviolet radiation, ensuring long-term performance. The inclusion of UV stabilizers and the use of specialized coatings often increase the production costs. Additionally, the manufacturing process for UV-resistant tapes typically involves more precise formulation and quality control to ensure that the tapes meet the necessary performance standards for outdoor and high-exposure applications.

Opportunity in the UV-resistant Adhesive Tape Market

Growth in Green and Sustainable Products

As sustainability continues to gain traction across industries, there is a growing opportunity to innovate UV-resistant adhesive tapes using eco-friendly materials. Traditional adhesive tapes often contain materials that are not biodegradable or are harmful to the environment, such as petroleum-based plastics and non-recyclable backing materials. However, with increasing demand for green products, manufacturers are exploring alternatives that align with sustainability goals. For instance, there is potential to develop UV-resistant tapes using bio-based polymers, recycled materials, and solvent-free adhesives, reducing the environmental impact during both production and disposal. Such innovations not only help meet environmental regulations but also cater to consumers and businesses that prioritize sustainability.

Trends for the UV-resistant Adhesive Tape Market

Increase in Demand for Multi-Functional Tapes

The trend toward multi-functional adhesive tapes are becoming increasingly prominent, as industries seek products that offer a combination of benefits beyond just UV resistance. Modern adhesive tapes are being designed to provide enhanced functionality, such as weatherproofing, heat resistance, and noise reduction, in addition to their ability to withstand UV radiation. This trend responds to the growing demand for materials that can perform well under various environmental conditions, offering increased value and versatility for end-users.

For example, in construction, multi-functional tapes are being used to seal building materials not only to protect them from UV damage but also to provide thermal insulation and soundproofing properties, making them ideal for energy-efficient and noise-reducing applications in buildings. In automotive applications, tapes with both UV resistance and heat resistance are essential for bonding components exposed to extreme temperatures while ensuring that the adhesive remains effective despite prolonged sun exposure.

Segments Covered in the Report

By Type

o Single-sided

o Double-sided

By Application

o Automobile

o Aerospace

o Electronics Industry

o Manufacturing Industry

o Other Applications

Segment Analysis

By Type Analysis

On the basis of type, the market is divided into single-sided and double-sided. Among these, single-sided segment acquired the significant share in the market owing to its widespread applications across various industries. Single-sided tapes are commonly used for tasks such as sealing, masking, and surface protection, where only one side requires adhesive properties. Their versatility and ease of application make them a preferred choice in sectors like construction, automotive, and electronics. For instance, single-sided UV-resistant tapes are utilized for masking during painting processes, protecting surfaces from UV damage, and providing insulation in electronic components.

By Application Analysis

On the basis of application, the market is divided into automobile, aerospace, electronics industry, manufacturing industry, and other applications. Among these, electronics industry held the prominent share of the market due to its extensive use in semiconductor manufacturing processes. UV-resistant tapes are essential in applications such as wafer dicing, back grinding, PCB grinding, and glass dicing, where they provide strong adhesion and withstand extreme conditions of heat and pressure.

The continuous growth of the electronics and semiconductor industries, driven by the increasing demand for smaller electronic components like ICs and microchips, has significantly contributed to the demand for UV-resistant tapes. These tapes ensure precise and efficient manufacturing processes, making them indispensable in the electronics sector.

Regional Analysis

North America Dominated the Market with the Highest Revenue Share

North America held the most of the share of 32.8% of the market. The region boasts a well-established industrial base, with significant demand from diverse sectors such as automotive, aerospace, electronics, and construction, all of which rely on high-performance UV-resistant tapes for various applications. The automotive industry in North America, particularly in the United States, uses these tapes extensively for bonding, sealing, and protective applications in vehicle manufacturing, especially for outdoor and UV-exposed components.

Similarly, the aerospace sector in North America, which is home to major manufacturers and suppliers, utilizes UV-resistant tapes for both internal and external components that need to endure harsh environmental conditions, including exposure to UV rays.

Competitive Analysis

The competitive landscape of the UV-resistant adhesive tape market is characterized by the presence of several key players vying for market share through innovation, product differentiation, and strategic partnerships. Leading manufacturers are focused on developing advanced UV-resistant tapes that offer enhanced durability, multi-functional features, and eco-friendly materials to meet the growing demand for sustainable solutions. Companies such as 3M, tesa SE, Avery Dennison, and Nitto Denko Corporation are dominant players in the market, with strong R&D capabilities and extensive distribution networks that allow them to cater to a wide range of industries, including automotive, construction, aerospace, and electronics.

Key Market Players in the UV-resistant Adhesive Tape Market

o 3M

o Chukoh Chemical

o Advance Tapes

o CMC Klebetechnik

o Guangzhou Broadya Adhesive Products Company

o Distribuciones Julmarsa

o Isoltema Group

o Hoffmann Group

o Nitto

o Metalnastri

o Suzhou Shihua New Material Technology Corporation

o Tesa

o Ve-ge

o Tesa

o Scapa Industrial

o Other Key Players

|

Report Features |

Description |

|

Market Size 2023 |

USD 562.4 Million |

|

Market Size 2033 |

USD 1,343.7 Million |

|

Compound Annual Growth Rate (CAGR) |

9.1% (2023-2033) |

|

Base Year |

2023 |

|

Market Forecast Period |

2024-2033 |

|

Historical Data |

2019-2022 |

|

Market Forecast Units |

Value (USD Million) |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

By Type, Application, and Region |

|

Geographies Covered |

North America, Europe, Asia Pacific, and the Rest of the World |

|

Countries Covered |

The U.S., Canada, Germany, France, U.K, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil |

|

Key Companies Profiled |

3M, Chukoh Chemical, Advance Tapes, CMC Klebetechnik, Guangzhou Broadya Adhesive Products Company, Distribuciones Julmarsa, Isoltema Group, Hoffmann Group, Nitto, Metalnastri, Suzhou Shihua New Material Technology Corporation, Tesa, Ve-ge, Tesa, Scapa Industrial, and Other Key Players. |

|

Key Market Opportunities |

Growth in Green and Sustainable Products |

|

Key Market Dynamics |

Rising Demand for Outdoor Applications |

📘 Frequently Asked Questions

1. Who are the key players in the Tungsten Carbide Powder Market?

Answer: 3M, Chukoh Chemical, Advance Tapes, CMC Klebetechnik, Guangzhou Broadya Adhesive Products Company, Distribuciones Julmarsa, Isoltema Group, Hoffmann Group, Nitto, Metalnastri, Suzhou Shihua New Material Technology Corporation, Tesa, Ve-ge, Tesa, Scapa Industrial, and Other Key Players.

2. How much is the Tungsten Carbide Powder Market in 2023?

Answer: The Tungsten Carbide Powder Market size was valued at USD 562.4 Million in 2023.

3. What would be the forecast period in the Tungsten Carbide Powder Market?

Answer: The forecast period in the Tungsten Carbide Powder Market report is 2024-2033.

4. What is the growth rate of the Tungsten Carbide Powder Market?

Answer: Tungsten Carbide Powder Market is growing at a CAGR of 9.1% during the forecast period, from 2024 to 2033.

🔐 Secure Payment Guaranteed

Safe checkout with trusted global payment methods.

🌟 Why Choose Infinity Market Research?

- Accurate & Verified Data:Our insights are trusted by global brands and Fortune 500 companies.

- Complete Transparency:No hidden fees, locked content, or misleading claims — ever.

- 24/7 Analyst Support:Our expert team is always available to help you make smarter decisions.

- Instant Savings:Enjoy a flat $1000 OFF on every report.

- Fast & Reliable Delivery:Get your report delivered within 5 working days, guaranteed.

- Tailored Insights:Customized research that fits your industry and specific goals.